A treating method for volatile pollutants of solvent-type paint

A technology of volatile pollutants and treatment methods, applied in the field of VOC purification treatment, can solve the problems of difficult operation cost, poor purification effect, high operation cost, etc., and achieve strong operation convenience, outstanding environmental protection benefits, and strong cost advantage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

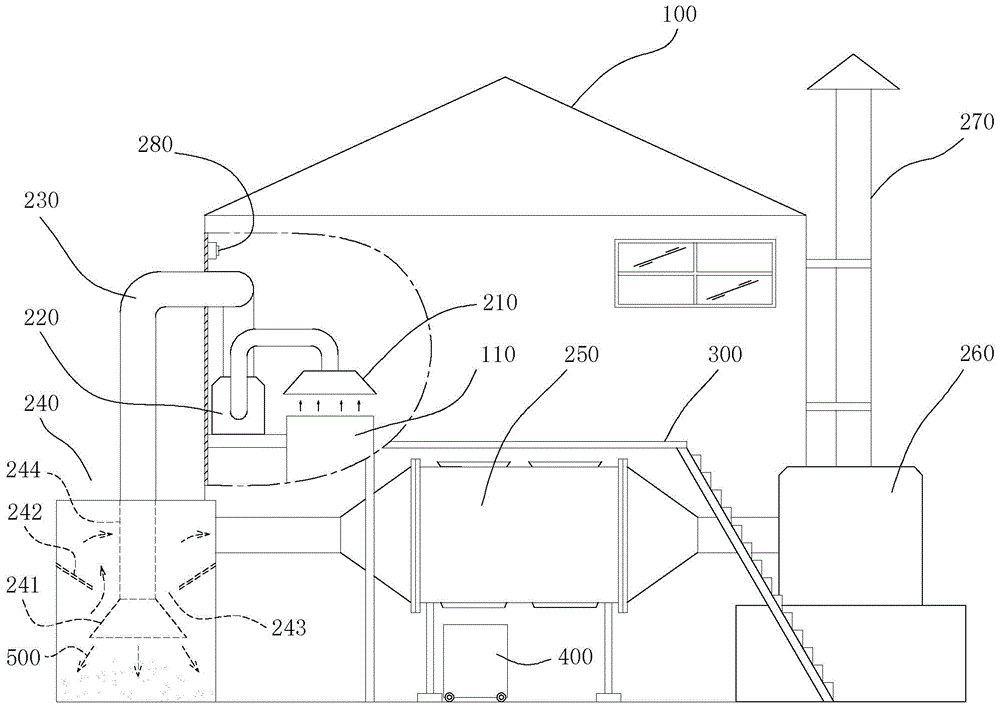

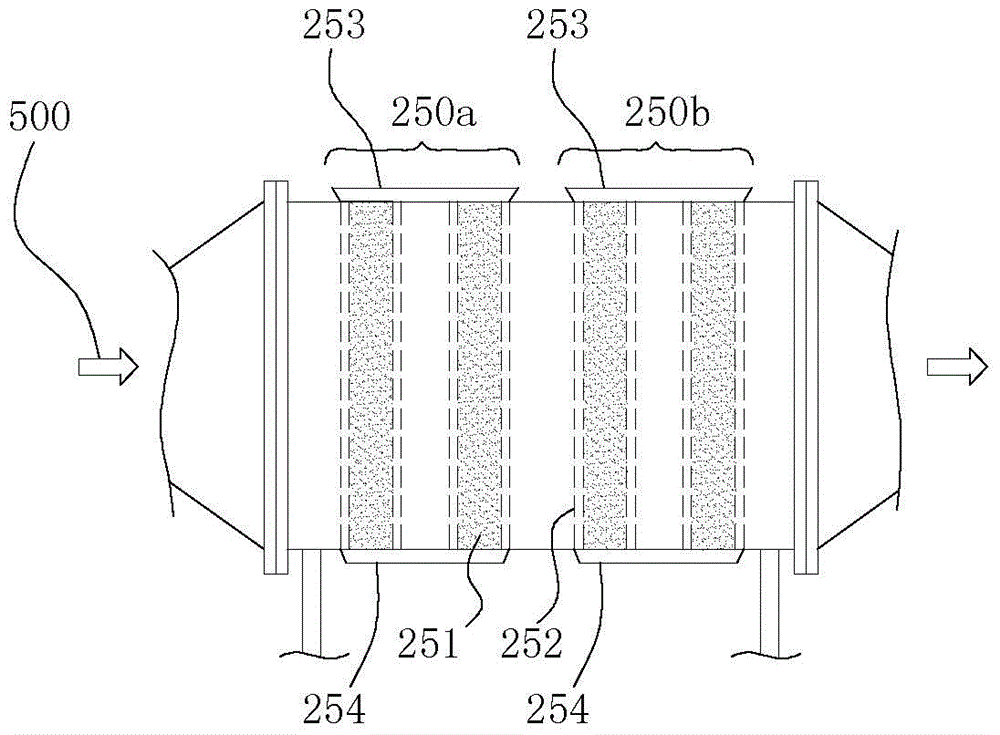

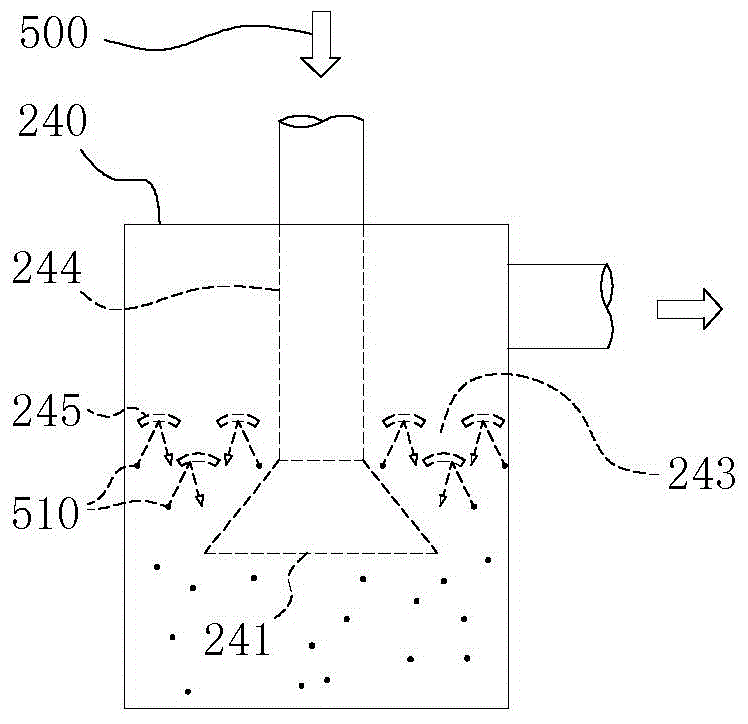

[0082] Such as figure 1 , 5 As shown, a solvent-based paint preparation workshop 100 has 14 paint mixing tanks 110 in total. When the VOC concentration detection device 280 detects that the VOC concentration in the workshop reaches 200mg / Nm 3 , that is to start the fan to exhaust, so that the gas emitted by the paint mixing tank 110 is absorbed by the suction hood 210 corresponding to each paint mixing tank 110 and enters the adsorption tower 250 through a closed pipeline for processing. Before the gas enters the adsorption tower 250, it is processed by the mechanical dust collector 240. The mechanical dust collector 240 specifically adopts figure 1 structure shown in . The gas after being adsorbed and purified by the adsorption tower 250 is directly discharged to the outside atmosphere, and the VOC concentration in the discharged gas is kept at ≤130mg / Nm 3 . 700kg activated carbon is housed in the adsorption tower 250 . After the solvent-based paint preparation workshop...

Embodiment 2

