Patents

Literature

39results about How to "Guaranteed packaging effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

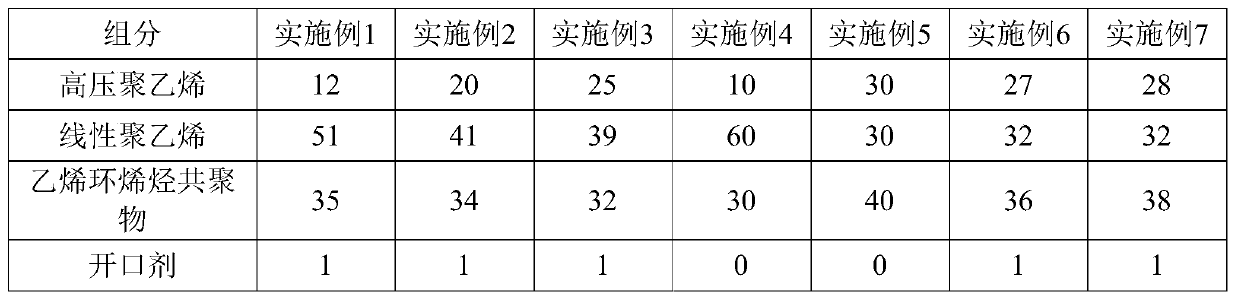

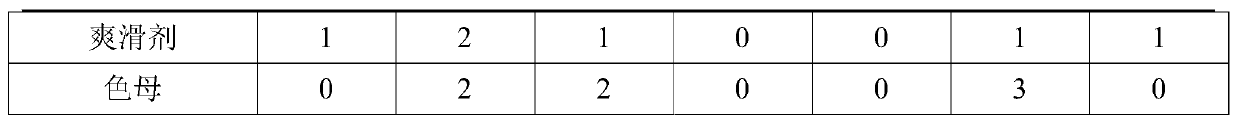

Easily-torn PE film material, and preparation method and applications thereof

InactiveCN110157074ASimplify production stepsReduce manufacturing costSynthetic resin layered productsDomestic articlesFilm materialLamellar structure

The invention relates to an easily-torn PE film material, and a preparation method and applications thereof. The easily-torn PE film material possesses a layer structure, and comprises a film layer composed of, by weight, 55 to 70% of polyethylene, 30 to 40% of an ethene cycloolefin copolymer, and 0 to 5% of a processing auxiliary agent. The easily-torn PE film material possesses a simple layer structure; cooperation of one or a plurality of material hoppers in a film blowing machine extrusion unit and a film blowing machine are adopted for one time film blowing to obtain a single layer film,double layer coextrusion film and three layer coextrusion film material, application range is widened, and package requirements of PE common package bags, paper package bags, sanitary napkin package bags, or paper diaper package bags are satisfied. The easily-torn PE film material can be torn by hands along any direction, no tearing deviation is caused, package bags can be opened without using anytools, and it is extremely convenient to use.

Owner:厦门市杏林意美包装有限公司

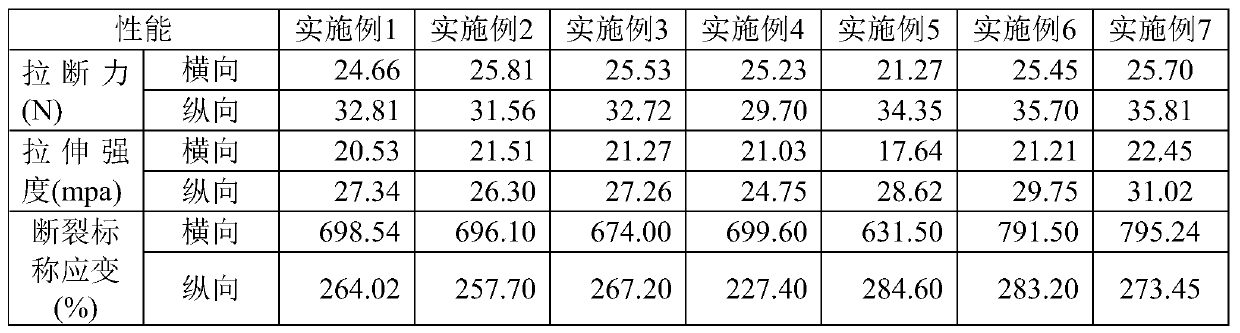

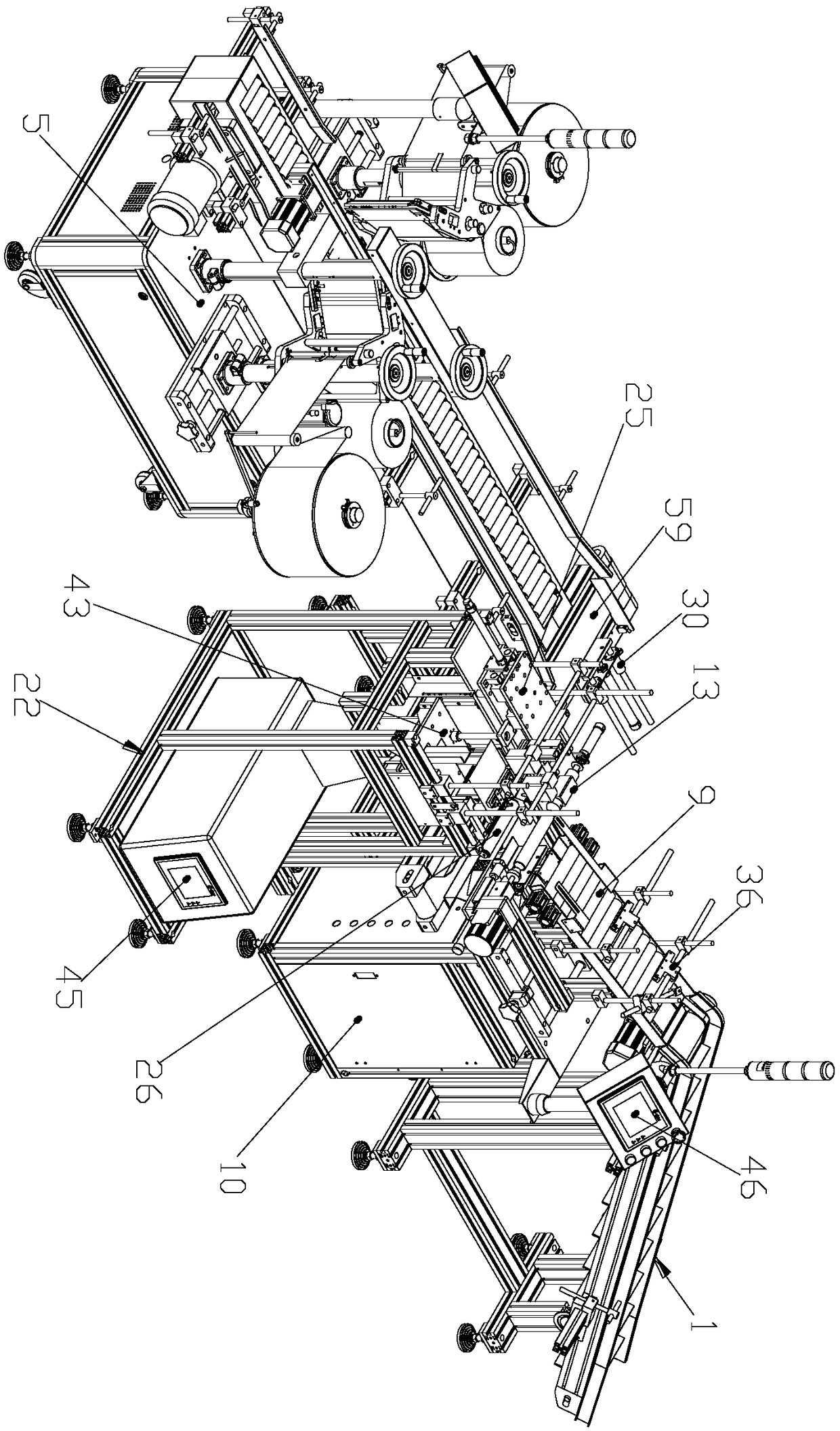

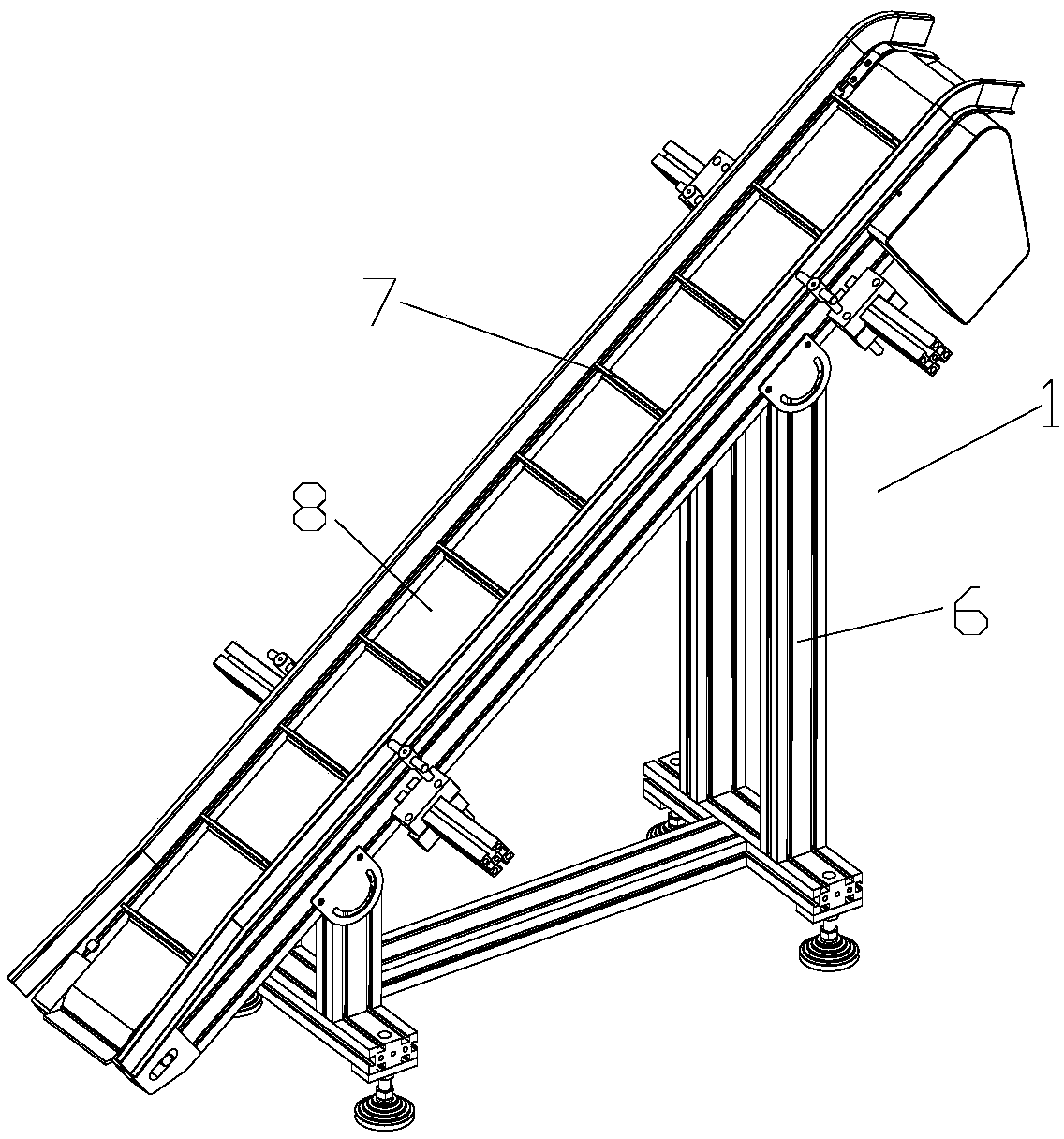

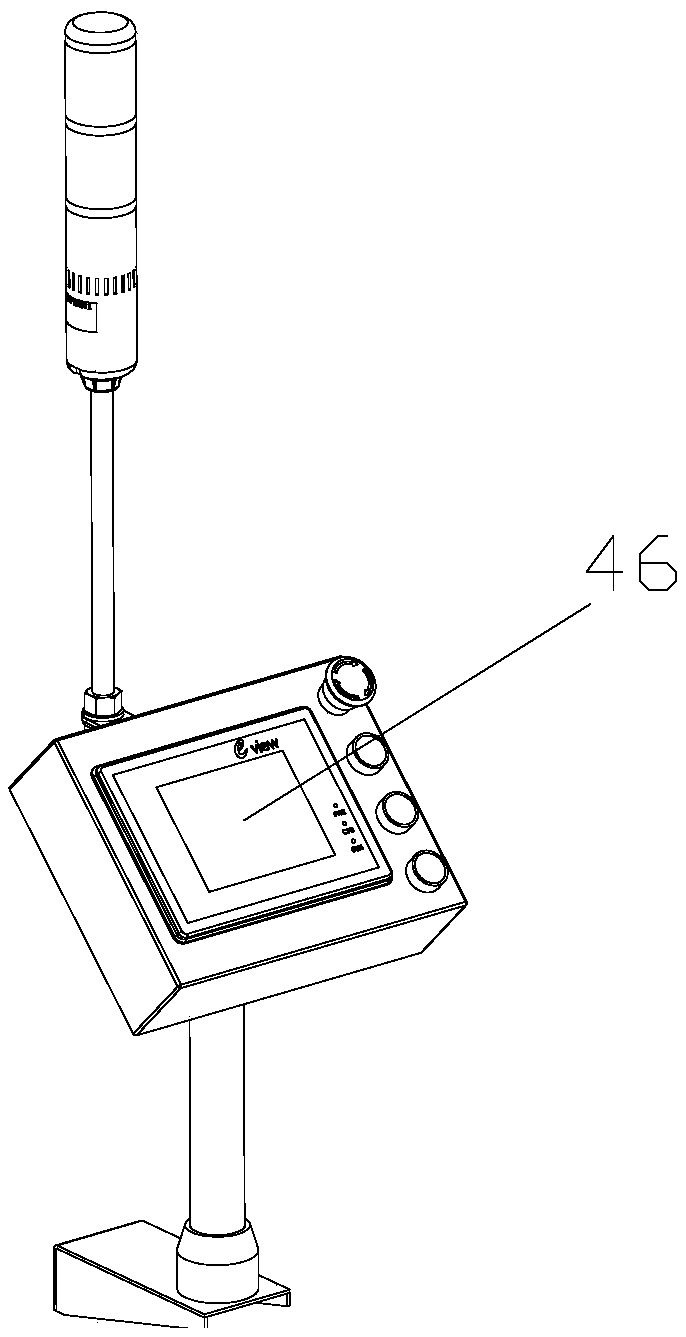

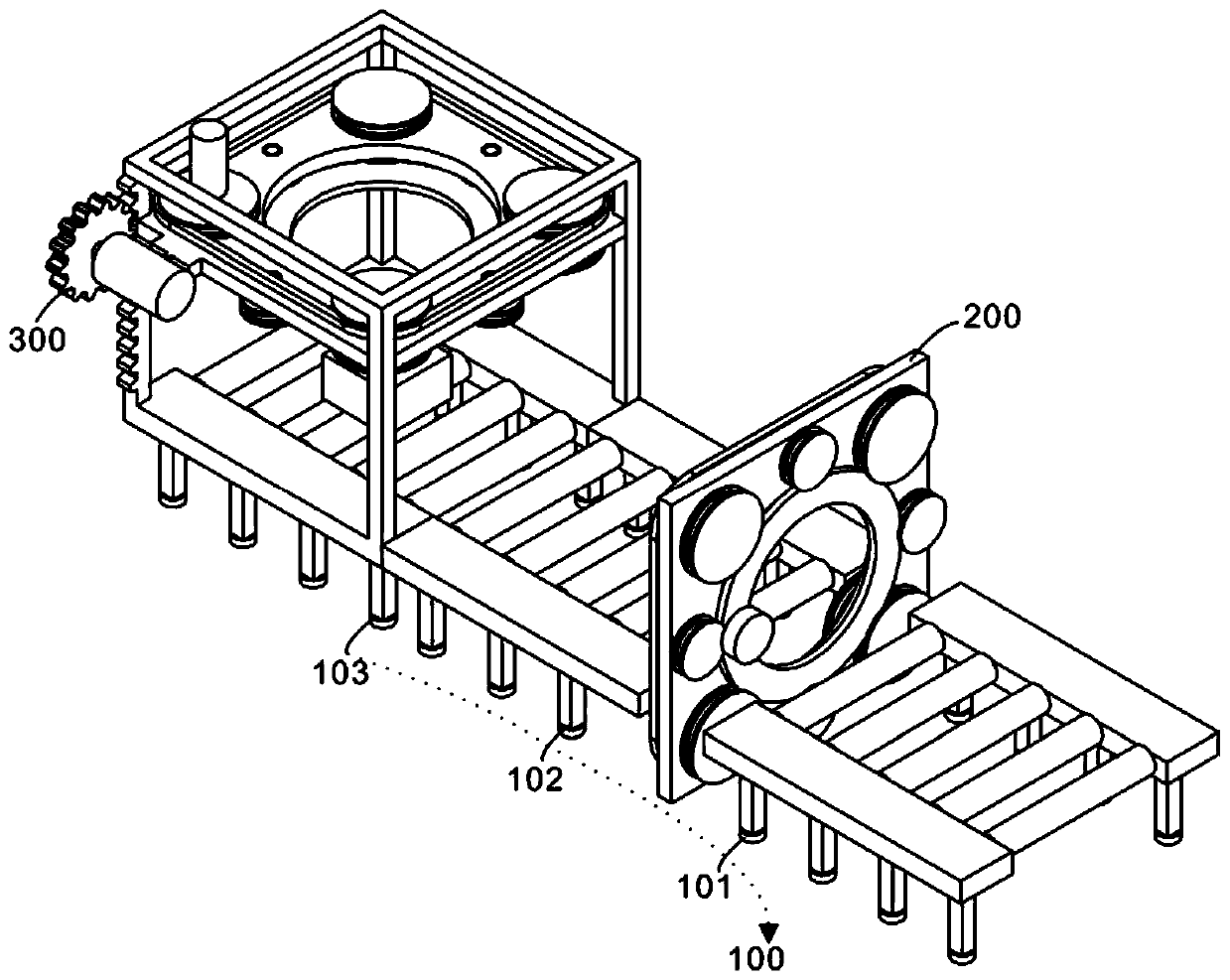

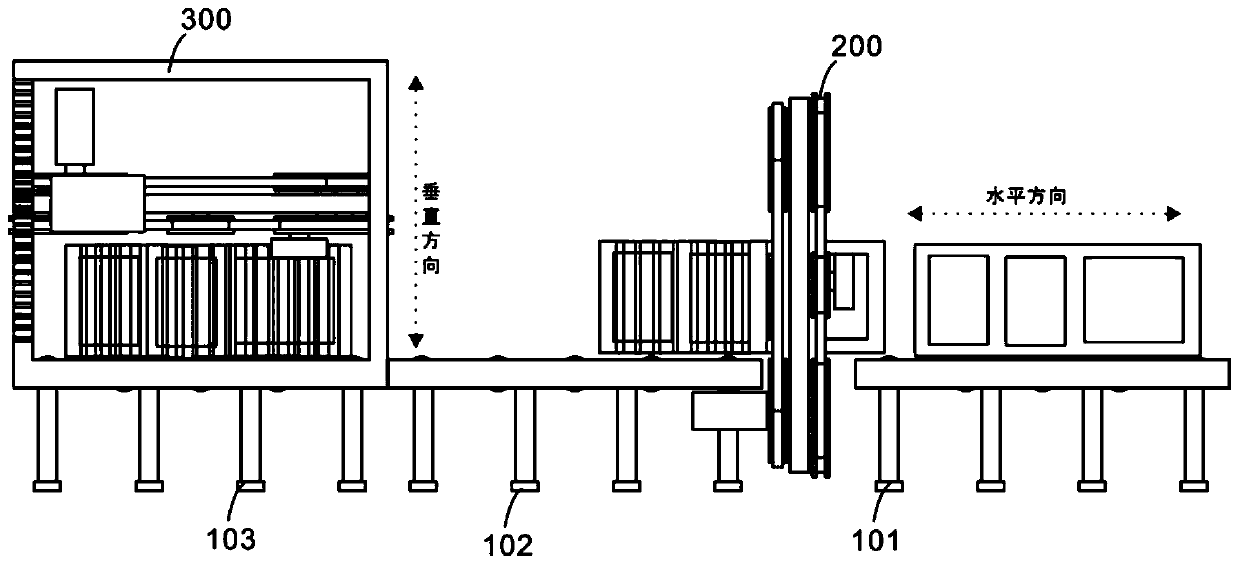

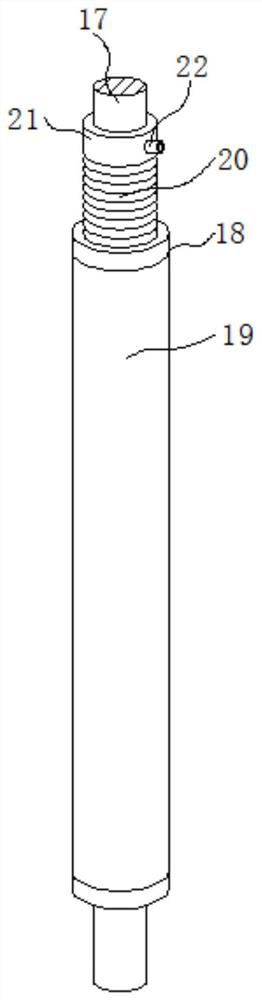

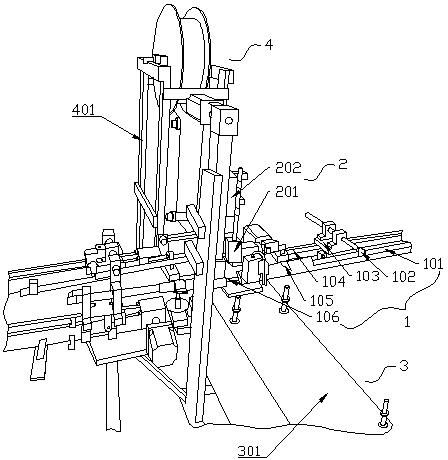

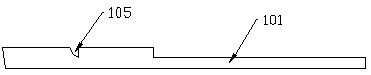

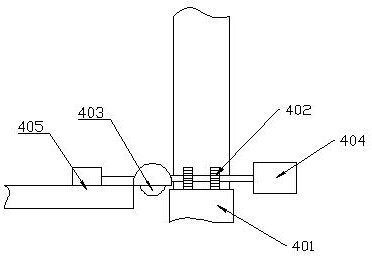

Packaging production line and packaging method for freshness protection packages

PendingCN109279126AImprove packaging efficiencyFully automatedLabelling machinesProduction lineEngineering

The invention discloses a packaging production line and a packaging method for freshness protection packages. The packaging production line comprises a conveying device, a discharging positioning device, a curved face labeling device, a transition conveying device and a side face labeling device. Unpackaged rolled freshness protection packages at the bottom end are sequentially conveyed to the topend. The discharging positioning device is in butt connection with the top end of the conveying device and conveys single rolled freshness protection packages to the label rolling position in sequence, and the rolled freshness protection packages at the label rolling position are clamped and rotated. The curved face labeling device is arranged at the downstream position of the discharging positioning device, and in the rotating process of the rolled freshness protection packages, labels are conveyed to the label rolling position to enable the labels to be stuck to the rolled freshness protection packages along with rotation of the rolled fresh protection packages. The transition conveying device is arranged at the labeling position and conveys the rolled freshness protection packages. Theside face labeling device is arranged at the downstream position of the curved face labeling device and carries out side face labeling on the curved-face-labeled rolled freshness protection packages.According to the packaging production line, automatic packaging of the freshness protection packages from feeding to positioning to labeling is achieved, the packaging efficiency is improved, and thelabor cost is reduced.

