Patents

Literature

58results about How to "Good quality and stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

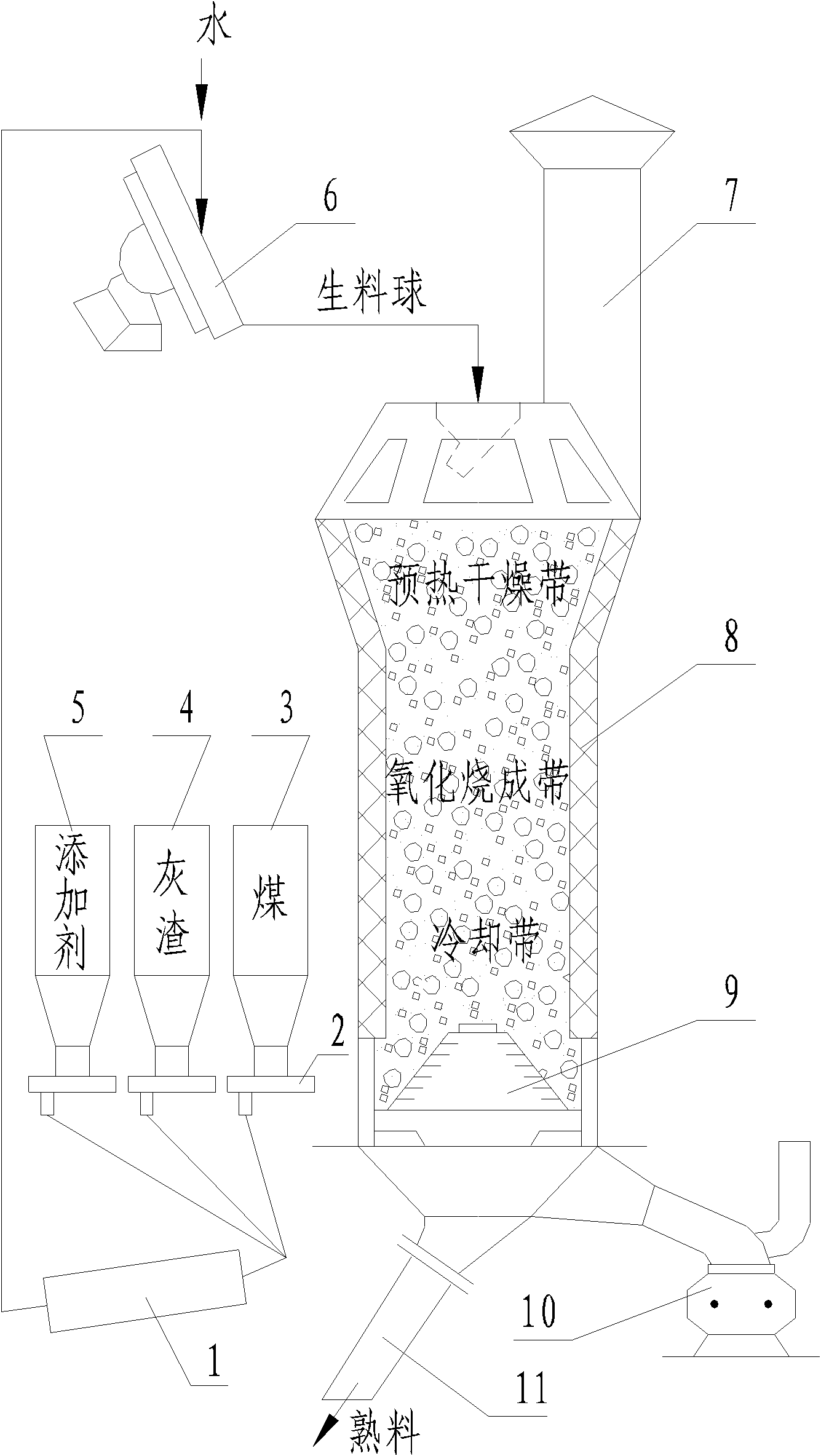

Pelletizing and calcination method for vanadium-containing stone coal ash

The invention relates to a pelletizing and calcination method for vanadium-containing stone coal ash. The equipment adopted by the method includes a moving-bed calcinator, which comprises a vertical furnace body, a chimney, a clinker discharger and a fan. The method includes the following steps that: NaCl, CaF2 and CaCO3 are prepared into complex additive, vanadium-containing stone coal, the complex additive and anthracite or stone coal as fuel needed by calcination are mixed into mixture material, the mixture material is uniformly mixed, fine-ground and pelletized into raw pellets, the raw pellets are fed into the furnace body via a feeder on the top of the furnace body, meanwhile, the fan blows the air into the furnace body via the clinker discharger on the bottom of the furnace body, the raw pellets and the air are calcined and reversely flow under the internal temperature condition of 800 DEG C to 900 DEG C, the calcined material enters the clinker discharger and is discharged out of the furnace body via the clinker discharger, and after cooling, clinker for the leaching of V2O5 is produced; and after calcination, the air is exhausted out via the chimney on the top of the furnace body. The technique and the equipment adopted by the method are relatively simple, the heat utilization rate is high, the product quality is stable, and the production cost is low.

Owner:ZHEJIANG UNIV

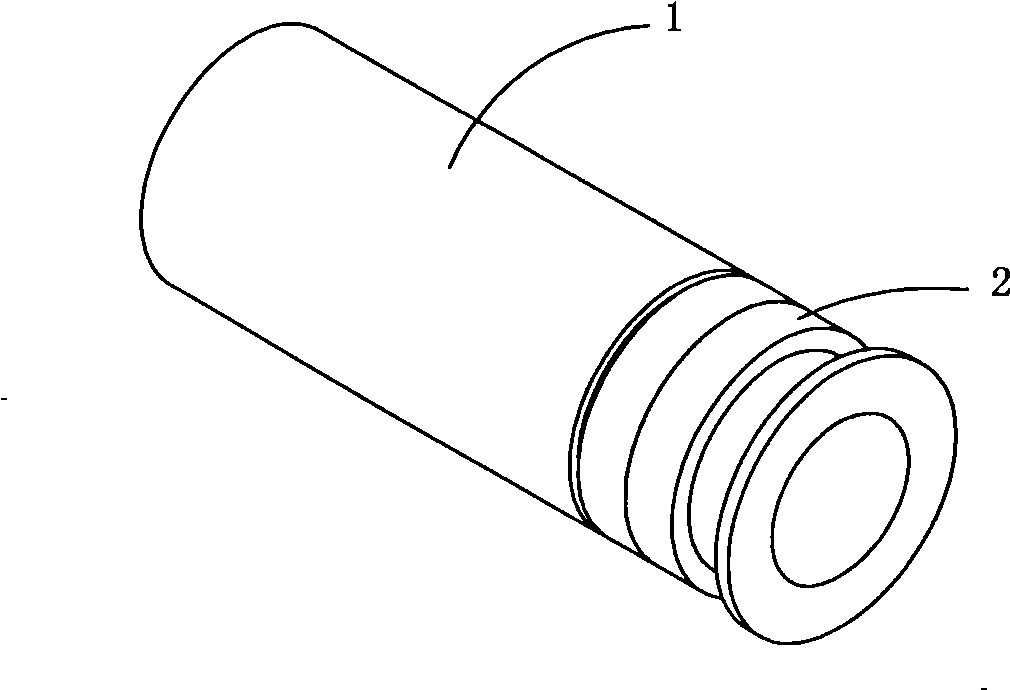

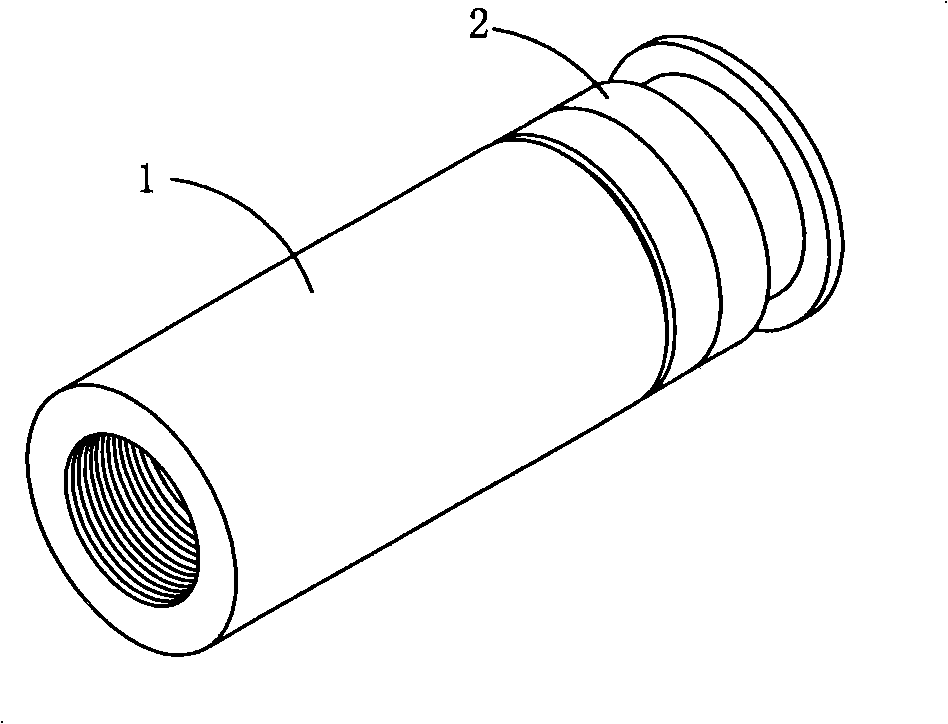

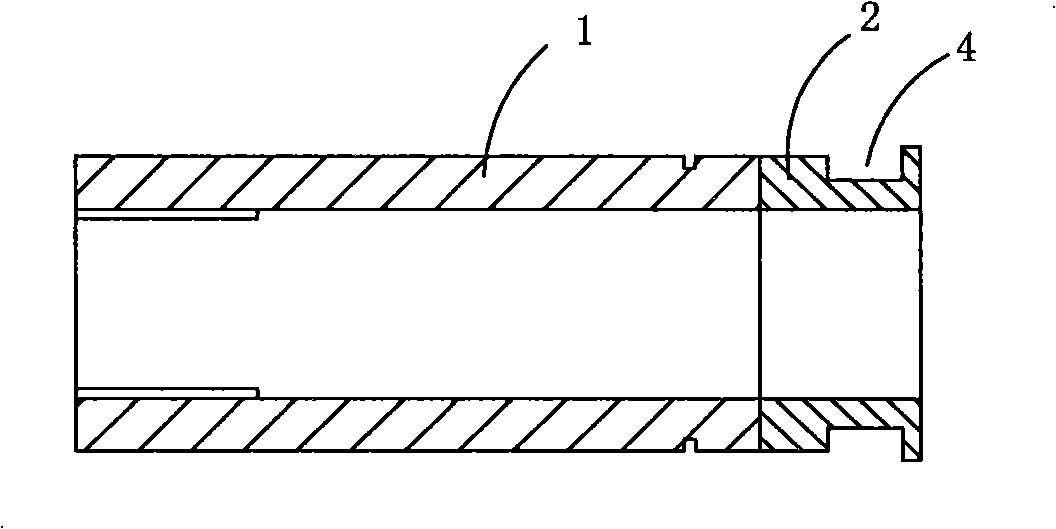

Cuprum aluminum socket connector for conductivity as well as manufacturing method and use thereof

InactiveCN101330174AHigh strengthImprove wear resistanceContact materialsContact member manufacturingElectrical resistance and conductanceLow voltage

The invention discloses a copper-aluminum socket connector for the electric conduction, the preparation method thereof and the application thereof. The socket connector comprises an aluminum body and a copper plug integrated into a whole by welding. The preparation method comprises the following steps: (1) manufacturing the molded aluminum body and the copper plug, and cleaning the welding surfaces of both the aluminum body and the copper plug; and (2) welding the aluminum body and the copper plug into an integrated part by adopting a flash welder or a spin friction welder to obtain the copper-aluminum socket connector semi-product for the electric conduction. The socket connector is mainly applied to a moving contact, a static contact or a conductive contact arm in a high and low voltage switch cabinet or a vacuum circuit breaker. The socket connector has the advantages of non-contact resistance, no galvanic corrosion, smaller resistance, less current conveyance loss, improved current transmission efficiency and reduced power transmission and transformation loss.