[0084] The difference from Example 1 is only that the formulation of the activator is different. The activator in Example 2 is formed by mixing 2% by weight of ammonium chloride, 5% by weight of phosphoric acid, 2% by weight of oxalic acid and deionized water of the remaining weight. Also after accumulative production of 5,000 tons of solvent-based coatings, the activated carbon regenerated for the fifth time was tested, and its adsorption performance remained at 93% of the original adsorption performance.

Embodiment 3

[0086] Such as figure 1 , 3 As shown, a solvent-based paint preparation workshop 100 has 14 paint mixing tanks 110 in total. When the VOC concentration detection device 280 detects that the VOC concentration in the workshop reaches 200mg / Nm 3 , that is to start the fan to exhaust, so that the gas emitted by the paint mixing tank 110 is absorbed by the suction hood 210 corresponding to each paint mixing tank 110 and enters the adsorption tower 250 through a closed pipeline for processing. Before the gas enters the adsorption tower 250, it is processed by the mechanical dust collector 240. The mechanical dust collector 240 specifically adopts image 3 structure shown in . The gas after being adsorbed and purified by the adsorption tower 250 is directly discharged to the outside atmosphere, and the VOC concentration in the discharged gas is kept at ≤120mg / Nm 3 . 700kg anhydrous calcium chloride is housed in the adsorption tower 250 . After 800 tons of solvent-based paints a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com