Owner:中山市信华智能自动化设备有限公司

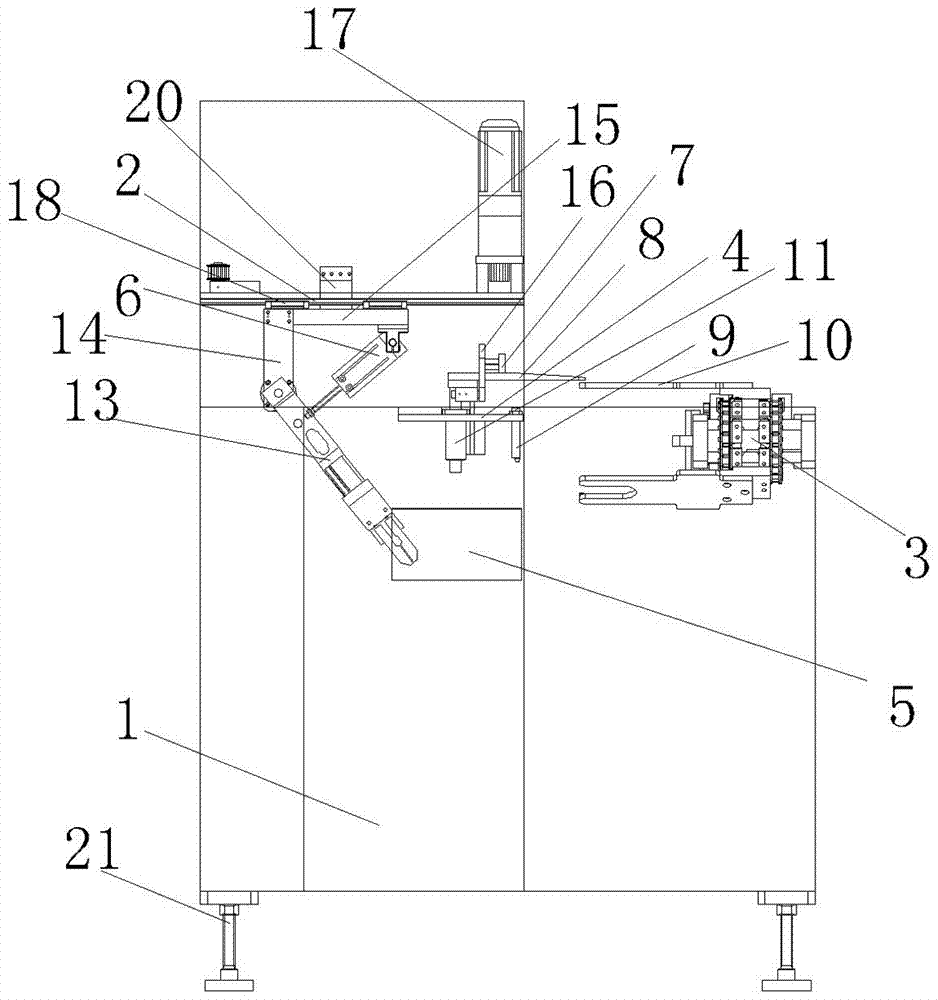

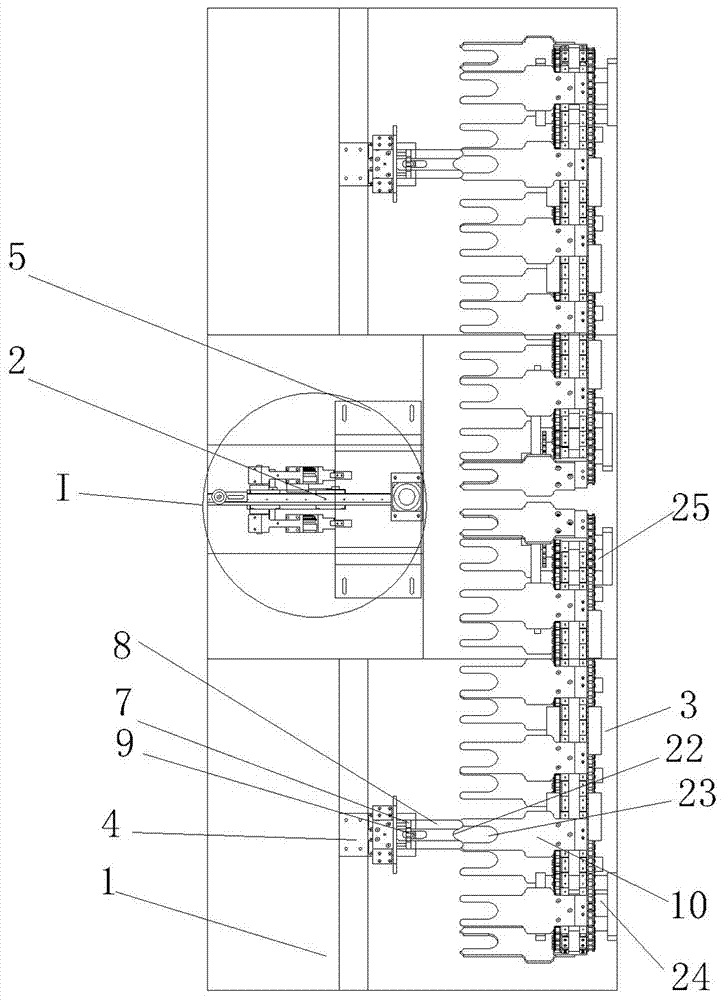

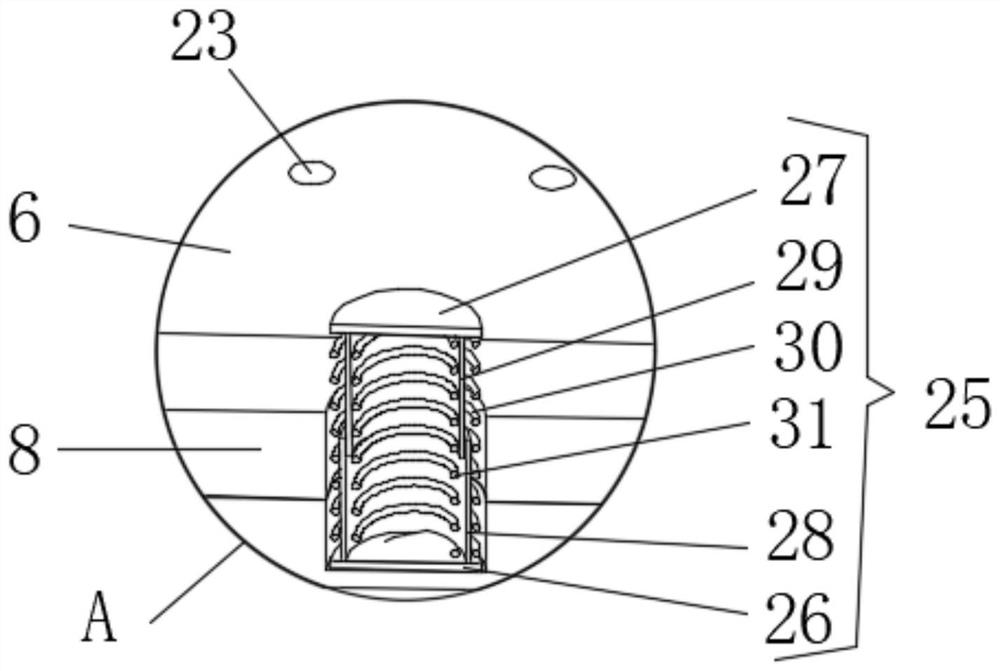

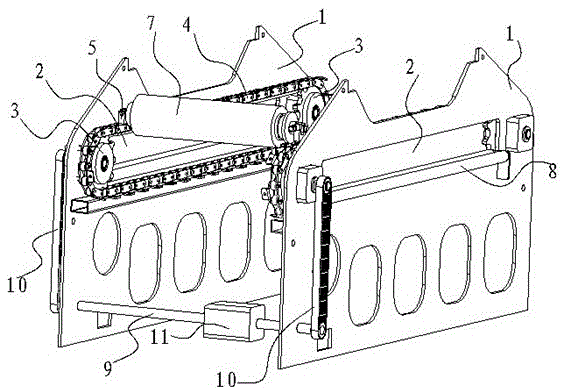

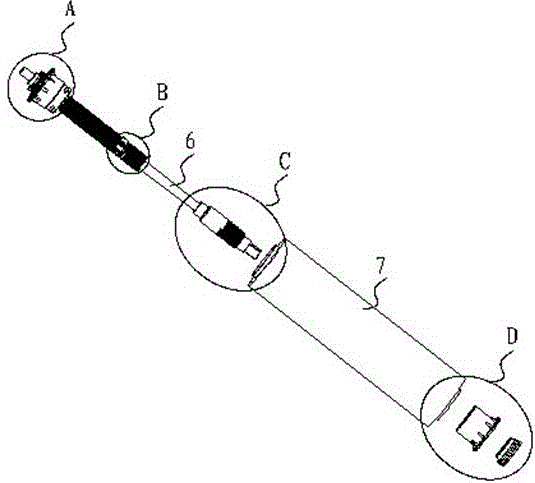

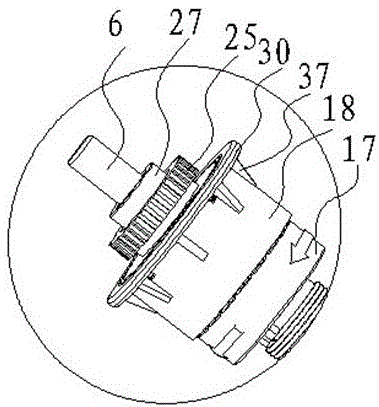

Horizontal type glove automatic turnover discharging machine and turnover discharging method thereof

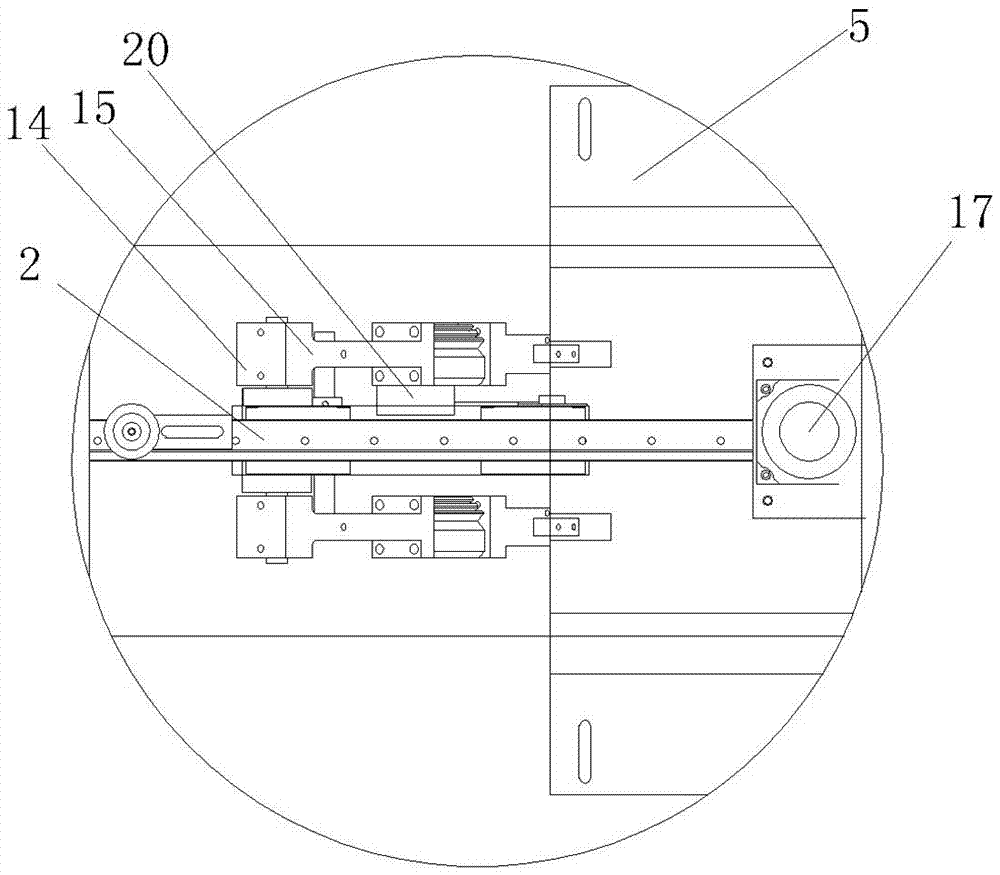

ActiveCN107264899AReduce labor intensityReduce in quantityPackaging automatic controlRobot handTransmission belt

The invention discloses a horizontal type glove automatic turnover discharging machine. The machine comprises a rack, a mechanical arm unit, a discharging transfer plate, a PLC, two feeding units and two auxiliary turnover units; the mechanical arm unit can achieve the horizontal linear movement and vertical direction turnover motion, each feeding unit comprises a transmission belt, multiple feeding plates and a transmission motor for driving the transmission belt, each auxiliary turnover unit comprises a turnover plate, a turnover plate lifting air cylinder and a glove inductor, the turnover plates can achieve the vertical liner motion, the ends of the turnover plates correspond to the ends of the feeding plates, the position of the mechanical arm unit corresponds to the position of the feeding plate and the position of the discharging transfer plate, the glove inductor is connected with the signal receiving end of the PLC, and the control end of the PLC is connected with a turnover plate lifting air cylinder. The machine is used in cooperation with a packaging machine, turnover and discharging speed is high, labor intensity of workers is reduced, production efficiency is improved, manual cost is reduced, and the product turnover effect and the packaging effect are ensured.

Owner:杭州天琅自动化设备有限公司

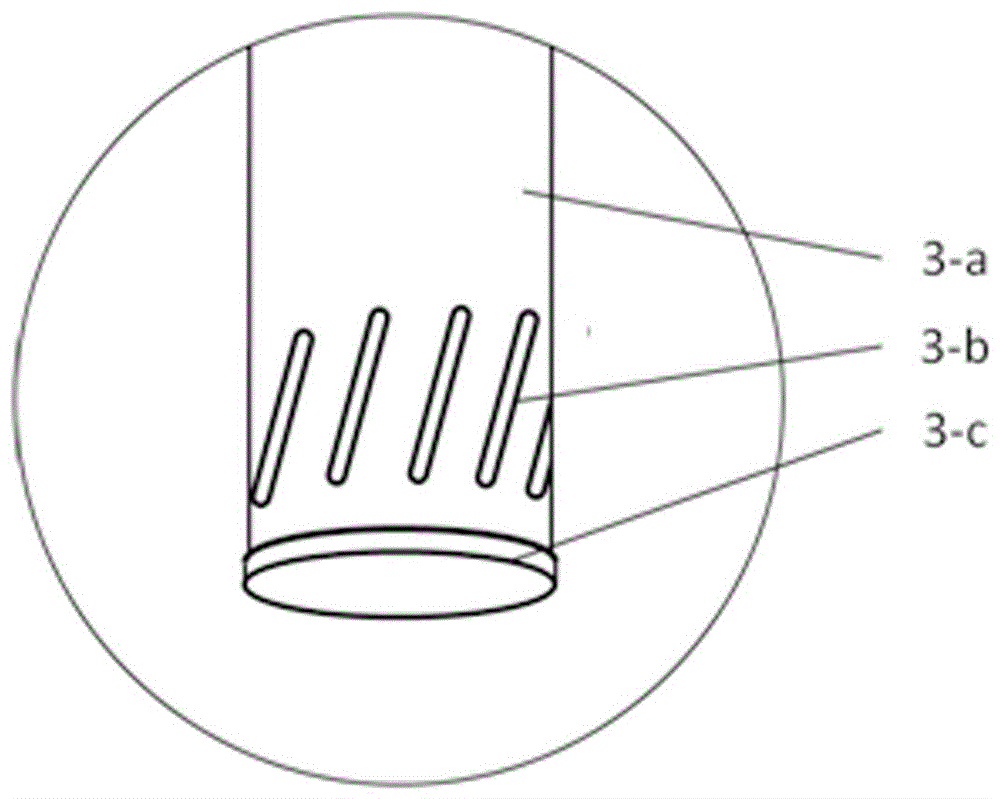

Surface anti-corrosive ventilating type nanomaterial industrial paper packing bag and its application

InactiveCN1594042AGuaranteed packaging effectEfficient separationFlexible coversWrappersSilica HydrateEngineering

This invention is about a packing bag for industrial paper, to be exact, this packing bag is made of nanophase materials and its surface is permeable but antiseptic. Inside the bag is plastered a layer of film in which some tiny holes are made from internal to external. The film is made of polythene, polypropylene and polythene or polypropylene containing silica hydrated. This invention has such following advantages: 1) better antisepsis, because the invention films a kind of high molecular material( high pressure polythene or polypropylene) onto the surface of a packing bag for average paper and forms into a new type of compound paper-packing material, it is a better and more effective solution to antisepsis; 2) that the bag has a good air delivery from inside to outside and excellent feasibility, so it improves the mechanic intensity of brown packing paper and waterproofing and damp proofing; 3) its film is even spilled.

Owner:天威英利

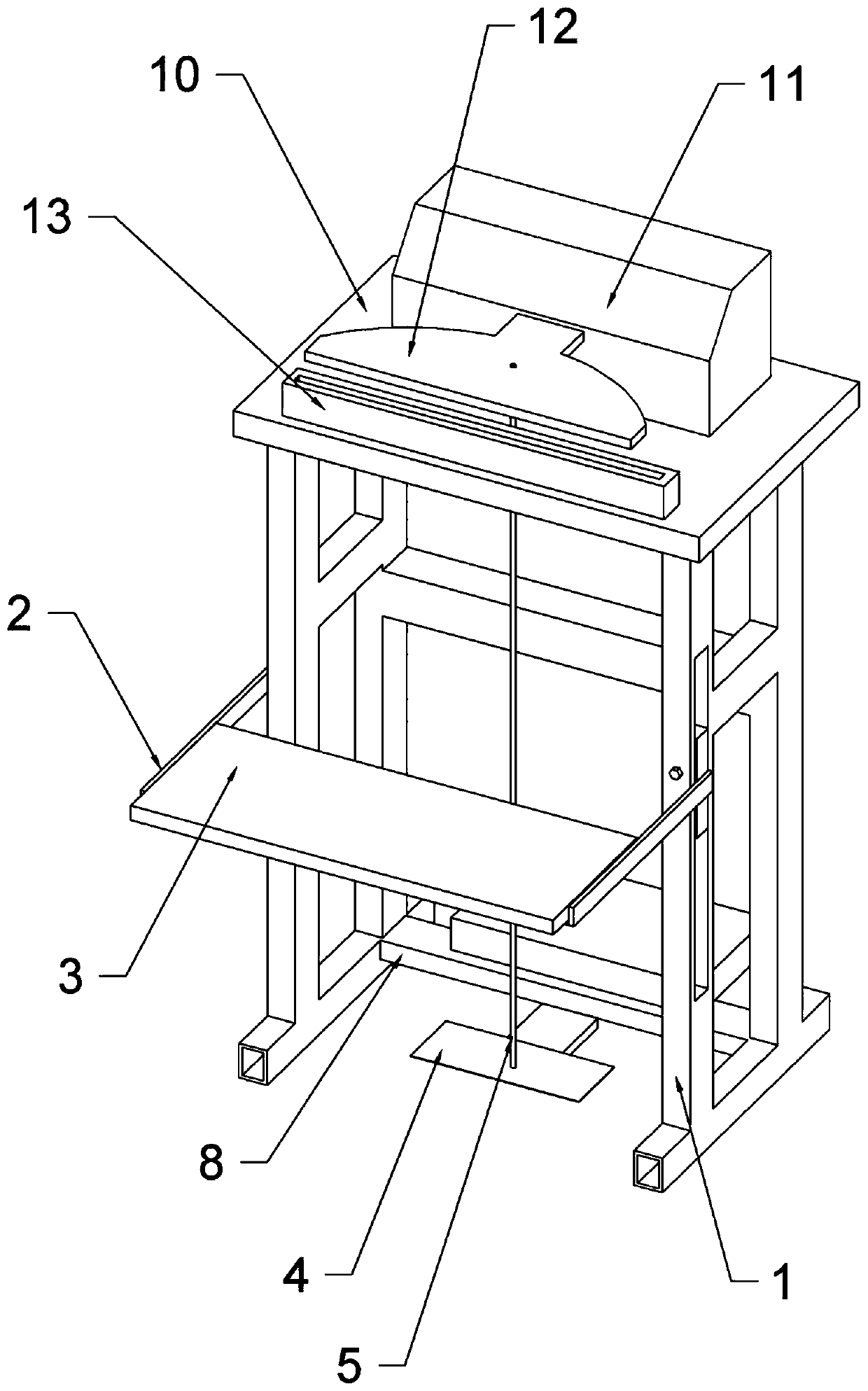

Box sealing and packaging platform based on intelligent automation

InactiveCN112278438AGuaranteed packaging efficiencyGuaranteed packaging effectWrapper twisting/gatheringAdhesive beltStructural engineering

The invention discloses a box sealing and packaging platform based on intelligent automation, and relates to the technical field of intelligent equipment. The box sealing and packaging platform comprises supporting seats; a power transmission belt is arranged between the two supporting seats; bearing frames are arranged on the two opposite sides of the power transmission belt; the two bearing frames are correspondingly fixed at the upper parts of the two supporting seats; a rotary clamping assembly is arranged between the two bearing frames; the rotary clamping assembly is used for adjusting the position of a packaging box; a pressing assembly is arranged above the rotary clamping assembly; the pressing assembly is used for pressing an upper cover plate of the packaging box; supporting columns are vertically fixed to the two opposite sides of the two bearing frames; the upper ends of the four supporting columns are connected through a fixing frame; an adhesive tape mounting rod and a gluing assembly are arranged on the inner side of the fixing frame; and the gluing assembly is used for adhering an adhesive tape to the packaging box. The box sealing and packaging platform is reasonable in structural design and convenient to use, the box sealing and packaging efficiency and effect are effectively guaranteed, and the high market application value is achieved.