Owner:梁楚欣

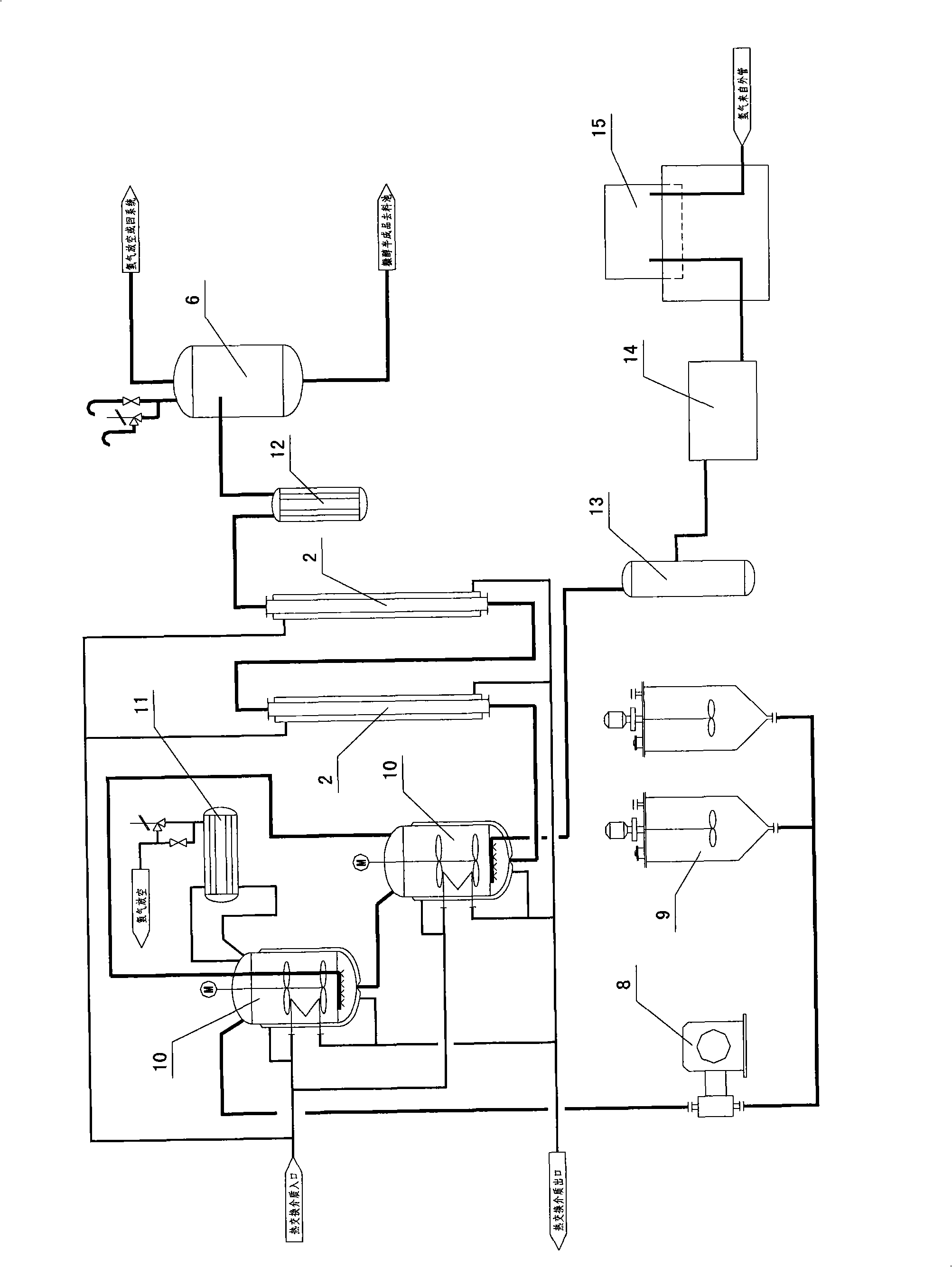

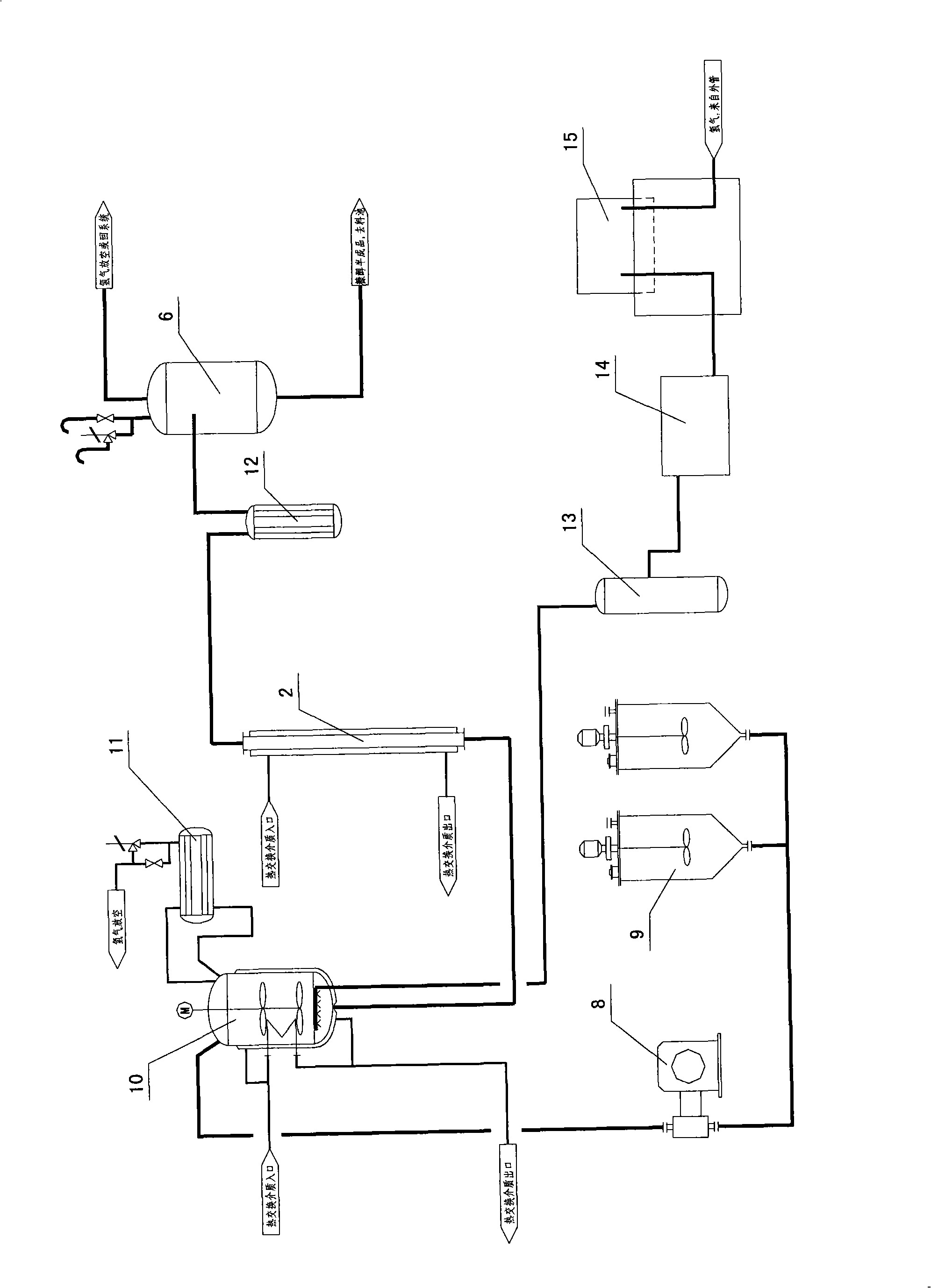

Method and system for preparing furfuryl alcohol by furfural liquid phase hydrogenation

The invention relates to a method for preparing furfuryl alcohol by taking furfural as a material through hydrogenation and a system thereof. The method disclosed in the invention includes the steps as follows: one or a plurality of complete mixing flow reactors and one or a plurality of plug-flow reactors are connected in series for combined-use; reaction materials are continuously arranged in the reactors for continuous reaction so as to obtain the furfuryl alcohol, wherein, the reaction materials include the material of furfural, a catalyst and hydrogen. The invention also relates to a system used in the method. The method of the invention has the advantages of low reaction temperature, stable operation as well as less material and energy consumption.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Sulbenicillin sodium and sulbenicillin sodium used for injection

InactiveCN102161667AReduce contentReduce pollutionAntibacterial agentsPowder deliveryDichloromethanePhenylacetic acid

The invention provides a synthesis method of sulbenicillin sodium and sulbenicillin sodium used for injection, which comprises the concrete steps of: using 6-APA and BSA to synthesize an organic salt, and dissolving the organic salt into dichloromethane; using a sulphur phenylacetic acid triethylamine salt and pivaloyl chloride to make mixed anhydride; carrying out anhydrous condensation on the sulphur phenylacetic acid triethylamine salt and the pivaloyl chloride in the dichloromethane; and then forming a sodium salt, free-drying and obtaining a finished product. The new technical process is stable and feasible, better and stable in product quality and strong in operability of production, and reduces the environmental pollution.

