Packaging bag composite material into which sucking pipette can be easily inserted

A technology of composite materials and layer materials, which is applied in the field of composite materials for packaging bags where straws are easy to insert, can solve the problems of inconvenience to consumers, difficulty in promotion and use, spillage of beverages, etc., and achieve the effect of hygienic safety, reliability and wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

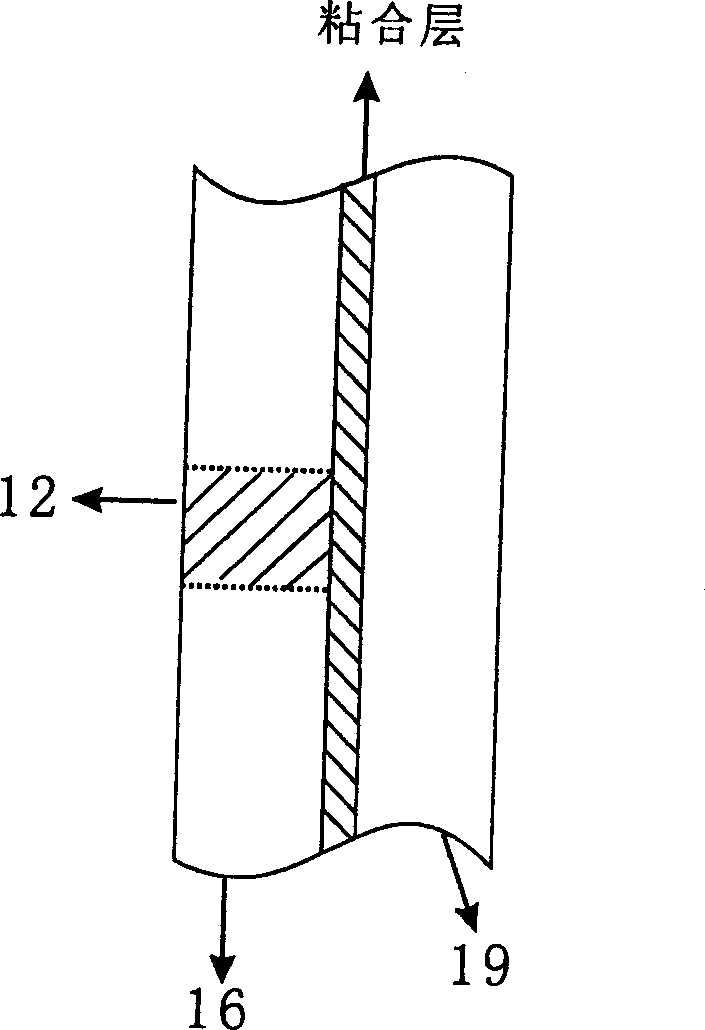

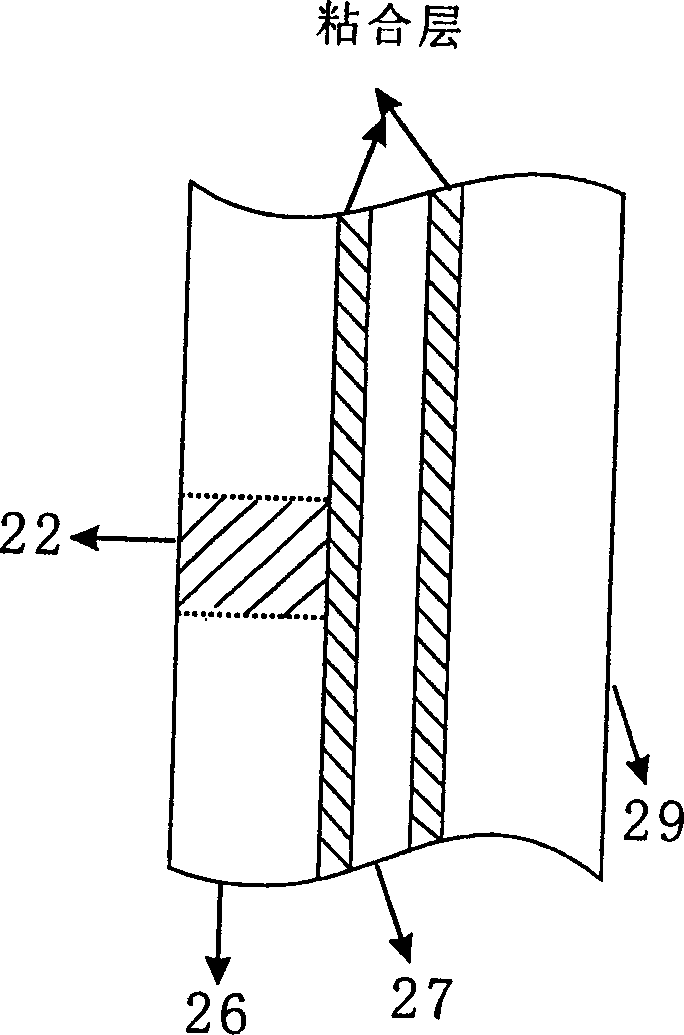

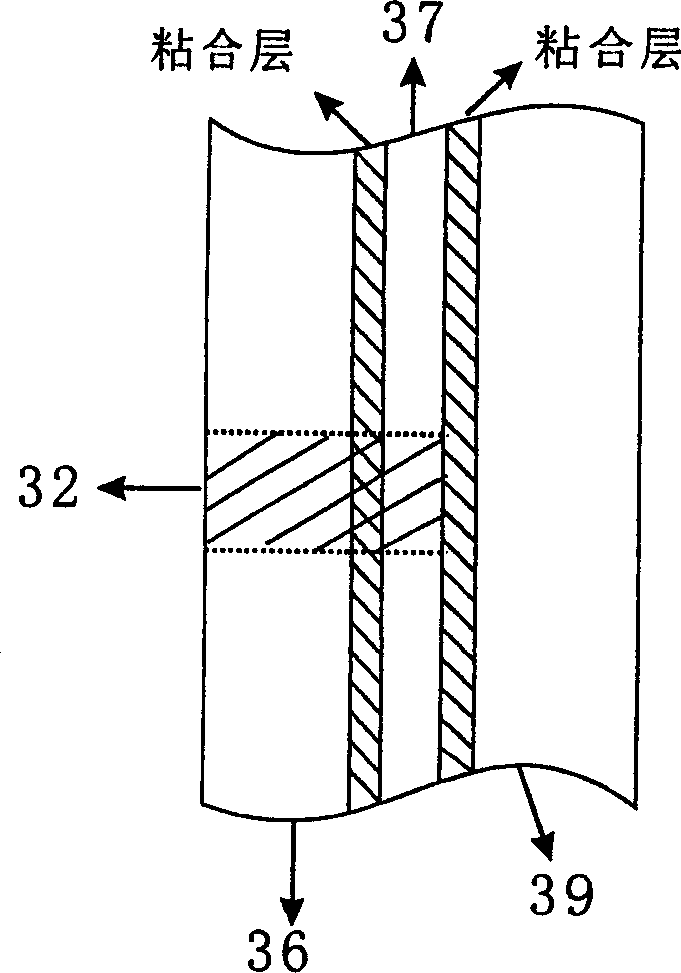

[0024] figure 1 Shows the first embodiment of the present invention. It is a side cross-sectional view of the composite material pre-puncture area. It is composed of two layers of materials. From the outside to the inside are the biaxially oriented polypropylene film 16 as the printing layer and the polyethylene as the sealing layer.膜19。 Film 19. A socket 12 is formed on layer 16, and layer 19 serves as a sealing layer. There is an adhesive layer between layer 16 and layer 19.

[0025] As the second embodiment of the present invention, figure 1 The side cross-sectional view of the composite material pre-puncture area in is composed of two layers of materials. From the outside to the inside, there are a biaxially oriented polypropylene film 16 and a vacuum aluminized cast polypropylene film 19. A socket 12 is formed on layer 16, and layer 19 serves as a sealing layer.

[0026] As the third embodiment of the present invention, figure 1 The side cross-sectional view of the compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com