Owner:马鞍山昌亚智能科技有限公司

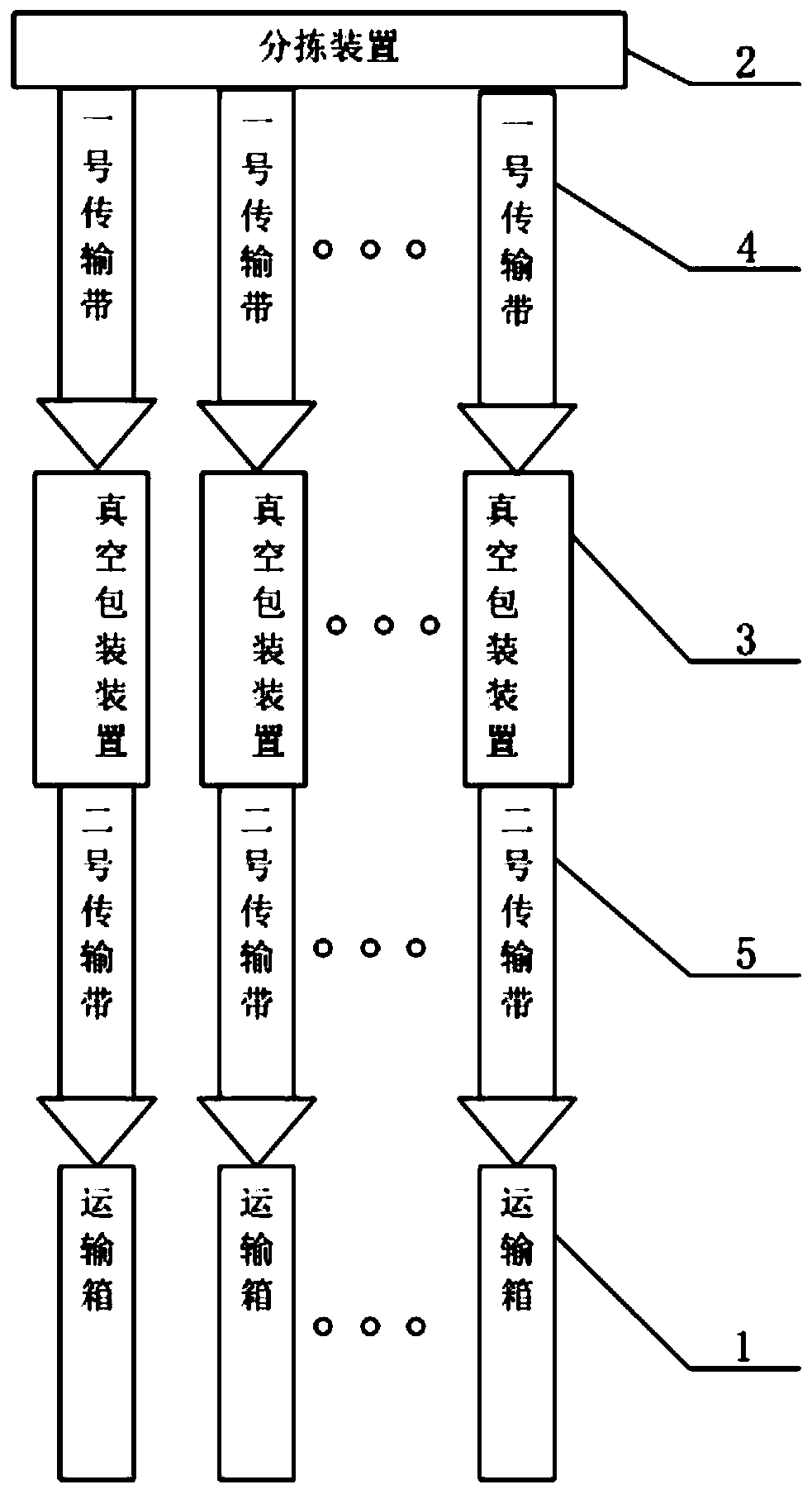

Logistics packaging, verifying and ex-warehouse method and system

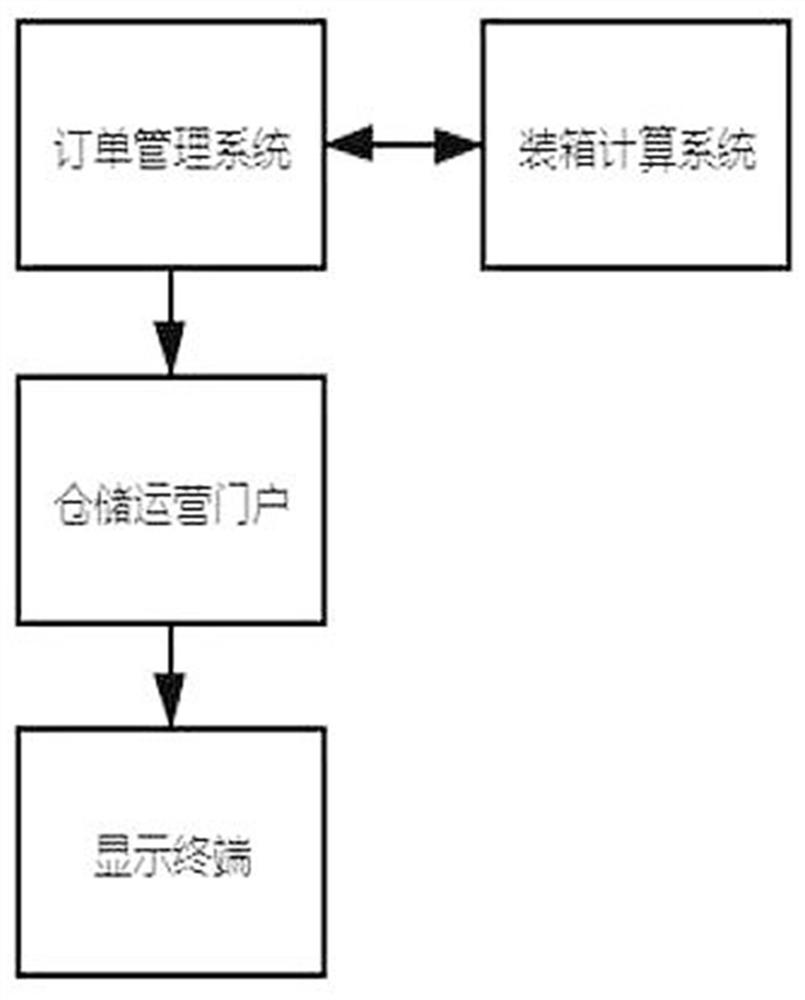

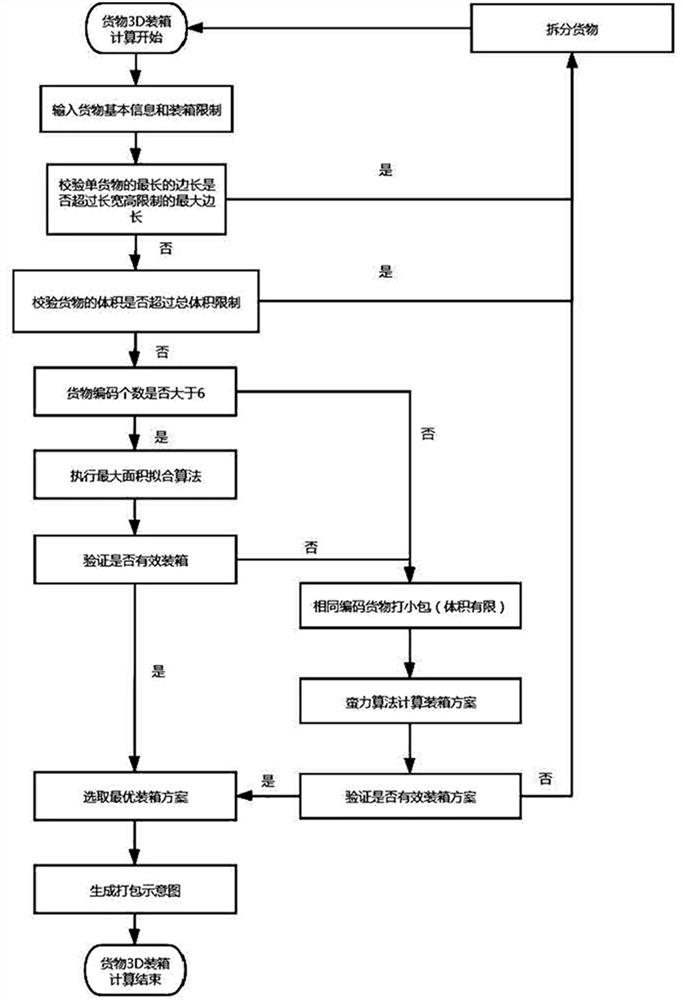

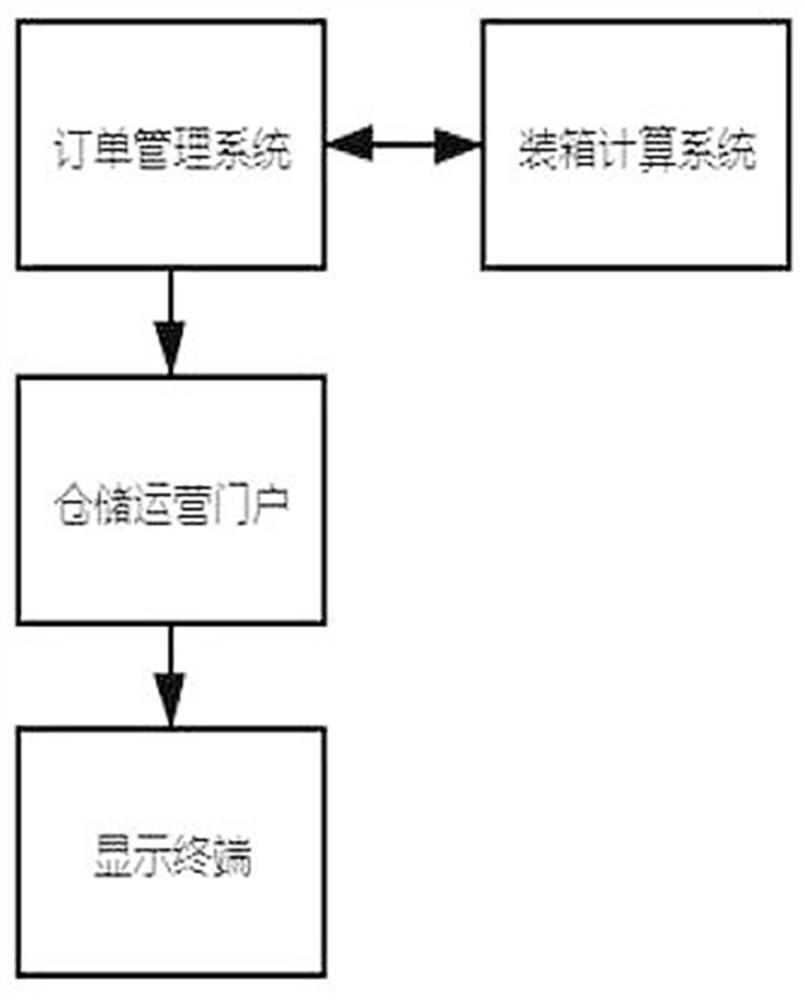

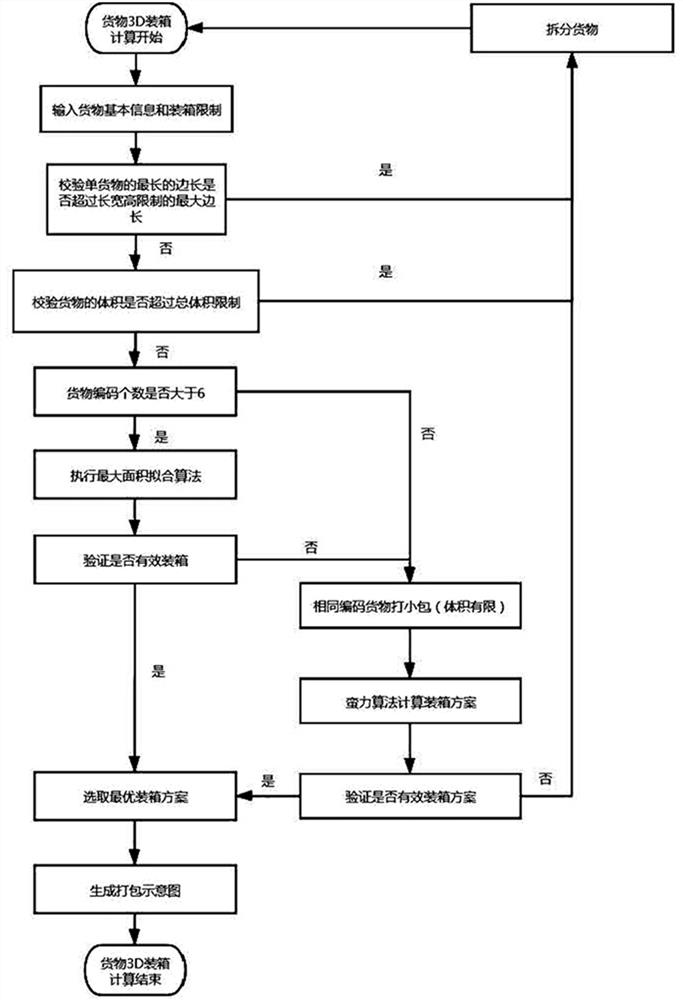

InactiveCN112124837AImprove efficiencyReasonable use of carton spacePackaging automatic controlLogisticsManagement systemManufacturing engineering

The invention discloses a logistics packaging, verifying and ex-warehouse method and system, and relates to the technical field of logistics packaging. The logistics packaging, verifying and ex-warehouse system comprises an order management system, a boxing calculation system, a storage operation system and a display terminal. According to the logistics packaging, verifying and ex-warehouse methodand system, after the order management system receives an order, the boxing calculation system calculates a proper packaging scheme according to basic information of goods, and packaging personnel select a corresponding packaging box according to a boxing schematic diagram and package the goods, a plurality of packaging schemes are calculated through an algorithm according to the packaging requirements, number, size and carton specification of goods, each packaging scheme comprises the specific placement position, placement sequence and carton number of the goods, then one most suitable scheme is selected from different schemes, finally the most suitable scheme is displayed to packaging workers through an interface, the display content comprises which goods are packaged into which carton,the placement positions of the goods and the placement sequence of the goods, so that the boxing effect is guaranteed, and the efficiency is improved.

Owner:深圳市万邑通信息科技有限公司

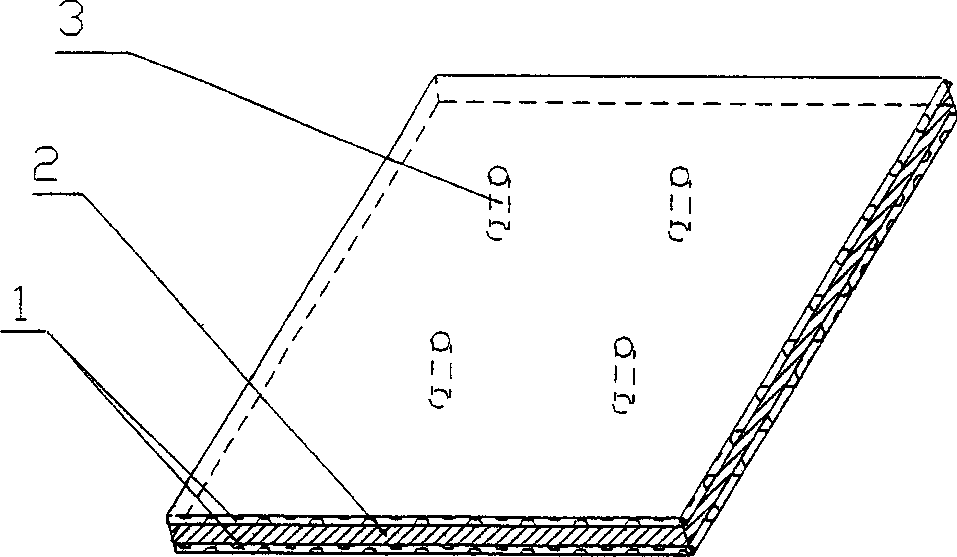

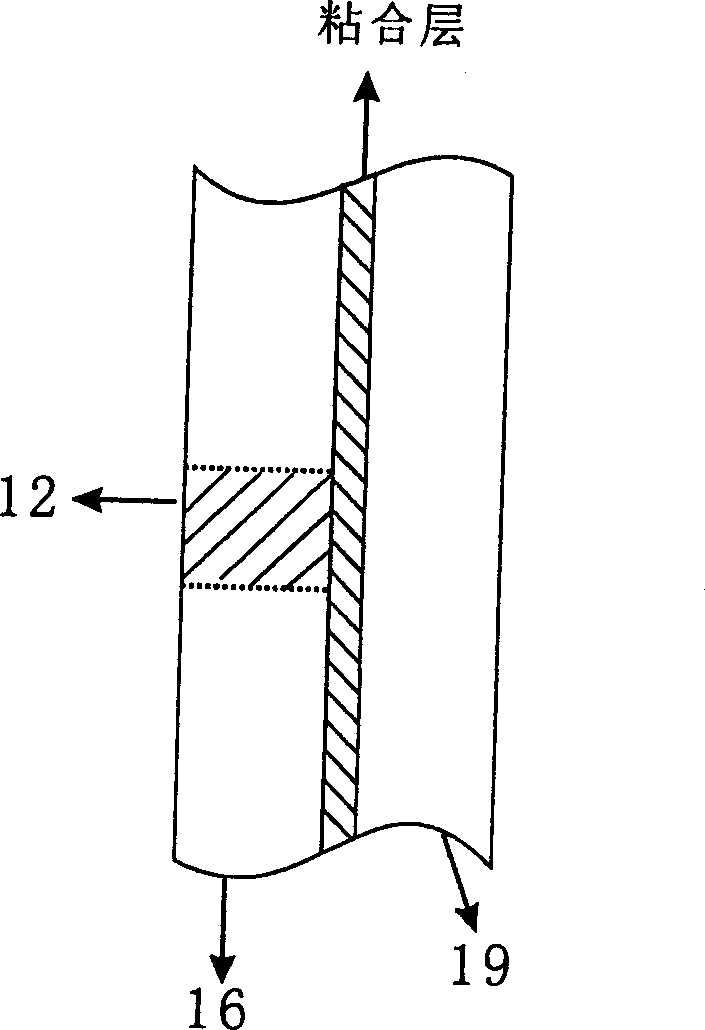

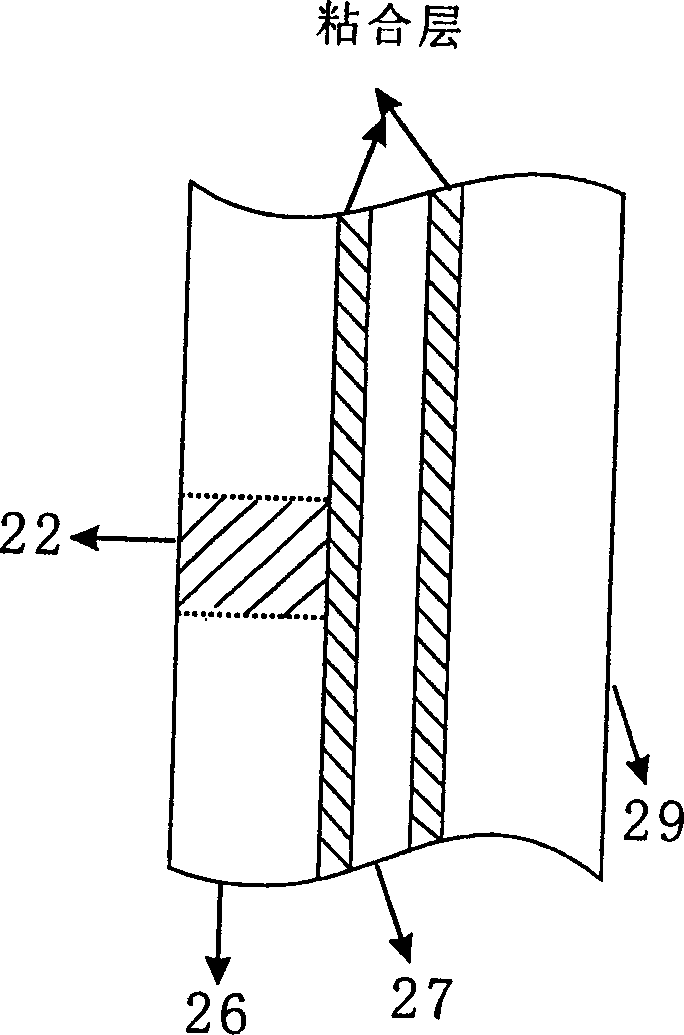

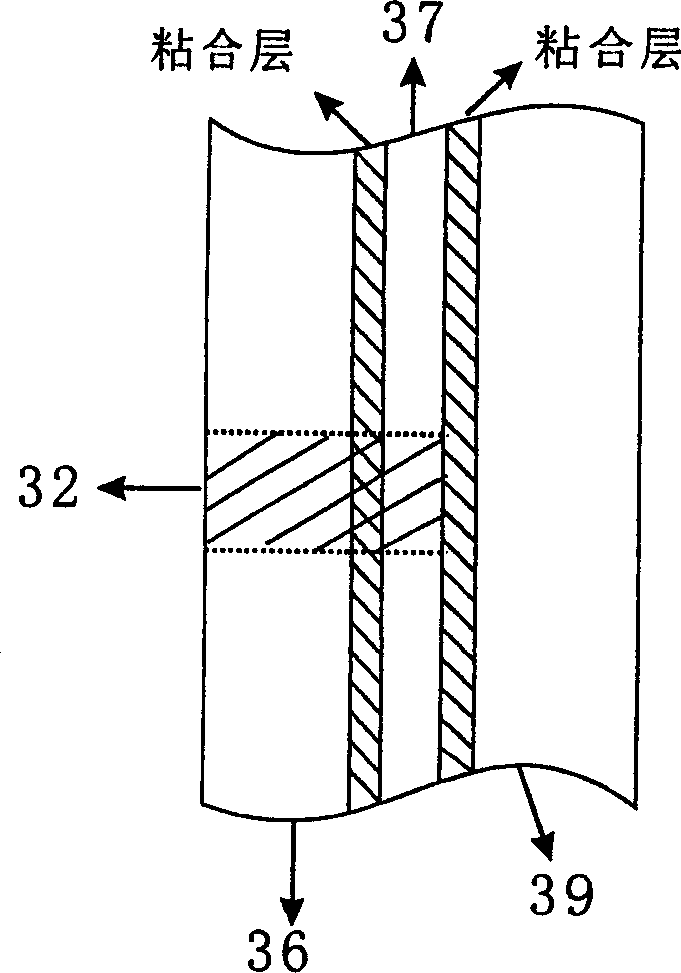

Packaging bag composite material into which sucking pipette can be easily inserted

InactiveCN1400145AGuaranteed packaging effectComplete Package PerformanceSynthetic resin layered productsRigid containersPipetteEngineering

The present invention relates to a composite material for beverage packaging bag into which the sucking tube can be easily inserted. Said composite material is made of more than two layers of materials and combining them together. In the composite material one layer is used as inserting hole at least, and another at least one layer is used as sealing layer of said inserting hole. Said invention is safe and reliable, and does not increase production cost.