Owner:辽宁科泰生物基因制药股份有限公司

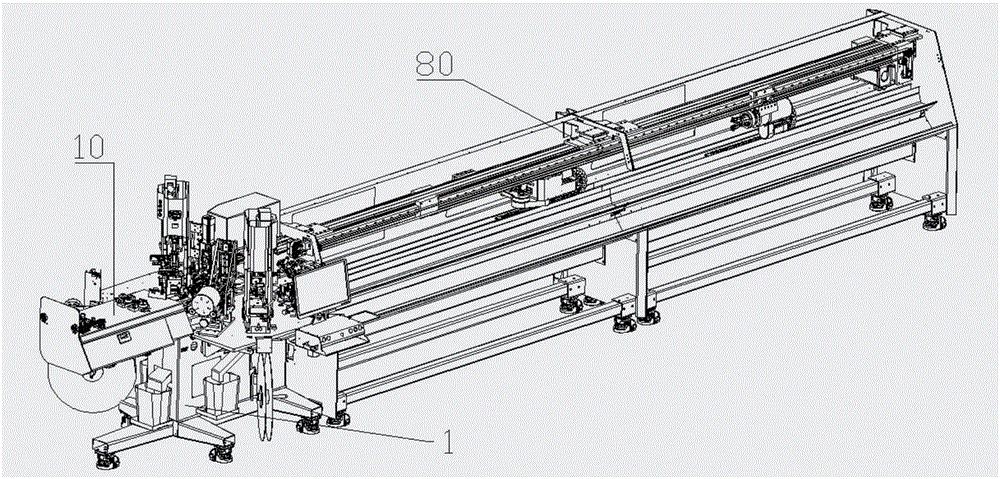

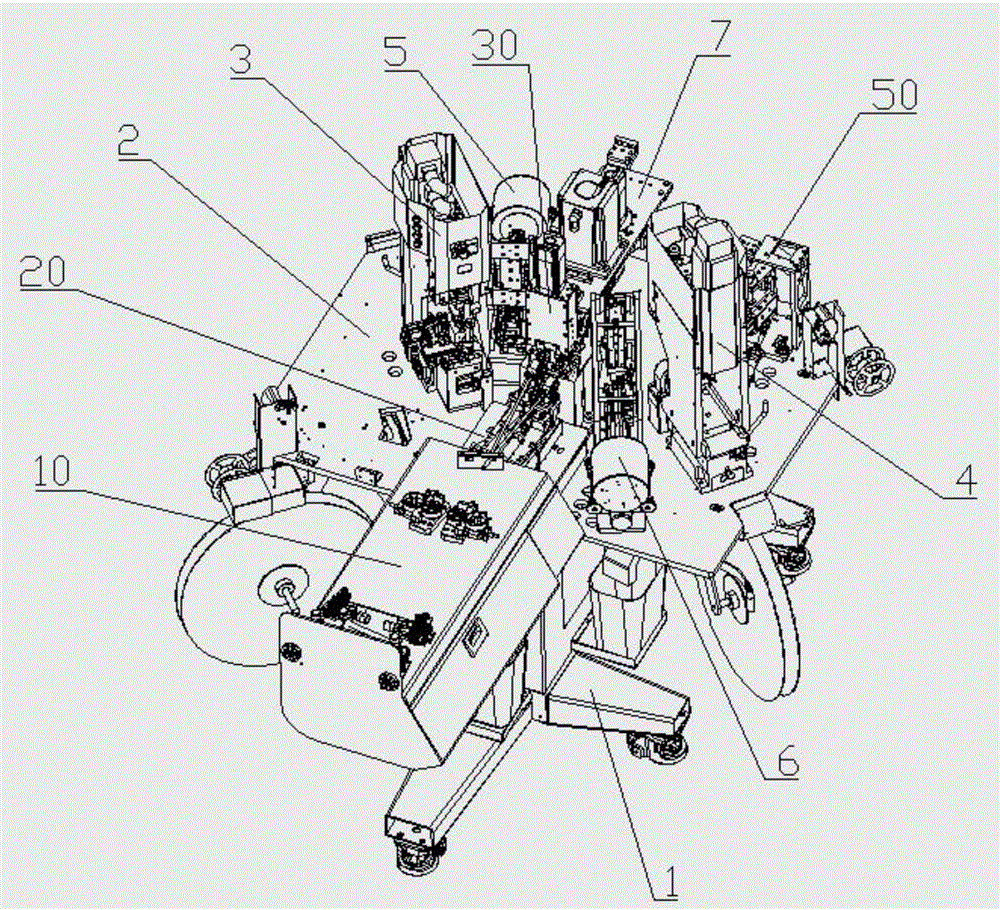

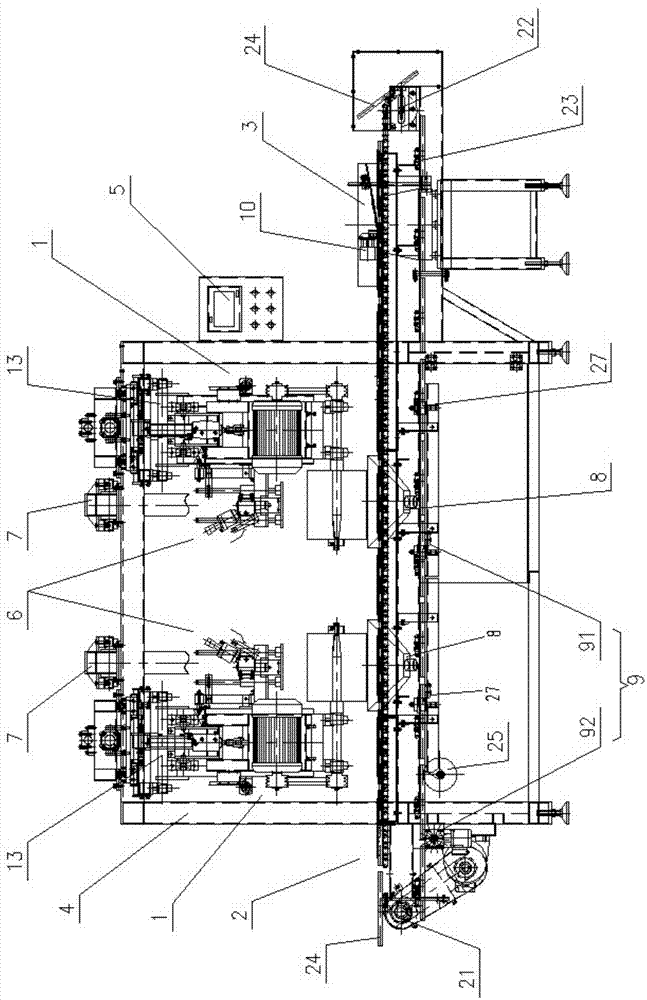

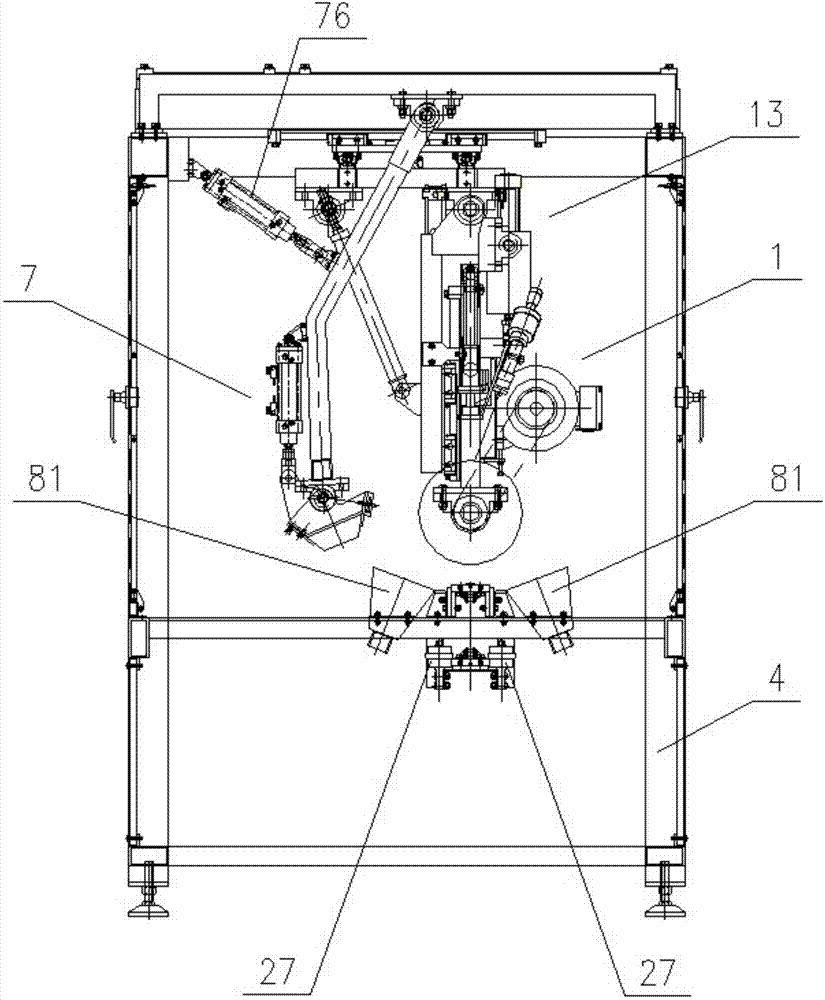

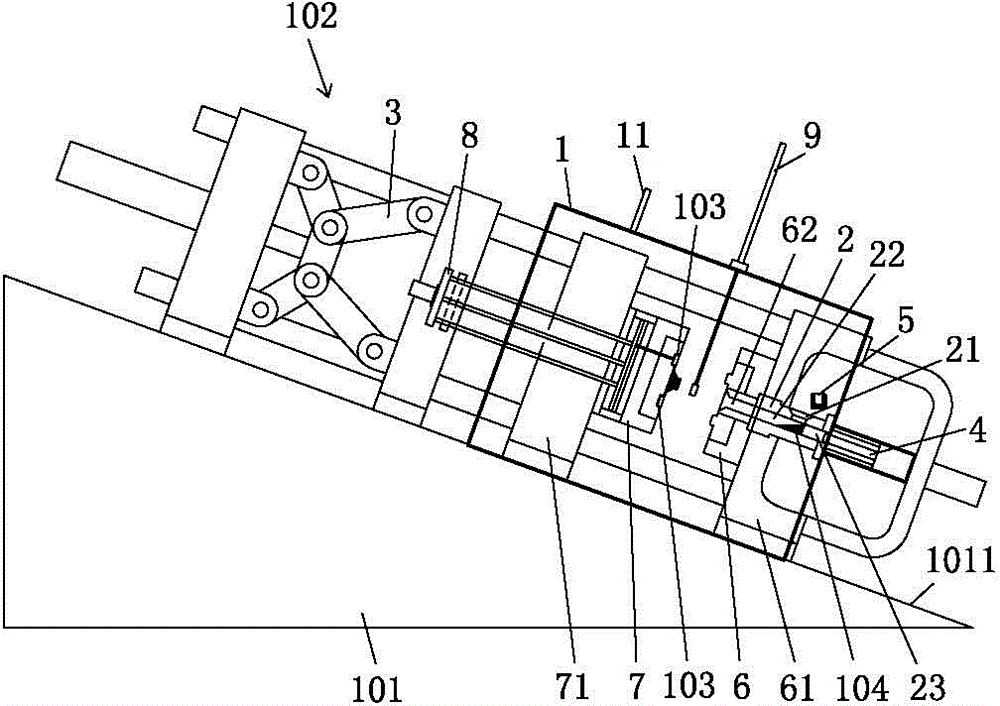

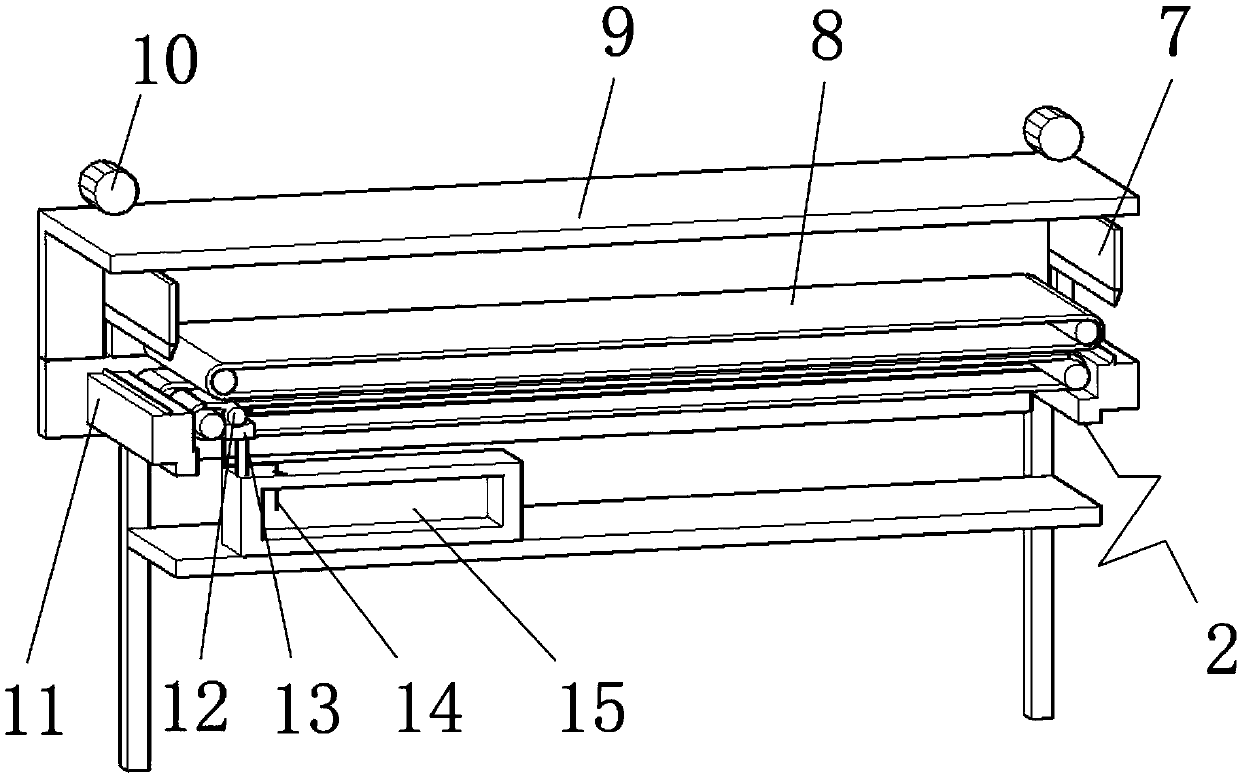

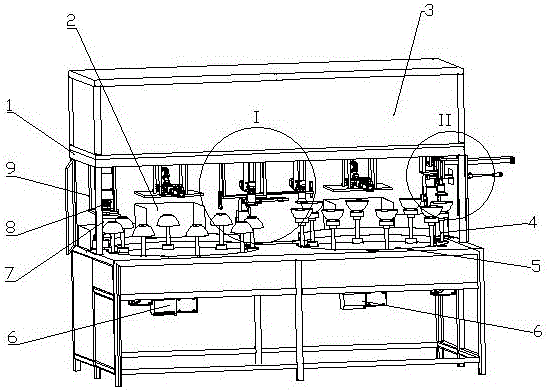

Fully automatic twisted-pair wire processing equipment

ActiveCN106848801AIncrease productivityImprove machining accuracyConnection formation by deformationWire cuttingFully automatic

The invention discloses fully automatic twisted-pair wire processing equipment, which comprises a main machine frame, wherein a work table is arranged on the main machine frame; a straightening module is arranged on the main machine frame and is positioned at the left side of the work table; a front end rotating moving arm, a double-line cutting module and a back end rotating moving arm are sequentially arranged in the position, positioned in the same straight line with the straightening module, on the work table from left side to right side; a bolt passing module, a press connecting module and a front end transfer twisted wire module are sequentially arranged on the work table and are positioned in front of the double wire cutting module from left side to right side; a press connecting module and a bolt passing module are sequentially arranged on the work table and positioned behind the double wire cutting module from left side to right side; a back machine frame is arranged on the main machine frame and positioned at the right side of the work table; a wire pulling module, a back end transfer module and a high-speed twisting wire module are sequentially and glidingly arranged on the back machine frame from the left side to the right side. The automation is completely realized in the whole process; the production efficiency is greatly improved; in addition, the processing precision is high; the quality stability is high; the production cost is low.

