Novel lithium ion battery aluminum plastic soft packaging film

A flexible packaging film, aluminum-plastic technology, applied in the direction of secondary batteries, battery pack parts, circuits, etc., can solve the problems that the heat-resistant resin layer cannot be directly applied, the molecular weight is low, and the coating cannot meet the stamping and forming requirements, etc., and achieve good Chemical resistance, simple preparation process, and the effect of preventing embrittlement of aluminum foil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

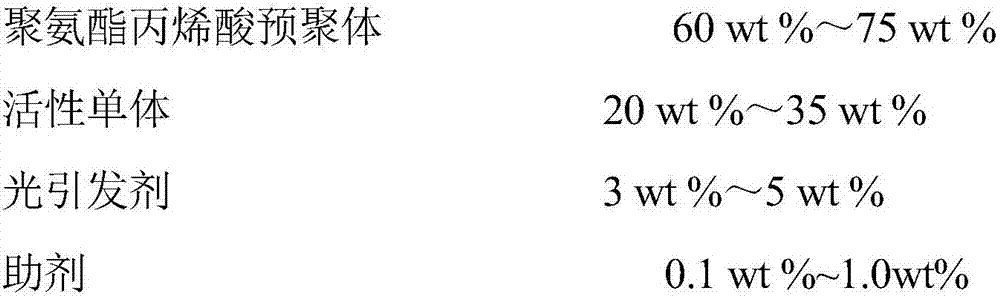

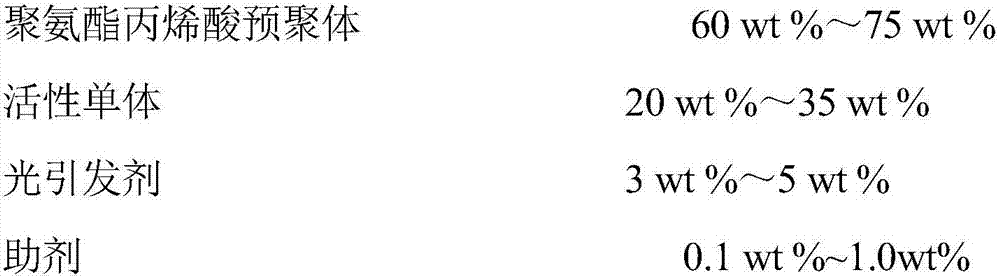

[0039] The preparation method of polyurethane acrylic acid UV curing coating;

[0040] According to the formula, the polyurethane acrylic acid prepolymer, active monomer, photoinitiator and auxiliary agent are added into the reactor and stirred evenly to prepare the polyurethane acrylic acid UV-curable coating.

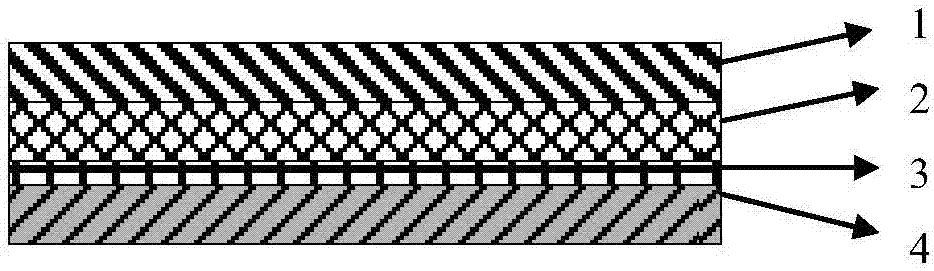

[0041] Preparation method of aluminum-plastic flexible packaging film

[0042] The prepared polyurethane acrylic UV-curable coating is coated on the matt surface of the aluminum foil layer by conventional methods such as scraping or spraying, and the coating is cured by UV light; then the passive film layer of the aluminum foil and the thermoplastic resin layer are passed through the glue The adhesive is dry compounded to obtain an aluminum-plastic flexible packaging film for lithium-ion batteries.

Embodiment 1

[0045] The components of polyurethane acrylic UV-curable coatings are:

[0046]

[0047] Preparation of aluminum-plastic flexible packaging film:

[0048] Coat 100 μm of the above-mentioned polyurethane acrylic UV-curable coating on a 35 μm aluminum foil (matt surface), irradiate and cure under a mercury arc of 1000 W, etc., and then dry compound the 100 μm single-layer cast polypropylene through an adhesive On the surface of the organic passivation film layer (with a thickness of 1 μm) of the aluminum foil, an aluminum-plastic soft packaging film for the lithium ion battery is obtained.

Embodiment 2

[0050] The components of polyurethane acrylic UV-curable coatings are:

[0051]

[0052] Preparation of aluminum-plastic flexible packaging film:

[0053] Coat 80 μm of the above-mentioned polyurethane acrylic UV-curable coating on a 55 μm aluminum foil (matte surface). compound on the surface of the inorganic passivation film layer (thickness is 1 μm) of the aluminum foil to obtain the aluminum-plastic flexible packaging film for the lithium-ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com