Owner:JIXIANG DECORATING & CRAFTS FACTORY CO LTD SHANTOU

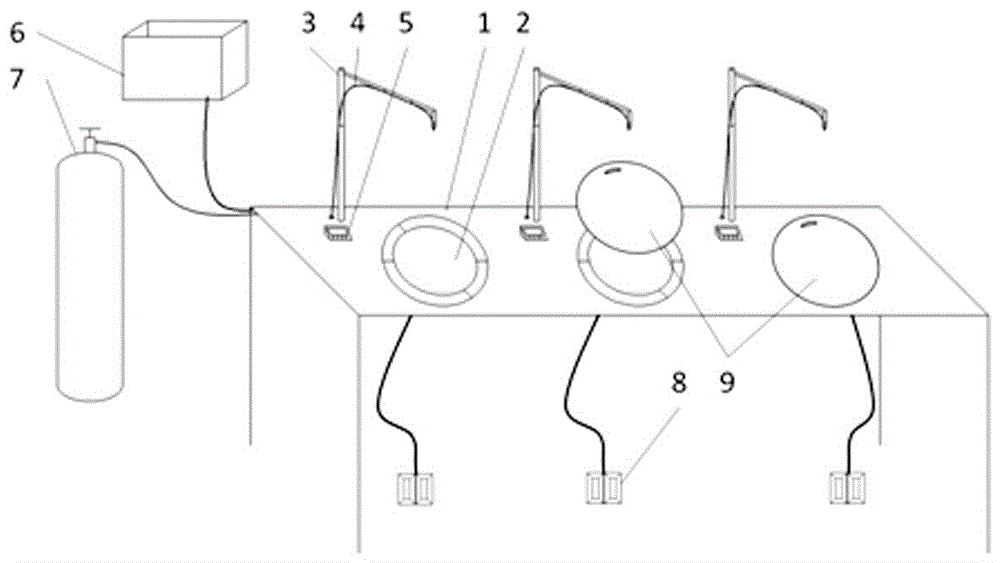

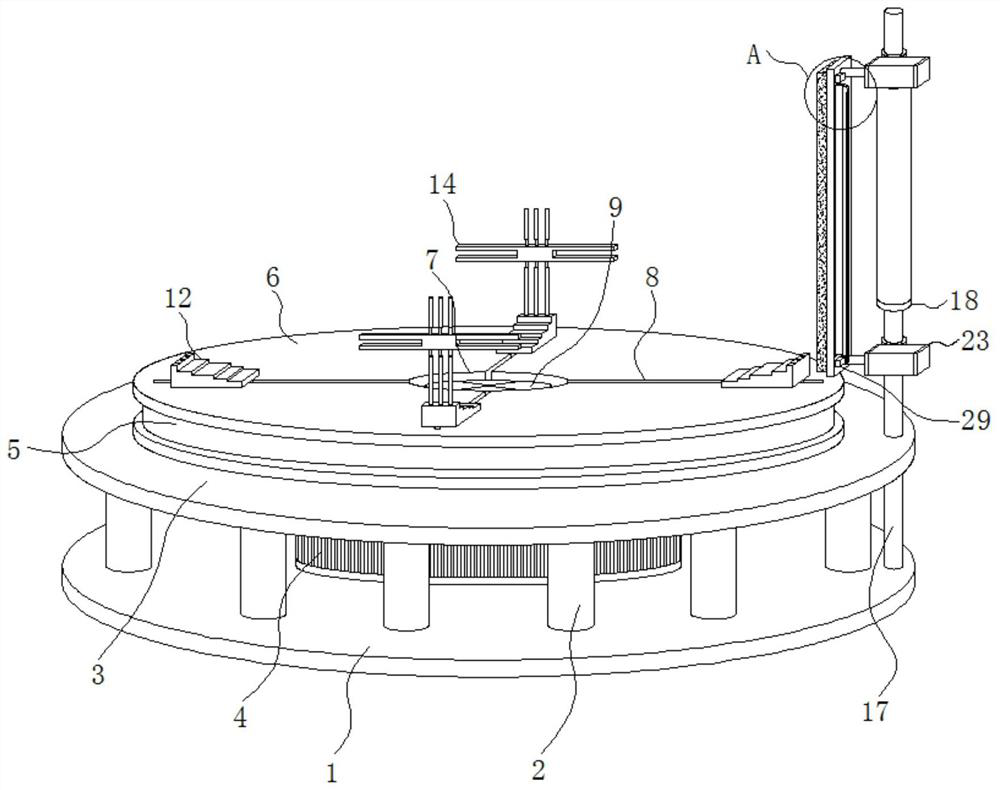

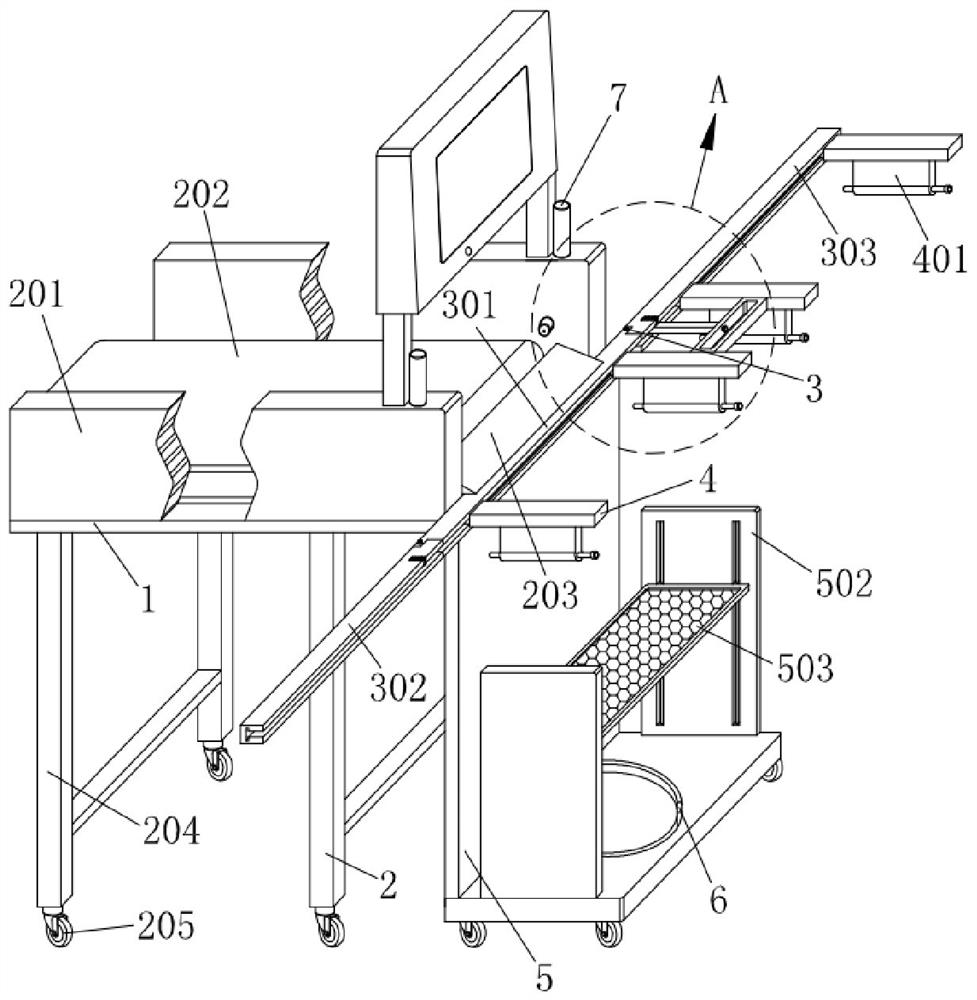

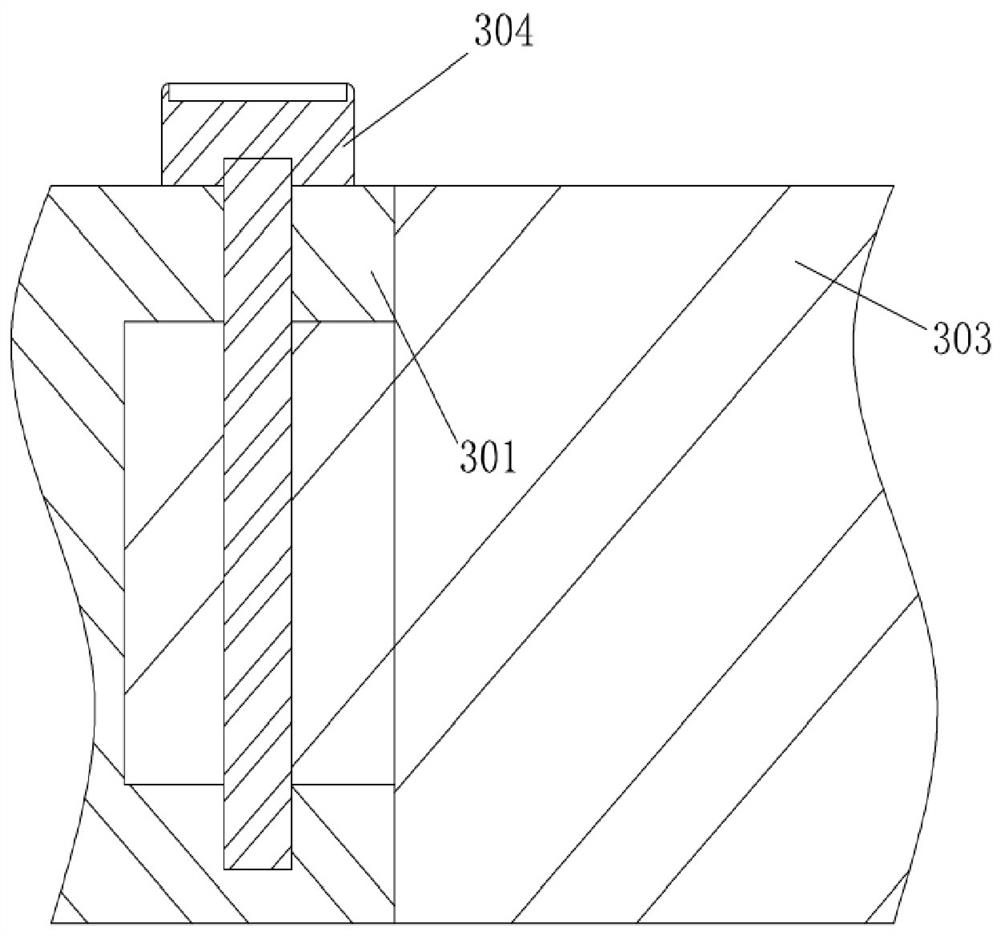

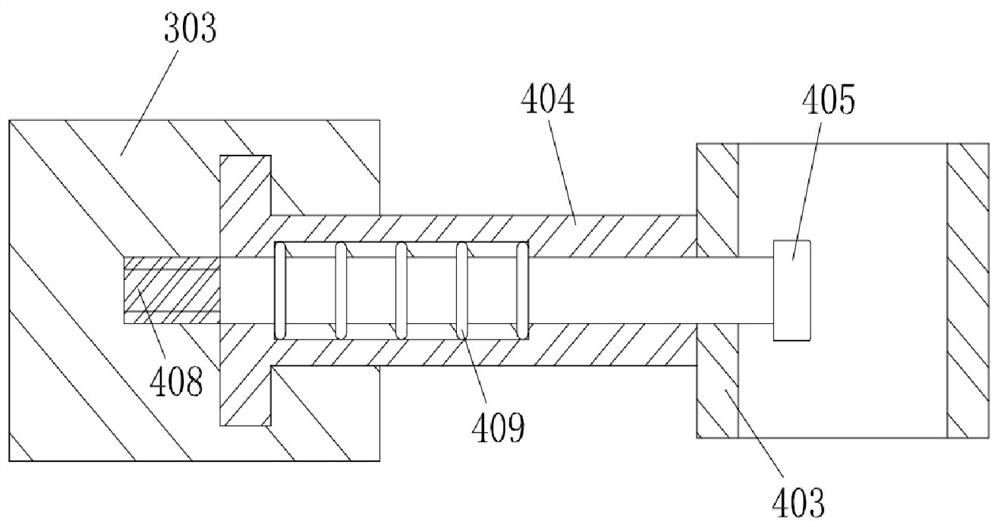

Aquatic product seedling watering, oxygenating and packaging work table

InactiveCN106508776AAvoid harmSimple and strong structurePisciculture and aquariaWrapper twisting/gatheringWater storageAquatic product

The invention aims at providing an aquatic product seedling watering, oxygenating and packaging work table, and belongs to the technical field of aquatic product machines. The structure of the aquatic product seedling watering, oxygenating and packaging work table comprises a workbench main body formed by supporting a table top through feet, a hole is formed in the table top, an electronic platform scale is erected in the hole, and a display screen, displaying the weight, of the electronic platform scale is arranged on the table top; a water pipe is erected on the table top, the water outlet end of the water pipe is located over the platform scale, and the water inlet end of the water pipe is connected with a water pump or arranged on water storage equipment located at a high position; the table top is further provided with a gas pipe which is arranged along the water pipe and bound on the water pipe, the gas outlet end of the gas pipe and the water outlet end of the water pipe are bound to the same position, and the gas inlet end of the gas pipe is connected with an oxygen bottle. According to the aquatic product seedling watering, oxygenating and packaging work table, line production cooperation is convenient, the packaging effect is guaranteed while the labor intensity and the requirements on worker experience are reduced, damage to aquatic product seedlings in the packaging process is avoided, and the very good practicability and applicability to multiple kinds of seedling fields or seedlings are achieved.

Owner:BEIHAI YISHENGYUAN AGRI TRADE CO LTD

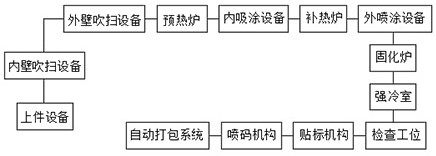

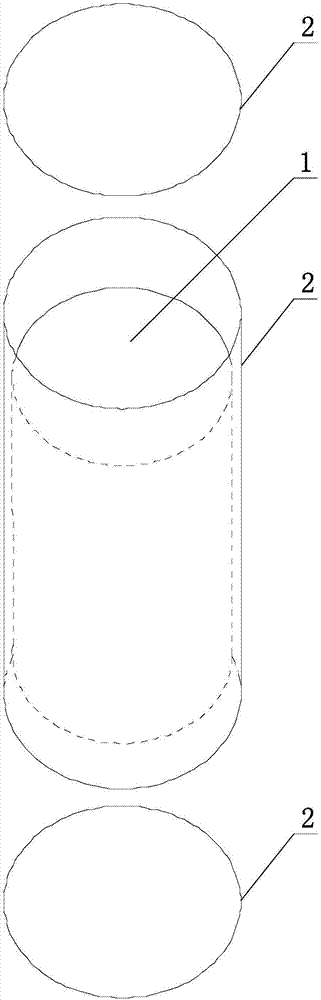

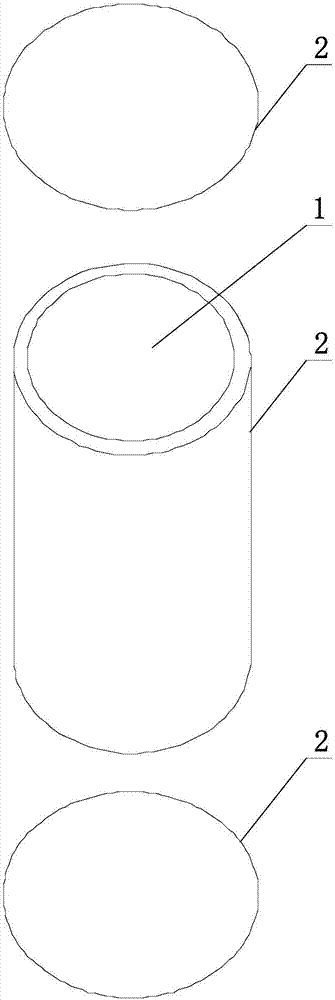

Production line for coating inner wall and outer wall of metal pipe

ActiveCN113830384AEasy to store and placeImprove packaging efficiencyWrappers shrinkageSpray boothsCooling chamberEngineering

The invention relates to a production line for coating the inner wall and the outer wall of a metal pipe. The production line comprises a feeding device, an inner wall purging device, an outer wall purging device, a preheating furnace, an inner suction coating device, a heat supplementing furnace, an outer spraying device, a curing furnace, a forced cooling chamber, an inspection station, a labeling mechanism, a code spraying mechanism and an automatic packaging system which are sequentially arranged from front to back, the automatic packaging system comprises an material collecting and steering conveying mechanism, bagging and film covering mechanisms, an electromagnetic carrying mechanism, a hexagonal forming device, a horizontal winding device, a semi-automatic steel belt bundling mechanism, a bundling machine conveying line, a steel pipe conveying, transferring and storing mechanism, a steel pipe weighing mechanism and an electric control box, the bagging and film covering mechanisms and the code spraying mechanism are in butt joint through the material collecting and steering conveying mechanism, the material collecting and steering conveying mechanism conveys at least two workpieces to the bagging and film covering mechanisms at a time, and correspondingly, the multiple bagging and film covering mechanisms are arranged and synchronously conduct bagging and shrinking. The production line can guarantee the quality of the workpieces and improve the packaging efficiency.

Owner:ZHEJIANG KINGLAND PIPELINE & TECH CO LTD

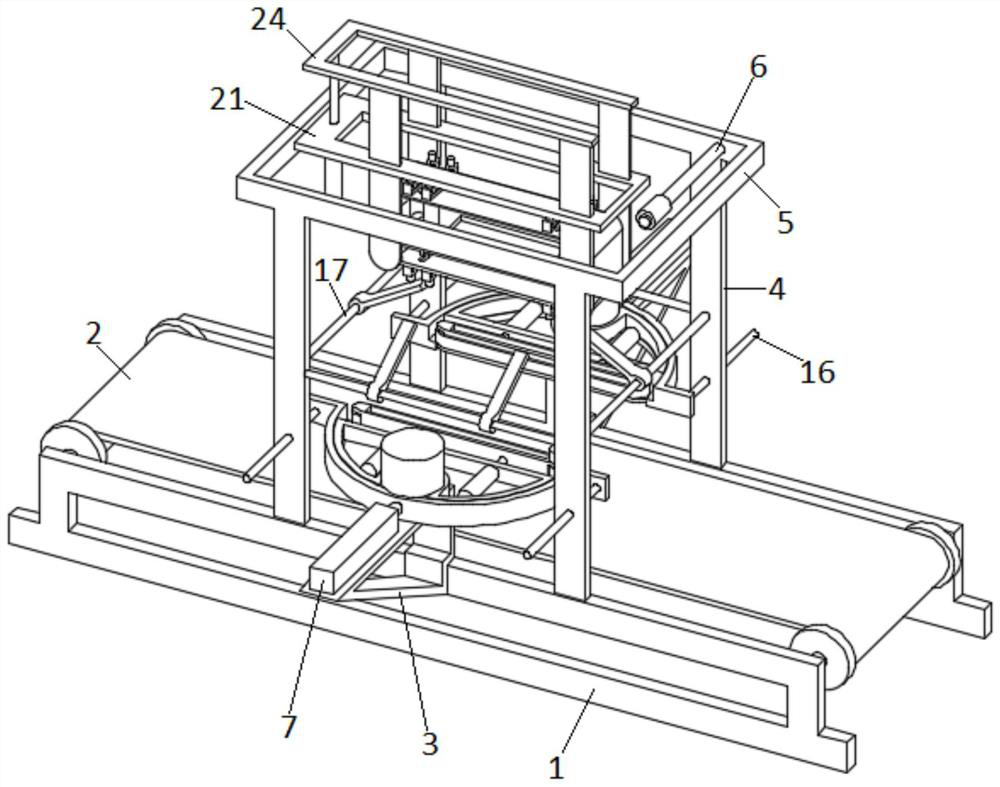

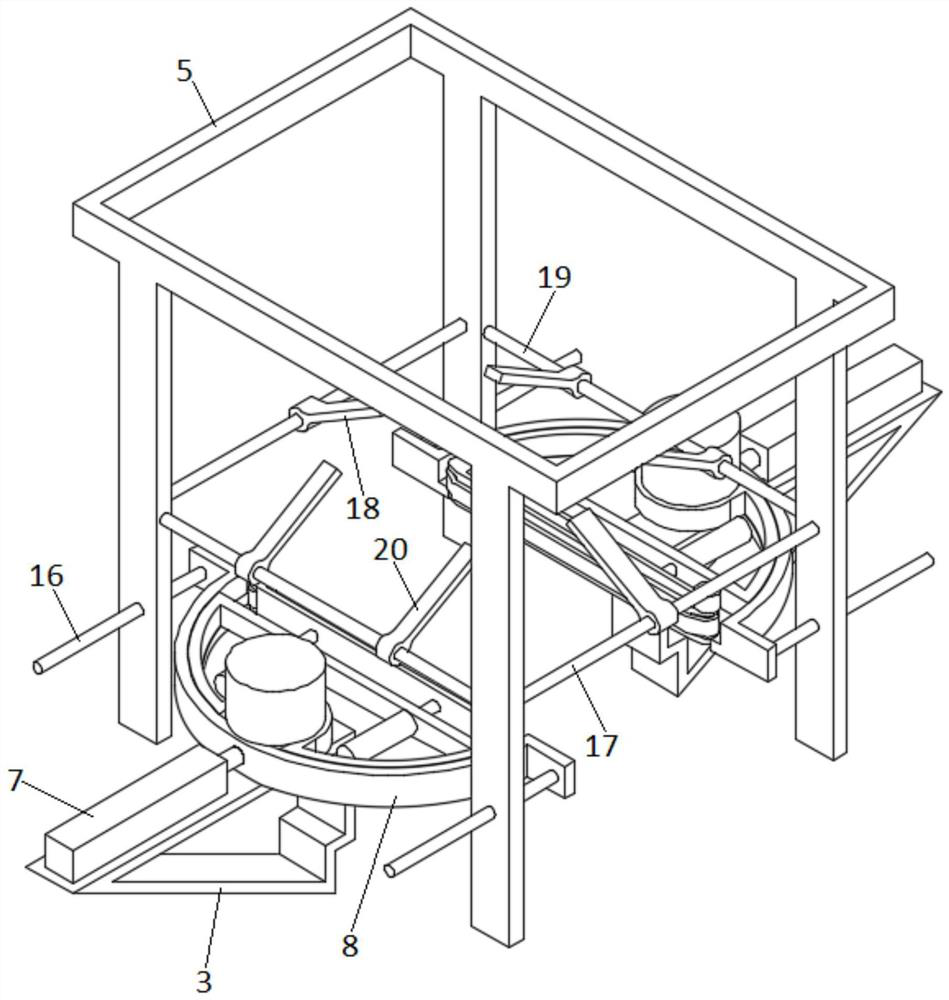

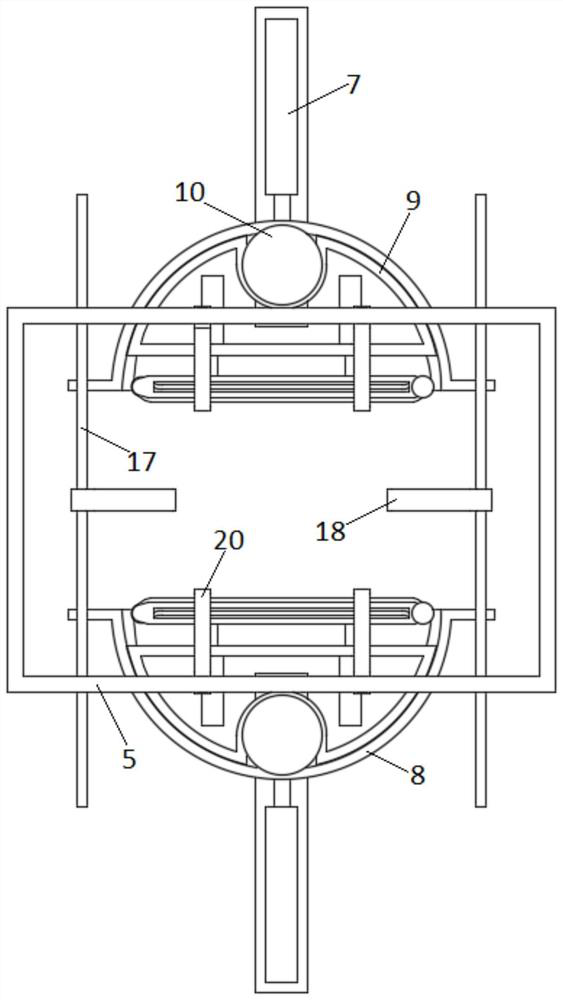

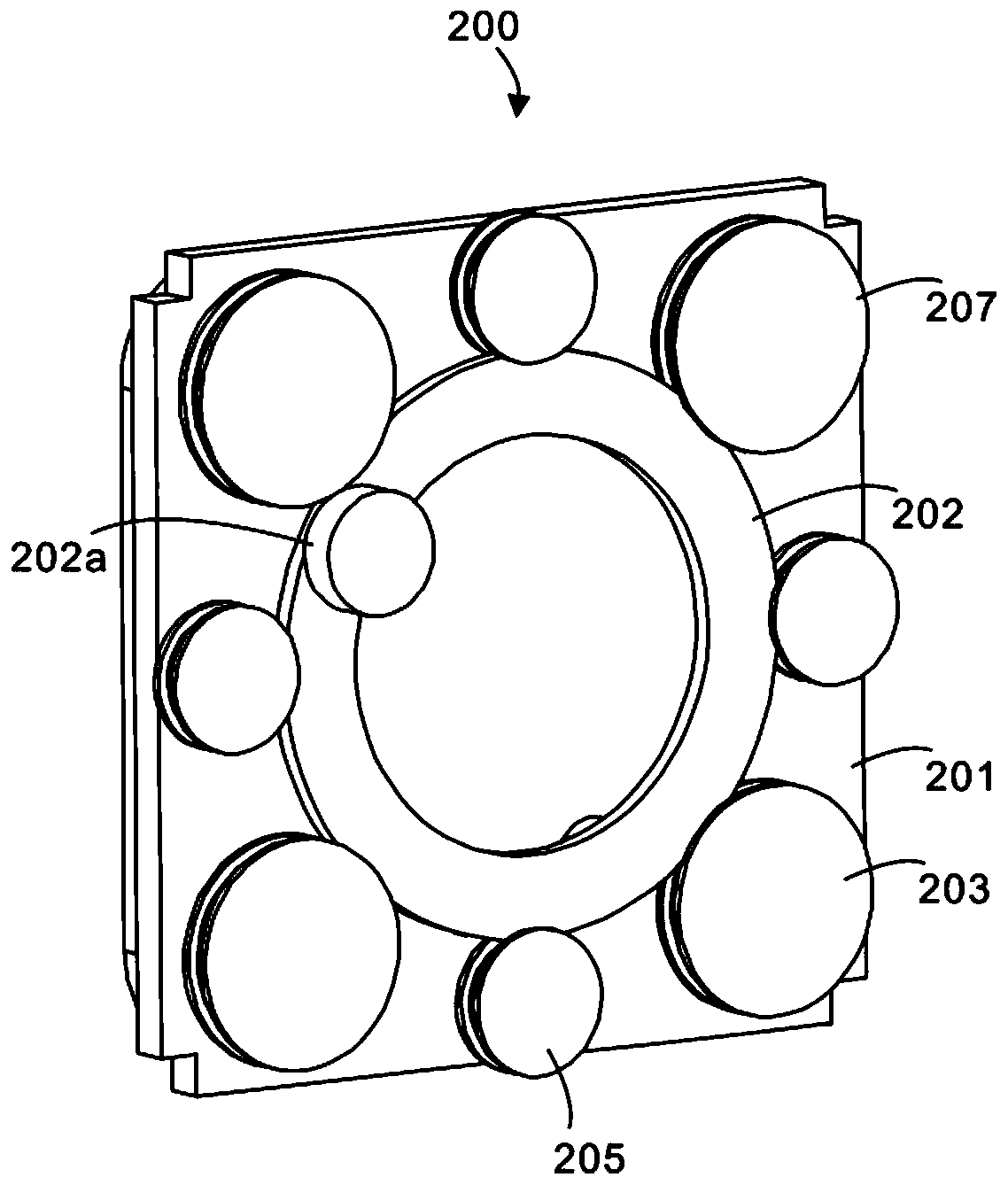

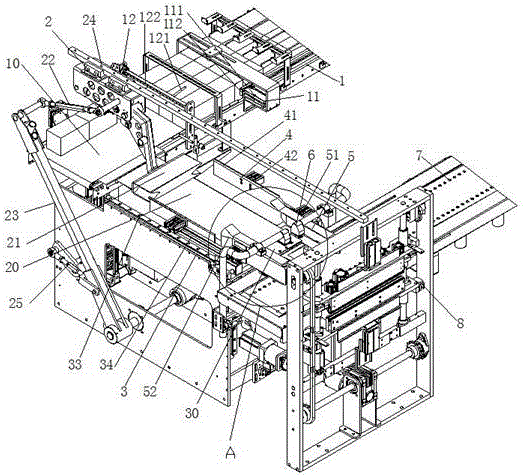

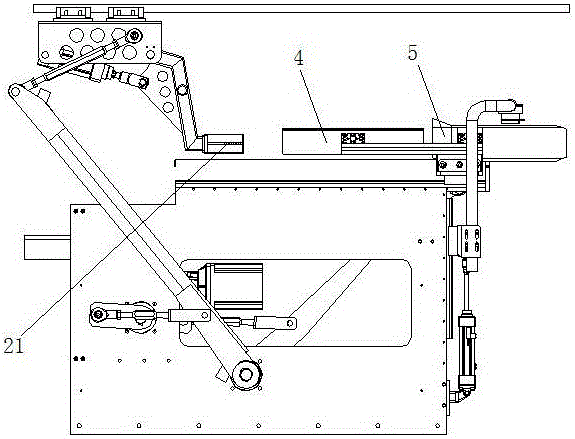

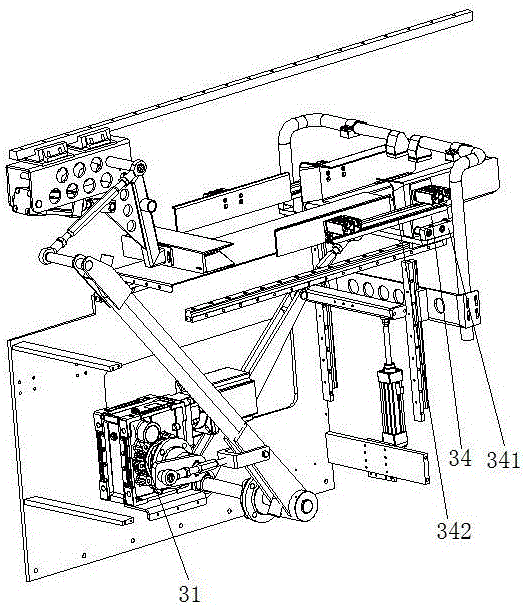

Packing machine for primary and secondary fusion complete switch testing equipment