Owner:HEBI HAICHANG SPECIAL EQUIP

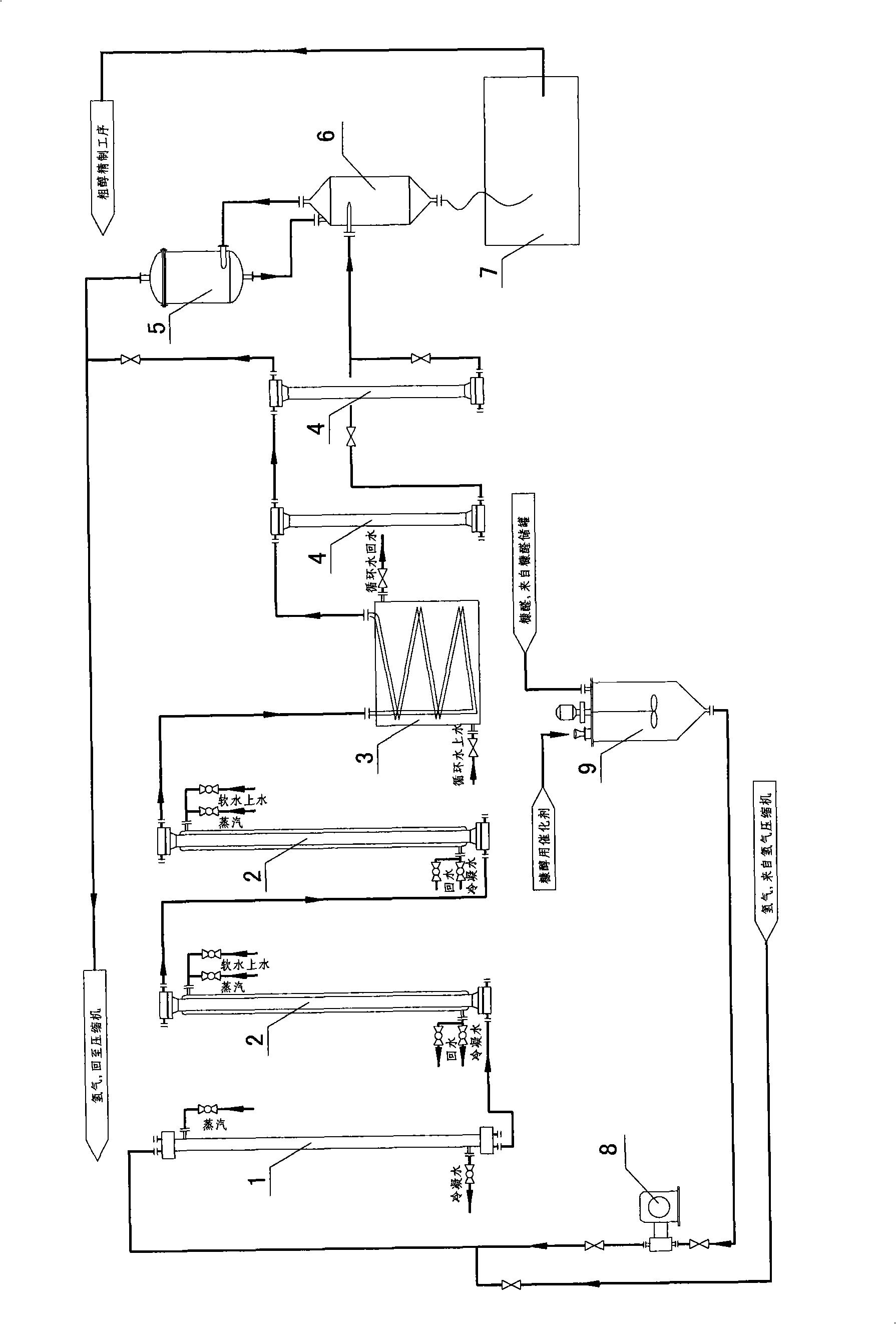

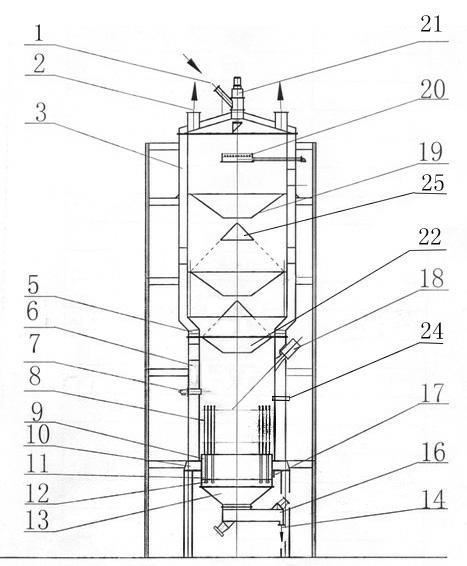

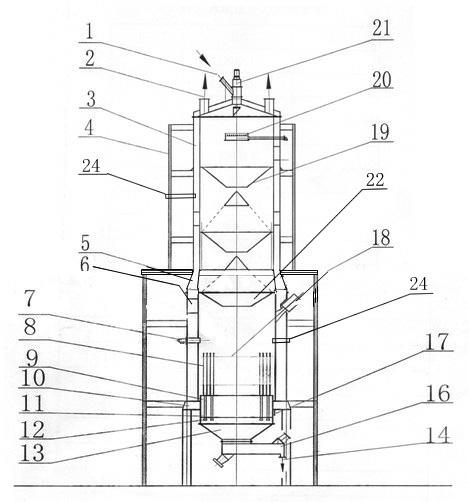

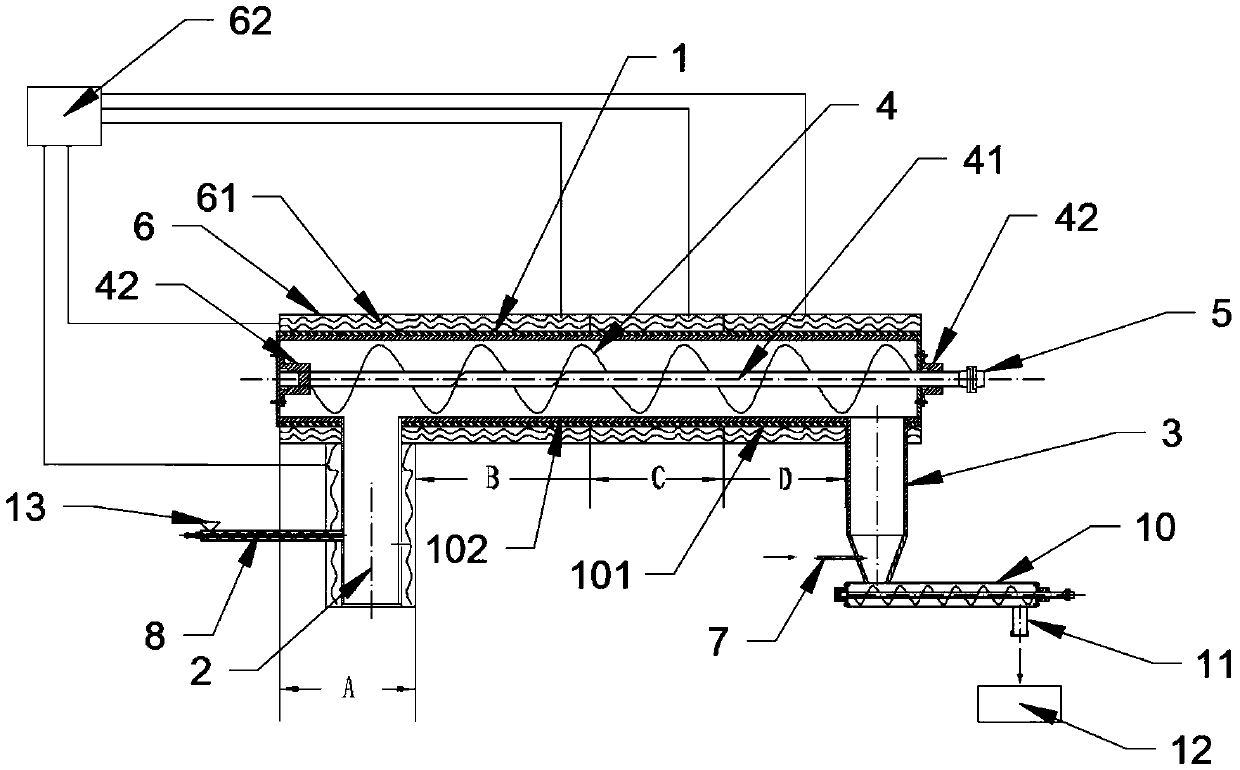

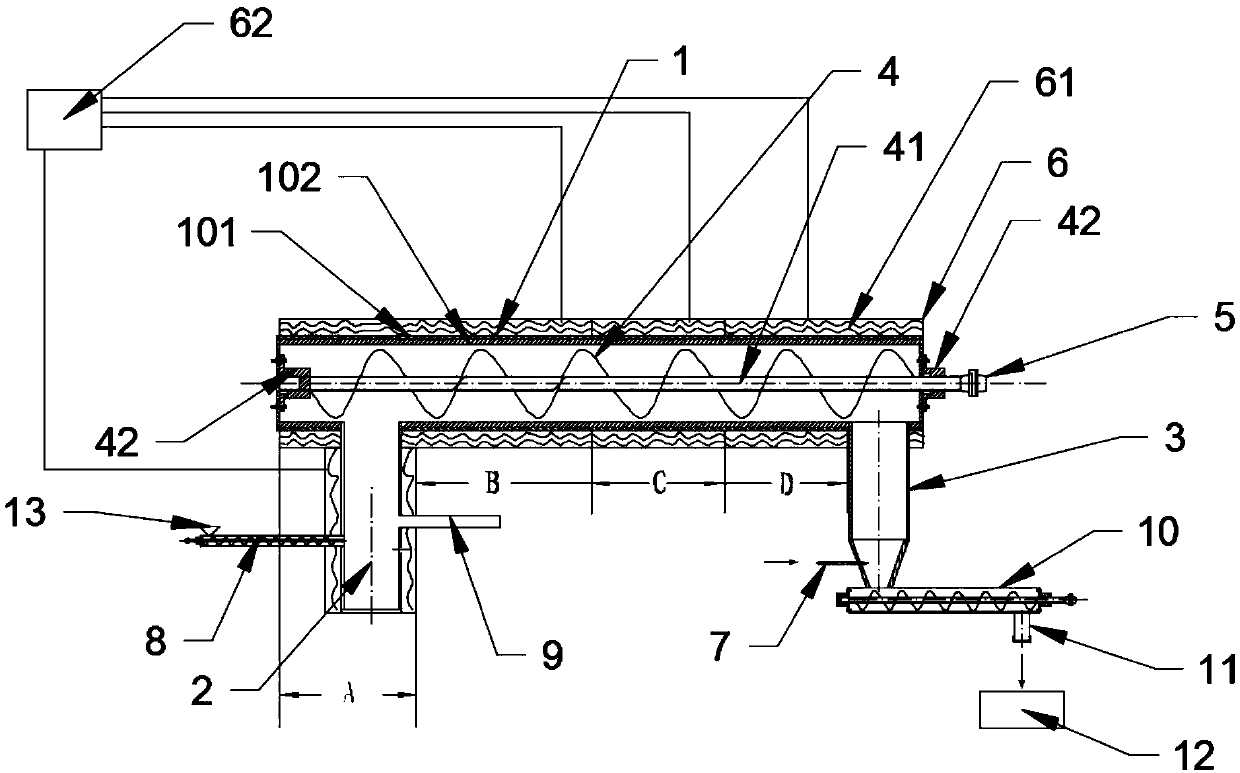

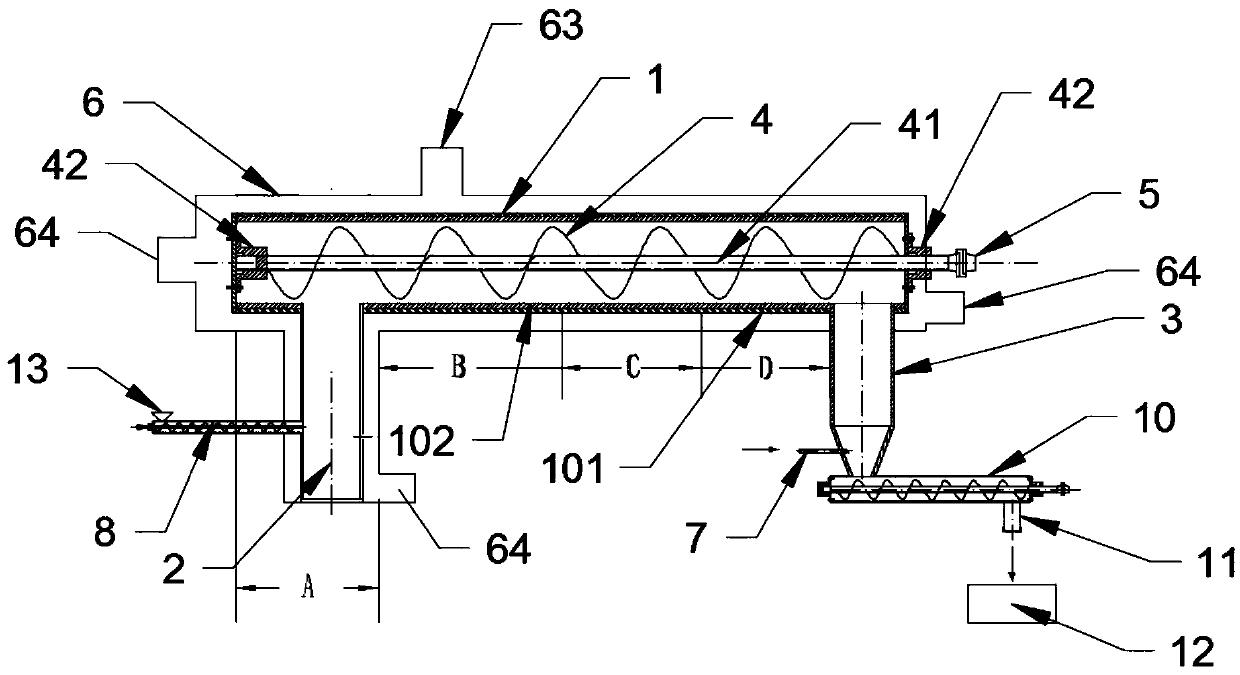

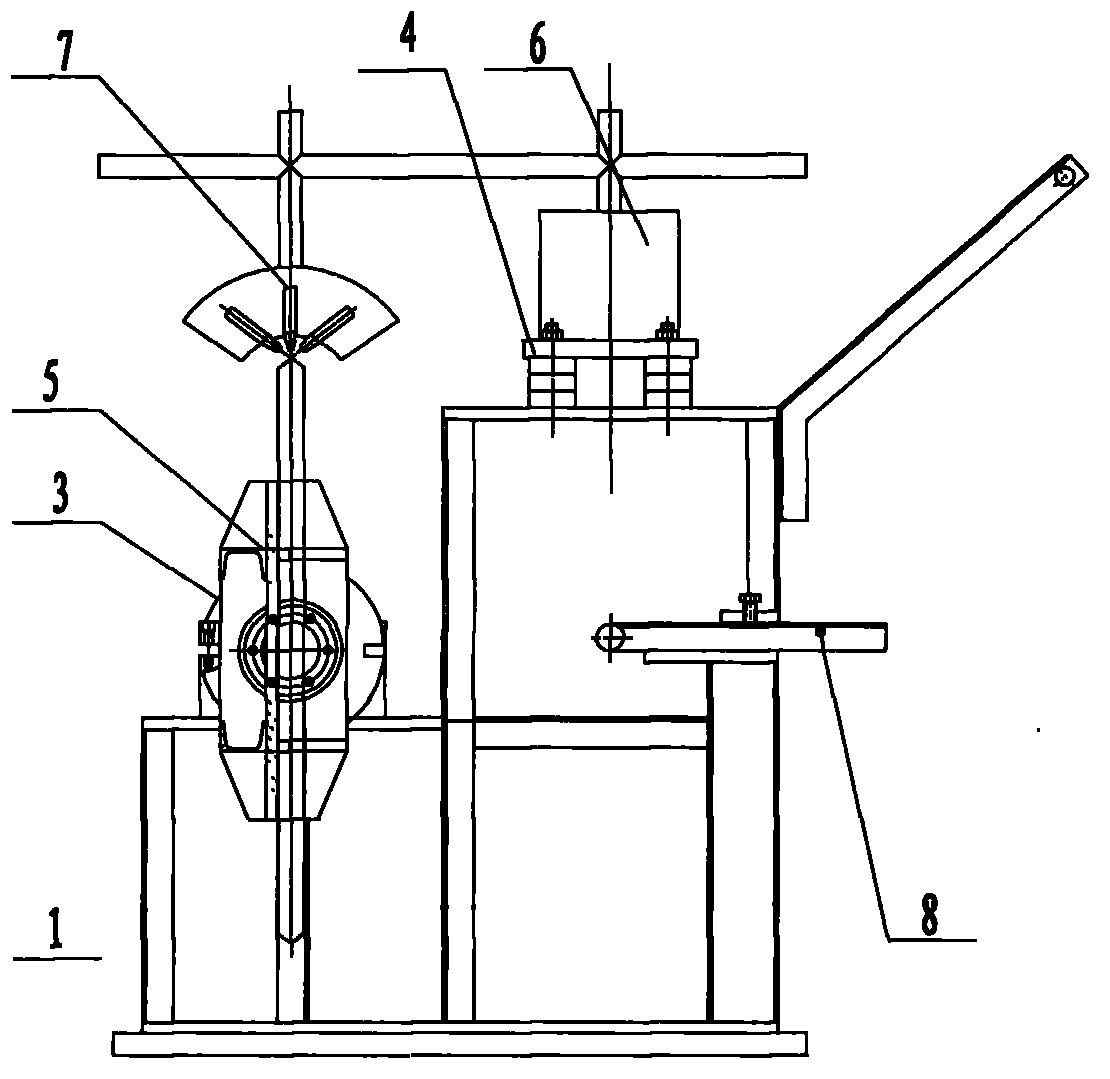

Full-counterflow heat exchange two-section type casting waste sand roasting furnace

ActiveCN102125982AWide rangeIncrease productivityMould handling/dressing devicesSand separatorTuyere

The invention discloses a full-counterflow heat exchange two-section type casting waste sand roasting furnace which comprises an upper-section furnace body, a lower-section furnace body, a sand adding device arranged at the top of the upper-section furnace body, a sand collecting hopper arranged at the junction of the upper-section furnace body and the lower-section furnace body, a burning machine, a burner, an air inlet, a lower sand collecting hopper and a sand outlet, wherein the burning machine, the burner and the air inlet are arranged on the lower-section furnace body, and the lower sand collecting hopper and the sand outlet are arranged at the bottom of the lower-section furnace body; and a pneumatic sand separator is arranged at the upper part of the upper-section furnace body, anin-furnace heat exchange device is arranged in the lower part of the lower-section furnace body, a temperature sensor is arranged on the lower-section furnace body, or the temperature sensors are arranged on the upper-section furnace body and the lower-section furnace body respectively, and the sensed data output end is connected with a data processing system connected outside of the furnace. Thefull-counterflow heat exchange two-section type casting waste sand roasting furnace has the following advantages: the waste sand processing range is wider, and the production efficiency is high; the temperature of the roasting furnace is moderate, and reclaimed sand is better in quality and stable; and the heat exchange efficiency in an in-furnace system is high, the burning heat utilization of organic matters and carbon in waste sand is good, and the roasting furnace is further conductive to protecting resources and is environment-friendly.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

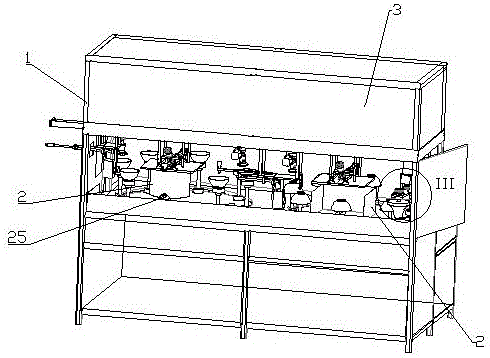

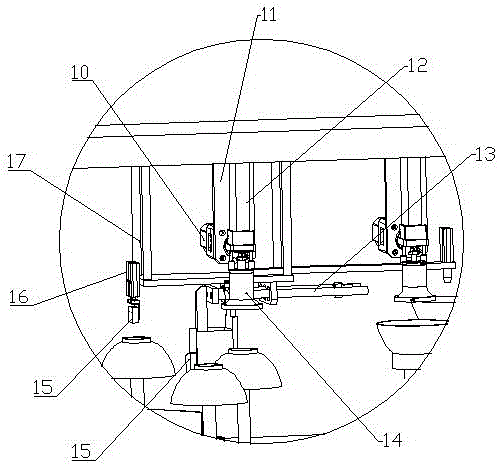

Fully-automatic polishing machine

InactiveCN103878673AHigh degree of mechanizationImprove efficiencyPolishing machinesGrinding drivesFully automaticSpatial motion

The invention provides a fully-automatic polishing machine which comprises a polishing mechanism, a material conveying mechanism, a feeding mechanism, a machine frame and a controller. The polishing mechanism comprises a polishing wheel, a rotary driving device and a spatial motion mechanism. The material conveying mechanism comprises a conveying chain and multiple material bearing templates. The feeding mechanism is located at the head end of the material conveying mechanism and provided with a feeding switching device. Thus, under the control of the controller, the feeding mechanism is controlled to be started and stopped by the feeding switching device, the material bearing templates of the material conveying mechanism are intermittently fed one by one, the material bearing templates are driven to move forwards through the conveying chain, a material to be polished is conveyed to the polishing mechanism, and under the spatial position adjustment of the spatial motion mechanism and rotary driving of the rotary driving device, the material to be polished of the corresponding material bearing template is polished by the polishing wheel. Thus, organic continuous polishing operation can be conducted by the polishing machine, the mechanical degree of the whole device is high, the polishing operation is conducted more smoothly, efficiency is high, and practicality is high.

