Water-based polyurethane varnish and method for preparing same

A water-based polyurethane and varnish technology, applied in the chemical field, can solve the problems of poor dry and wet rub resistance, increased film hardness, unsatisfactory light resistance, yellowing resistance and other physical properties, and achieve narrow molecular weight distribution and excellent mechanical properties. , Excellent photostability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

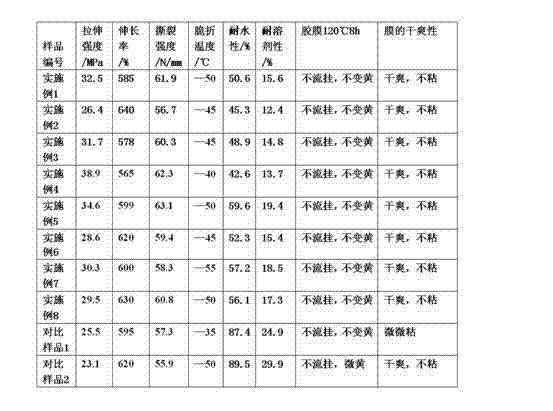

Embodiment 1

[0043] Taking the production of 475 kg of water-based polyurethane varnish as an example, the raw material formula ratio adopts the lower limit value, and the product brand of Asahi Kasei, polycarbonate diol PCDL-T4671 (molecular weight 1000), dihydroxy Methylpropionic acid, 1.6-hexanediol, dimethylaminoethanol, and isophoronediamine subspecies.

[0044] Raw material components and formula: polycarbonate diol PCDL-T4671 (molecular weight: 1000): 57.28 kg, H 12 DMI: 36 kg, bismuth sulfonic acid-based catalyst: 0.126 kg, dimethylolpropionic acid: 4.64 kg, 1,6-hexanediol: 0.4 kg, acetone: 48 kg, dimethylaminoethanol: 3.08 kg, antioxidant Agent 1010: 0.28 kg, deionized water: 364 kg, isophorone diamine: 0.8 kg, propylene glycol carbonate: 8 kg, double-terminated hydroxyl polyether modified silicone oil: 0.8 kg.

[0045] Its preparation method steps are as follows:

[0046] 1. Dehydration treatment of polycarbonate diol PCDL-T4671 (molecular weight: 1000)

[0047] Add polycarbonat...

Embodiment 2

[0059] Taking the production of 422 kg of water-based polyurethane varnish as an example, the ratio of raw materials adopts the upper limit value, and the product brand of Asahi Kasei, polycarbonate diol PCDL-T4672 (molecular weight: 2000), dihydroxy Methyl butyric acid, ethyl butyl propylene glycol, dimethylaminoethanol, isophorone diamine sub-species.

[0060] Formula: polycarbonate diol PCDL-T4672 (molecular weight: 2000): 62.8 kg, H 12 DMI: 31.2 kg, bismuth sulfonic acid catalyst: 0.252 kg, dimethylol butyric acid: 5.12 kg, ethyl butyl propylene glycol: 1.90 kg, acetone: 57.6 kg, dimethylaminoethanol: 3.40 kg, antioxidant 1010 : 0.32 kg, deionized water: 304 kg, isophorone diamine: 1.6 kg, propylene glycol carbonate: 12 kg, double-terminated hydroxyl polyether modified silicone oil: 0.8 kg.

[0061] Its preparation method steps are as follows:

[0062] 1. Dehydration treatment of polycarbonate diol PCDL-T4672 (molecular weight: 2000)

[0063] Add polycarbonate diol PCDL...

Embodiment 3

[0075] Taking the production of 476 kg of water-based polyurethane varnish as an example, the raw material formula ratio adopts the middle value, and the product brand of Asahi Kasei, polycarbonate diol PCDL-T4691 (molecular weight: 1000), dimethylol Propionic acid, 1,10-decanediol, triethylamine, diethylenetriamine lower species.

[0076] formula:

[0077] Polycarbonate diol PCDL-T4691 (molecular weight 1000): 60.04 kg, H 12 DMI: 33.6 kg, bismuth sulfonic acid catalyst: 0.189 kg, dimethylolpropionic acid: 4.88 kg, 1,10-decanediol: 0.59 kg, acetone: 52.8 kg, triethylamine: 3.68 kg, antioxidant 1010: 0.54 kg, deionized water: 364 kg, diethylenetriamine: 0.48 kg, propylene glycol carbonate: 8 kg, double-terminated hydroxyl polyether modified silicone oil: 0.8 kg.

[0078] Its preparation method steps are as follows:

[0079] 1. Dehydration treatment of polycarbonate diol PCDL-T4691 (molecular weight: 1000)

[0080] Add the polycarbonate diol PCDL-T4691 into a dry stainless s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com