The invention discloses a packing machine for primary and secondary fusion complete switch testing equipment. The packing machine comprises a conveying assembly, a horizontal winding assembly and a vertical winding assembly, wherein the conveying assembly is divided into a first conveyor, a second conveyor and a third conveyor, the two ends of the second conveyor are correspondingly adjacent to the first conveyor and the second conveyor, the horizontal winding assembly is arranged between the first conveyor and the second conveyor, the vertical winding assembly is arranged above the third conveyor, the horizontal winding assembly comprises a first support, a rotating body, a rotating driving piece, a first driving motor and a limiting piece, the rotating driving piece and the limiting piece are both arranged on the first support, and the rotating driving piece and the limiting piece both cooperate with the rotating body. According to the packing machine, through mutual cooperation among the conveying assembly, the horizontal winding assembly and the vertical winding assembly which are arranged, the testing equipment can be packed in all aspects without turning or pressing the testing equipment, so that the packing effect is ensured, and the packing efficiency is also improved.

Owner:SHANGHAI WISCOM SUNEST ELECTRIC POWER TECH

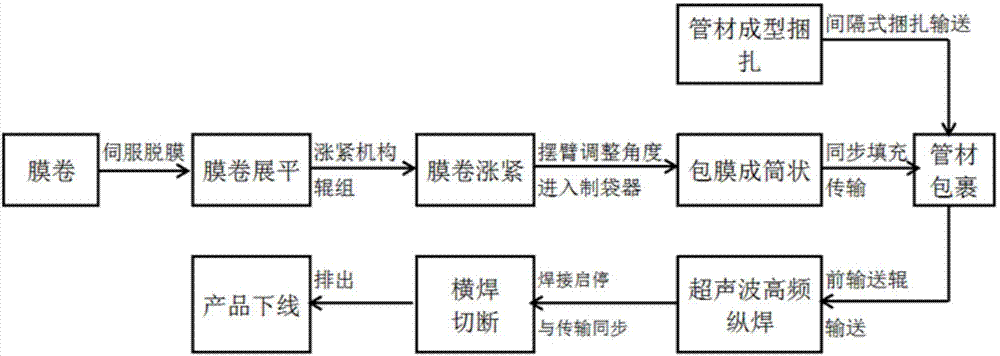

Pipe packaging technology

InactiveCN104118590AAvoid damageRunning at the same speedConveyor wrappingWrapper twisting/gatheringEngineeringUltimate tensile strength

The invention discloses a pipe packaging technology. The pipe packaging technology is characterized by including the following steps that first, pipes are formed and bound; second, the pipes are wrapped; third, ultrasonic high-frequency longitudinal welding is performed; fourth, transverse welding cutting is performed; fifth, the products are discharged off the line. The pipe packaging technology is reasonable in design, a sorting machine, a binding machine and a packaging machine are fully utilized, it is guaranteed that the running speed of the pipes is consistent with that of packaging film, the pipes are stationary relative to the packaging film, damage to the pipes is prevented, labor intensity can be reduced, working efficiency can be improved, and the packaging effect can be guaranteed.

Owner:BEIJING XINSHI CREATIVE PACKAGING MACHINERY

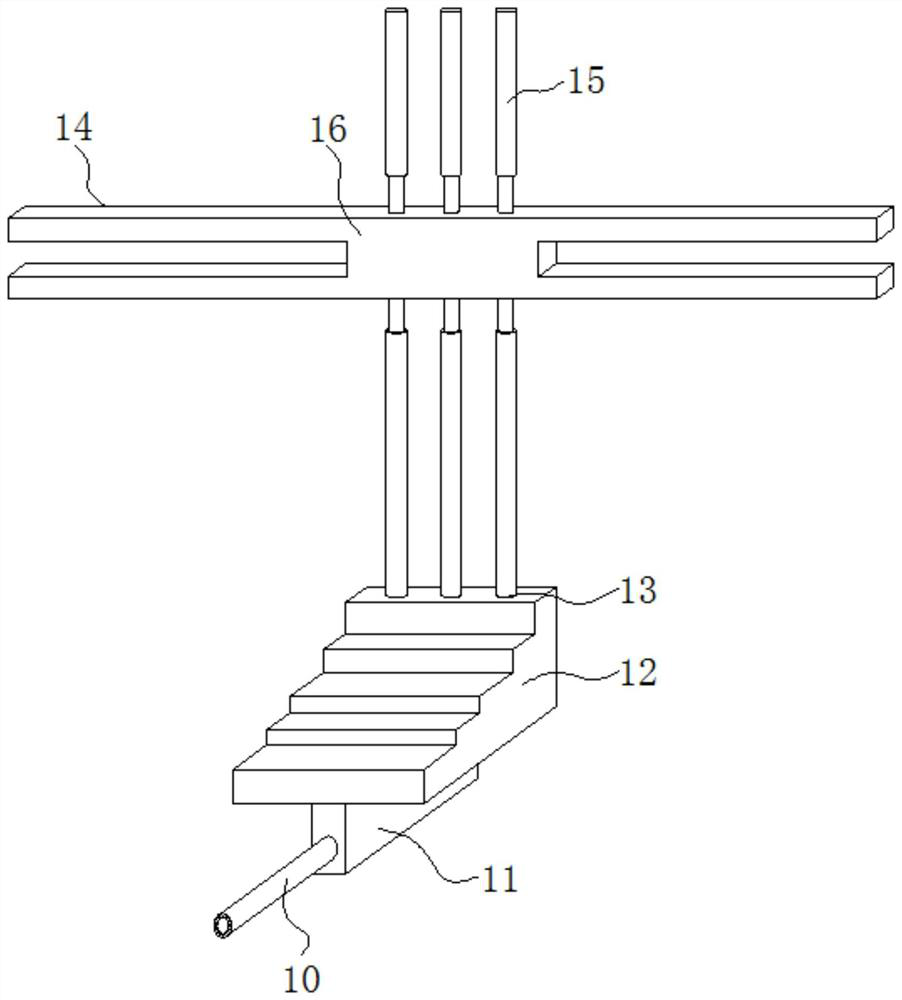

Heat exchanger automatic packaging machine with edge cutting function

PendingCN112265681AWith trimming functionSave human effortWrapping material feeding apparatusWrapping with article rotationElectric machineryEngineering

The invention discloses a heat exchanger automatic packaging machine with an edge cutting function, and relates to the technical field of heat exchanger packaging machines. Specifically, the heat exchanger automatic packaging machine comprises a bottom disc, holding mechanisms, a mounting rod, a film winding mechanism, a film pressing mechanism and a film cutting mechanism, wherein a motor is mounted in the center of the upper surface of the bottom disc, the center of the lower surface of a rotating disc is connected with the output end of the motor, the holding mechanisms are assembled on theupper sides of stepped clamping jaws through insertion holes, the mounting rod vertically penetrates through one side of the edge of a bearing disc, the film winding mechanism is installed on the upper section of the mounting rod, the film pressing mechanism is installed on one side of the film winding mechanism, and the film cutting mechanism is assembled on the film pressing mechanism. According to the heat exchanger automatic packaging machine with the edge cutting function, the rotating disc can be driven to rotate through the motor, then heat exchangers stacked on the rotating disc can be driven to rotate, and then film roll packaging can be conducted on the heat exchangers. Convenience and rapidness are achieved, manpower and time are saved, and the packaging efficiency is improved.

Owner:WUXI JIALONG HEAT EXCHANGER

Activated carbon bag batch production machine and method

InactiveCN112298630AGuaranteed packaging effectQuality assuranceWrapper twisting/gatheringSolid materialActivated carbonProcess engineering

The invention provides an activated carbon bag batch production machine and a method. The machine comprises a bottom plate, an adjusting unit, a fixing sleeve disc, an inner sleeve unit, a vibration unit, a thermoplastic unit, a fixing unit, and a feeding unit. The activated carbon bag batch production machine and the method can solve the problems that an activated carbon bag is fluffy and difficult to package and sew due to the fact that activated carbon in the activated carbon bag is too loose in the packaging process of the activated carbon bag in the prior art; the quantity of the activated carbon in existing activated carbon bags is fixed, so that the quantity of each activated carbon bag is not fixed; and the existing activated carbon bags are low in sewing efficiency, manual bag tying packaging is mostly adopted, and the packaging efficiency is affected.

Owner:南京众荣环保技术开发有限公司

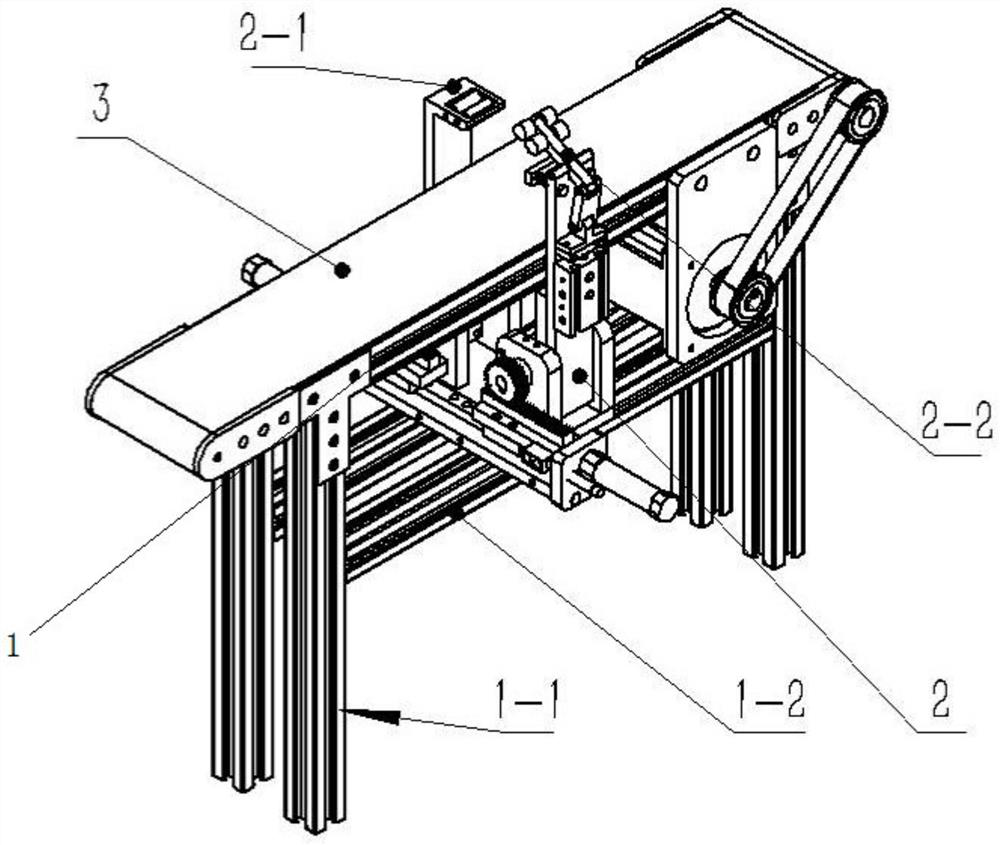

Material holding type conveying method for preformed-bag packer

ActiveCN105752402ADoes not pinch and squeezeImprove delivery efficiencyPackagingEngineeringMechanical engineering

The invention discloses a material holding type conveying method for a preformed-bag packer and belongs to the technical field of material packing. The material holding type conveying method is characterized by including the steps of firstly, conveying materials into a holding mechanism; secondly, conveying the materials by a holding way to a to-be-pushed work station and opening preformed bags by a bag opening mechanism; thirdly, pushing the materials by a pushing mechanism while driving the preformed bags to move opposite the materials by the bag opening mechanism. The material holding type conveying method is adaptable to both regular materials in bulk and irregular materials in bulk; the material holding type conveying way is stabler than the material clamping type conveying way and squeezing of the materials is avoided; thus, material conveying efficiency is improved, and efficiency of preformed bag packing is improved.

Owner:上海松川峰冠包装自动化有限公司

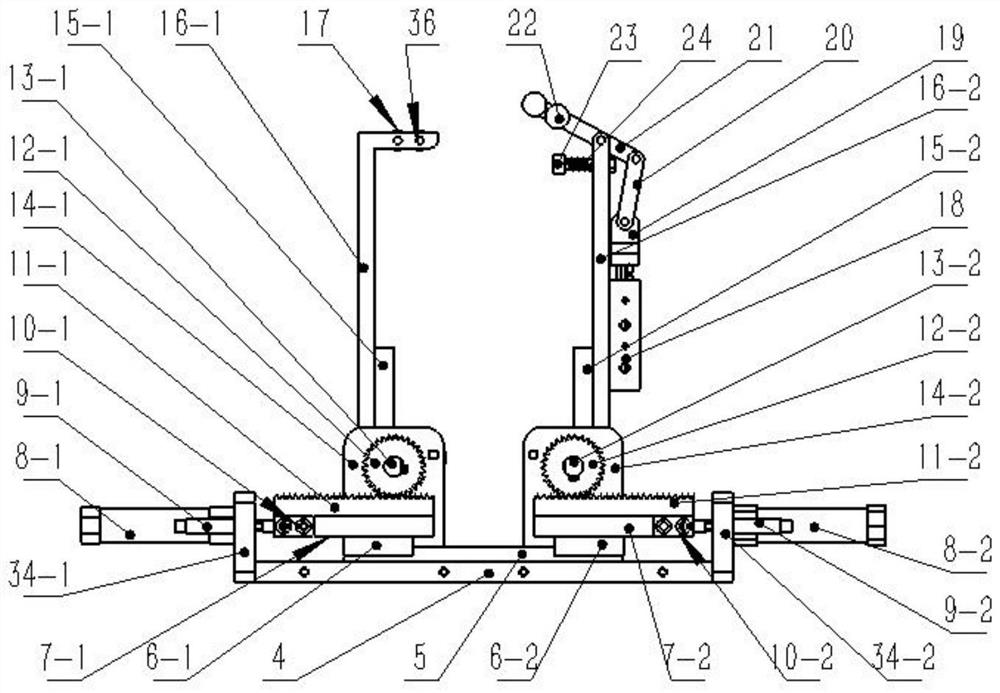

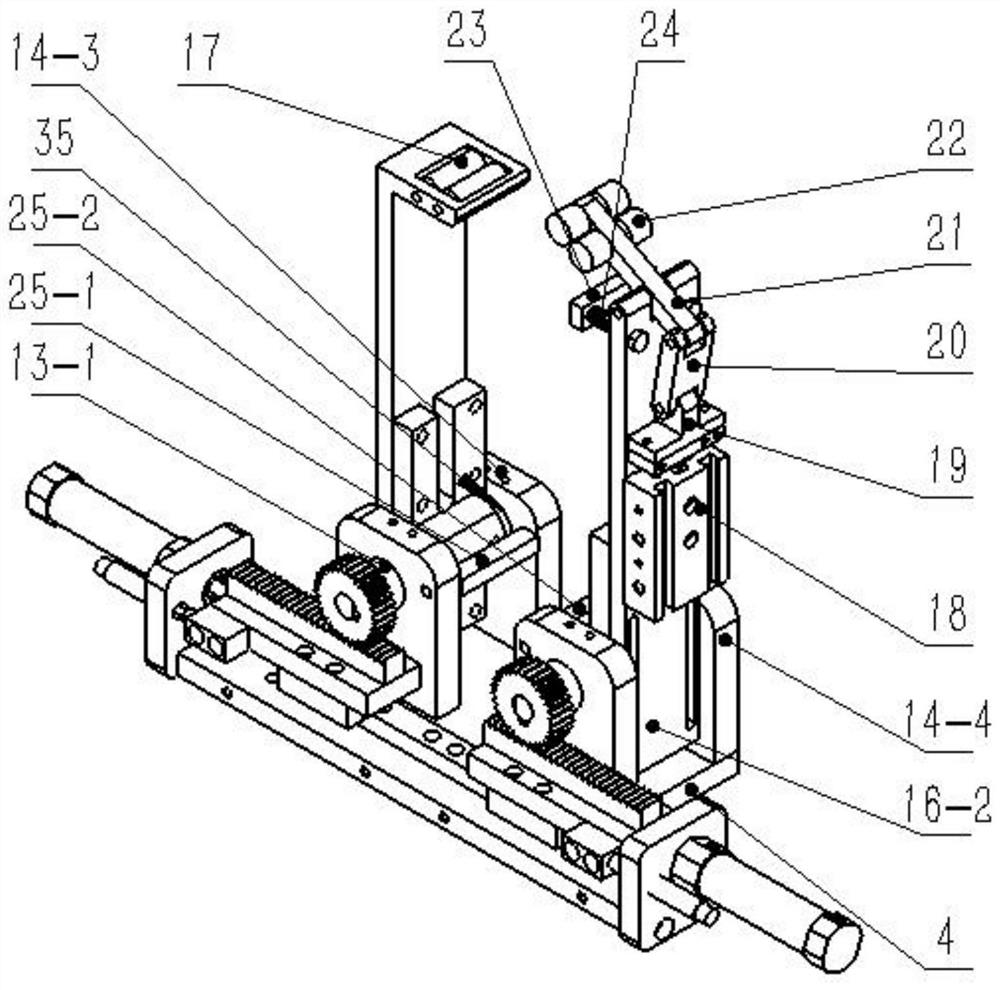

Swing-type sock waist seal automatic paper folding device

InactiveCN112158401AAvoid complexityCompact structureWrapper folding/bending apparatusGear wheelStructural engineering

The invention discloses a swing-type sock waist seal automatic paper folding device which comprises a machine frame. The machine frame comprises a vertical machine frame body, a conveying belt is arranged on the upper part of the vertical machine frame body, a transverse machine frame body is connected to the middle of the vertical machine frame body, a paper folding assembly bottom plate is arranged on the transverse machine frame body, a sliding rail is installed on the paper folding assembly bottom plate, and a paper folding assembly is installed on the sliding rail. A gear and a rack are used for driving a bending plate to swing to bend a paper card, a spring baffle is used for guaranteeing side edge bending, a double linkage rod air cylinder is used for driving a paper pressing bending block to guarantee upper side bending, the design that the bending plate can be adjusted up and down enables the device to achieve the waist sealing function for socks with different thicknesses, the occupied area is small, the cost is low, and the universality of the device is greatly improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