Owner:HUA LIAN GARMENT COMPONENT ENTERPRISE

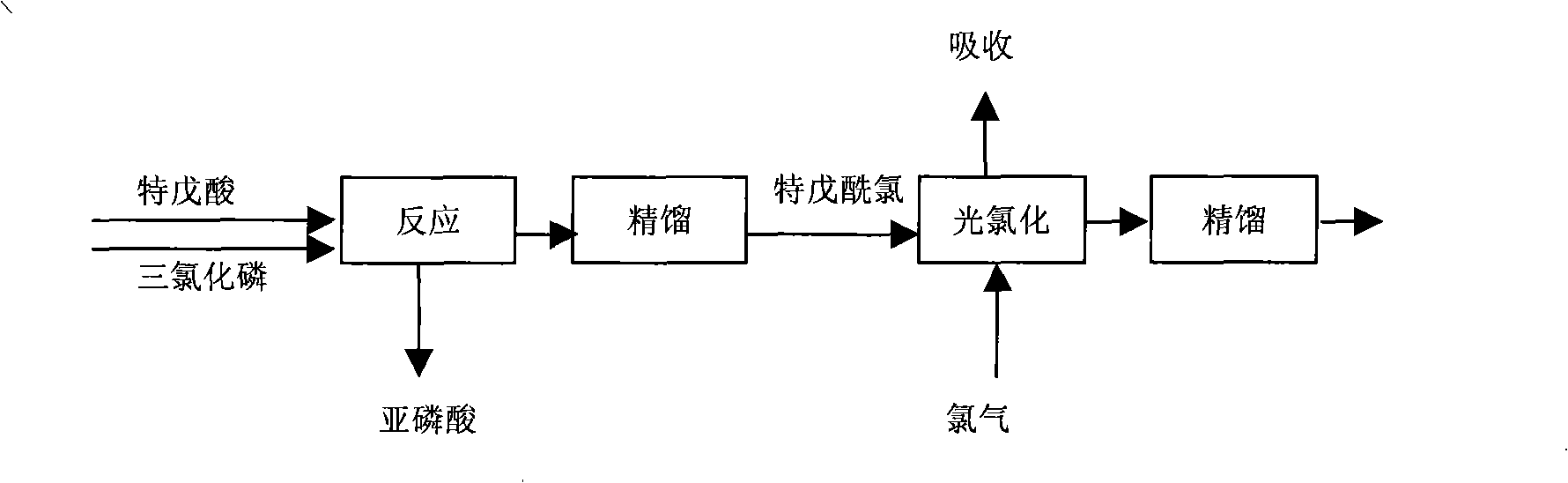

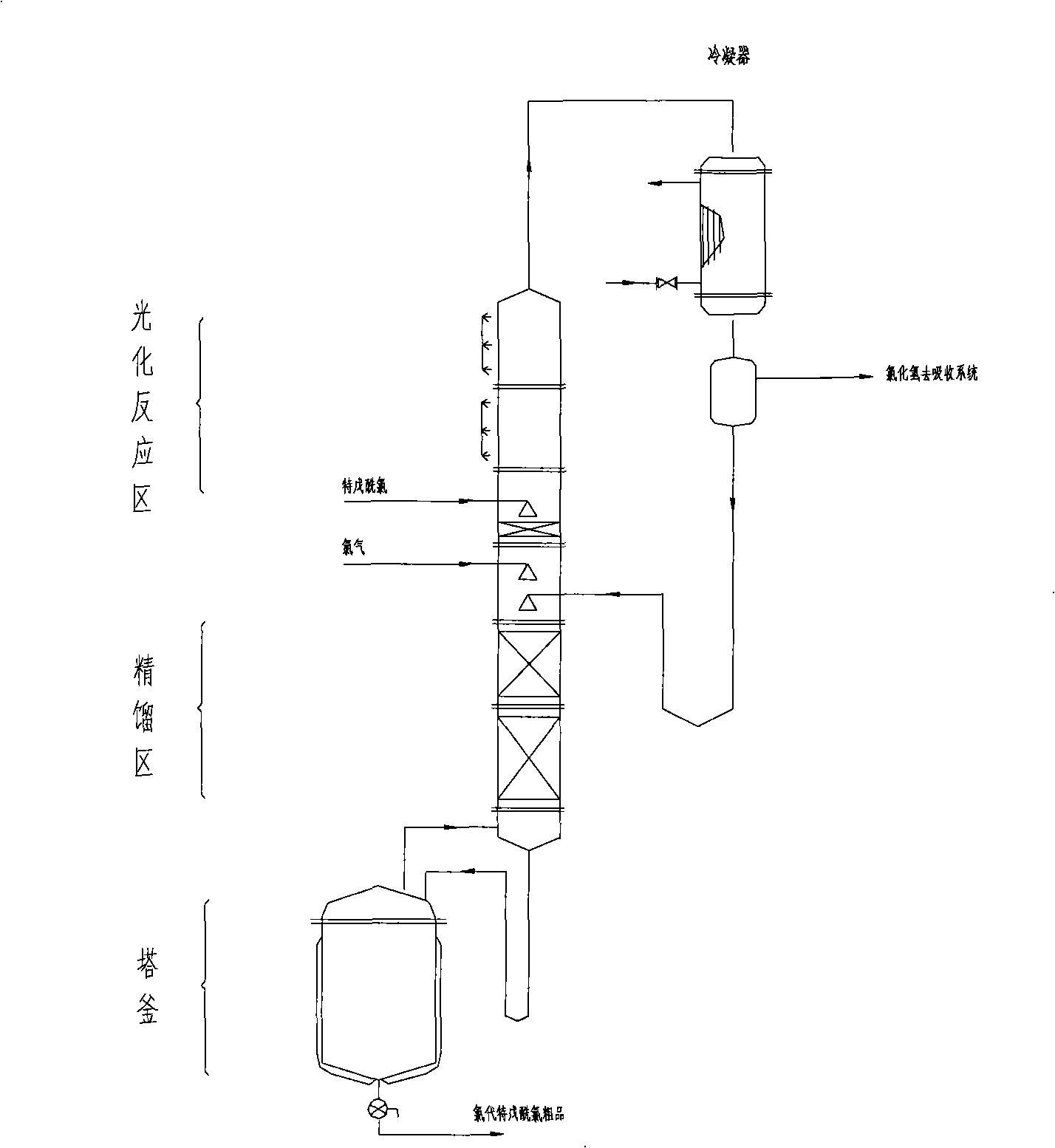

Process for preparing chloro-pivalyl chloride

ActiveCN101311155AMild process conditionsSimple and fast operationOrganic compound preparationChemical industryPivalic acidGas phase

The invention relates to a preparation method for chloro-pivaloyl chloride, in particular to a method that pivalic acid is taken as starting material to synthesize pivaloyl chloride by phosphorus trichloride acyl chlorination; then, gas-phase photocatalysis chlorination is carried out on the pivaloyl chloride by adopting reactive rectification technique; finally the chloro-pivaloyl chloride is prepared by vacuum rectification. The method of the invention can effectively inhibit the generation of multi chlorine substitutes and has simple production technique, safe operation, no pollution, low production cost and high production quality.

Owner:JIANGSU JIANNONG PLANT PROTECTION CO LTD

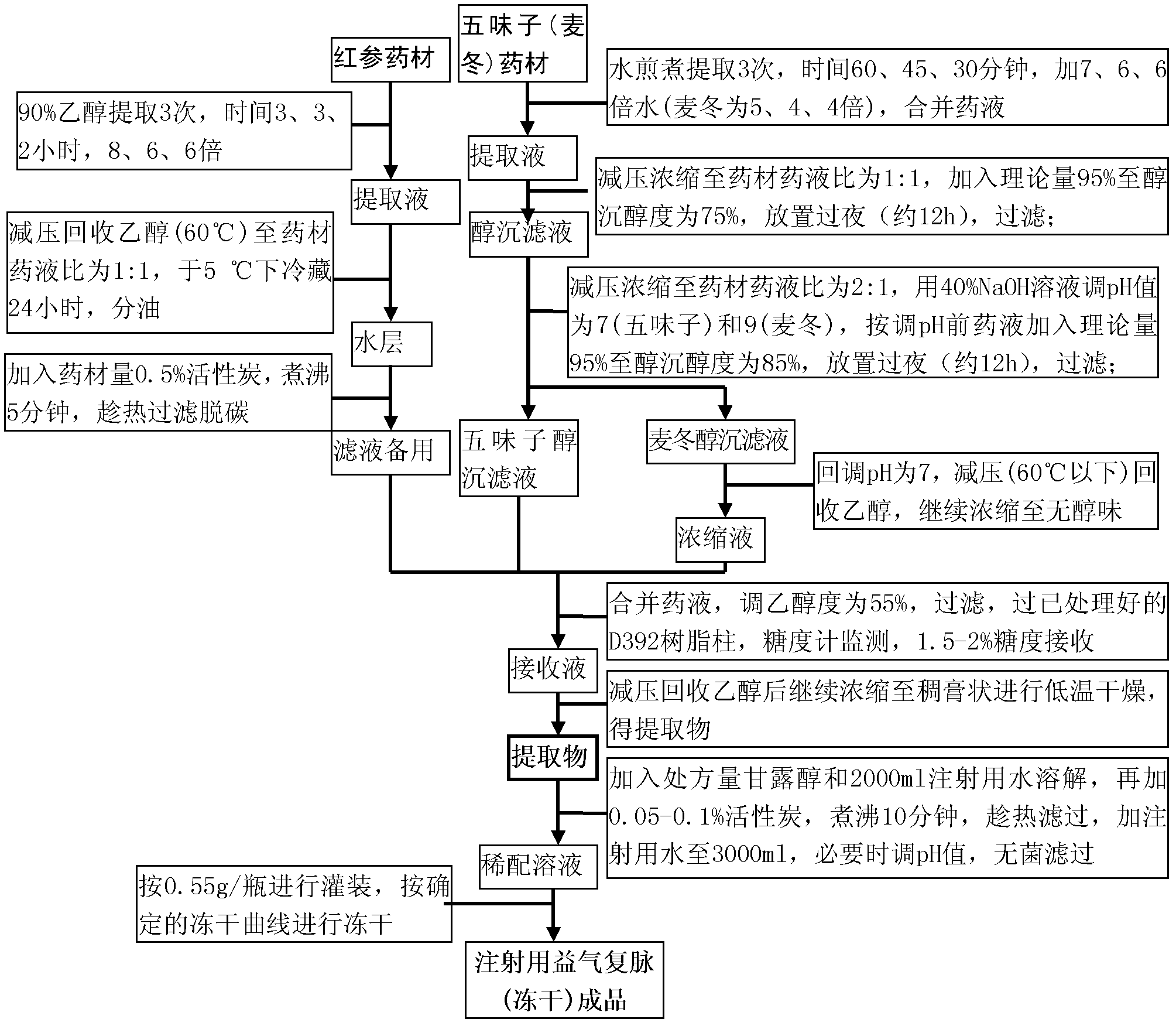

Qi tonifying and pulse restoring preparation

ActiveCN102988719ALight colorImprove solubilityPowder deliveryLyophilised deliveryActive componentMedicine

The invention relates to a traditional Chinese medicinal preparation, and especially relates to a qi tonifying and pulse restoring preparation. The preparation is prepared through an improved method. The method comprises the following steps: 1, extracting Radix Ginseng Rubra by ethanol; 2, extracting Radix Ophiopogonis and Chinese magnoliavine by water, and precipitating twice by ethanol; 3, mixing a Radix Ginseng Rubra extract liquid obtained in step 1, and a Radix Ophiopogonis extract liquid and a Chinese magnoliavine extract liquid obtained in step 2 to obtain a mixed liquid, allowing the mixed liquid to pass through a D392 resin column, receiving the eluant when glucose flows out, concentrating, and drying to obtain extract products; and 4, using the extract products as medicinal active components to prepare the medicinal preparation.

