Easily-torn PE film material, and preparation method and applications thereof

A film material and composite film technology, applied in the field of PE materials, can solve the problem of inconvenient opening of PE packaging materials with bare hands, and achieve the effect of expanding the application field, reducing production costs, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

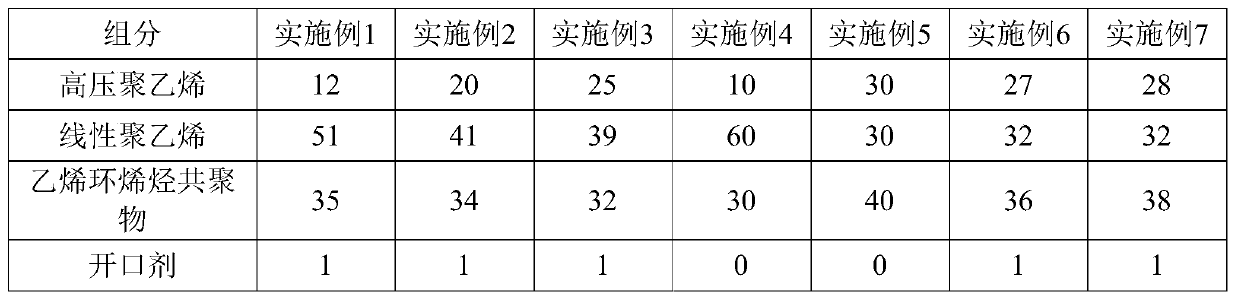

Embodiment 1

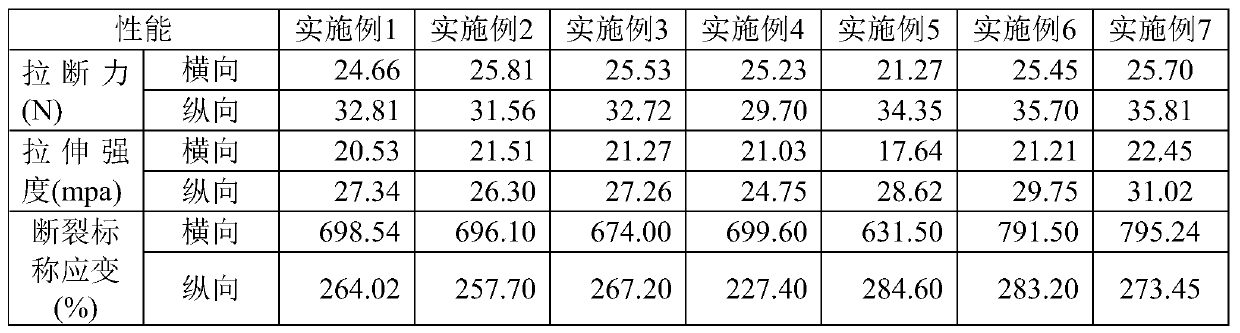

[0071] Prepare the easy-to-tear PE single-layer film, weigh the raw materials according to Table 1, mix them evenly, and add them to the hopper of the extrusion unit of the blown film machine; raise the temperature of the die head of the blown film machine to 175-205°C, set 3-6 In the extrusion section, after the material is plasticized, the air compressor is inflated to form a film; after being cooled by the air ring, it is cut and rolled to obtain a PE single-layer film with a thickness of 0.03mm. The easy-to-tear PE film material can be torn by hand in any direction, and can be torn along a straight line in the horizontal and vertical directions without causing tear deviation. The packaging bag can be opened without borrowing any tools, which is very convenient to use.

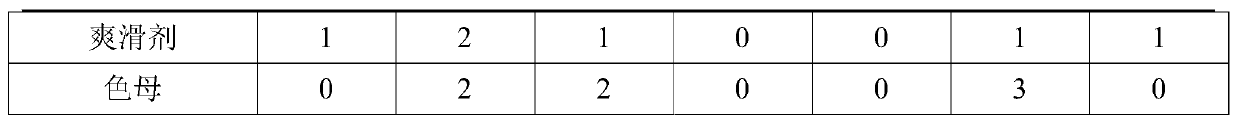

[0072] Table 1 Single-layer film formula table %

[0073]

[0074]

Embodiment 2

[0076] The dosage of each component is shown in Table 1, the preparation method is the same as in Example 1, and the PE monolayer film is 0.05mm.

Embodiment 3

[0078] The dosage of each component is shown in Table 1, the preparation method is the same as in Example 1, and the thickness of the PE monolayer film is 0.06mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com