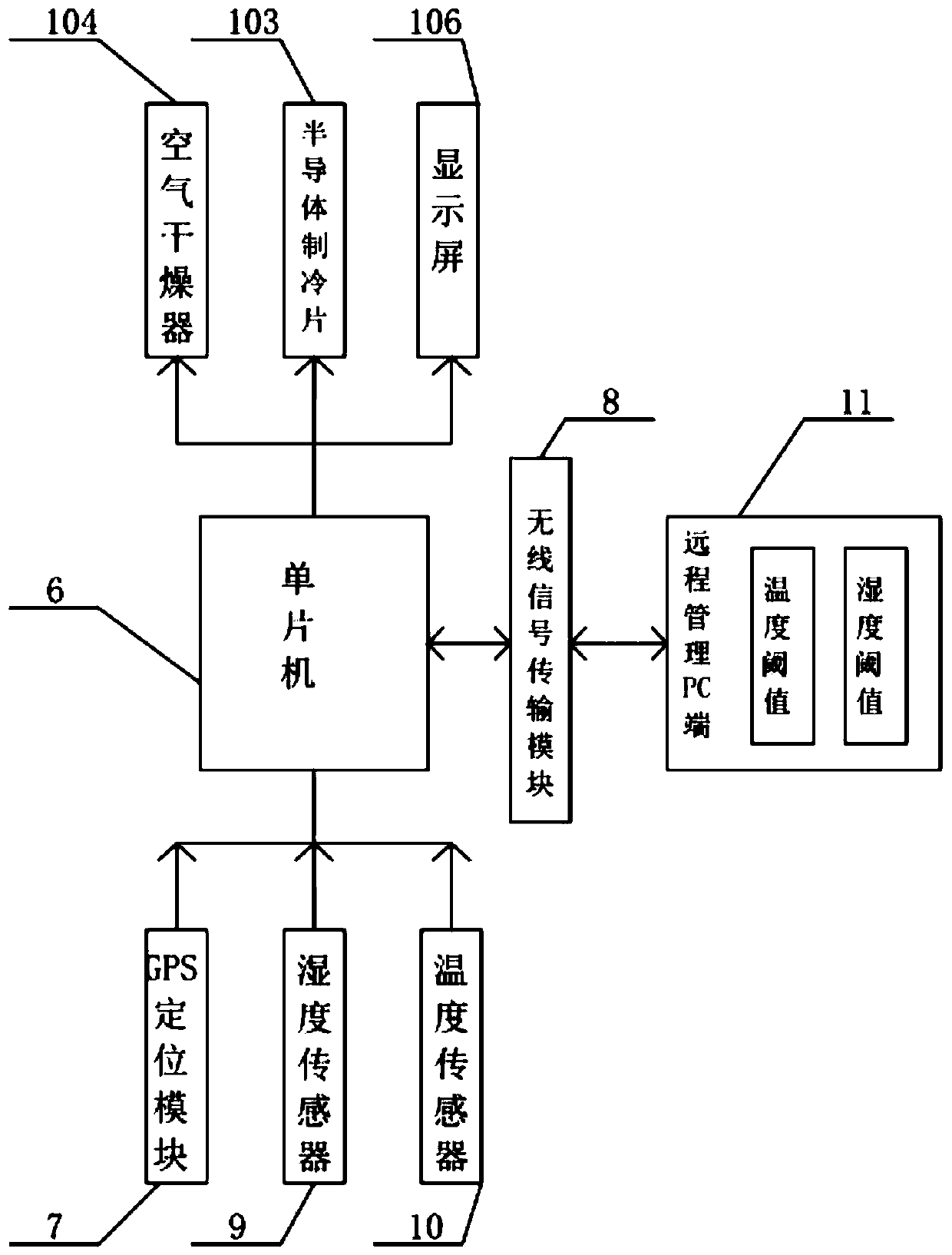

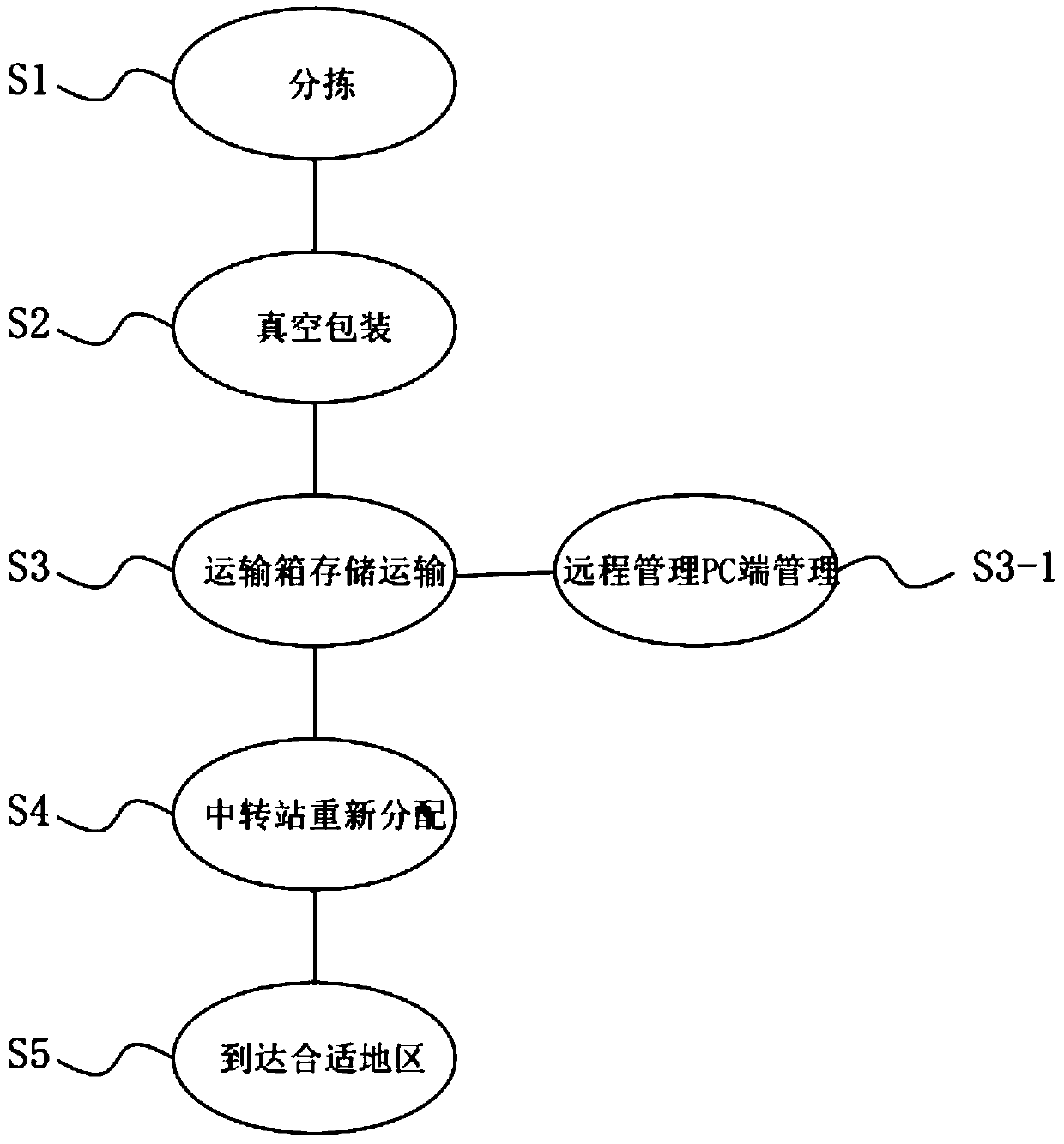

Clothing packaging and transportation management system and management method thereof

InactiveCN111158283AGuaranteed packaging effectImprove work efficiencyProgramme controlComputer controlMicrocontrollerTransportation management system

The invention discloses a clothing packaging and transportation management system and a management method thereof. Different types of clothes can be sorted through the sorting device; the sorted clothes are subjected to vacuum packaging through a vacuum packaging device; and finally, the packaged clothes are conveyed into a conveying box. A semiconductor chilling plate, an air dryer and a controldevice are mounted on the box wall of the transport box in an embedded manner; the control device comprises a control shell, a single-chip microcomputer, a GPS positioning module and a wireless signaltransmission module, wherein the single-chip microcomputer, the GPS positioning module and the wireless signal transmission module are arranged in the control shell; and the temperature, the humidityand the transportation arrival position in the transport box can be monitored and checked through the remote management PC terminal. The system has the advantages that the packaging efficiency is high, the clothing transportation process can be monitored, and clothing redistribution of the transfer station is accelerated, and the system is mainly used for clothing packaging and transportation management.

Owner:繁昌县纺东服饰有限公司

A packaging device for garlic processing

ActiveCN113716134BAvoid taking up packaging timeGuaranteed packaging efficiencyCleaningPackaging machinesAgricultural engineeringStructural engineering

The present invention relates to the technical field of garlic processing, in particular to a packaging device for garlic processing, comprising a mounting plate, a transmission mechanism is arranged on the mounting plate, a fixing mechanism is arranged on the mounting plate, and a There is a bag-hanging mechanism, a receiving mechanism is provided on the placement plate, a shaking mechanism is provided in the receiving mechanism, and a cleaning mechanism is provided on the transmission mechanism; the fixing mechanism is set on the placement plate, and the bag-hanging mechanism is set on the On the fixing mechanism, through the cooperation of the bag hanging mechanism and the fixing mechanism, it is convenient to use two sets of different hanging racks to realize the hanging of the packaging bag for the next group of garlic in advance during the operation of the equipment, avoiding excessive occupation of packaging time , to ensure the packaging efficiency; the receiving mechanism is set on the placement plate, which is convenient for buffering and protecting the garlic during packaging, preventing the garlic from falling from a higher place at the beginning, thereby avoiding more garlic at the bottom of the bag Crushed cloves ensure the packaging effect and subsequent sales of garlic.

Owner:邳州东泰食品有限公司

Waterproof material packaging machine

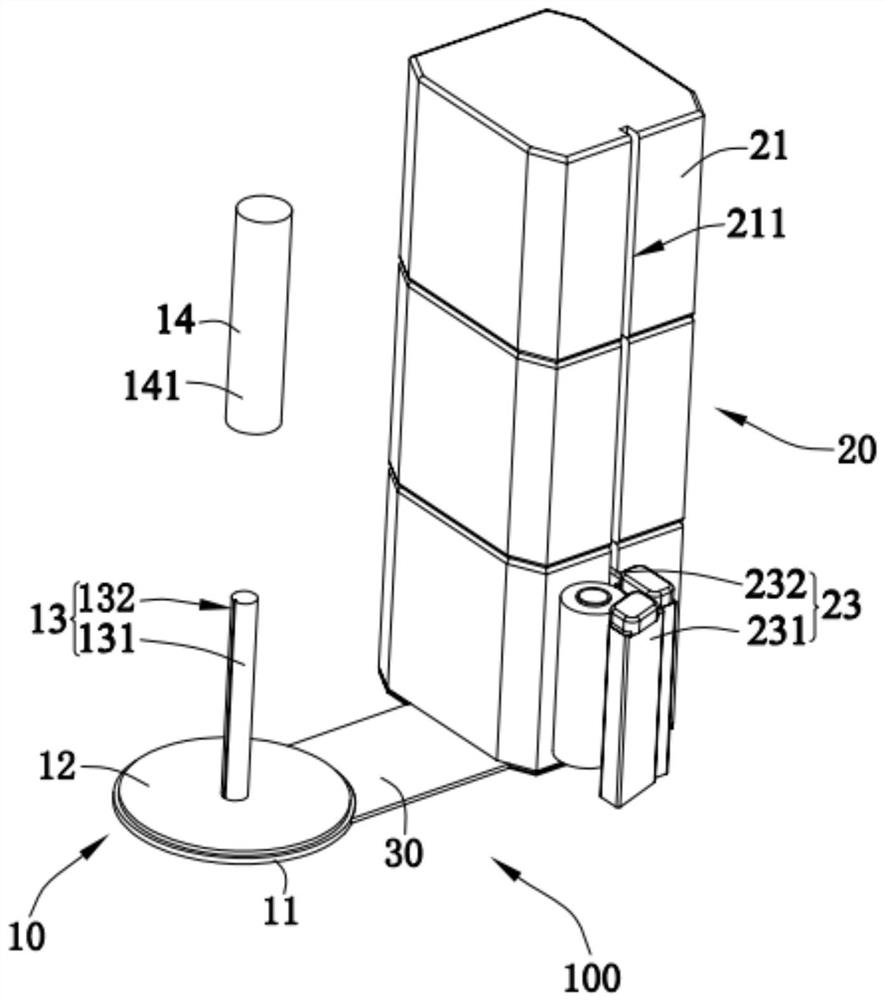

The invention provides a waterproof material packaging machine. The waterproof material packaging machine comprises a bearing mechanism, a film laminating mechanism and a connecting plate, wherein thebearing mechanism comprises a base, a rotary table, a rotary table driving mechanism, a limiting supporting column and a limiting supporting sleeve; the limiting supporting column is arranged in thecenter of the rotary table; the limiting supporting sleeve is detachably connected with the limiting supporting column; the diameter of the limiting supporting sleeve is larger than that of the limiting supporting column; the film laminating mechanism comprises a stand column, a lifting driving mechanism and a packaging film fixing frame; a concave groove is formed in the stand column; the packaging film fixing frame is connected with the lifting driving mechanism through the concave groove; the lifting driving mechanism is used for driving the packaging film fixing frame to ascend and descend; and the connecting plate is connected with the bearing mechanism and the film laminating mechanism. Compared with the prior art, the waterproof material packaging machine can effectively support packaged waterproof materials, and therefore the packaging effect is guaranteed, and the packaging efficiency is improved.

Owner:怀化市建新建材股份有限公司

Novel masonry top mortar plugging tool

ActiveCN114278106AImprove filling effectGuaranteed tightnessBuilding material handlingSolid waste managementCement mortarArchitectural engineering

The invention relates to the technical field related to building construction, in particular to a novel masonry top mortar plugging tool which comprises a first plugging assembly, a second plugging assembly, a connecting piece and a feeding assembly. The first plugging assembly is formed by combining a first plugging plate, a first upper sealing plate and a first lower sealing plate; the first upper sealing plate and the first lower sealing plate are both fixedly connected to the first plugging plate, and the first plugging assembly is located on the outer side of a pouring beam and the outer side of a building wall. According to the masonry top mortar plugging tool formed by combining the first plugging assembly, the second plugging assembly, the connecting piece and the feeding assembly, the two sides of a gap between a pouring beam and a building wall are plugged through the first plugging assembly and the second plugging assembly, so that the filling effect of cement mortar is effectively improved, the plugging leakproofness is guaranteed, and the construction efficiency is improved. And later top cracking is avoided, so that the overall filling effect is ensured.

Owner:CHINA CONSTR EIGHTH ENG DIV

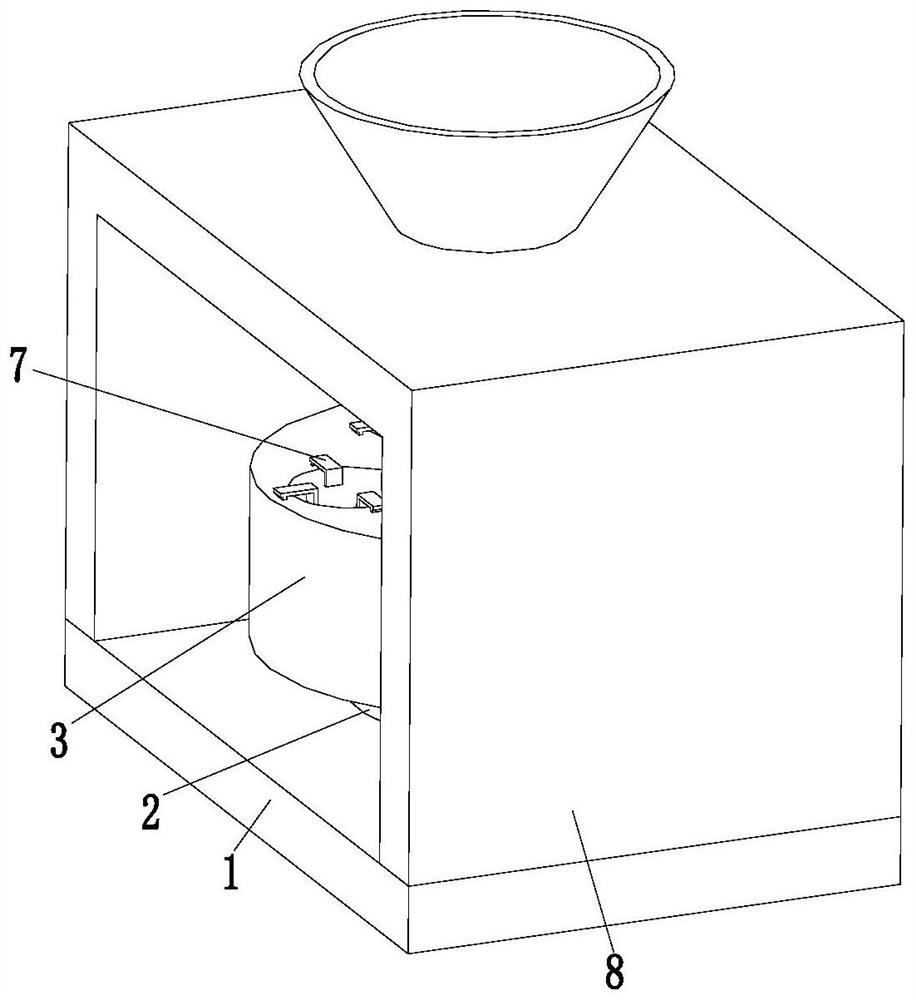

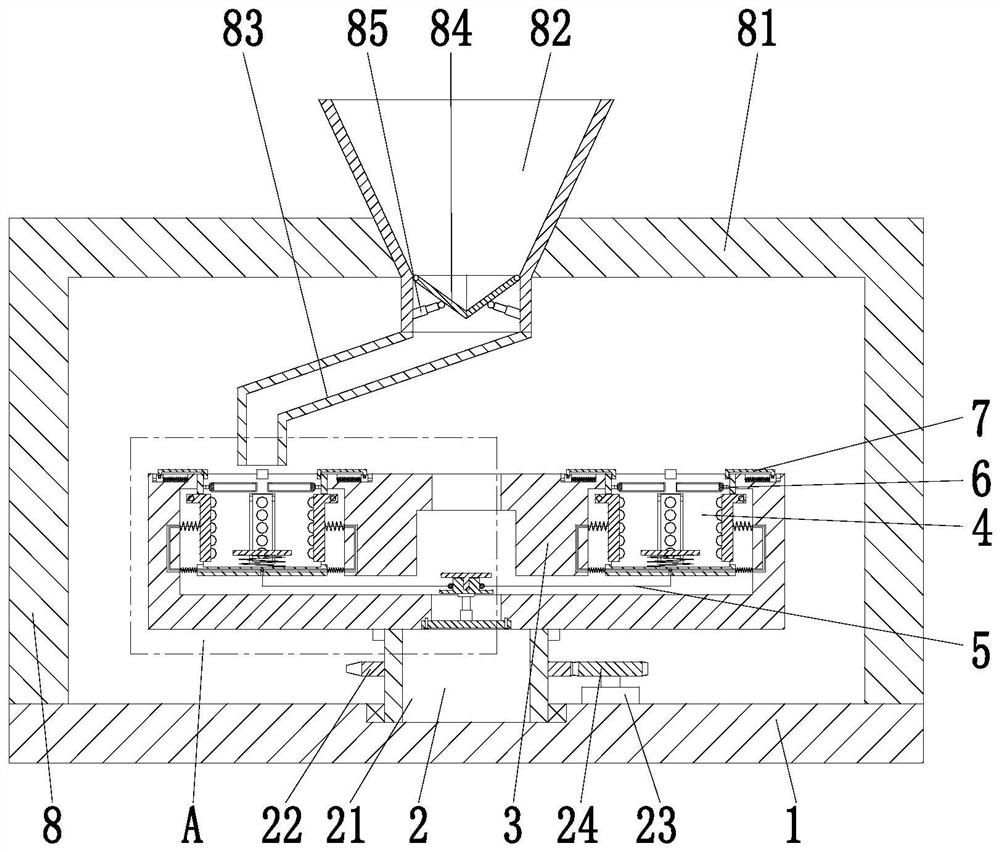

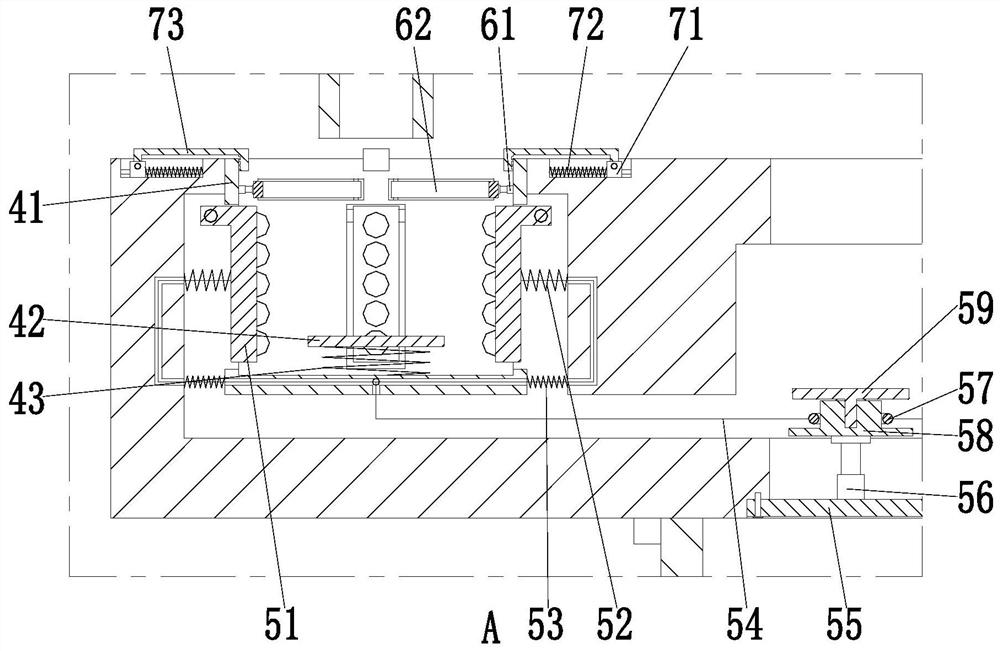

a packaging machine

ActiveCN104354890BEasy to fixAutomate the packaging processConveyor wrappingPackaging machinesEngineeringPackaging machine

