Preparation method of mixed-crystal-form titanium dioxide fiber and product

A technology of titanium dioxide and mixed crystals, applied in the field of preparation of titanium dioxide fibers, can solve the problems of greenhouse gas greenhouse effect, limited reserves, air pollution, etc., and achieve the effects of no environmental pollution, low cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Dissolve 1ml of tetrabutyl titanate in 20ml of ethylene glycol, and stir for 2 hours at room temperature to form a clear solution;

[0039] 2) Dissolve 16g of potassium hydroxide in 20ml of aqueous solution, stir for 10min, pour the KOH solution into the tetrabutyl titanate solution in step 1), and stir at room temperature for 2h to form a clear precursor solution;

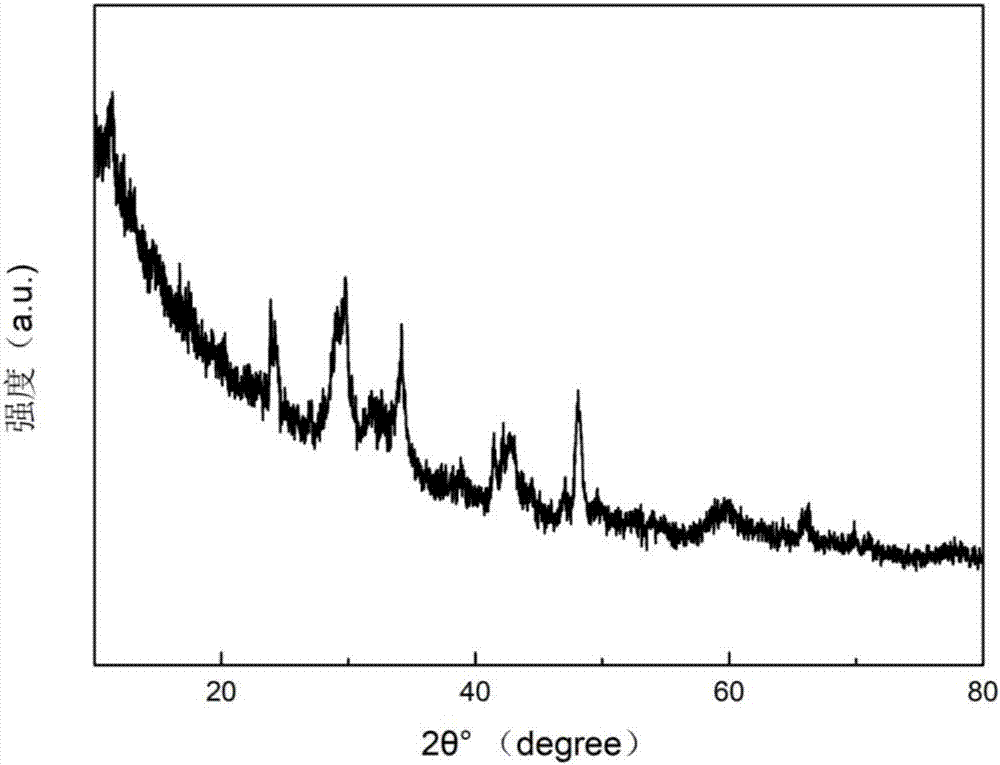

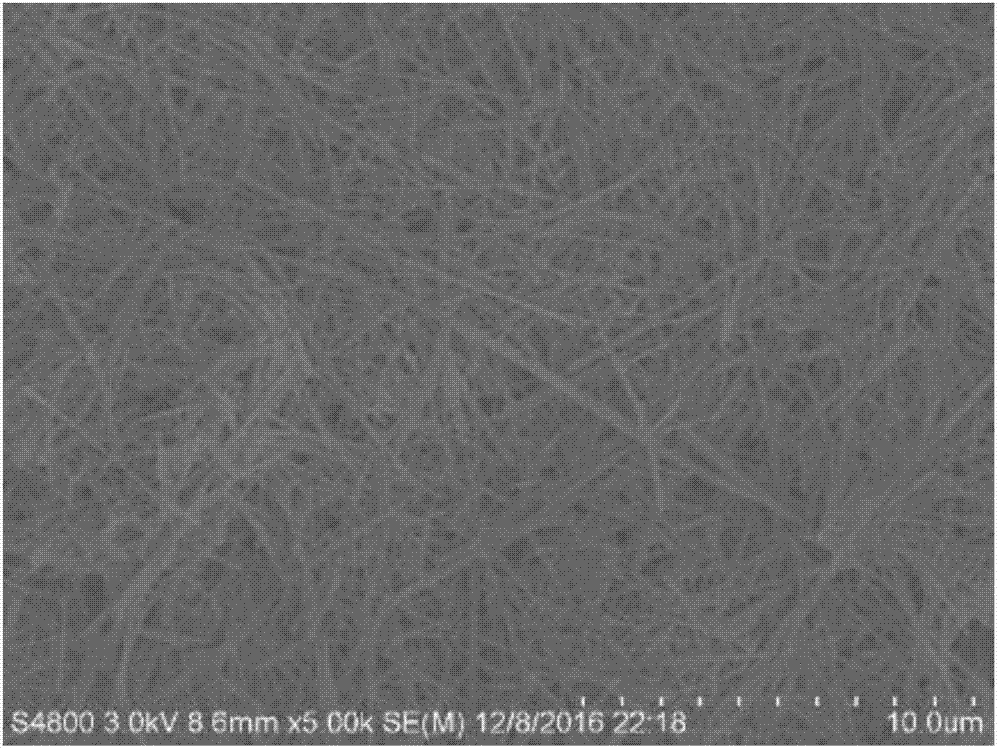

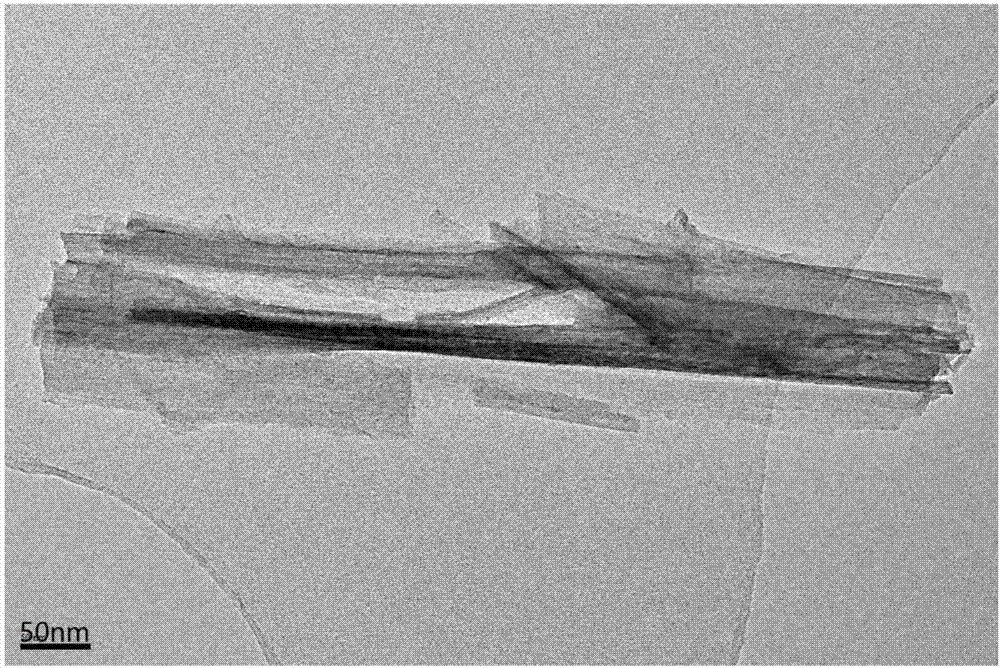

[0040] 3) Transfer the precursor solution to a 50ml polytetrafluoroethylene reactor for hydrothermal reaction at 180°C for 24 hours, filter the hydrothermal reaction product, wash with 0.1M dilute nitric acid, deionized water, and absolute ethanol, and dry Potassium titanate fiber (K 2 Ti 8 o 17 );

[0041] 4) Add 0.2g of polyvinyl alcohol into 100ml of water, heat to 90°C and stir for 1 hour to obtain a clear solution, and cool to room temperature;

[0042] 5) Dissolve the above-mentioned potassium titanate fiber in 30ml of 1.5M dilute nitric acid solution, add 10ml of the PVA aqueous solution in st...

Embodiment 2

[0048] 1) Dissolve 1ml of tetrabutyl titanate in 20ml of ethylene glycol, and stir for 2 hours at room temperature to form a clear solution;

