Packaging method of formed firework

A packaging method and fireworks technology, which is applied in the field of fireworks product packaging, can solve the problems of easy wrinkling of wrapping paper, poor packaging firmness, and easy loosening and falling off, so as to ensure the overall quality and aesthetics, fast packaging forming speed and good fit Tight and firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below, the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

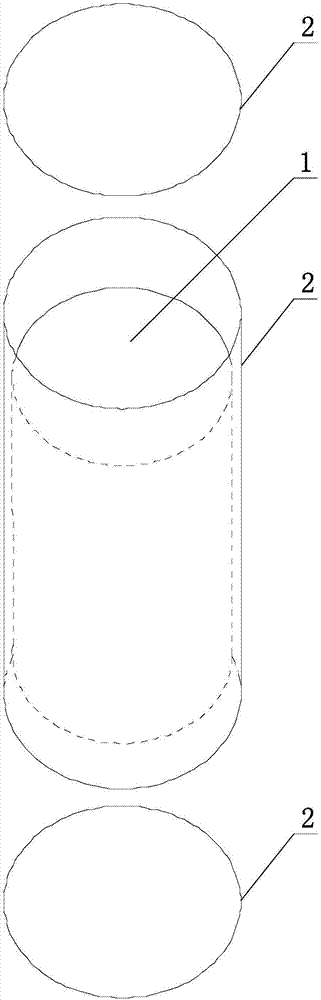

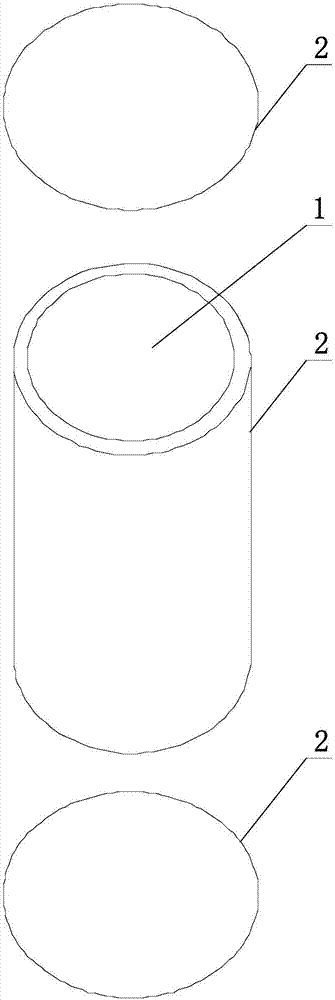

[0013] Such as figure 1 , figure 2 Shown, its composition, is made of molded fireworks body 1, heat-shrinkable film 2.

[0014] A packaging method for a shaped fireworks body, characterized in that it includes a shaped fireworks body 1 and a heat-shrinkable film 2, the heat-shrinkable film covers the shaped fireworks body with its two ends open, and the two ends of the heat-shrinkable film The opening is higher than the two ends of the corresponding shaped fireworks body, and the heat-shrinkable film is heated to shrink the heat-shrinkable film as a whole. When the heat-shrinkable film is closely attached to the shaped fireworks body, the open ends are shrinking. Under the action, the insides of the two ends of the corresponding shaped fireworks body are closely attached, and finally the heat-shrinkable films respectively correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com