Owner:TIANJIN TASLY ZHIJIAO PHARMA

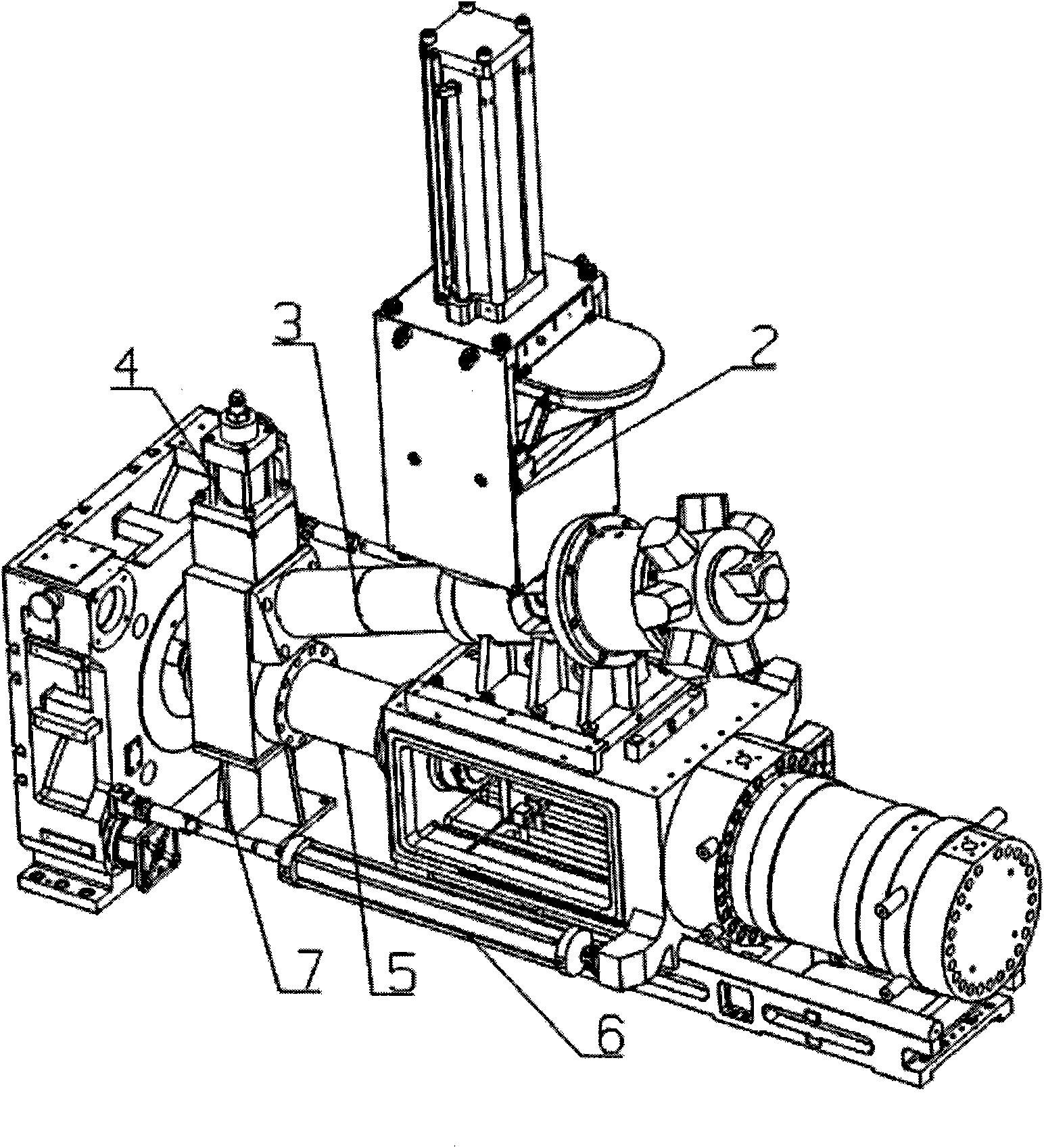

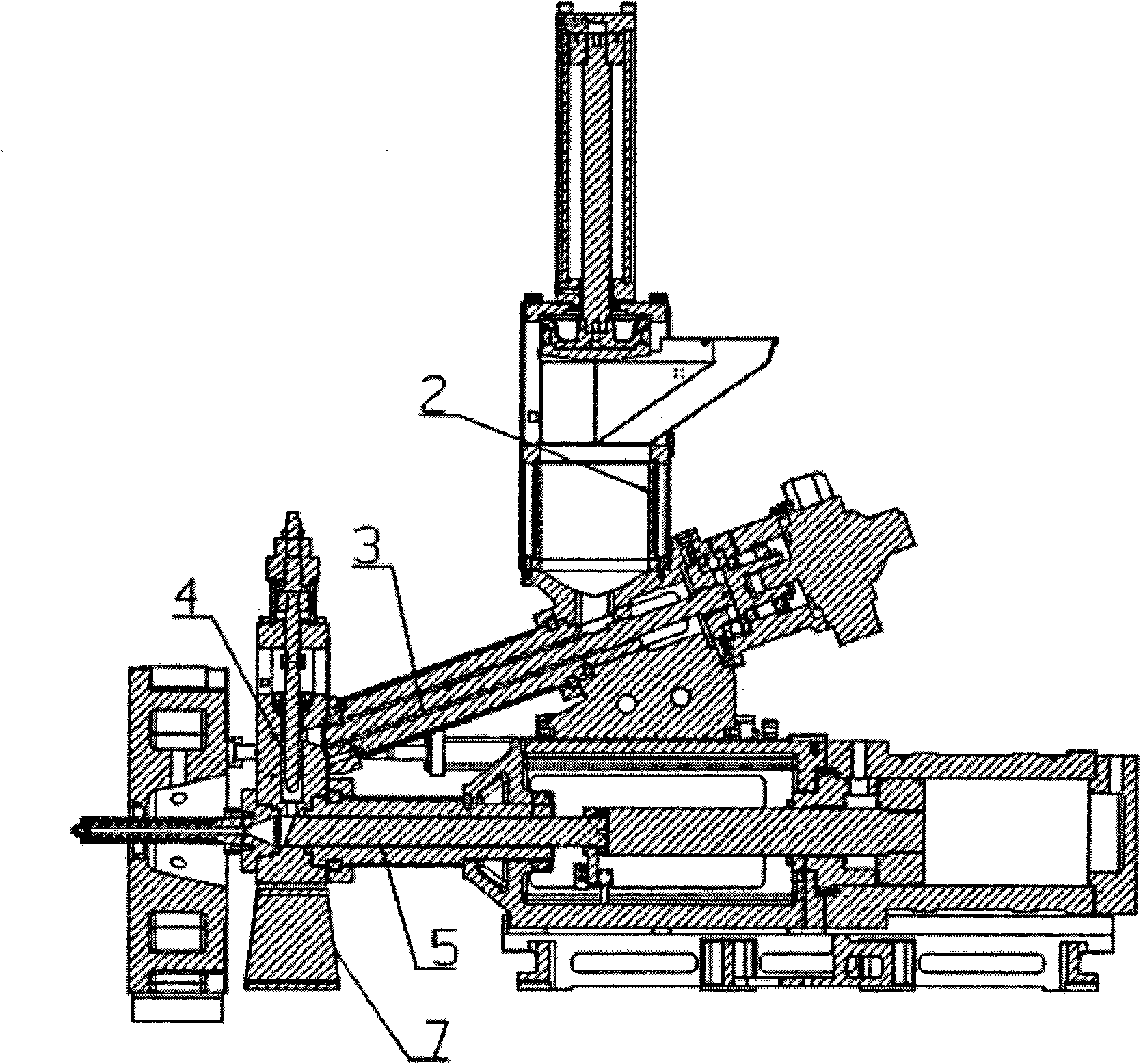

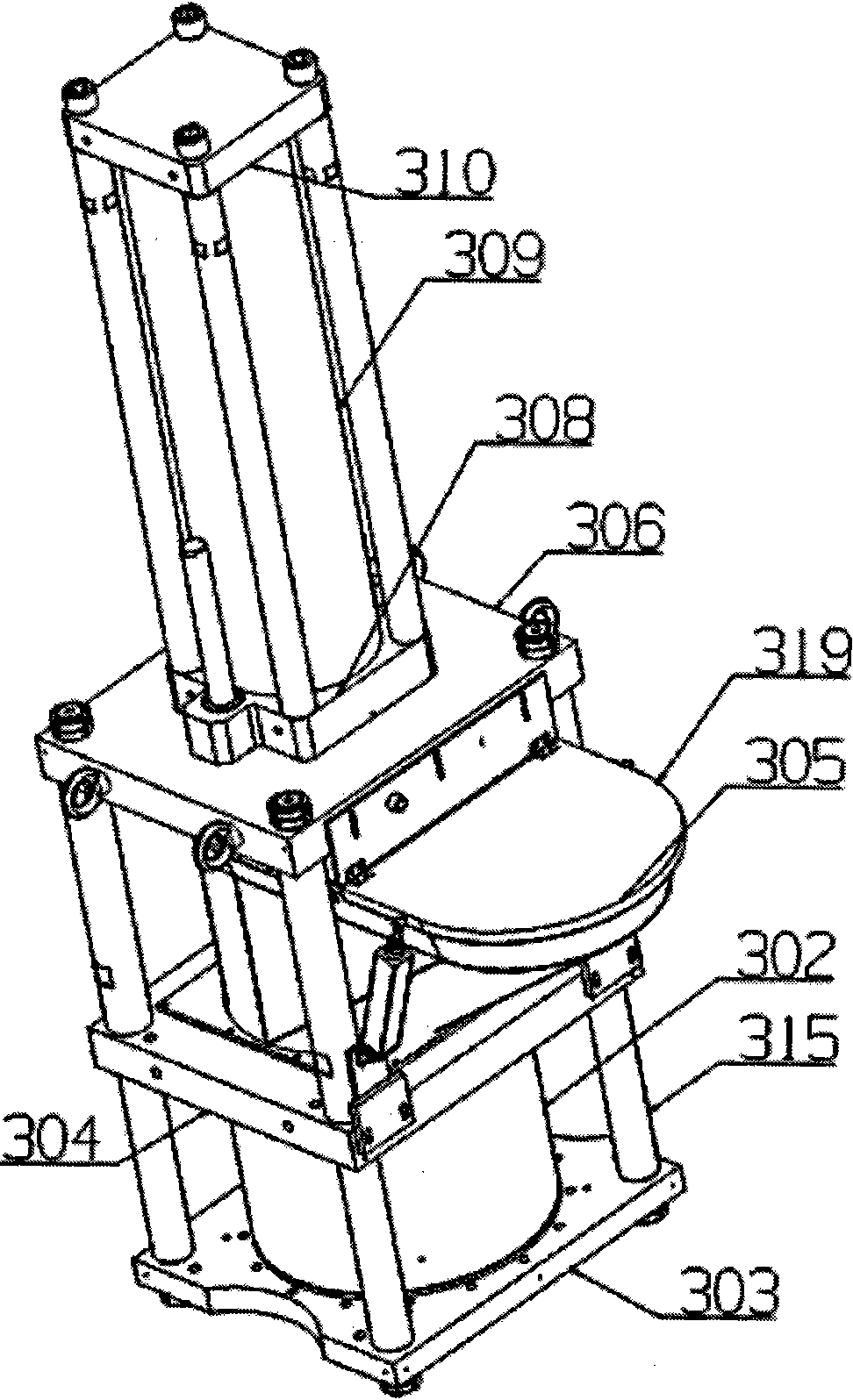

Injection moulding method of composite material mainly containing stone and injection moulding equipment

InactiveCN101830028AImprove pass rateEasy to produceCeramic shaping apparatusThermoplasticHeat resistance

The invention relates to injection moulding method and equipment of composite material mainly containing stone. The injection moulding method comprises the following steps of: a. putting used raw materials in a charging device, and then pushing the raw materials into a preplasticizing machine barrel of a preplasticizing device by a material compacting component in the charging device; b. under the condition of keeping the temperature to be 15-55 DEG C, compacting the raw materials along with the rotation of a preplasticizing screw rod and conveying to an injection machine barrel; c. under the condition that material injection force is 50-180MPa, injecting the raw materials in the injection machine barrel into a mould by a mould sprue; d. under the condition of keeping the temperature of the mould to be 140-200 DEG C, curing for 40-300 seconds; and e. opening mould to take out products. The invention has the advantages of simple production process, high yield of the produced products, high production efficiency and low production cost. The products have the advantages of good mechanical strength, fire resistance, heat resistance, corrosion resistance, good electrical property, low cost and the like and can replace most of thermosetting plastics and thermoplastic plastics, thereby reducing the application amount of plastic products and providing powerful support and guarantee for creating resource-saving and environmental-friendly industries.

Owner:HAITIAN PLASTICS MACHINERY GRP

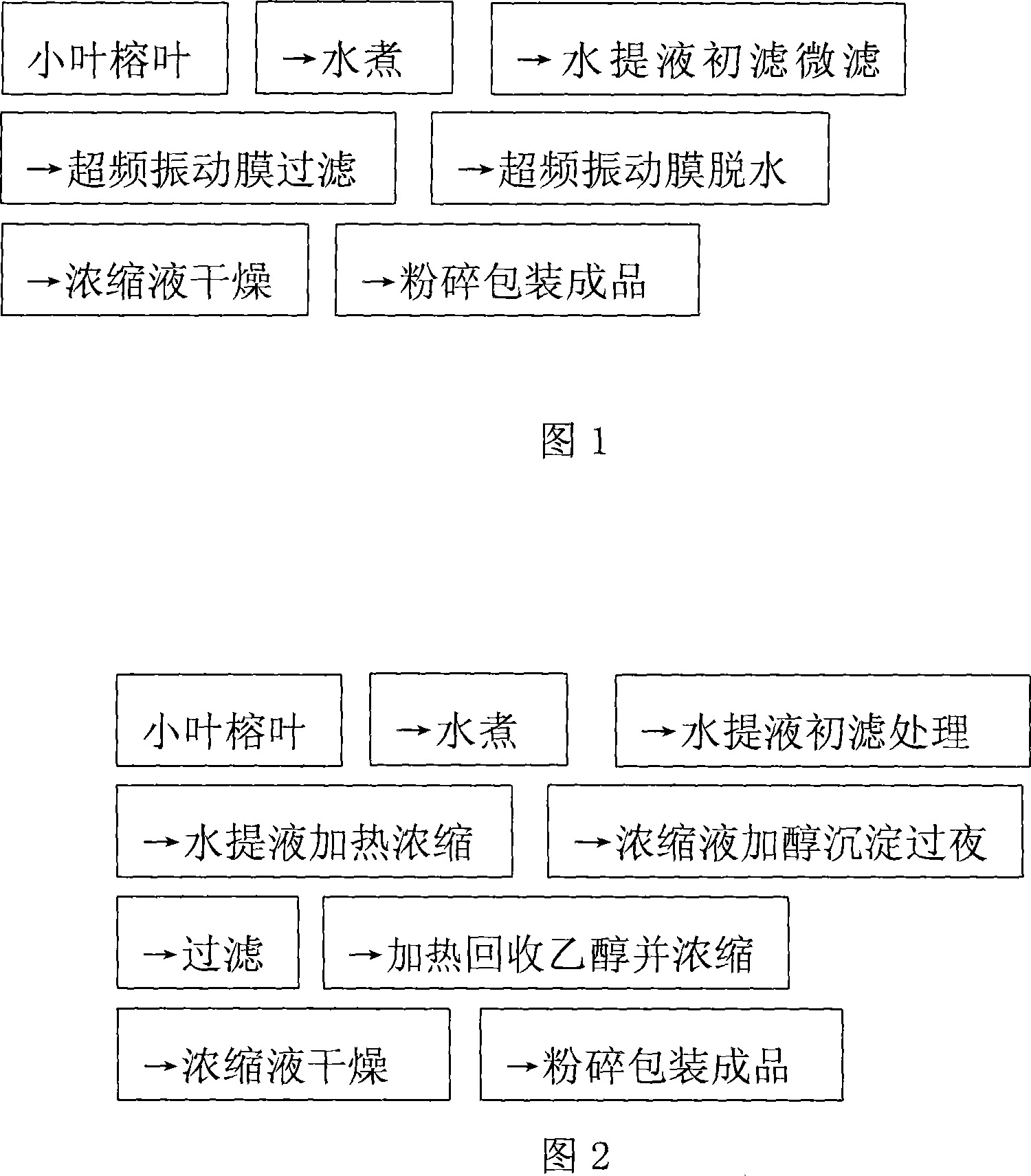

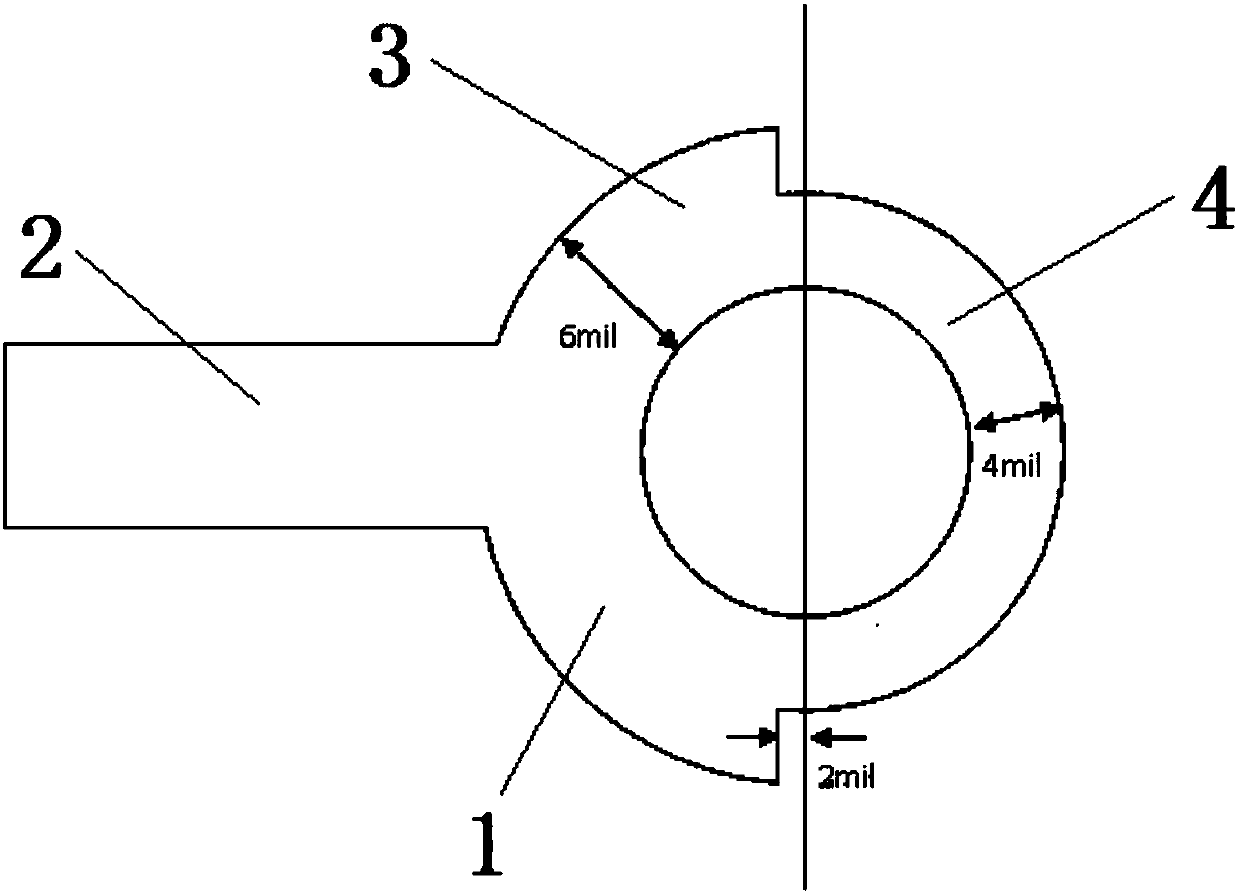

Method of preparing aqueous extract concrete of ficus microcarpa leaf

InactiveCN101152255ASimple processHigh content of active ingredientsAerosol deliveryOintment deliveryUltrafiltrationChemistry

The invention discloses the preparation method of an extract of India laurel fig leaf liquid, including the steps of airing or air-drying the India laurel fig, aqueous extracting, primary filtering and micro filtering the aqueous extracted liquid, ultrafiltrating and nano-filtrating by a superfrequency vibrating membrane, filtering and condensing by a superfrequency vibrating and dehydrating membrane, drying, crushing and packing. The technology of using the superfrequency vibrating membrane to filtering replaces the traditional alcohol precipitating by aqueous extraction and condensing by heating, and the invention is capable of improving the product quality, saving the energy and reducing the discharge and belongs to the method of saving the energy, reducing the discharge and being green and environmental protective. At the same time, the invention has important meaning for developing and improving the technology of traditional Chinese medicine extraction and separation.

Owner:GUANGDONG PHARMA UNIV

Automatic soy sauce and vinegar pouring method

InactiveCN101019637AMeet quality requirementsGood quality and stableVinegar preparationFood preparationYeastCooking & baking

The present invention is soy sauce and vinegar making process, and the soy sauce and the vinegar are bagged and blended with water before serving. The soy sauce making process includes the steps of processing material, preparing seed yeast, making yeast, fermenting and packing. The vinegar making process includes the steps of preparing material, fermenting, secondary fermenting, baking and packing. The present invention has the advantages of natural materials, reasonable material combination, natural making conditions and green products.

Owner:吕海

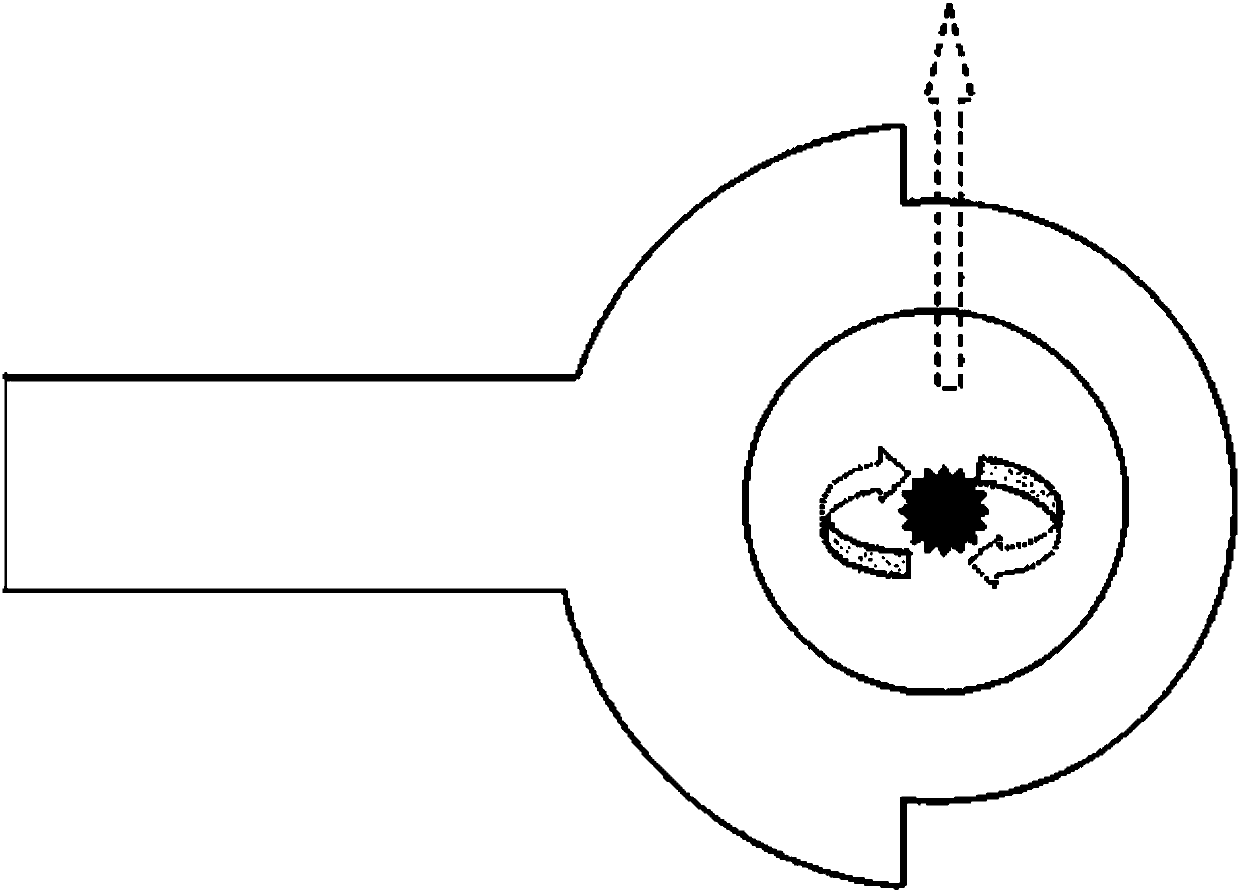

Manufacturing process of circuit board metallized half hole

InactiveCN108040438ASolve the lifting of the ring ringSolve sheddingPrinted element electric connection formationSand blastingMilling cutter

The invention discloses a manufacturing process of a circuit board metallized half hole. The manufacturing process includes the following steps: S1, preprocessing and acquiring a multi-layer board, wherein the front surface and the back surface of the multi-layer board are light copper surfaces; S2, manufacturing an outer-layer circuit pattern on the front surface and the back surface of the multi-layer board, wherein the outer-layer circuit pattern comprises a reserved metallized half hole; S3, printing the protective ink on the position where the metallized half hole needs to be manufacturedby means of a screen printer, wherein the protective ink needs to completely cover the ring of the metallized half hole; S4, milling the metallized half hole in the position where the metallized halfhole is manufactured; S5, washing the protective ink by using a fading ink; S6, brushing off the metal burrs generated during rotary cutting of a milling cutter by using a deburring machine; S7, spraying emery to the board by a sand blasting machine at a high speed, further removing burrs, so that the surface is smooth and flat; and S8, carrying out the subsequent processing. The method effectively solves the industrial general technical problems of the tilting and coming off of the ring and the residual copper wire burrs in the hole when the metallized half hole circuit board is produced.

