Color modified flame retardant PET (polyethylene terephthalate) and PC (polycarbonate) composite material and preparation method thereof

A composite material and modification technology, applied in the field of flame retardant PET and PC composite materials and their preparation, can solve the problems of reduced transparency and gloss, limited application occasions, yellowing of color and chromaticity, and achieves improved chromaticity, Improve the appearance of color, improve the effect of compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

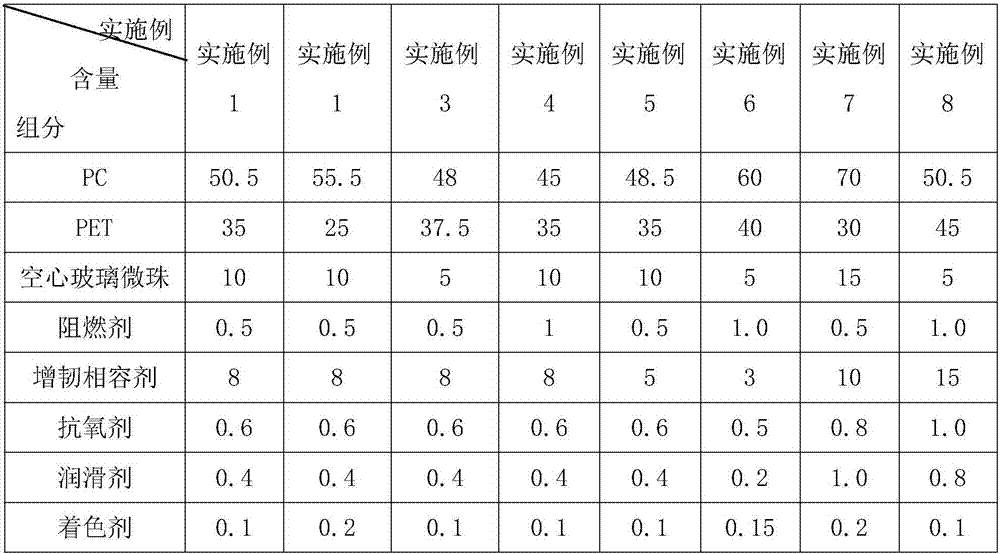

[0038] Example 1-5: A color-modified flame-retardant PET and PC composite material, prepared by the following steps, see Table 1 for its components and contents:

[0039] S0: Treatment of hollow glass microspheres: Dilute the silane coupling agent accounting for 1.5% of the total mass of the hollow glass microspheres with absolute ethanol in a water bath at 35-45° C. The mass ratio is 8:1. At 15-35°C, add the hollow glass microspheres weighed in proportion while stirring the diluent. After all the hollow glass microspheres are added, continue to stir for 5-10 minutes, and then add the hollow glass microspheres. 5% colorant of the total mass of beads, stirred for 2 hours, then dried at 80°C for more than 4 hours, and finally placed the dried powder in a closed container for later use; the silane coupling agent is γ-(2,3-epoxy Propoxy)propyltrimethoxysilane;

[0040] S1: Weigh each component according to the ratio in Table 1, wherein the hollow glass microspheres are the hollow...

Embodiment 9

[0047] Example 9: A color-modified flame-retardant PET and PC composite material, the difference from Example 1 is that the colorant is 0.1 part of A1.

Embodiment 10

[0048] Example 10: A color-modified flame-retardant PET and PC composite material, the difference from Example 1 is that the coloring agent is 0.1 part of A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com