[0049] 2) Dissolve 16g of potassium hydroxide in 20ml of aqueous solution, stir for 10min, pour the KOH solution into the tetrabutyl titanate solution in step 1), and stir at room temperature for 2h to form a clear precursor solution;

[0050] 3) Transfer the precursor solution to a 50ml polytetrafluoroethylene reactor for hydrothermal reaction at 180°C for 24 hours, filter the hydrothermal reaction product, wash with 0.1M dilute nitric acid, deionized water, and absolute ethanol, and dry Potassium titanate fiber (K 2 Ti 8 o 17 );

[0051] 4) Add 0.4g of polyvinyl alcohol into 100ml of water, heat to 90°C and stir for 1 hour to obtain a clear solution, and cool to room temperature;

[0052] 5) Dissolve the above-mentioned potassium titanate fiber in 30ml of 1.5M dilute nitric acid solution, add 10ml of the PVA aqueous solution in st...

Embodiment 3

[0054] 1) Dissolve 1ml of tetrabutyl titanate in 20ml of ethylene glycol, and stir for 2 hours at room temperature to form a clear solution;

[0055] 2) Dissolve 16 g of potassium hydroxide in 20 ml of aqueous solution, stir for 10 min, pour the KOH solution into the tetrabutyl titanate solution in step 1), and stir at room temperature for 2 h to form a clear solution;

[0056] 3) Transfer the precursor solution to a 50ml polytetrafluoroethylene reactor for 200°C, 30h hydrothermal reaction, filter the hydrothermal reaction product, wash with 0.1M dilute nitric acid, deionized water, and absolute ethanol, and dry Potassium titanate fiber (K 2 Ti 8 o 17 );

[0057] 4) Add 0.2g of polyvinyl alcohol into 100ml of water, heat to 90°C and stir for 1 hour to obtain a clear solution, and cool to room temperature;

[0058] 5) Dissolve the above-mentioned potassium titanate fiber in 30ml of 1M dilute nitric acid solution, add 10ml of the PVA aqueous solution in step 4) at the same t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com