Owner:TIGERBUILDER CIRCUIT SUZHOU

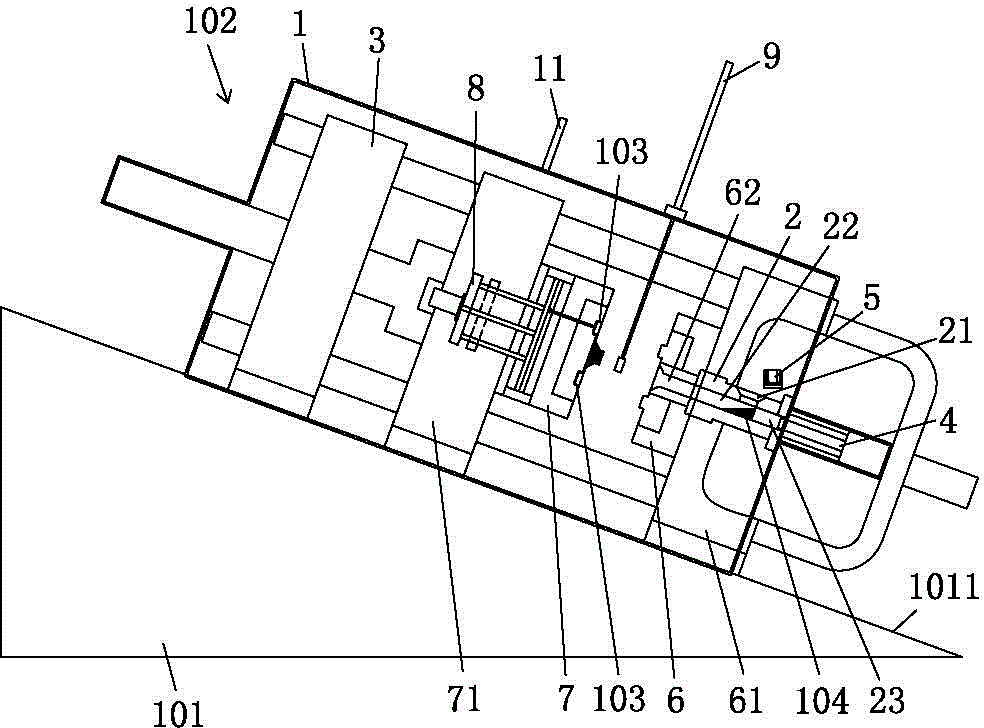

Horizontal die casting machine for amorphous alloy

InactiveCN104690245AThe function of temporarily storing molten soup is goodExtended service lifeAcute angleDie casting

The invention relates to the technical field of die casting machines, in particular to a horizontal die casting machine for amorphous alloy. The horizontal die casting machine comprises a machine frame and a die casting machine main body arranged on the machine frame. An acute angle is formed between the die casting machine main body and the horizontal level. The die casting machine main body comprises a vacuum chamber, a heating fusion device arranged in the vacuum chamber, a die casting storage barrel used for containing melt liquid poured out from the heating fusion device and a die mechanism used for receiving the melt liquid ejected out from the die casing storage barrel. The die casting machine main body further comprises a driving mechanism connected with the die mechanism and an ejection mechanism connected with the die casting storage barrel. The die casting machine can avoid forming melt liquid and scraps on the surface of a die, further avoid damage to the die and regular shutdown clearing, prolongs the service life of the die, improves production efficiency and can improve quality of cast amorphous alloy products.

Owner:WINTOP DONGGUAN INDAL TECH

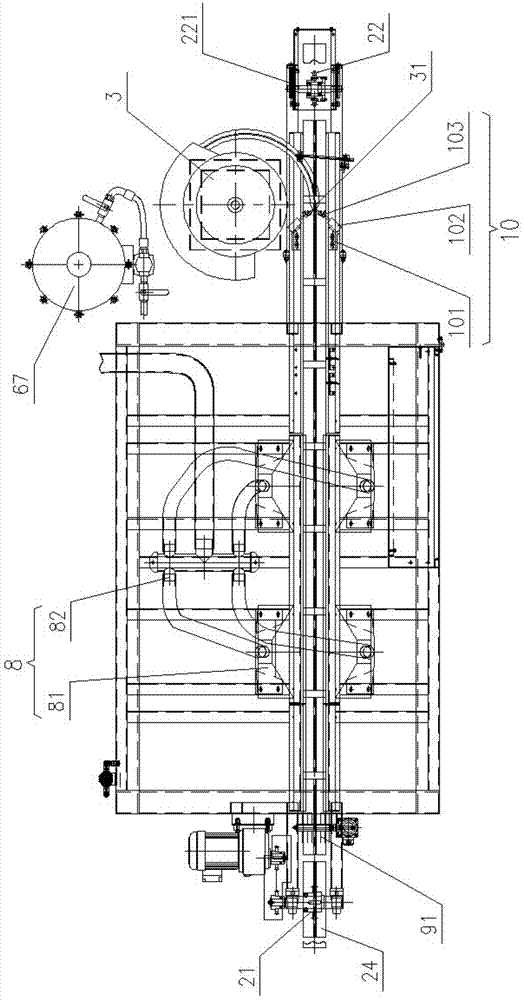

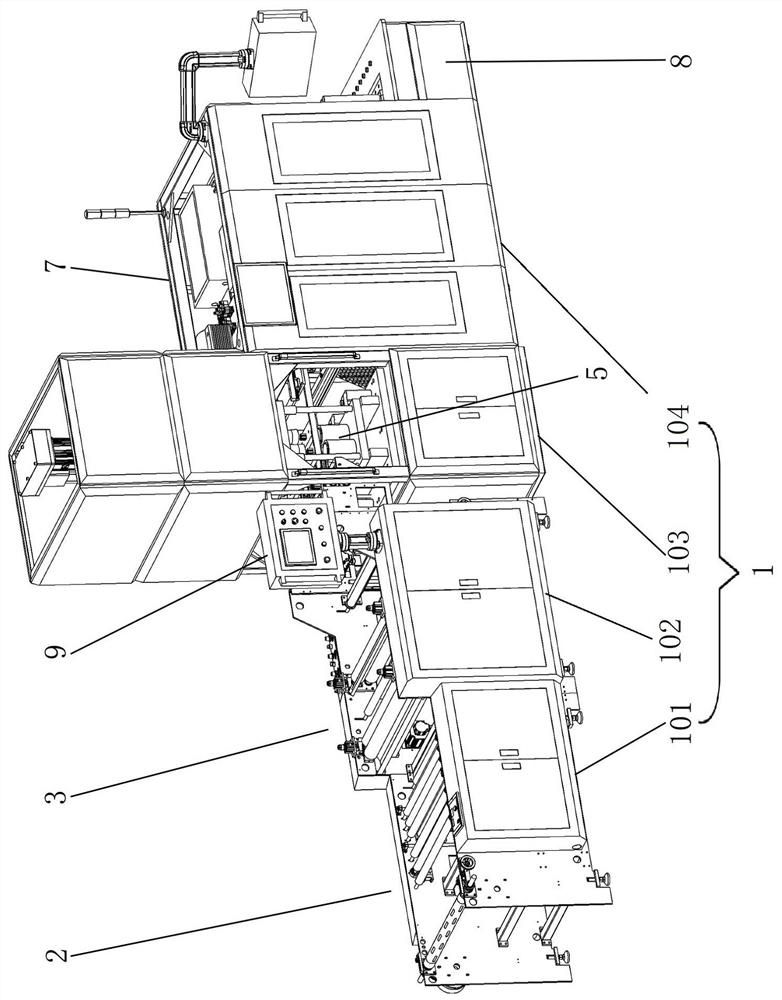

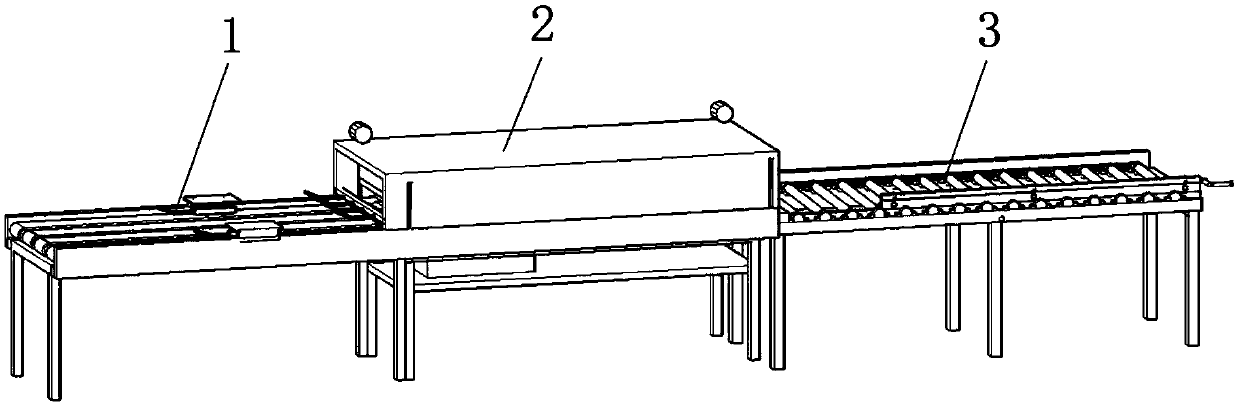

One-time forming production line of one-time edge-rolling paper cup

PendingCN113580650AThe mouth is full, smooth and beautifulGood quality and stableEnvelopes/bags making machineryBox making operationsRolling paperMolding machine

The invention discloses a one-time forming production line of a one-time edge-rolling paper cup. The one-time forming production line of the one-time edge-rolling paper cup comprises a frame, an unwinding mechanism, a paper surface treatment mechanism, an adjustable feeding traction mechanism, a stamping die forming mechanism, a mechanical arm part taking mechanism, a leftover material winding mechanism and a bagging and packaging workbench, wherein the paper surface treatment mechanism, the adjustable feeding traction mechanism, the stamping die forming mechanism, the mechanical arm part taking mechanism, the leftover material winding mechanism and the bagging and packaging workbench are mounted on the frame and sequentially distributed from left to right in the longitudinal direction of the frame according to the paper movement sequence. Compared with the prior art, the one-time forming production line of the one-time edge-rolling paper cup has the beneficial effects that due to the fact that the paper surface treatment mechanism is adopted to treat the surface of the paper, the paper achieves a certain procedure of oil and water separation performance and is integrally punched and formed under the optimal punch forming condition, so that the manufactured one-time edge-rolling paper cup has tidy and orderly folded edges of the cup body, a rolled opening is full, flat and attractive, the quality is good and stable, and the working efficiency is greatly improved.

Owner:GUANGDONG LIHONG PACKING CO LTD

Method for preparing terpin hydrate by virtue of continuous hydration

ActiveCN102718632AIncrease productivityIncrease profitPreparation by hydroxy group additionAcid waterReaction temperature

The invention discloses a method for preparing terpin hydrate by virtue of continuous hydration. The method is characterized by comprising the following steps of: under the conditions of certain acidity, temperature and acid water quantity, carrying out the continuous hydration on turpentine or pinene utilized as a raw material in a way of continuously feeding and discharging; and controlling the reaction temperature by adjusting the acid water concentration and the quantity of the acid water and red oil according to the detection data and the weight of materials, thus obtaining the terpin hydrate. Compared with the traditional intermittent hydration method, the method can be used for improving the production efficiency of the terpin hydrate by more than 30%, achieving the yield of 100% and improving the yield by 10%, and has the advantages of being high in production efficiency and yield, simple and convenient in technology, free from pollution, low in production cost, and the like.

Owner:FUJIAN SENFA BIOTECH

Method for preparing antimonous oxide ultrafine powder

ActiveCN106698513ASimple processing technologyGood quality and stableAntimony compoundsNanotechnologyAntimony oxideAntimony

The invention discloses a method for preparing antimonous oxide ultrafine powder, and relates to an alumina thin film. The method comprises the following steps: completely gasifying antimony oxide powder under high-temperature plasma jet at 3600-7500 DEG C by using a plasma generator as a heat source and adopting a gasified oxidation-condensation method to obtain gaseous antimony oxide to further obtain antimonous oxide ultrafine powder. The method for preparing antimonous oxide ultrafine powder has the advantages of easily available raw materials and simple processing process; and the antimonous oxide ultrafine powder has a granularity less than 0.25mm, high and stable quality and remarkable economic benefit, and opens broad prospect to large-scale industrial application of medium-low level antimony oxide ores and sulfur-oxygen mixed antimony ores.

Owner:上海深化实业有限公司

Conductive carbon fiber compound felt

InactiveCN104999741AConductiveGood quality and stableGlass/slag layered productsGlass fiberCarbon fibers

The invention relates to a conductive carbon fiber compound felt and belongs to the technical field of conductive glass fiber reinforced plastics. The conductive carbon fiber compound felt is characterized in that the conductive carbon fiber compound felt is formed by sewing carbon fiber felt and glass fiber felt. The conductive carbon fiber compound felt is reasonable in design, simple in structure and easy to produce, has the original electrical conductivity of carbon fibers and the intensity of glass fiber felt, and is used in the process of producing conductive glass fiber reinforced plastic anode tubes through a pultrusion process, the made conductive glass fiber reinforced plastic anode tubes are good and stable in quality, identical in size, free of deformation and waste, and high in production efficiency. The conductive carbon fiber compound felt can be widely applied to the process of producing conductive glass fiber reinforced plastic anode tubes and other conductive glass fiber reinforced plastic products through the pultrusion process.