Owner:江阴市巨匠铁艺工程有限公司

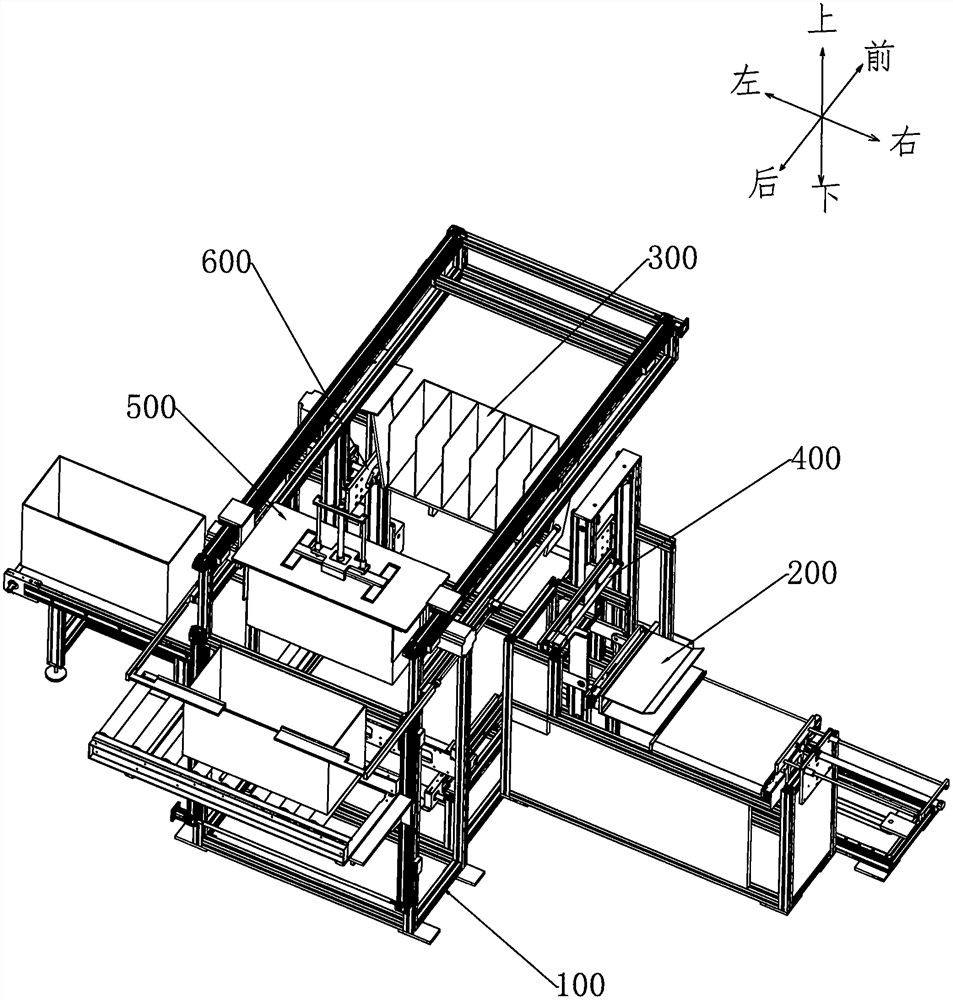

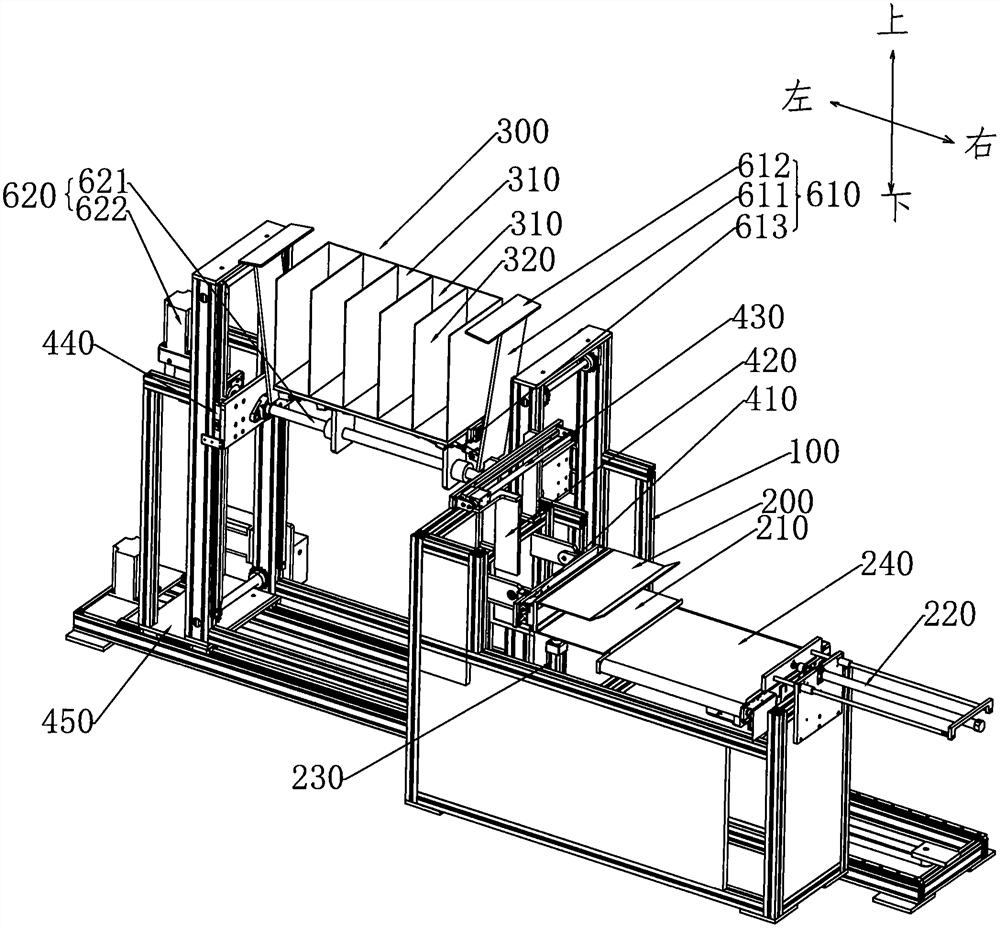

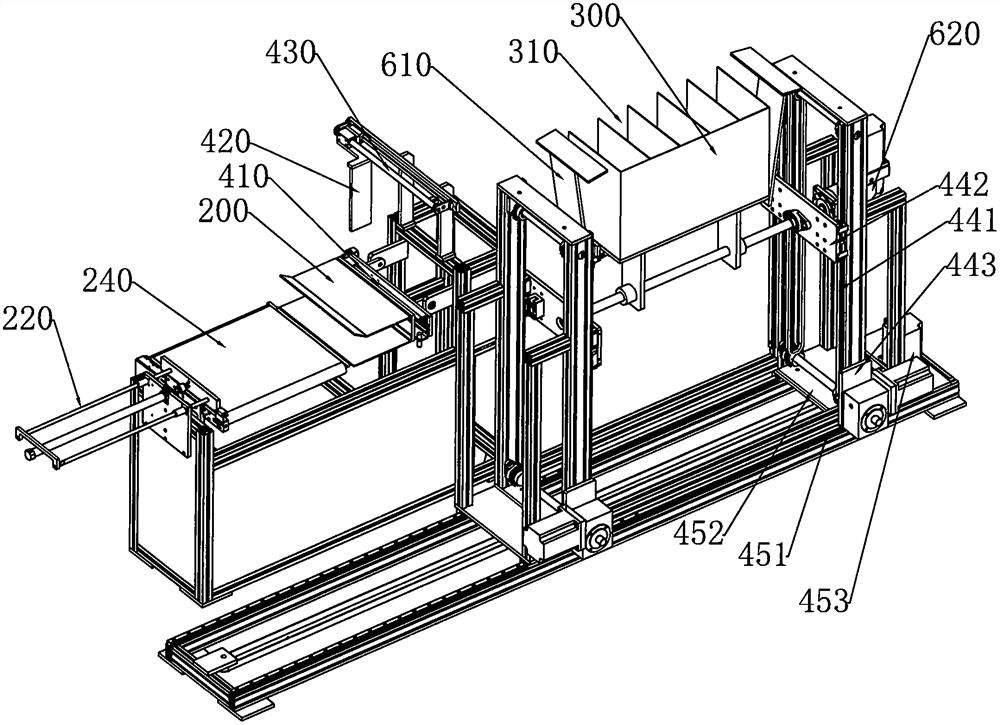

Bagged product boxing equipment

Owner:深圳市锐巽自动化设备有限公司

Shelf fresh-keeping combined treatment method for semen trigonellae fruits

PendingCN109527071AImprove disease resistanceNo invisible diseaseFruits/vegetable preservation by irradiation/electric treatmentFood ingredientsFlavorGamma irradiation

The invention discloses a shelf fresh-keeping combined treatment method for semen trigonellae fruits. Beta-aminobutyric acid spray coating before harvesting and S-nitrosoglutathione fumigation treatment after harvesting are carried out, and enclosing packaging technology with certain air permeability and gamma irradiation technology are combined to realize the purpose, so that the shelf life of semen trigonellae fruits at room temperature or 4-5DEG C can be significantly prolonged, and the semen trigonellae fruits also can maintain good hardness, flavor and nutritional quality.

Owner:LIAONING ACAD OF AGRI SCI

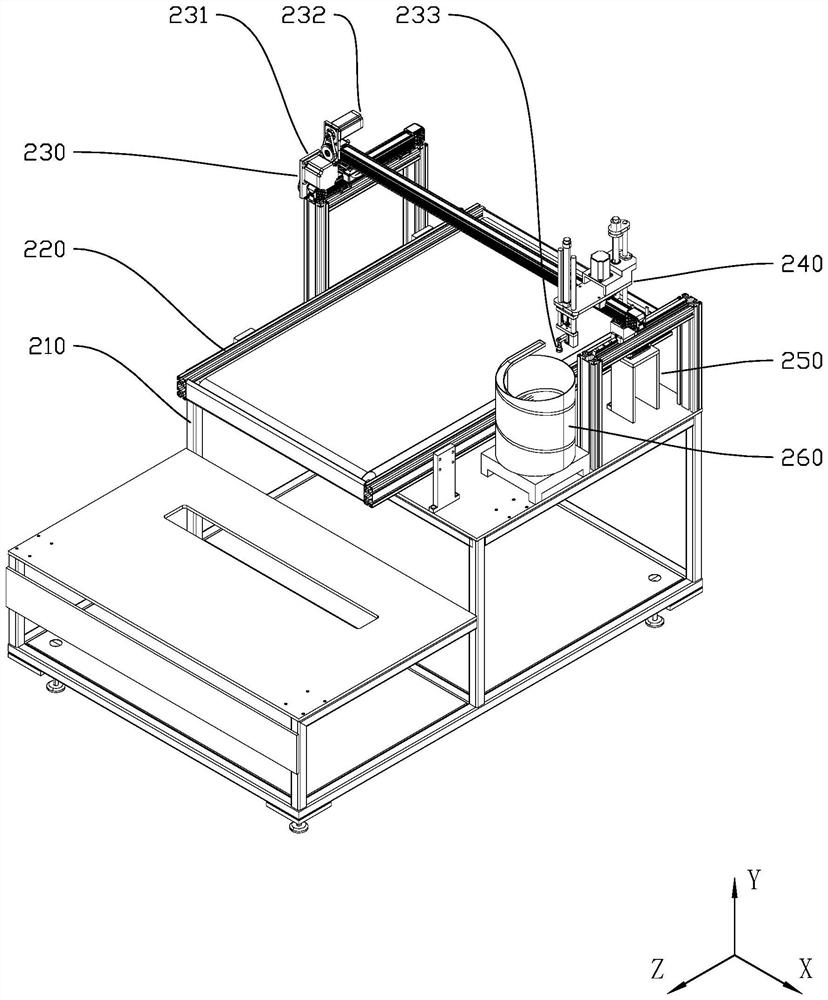

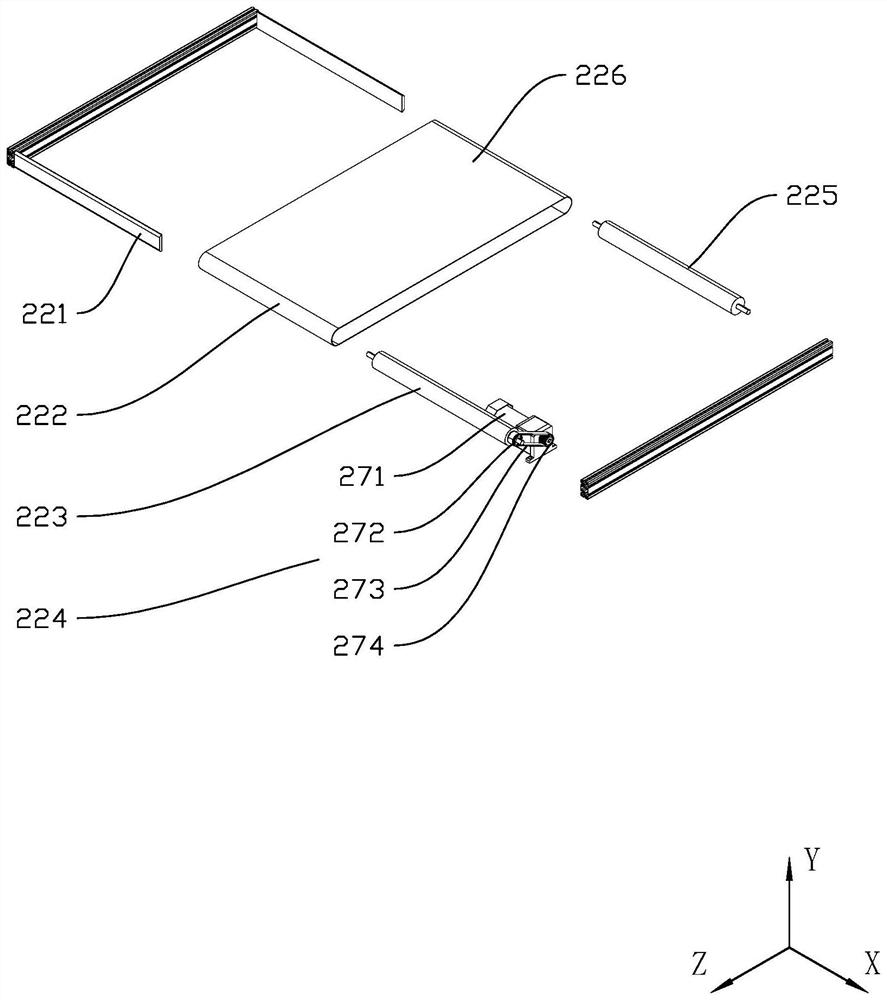

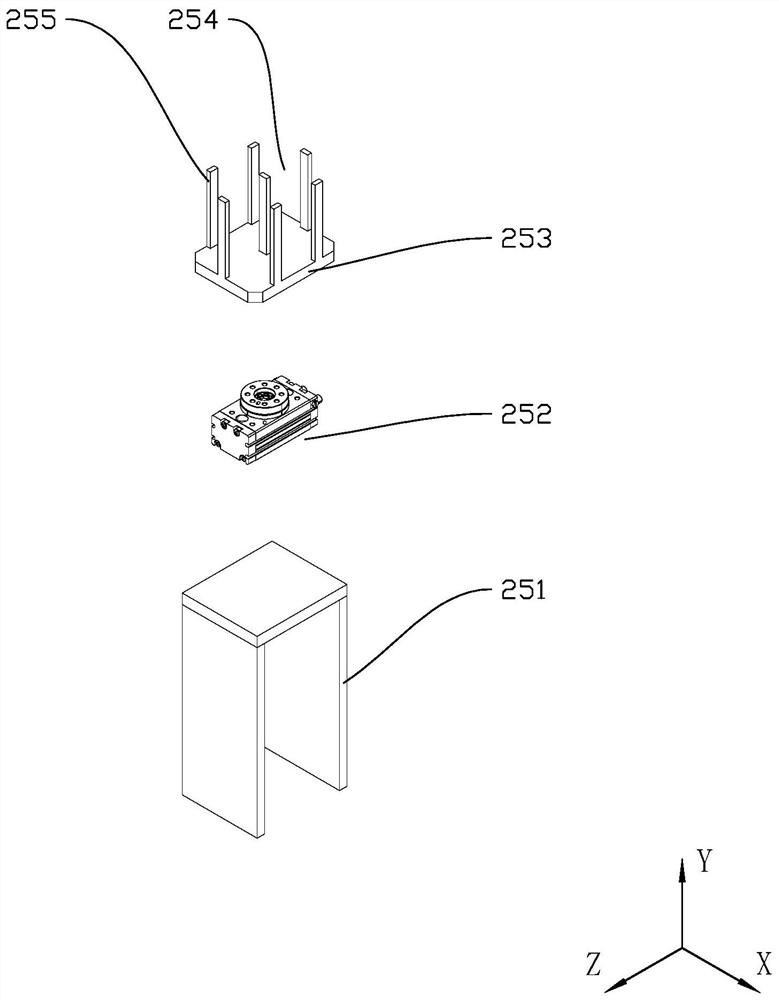

Material placing device and packaging equipment

PendingCN112027248AAvoid erosionGuarantee normal performancePackagingConveyor partsEngineeringMechanical engineering

The invention discloses a material placing device and packaging equipment. The material placing device comprises a rack and a first material placing assembly, a carrying platform is arranged on the rack, and the carrying platform can bear a first material; and the first material placing assembly comprises a first driving device, a second driving device, a third driving device and a first materialtaking head, the first material taking head can grab or release a second material, the first driving device can drive the first material taking head to move in the X-axis direction and the Z-axis direction, the second driving device can drive the first material taking head to move in the Y-axis direction, and the third driving device can drive the first material taking head to rotate around the axis on the XZ plane. According to the material placing device and the packaging equipment, a drying agent can tightly abut against stacked PCBs, the drying agent cannot be separated from the PCBs, andtherefore, the drying effect is good.

Owner:SHENZHEN DEXIN AUTOMATION EQUIP

Packaging equipment

InactiveCN113022918ASimple structureReduce volumeWrapping material feeding apparatusPackaging automatic controlRough surfaceMechanical engineering

The invention discloses packaging equipment, and belongs to the technical field of goods packaging. The packaging equipment structurally comprises a feeding part, a discharging part and a packaging part, wherein the discharging part is located between the feeding part and the packaging part and is used for bearing the feeding part and the packaging part, and a paper feeding mechanism is arranged at one side of the discharging part; the feeding part comprises a feeding groove for bearing materials, and a material pushing plate for pushing the materials to advance is arranged at one side of the feeding groove; and the discharging part comprises a pressing block for pressing the materials into a charging box, the packaging part comprises a packaging channel, the packaging channel is located on the moving track of the charging box, and the inner surface of a top plate of the packaging channel is a rough surface in order to rub the packaged materials in the charging box to rotate. According to the technical scheme, the packaging equipment is simple in structure, small in size, low in noise and low in cost, can better replace manual work to conduct winding drum type packaging on goods, conforms to the technical development trend of automation and digitization, and is supported by the country.

Owner:李萍

A method of logistics packaging, verification and delivery

InactiveCN112124837BGuaranteed packaging effectImprove efficiencyPackaging automatic controlLogisticsLogistics managementOrder management system

The invention discloses a method for verifying delivery of logistics packaging, and relates to the technical field of logistics packaging. The system of the present invention includes an order management system, a packing calculation system, a storage operation system, and a display terminal. After the method of the present invention receives an order through the order management system, the packing calculation system calculates a suitable packing plan based on the basic information of the goods, and the packing personnel Select the corresponding packing box according to the packing diagram and pack the goods. According to the packaging requirements, quantity, volume and carton specifications of the goods, the present invention calculates a plurality of packaging schemes through an algorithm. Appropriate solutions are finally displayed to the packing workers through the interface, including which goods are packed into which cartons, the location of the goods, and the order of the goods, which not only ensures the packing effect but also improves the efficiency.

Owner:深圳市万邑通信息科技有限公司

Packaging method of formed firework

InactiveCN107380562AQuality assuranceGuaranteed aestheticsWrappers shrinkageAdhesive glueThermal contraction

The invention discloses a packaging method of a formed firework. The packaging method of the formed firework is characterized in that the formed firework and a thermal contraction film are included; the two ends of the thermal contraction film are open, and the formed firework is sleeved with the thermal contraction film; the two open ends of the thermal contraction film are higher than the two ends, corresponding to the two open ends, of the formed firework; and when the thermal contraction film is heated, the whole thermal contraction film is contracted, the two open ends of the thermal contraction film are tightly attached to the inner sides of the edges of the two ends, corresponding to the two open ends, of the formed firework under the action of contraction while the thermal contraction film is tightly attached to the formed firework, and finally, sealing packaging of the two open ends, corresponding to the two ends of the formed firework, of the thermal contraction film is finished through heating. The packaging method of the formed firework has the advantages that the packaging and forming speed is higher, no glue is need for gluing, the thermal contraction film is tightly and firmly attached to the formed firework, no loosening or falling off occurs, and the whole quality and attractiveness of the finished packaged formed firework are guaranteed.

Owner:刘鹏

A rotary bonding device for beverage bottle wrapping paper

ActiveCN111547296BReduce workloadSimple and fast operationWrapper twisting/gatheringWrapping with article rotationElectric machineryPinion

The invention relates to the field of beverage bottle processing, in particular to a rotary bonding device for beverage bottle wrapping paper. The technical problem of the present invention is to provide a beverage bottle wrapping paper rotary bonding device that is easy to operate, can improve the packaging efficiency of beverage bottles, and can ensure the packaging effect and quality. A rotary bonding device for beverage bottle wrapping paper, including a bottom plate, a support frame, a support sleeve, a support, a placement plate, a turning lever, a turning plate, a pinion, a first connecting plate, a servo motor, a sector gear, and a tooth-missing gear etc.; one end of the support frame is fixedly installed on one side of the bottom plate, two of the support sleeves are fixedly installed on the support frame, and one of the support sleeves is fixedly installed on the other end of the support frame. The invention is easy to operate, just place the beverage bottle and wrapping paper, manually turn on the servo motor and the transmission motor, the beverage bottle can be automatically turned over, pressed and rotated, and the bonding and cutting of the beverage bottle wrapping paper can be completed, greatly reducing the It reduces the workload of the staff and improves the packaging efficiency of beverage bottles.

