Method for preparing monopotassium phosphate with co-production of potassium-ammonium dihydrogen phosphate

A technology of ammonium potassium dihydrogen phosphate and potassium dihydrogen phosphate is applied in the field of phosphorus chemical industry, and achieves the effects of good economic benefit, avoiding mother liquor treatment process and strong cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

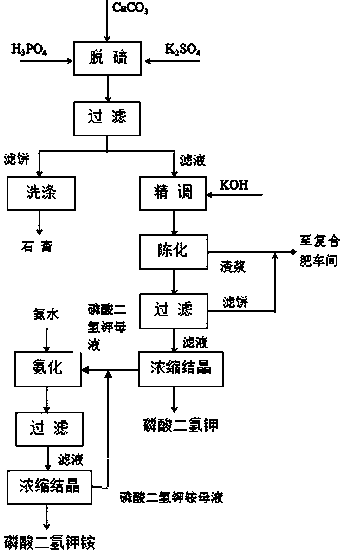

Image

Examples

Embodiment 1

[0027] Embodiment 1: a kind of method for preparing potassium dihydrogen phosphate co-production potassium dihydrogen phosphate ammonium comprises the following steps:

[0028] a. Mix wet-process phosphoric acid and potassium sulfate according to the molar ratio of 2.4:1, heat and stir to completely dissolve the solid;

[0029] b. Add water to calcium carbonate to make a slurry and add it to the solution obtained in step a. The amount added is based on the molar ratio of calcium carbonate and potassium sulfate 1.05:1. Cake I;

[0030] c. Add potassium hydroxide solution to the filtrate I obtained in step b to adjust the pH to 4.5, then add ammonium fluorosilicate according to 1.1 times the magnesium ion content in the solution, stir at 60° C. for 1 hour, and then age for 8 hours;

[0031] d. Filtrate the fully aged material in step c to obtain filtrate II and filter cake II; the filtrate II is concentrated, crystallized and dried to obtain potassium dihydrogen phosphate produ...

Embodiment 2

[0035] Embodiment 2: A kind of method for preparing potassium dihydrogen phosphate co-production potassium dihydrogen phosphate ammonium comprises the following steps;

[0036] a. Mix wet-process phosphoric acid and potassium sulfate according to the molar ratio of 2.2:1, heat and stir to completely dissolve the solid;

[0037] b. Add water to calcium carbonate to make a slurry and add it to the solution obtained in step a. The amount added is calculated according to the molar ratio of calcium carbonate and potassium sulfate 1.1:1. Maintain the temperature at 80°C, stir for 4 hours and then filter. Cake I;

[0038] c. Add potassium hydroxide solution to the filtrate I obtained in step b to adjust the pH to 4.5, then add ammonium fluorosilicate according to 1.1 times the magnesium ion content in the solution, stir at 40°C for 1 hour, and then age for 10 hours;

[0039] d. Filtrate the fully aged material in step c to obtain filtrate II and filter cake II; the filtrate II is co...

Embodiment 3

[0042] Embodiment 3: A kind of method for preparing potassium dihydrogen phosphate co-production potassium dihydrogen phosphate ammonium comprises the following steps;

[0043] a. Mix wet-process phosphoric acid and potassium sulfate according to the molar ratio of 2.2:1, heat and stir to completely dissolve the solid;

[0044] b. Add water to calcium carbonate to make a slurry and add it to the solution obtained in step a. The amount added is calculated according to the molar ratio of calcium carbonate and potassium sulfate 1.1:1. Maintain the temperature at 80°C, stir for 4 hours and then filter. Cake I;

[0045] c. Add potassium hydroxide solution to the filtrate I obtained in step b to adjust the pH to 4.7, then add ammonium fluorosilicate according to 1.1 times the magnesium ion content in the solution, stir at 70°C for 1 hour, and then age for 14 hours;

[0046] d. Filtrate the fully aged material in step c to obtain filtrate II and filter cake II; the filtrate II is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com