Owner:NINGXIA DAYAO BEVERAGE CO LTD

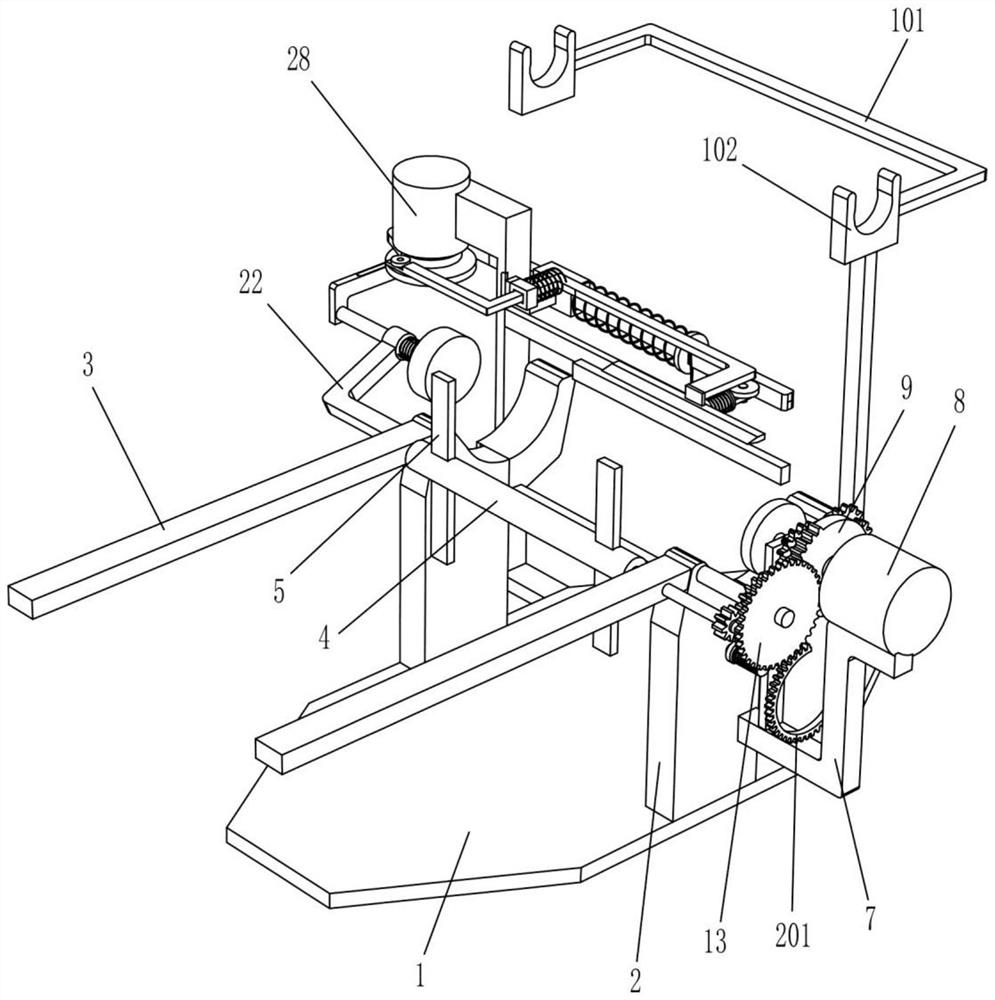

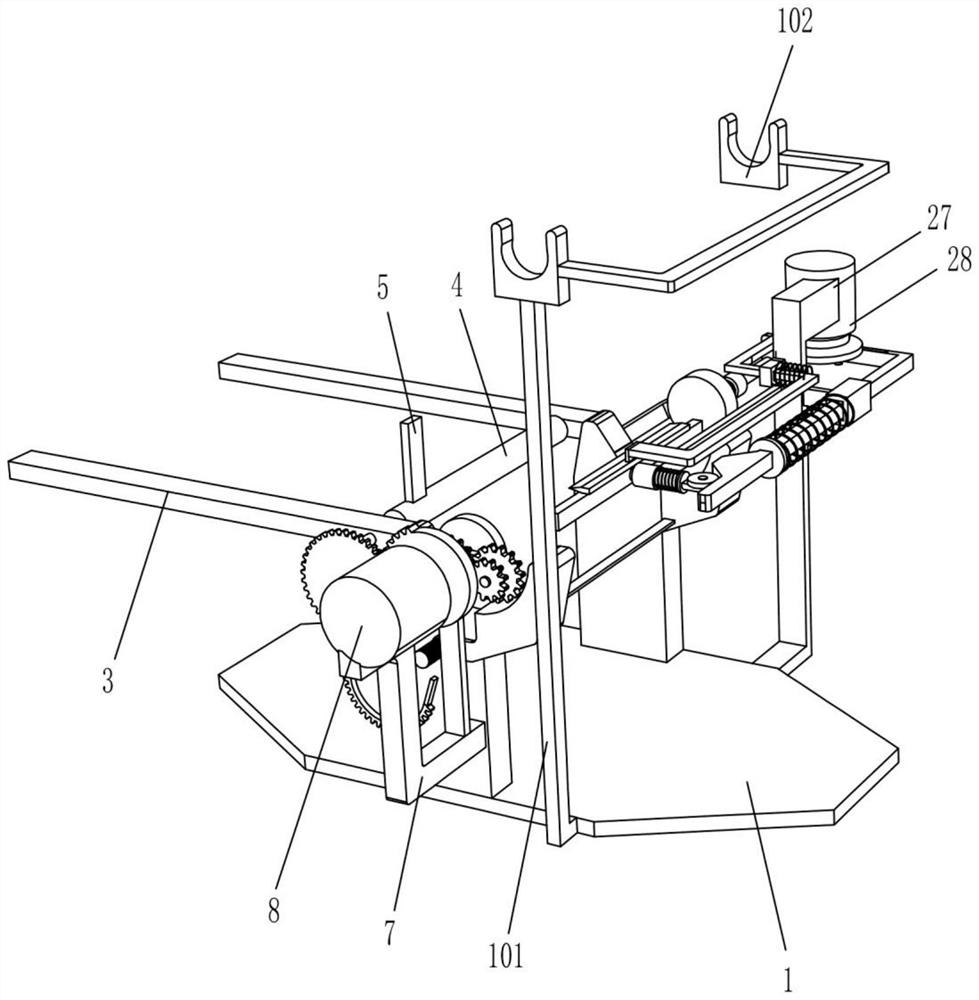

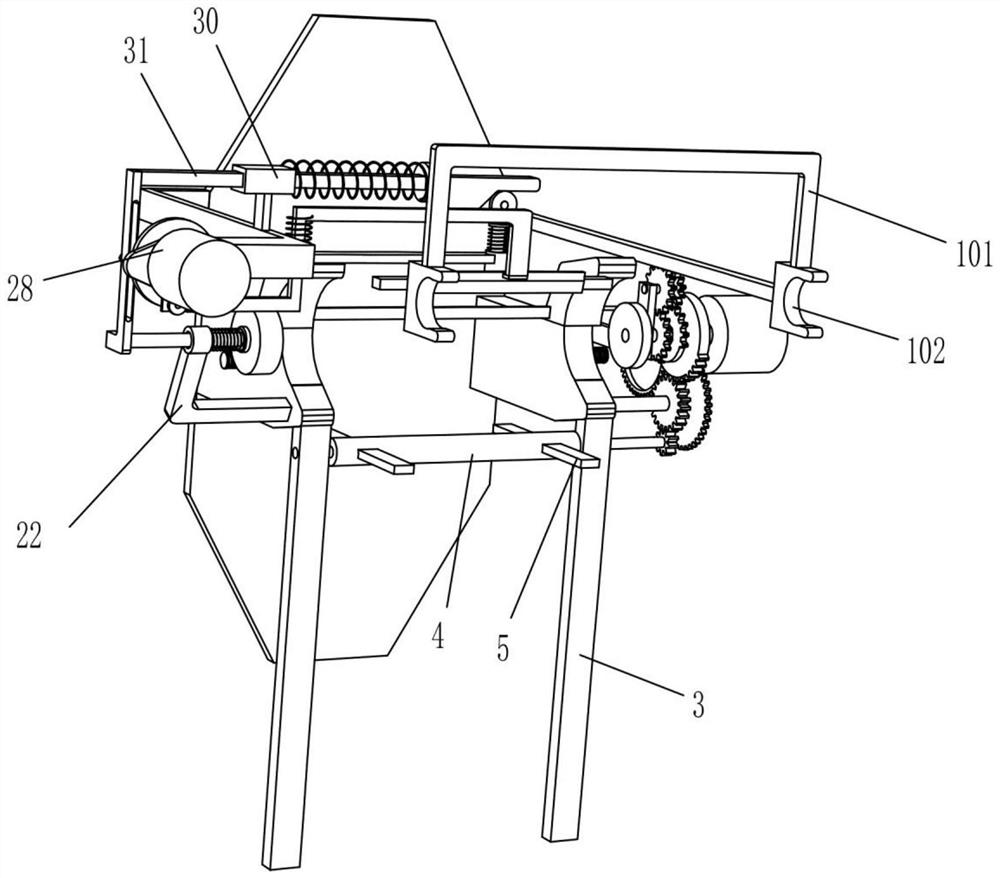

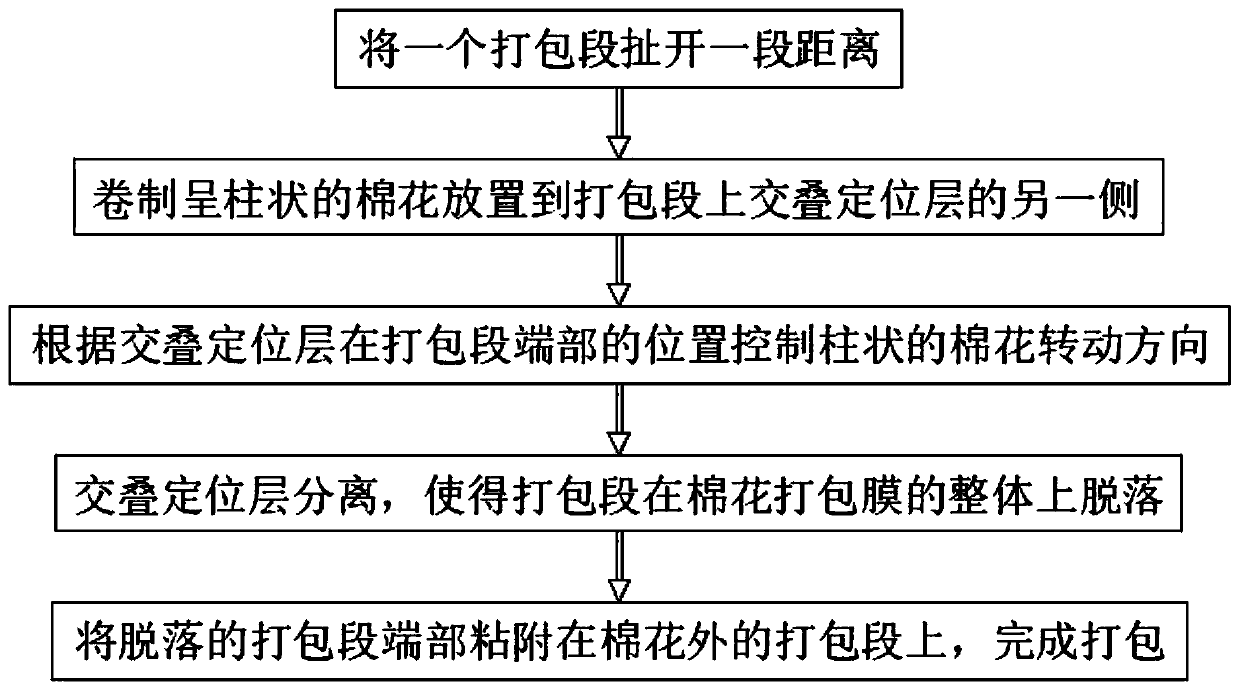

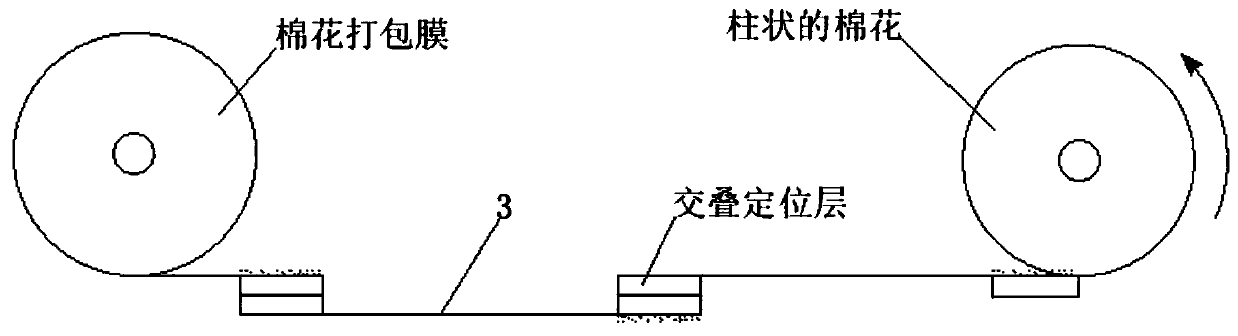

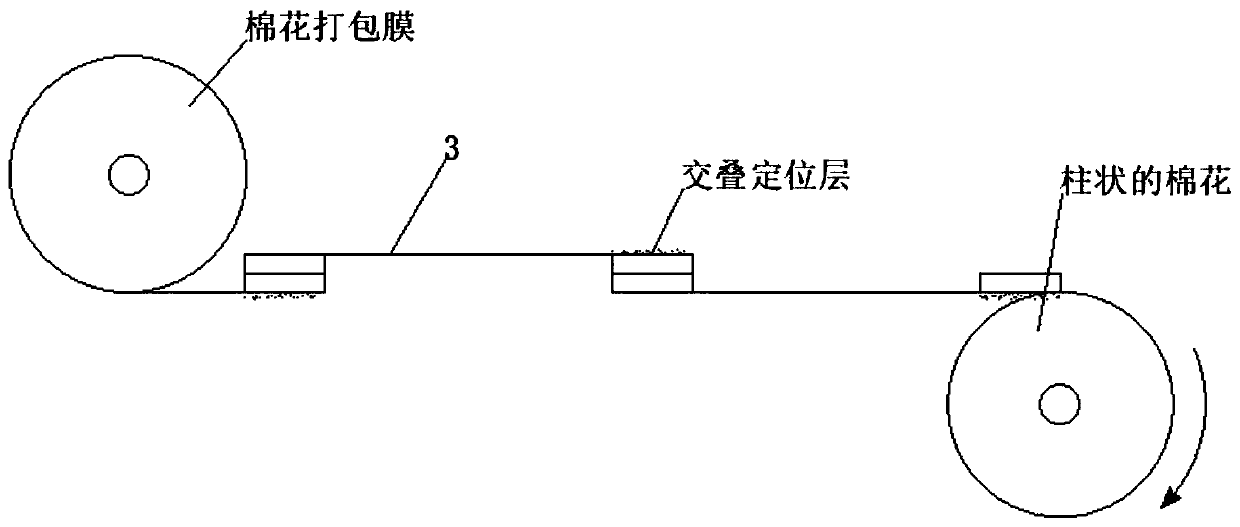

Staggered overlapping cotton baling method

ActiveCN111470084AClosely connectedNot prone to spillsWrapper twisting/gatheringWrapping with article rotationAdhesive glueEngineering

The invention discloses a staggered overlapping cotton baling method, and belongs to the field of cotton baling. In the staggered overlapping cotton baling method, adjacent packing sections are arranged in a staggered overlapping manner, meanwhile, overlapping positioning layers are arranged at the overlapping parts, and when columnar cotton is baled to the integrated overlapping positioning layers, the overlapping positioning layers are separated. In the process, wall breaking balls of glue breaking string balls can come out of glue breaking layers by breaking walls under the action of force,and it is effectively guaranteed that the glue breaking layers can certainly break during separation to make inside glue flow out; and then, the glue breaking layers are bonded to wool tufts on the other sides of the baling sections. The wool tufts can effectively improve the surface roughness of fluff base layers and meanwhile effectively increase the contact area of the fluff base layers and the glue breaking layers, so that the baled cotton is more tightly connected, the situation that a cotton baling film locally cracks in bonding and then the cotton scatters is not likely to occur, and thus the baling effect of the cotton is effectively improved.

Owner:阜康市准葛尔柏多盛农业科技有限公司

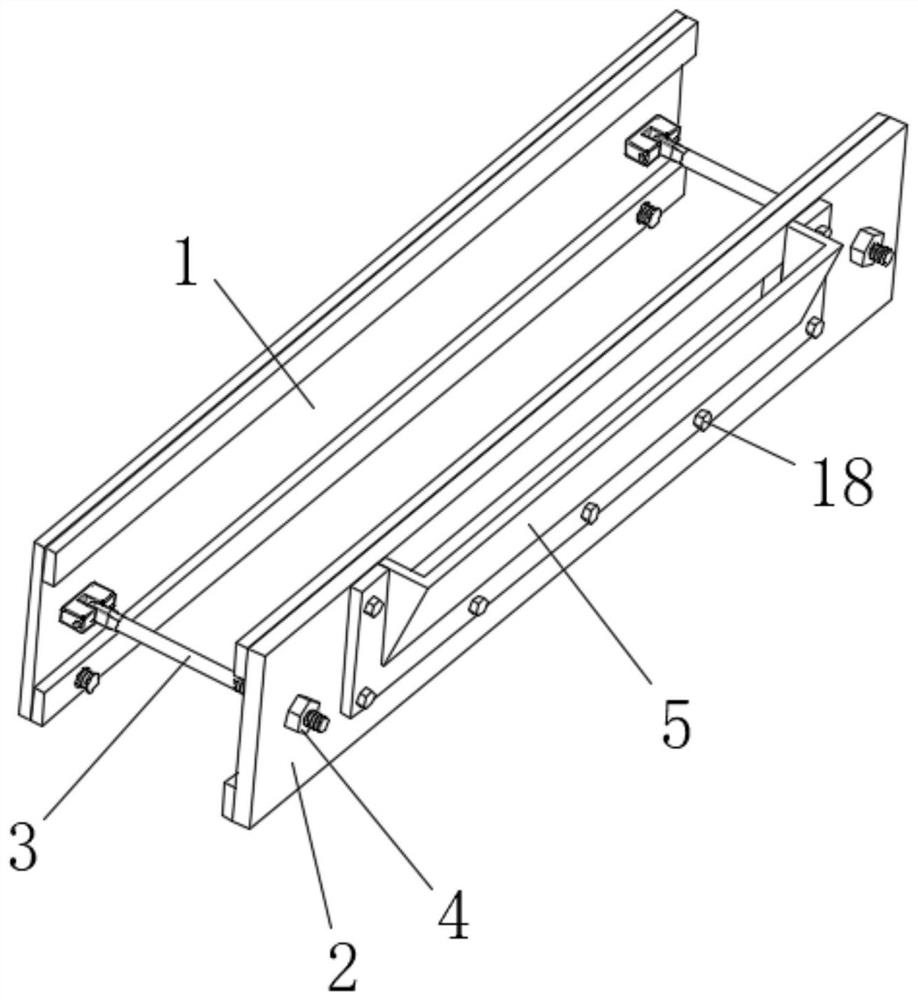

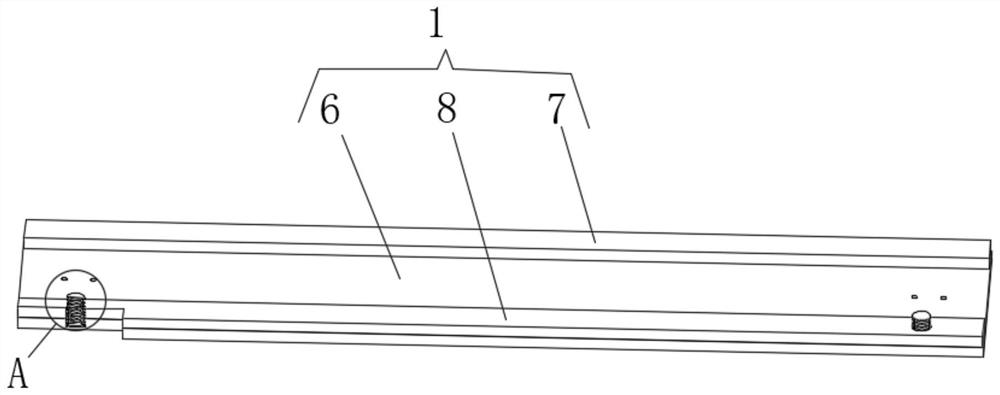

Capacitor carrier tape packaging transparent tape deviation detection tool

InactiveCN110422407AGuaranteed packaging effectGuaranteed paste effectPackaging automatic controlCapacitanceCapacitor

The invention relates to a capacitor carrier tape packaging transparent tape deviation detection tool. The tooling comprises an upper pressing cover and a lower carrying block, wherein the upper pressing cover and the lower carrying block are arranged in the horizontal direction and are oppositely arranged in the vertical direction, and the upper pressing cover and the lower carrying block can beconnected together in a clamped detachable mode. According to the detection tool, the packaging effect of capacitors is guaranteed, meanwhile, the time and the labor are saved, the pasting effect is guaranteed, and convenience is brought to use.

Owner:天津昌润鹏科技有限公司

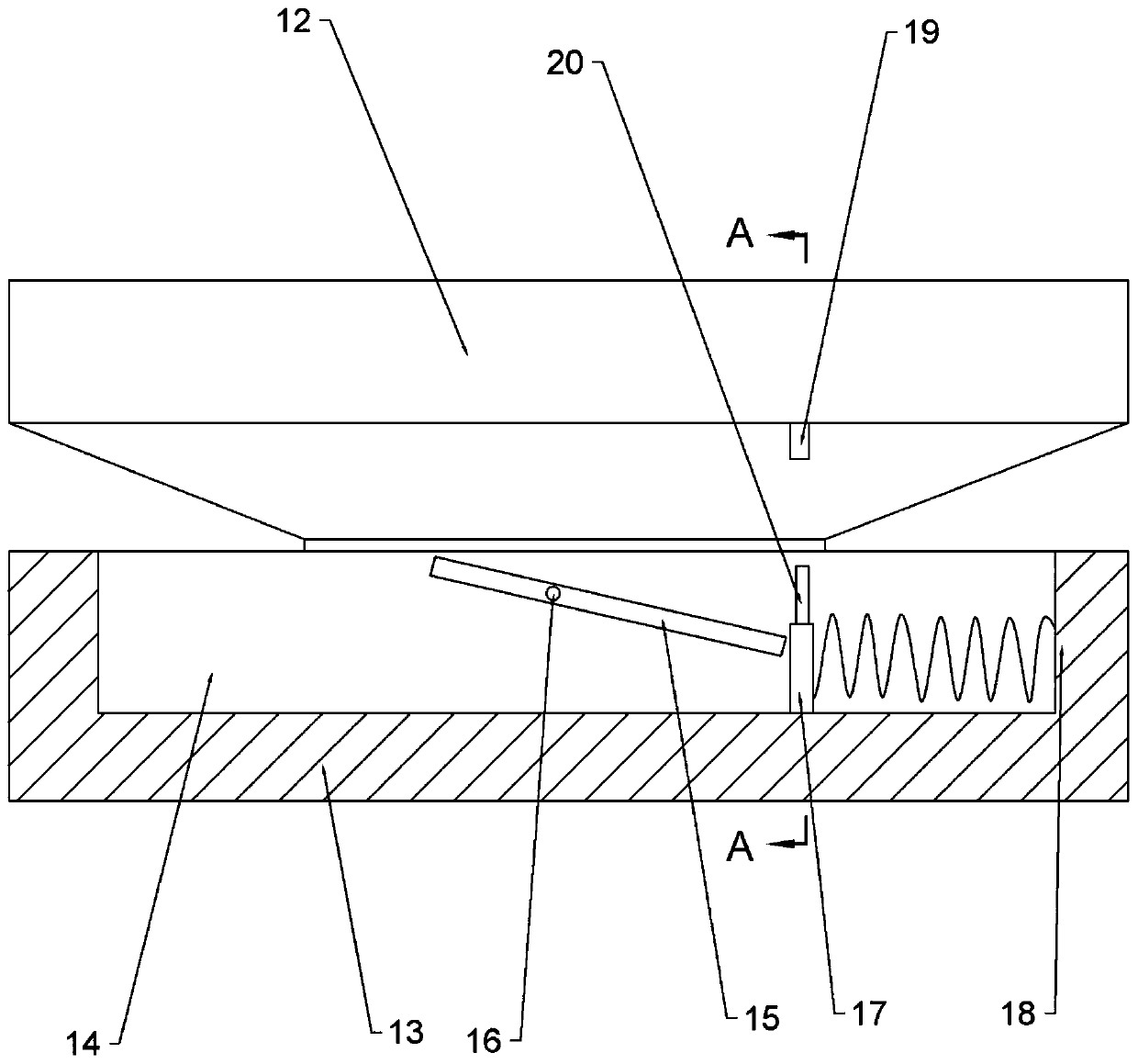

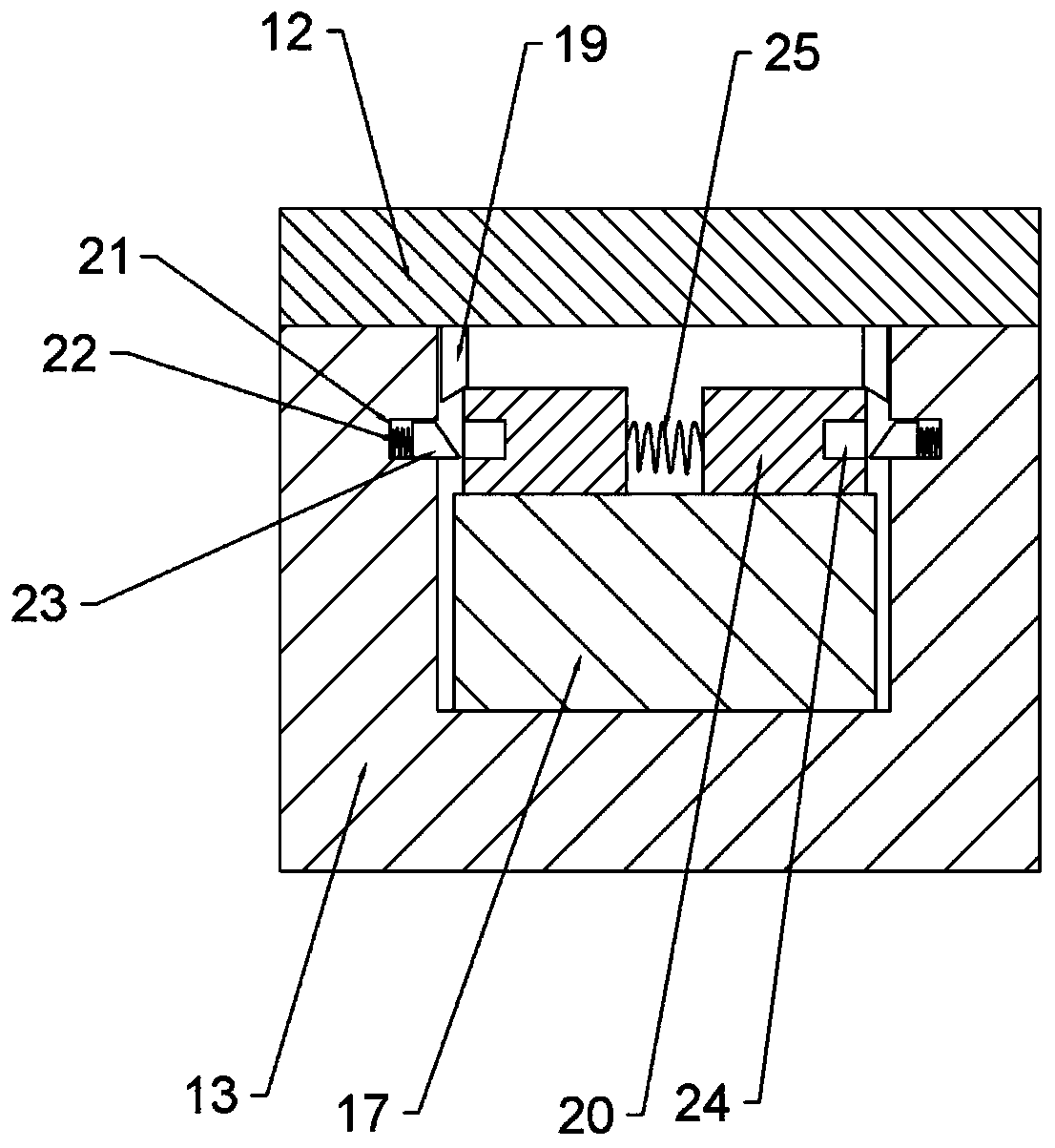

Pickled pepper packing device

InactiveCN109733687AGuaranteed packaging effectGuaranteed shelf lifeWrapper twisting/gatheringSlide plate

The invention belongs to the technical field of compression pickled pepper making devices, and discloses a pickled pepper packing device. The pickled pepper packing device comprises a machine frame, aworking platform and a first torsional spring; an upper clamping part and a lower clamping part are arranged on the working platform; heating structures are arranged at free ends of the upper clamping part and the lower clamping part; a sunken cavity is formed in the lower clamping part, the sunken cavity is internally provided with a spring, a lever and a pushing plate, wherein the pushing platecomprises a supporting plate and two sliding plates; the two sliding plates are located at the upper end of the supporting plate and slidably matched with the supporting plate; two ends of the springare connected with the supporting plate and the side wall of the sunken cavity correspondingly, the middle part of the lever is rotatably connected with the side wall of the sunken cavity, and two first oblique blocks are arranged at the lower end of the upper clamping part and located on two sides of the upper clamping part; a first pressure spring is arranged between the two sliding plate; grooves are formed in the surfaces, away from each other, of the two sliding plates; and groove bodies are formed in the two side walls of the sunken cavity, second oblique blocks are arranged in the groove bodies and can extend into the grooves, second pressure springs are arranged between the second oblique blocks and the inner walls of the groove bodies, and the first oblique blocks can be in contact with the two sliding plates correspondingly.

Owner:贵州省茂涵农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com