Owner:董树琪

High-yield cultivation method of shiitake mushroom or Huagu-type shiitake mushroom based on branch cut-logs

InactiveCN107637383AAvoid YieldAvoid quality problemsCultivating equipmentsMushroom cultivationGreenhouseFood safety

A high-yield cultivation method of shiitake mushroom or Huagu-type shiitake mushroom based on branch cut-logs comprises: 1) soaking branch cut-logs, grown for half month after Beginning of Winter, in10% lime water for 1 min, and using the sides floated on water as male sides and the opposite sides as female sides; 2) taking out the branch cut-logs, and piling them for 3-4 months with their male sides facing down; 3) inoculating a strain to the piled branch cut-logs, wherein a formula of the inoculated strain includes 87.5-94.5% of sawdust, 5-12% of bran, and 0.5-1.2% of gypsum powder; 4) after the strain attaches for 1.5 years, allowing fruiting, spraying with atomized water at the low temperature of 3-5 DEG C with a temperature difference of 10 DEG C and above, and keeping stuffiness after spraying until few mushrooms occur; 5) transferring to a greenhouse for the purpose of natural growth, and controlling the humidity of the greenhouse to 20-60%. The method of the invention has theadvantages that contamination risk, the yield and quality issues due to fruiting management level, and potential hazards of food safety can be avoided, the yield is higher, and the quality is better and more stable.

Owner:林安盛

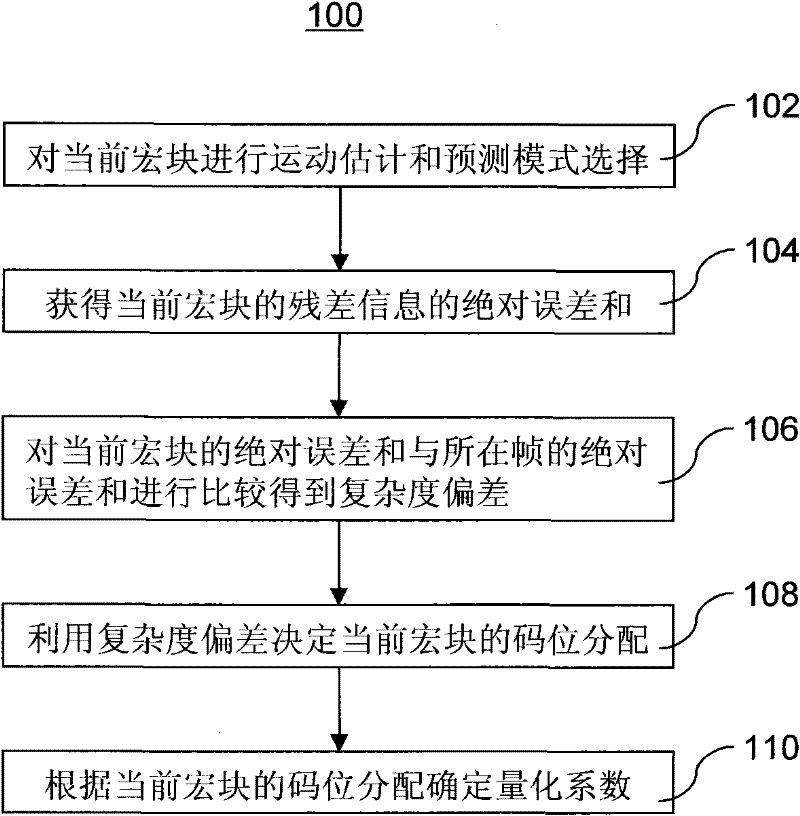

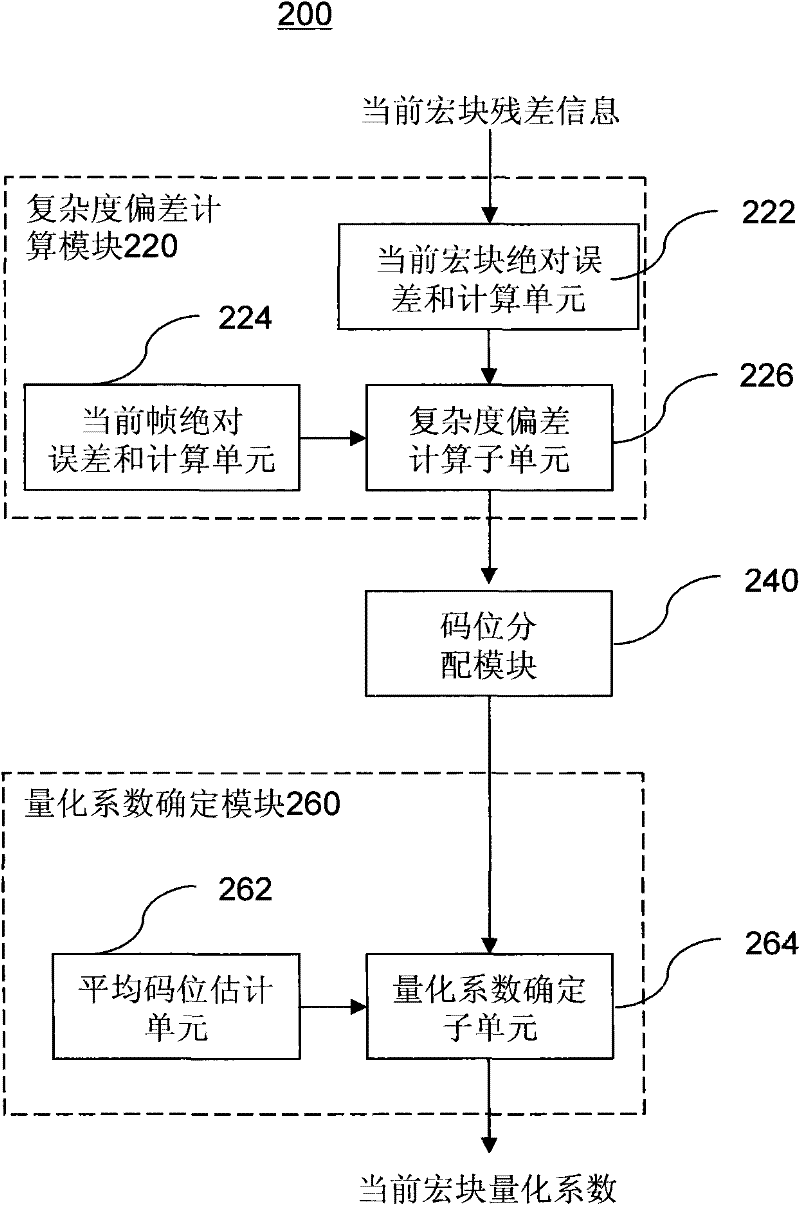

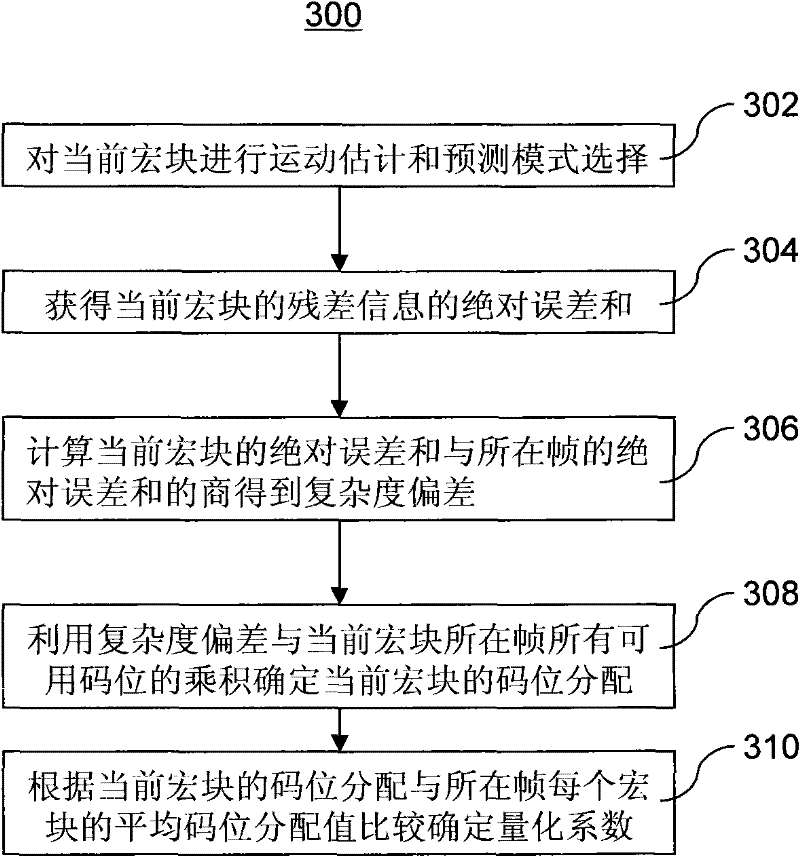

Bite rate control method and apparatus thereof

ActiveCN102231825AGood quality and stableReduce operational complexityPulse modulation television signal transmissionDigital video signal modificationRound complexityBit allocation

The invention discloses a bite rate control method and an apparatus thereof. The method comprises the following steps: calculating a complexity deviation between a present macroblock and a video frame that the macroblock is located at; carrying out bit allocation of the present macroblock according to the complexity deviation; and determining a quantization coefficient of the present macroblock according to the bit allocation of the present macroblock. In the prior art, bit allocation of a macroblock is carried out simply by dividing a macroblock number in a video frame of one frame by a bit of the video frame of the frame; compared with the bit allocation of the macroblock in the prior art, the bit allocations of macroblocks in the invention are respectively carried out by evaluating complexity deviations of all macroblocks, so that a complex macroblock can obtain more bits and thus the quality of a video image is good and stable. Moreover, the method for evaluating a complexity deviation of a macroblock is simple and effective, so that operation complexity can be reduced and effectiveness is also ensured.

Owner:WUXI ZGMICRO ELECTRONICS CO LTD

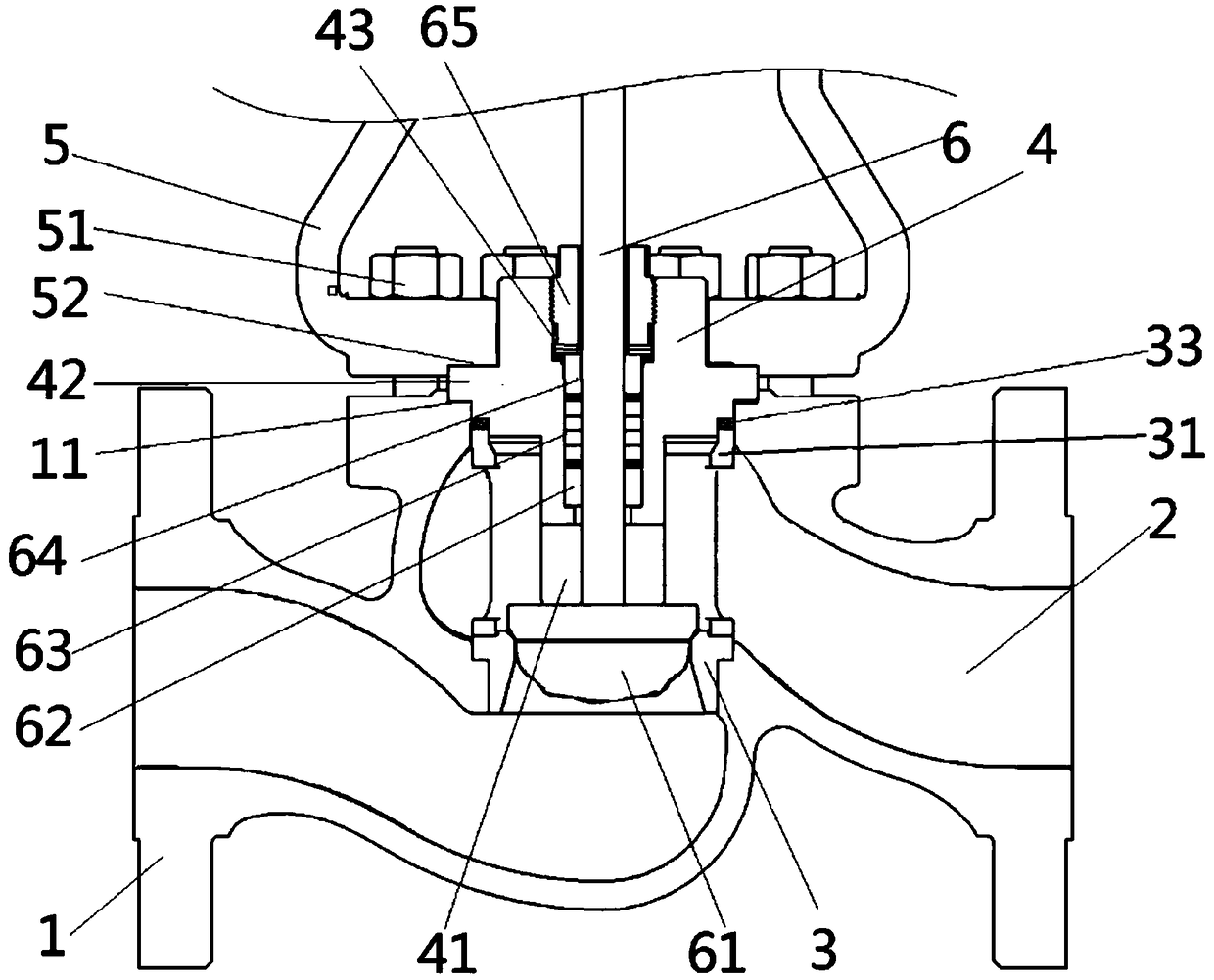

Integrated regulating valve

The invention discloses an integrated regulating valve. The integrated regulating valve comprises a lower valve body and a flow passage arranged in the lower valve body, a valve seat is fixedly arranged in the flow passage, and an upper valve body is arranged above the lower valve body; a valve cover is further arranged between the upper valve body and the lower valve body, and the upper valve body and the lower valve body cooperate to limit the valve cover; the valve cover is provided with an installation hole which is through in the axial direction; and a valve stem is arranged on the valvecover in a manner of being capable of rotating by itself, one end of the valve stem penetrates through the installation hole to extend into the flow passage, a valve element is fixedly arranged at theend extending to be arranged in the flow passage through friction welding, and the valve element and the valve seat can cooperate to open or close the flow passage. The integrated regulating valve has the beneficial effects that the structure is simple and design is exquisite, reasonable design of the structure of the regulating valve is carried out, a proper sealing form is adopted to ensure thesealing reliability, the sealing effect is improved, the medium leakage is avoided, and the service life of the regulating valve is prolonged.

Owner:FLOWSERVE FLUID MOTION & CONTROL SUZHOU

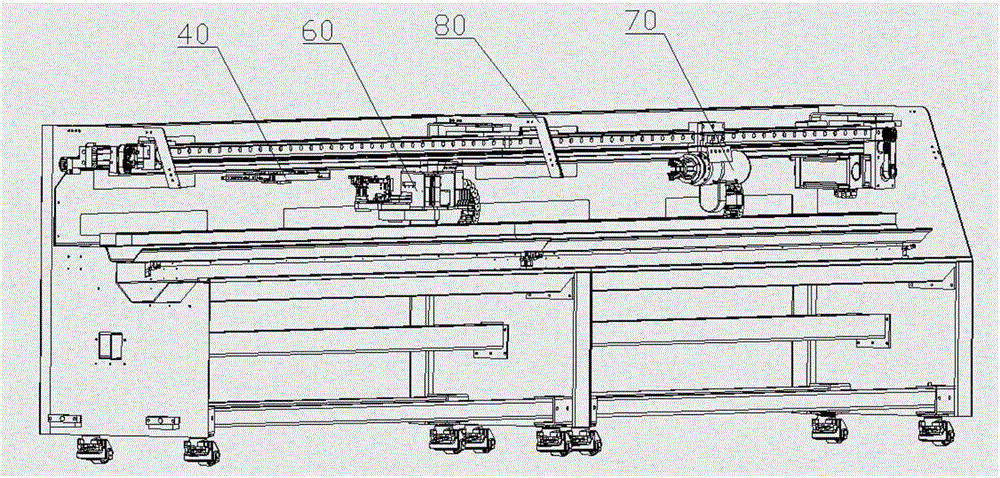

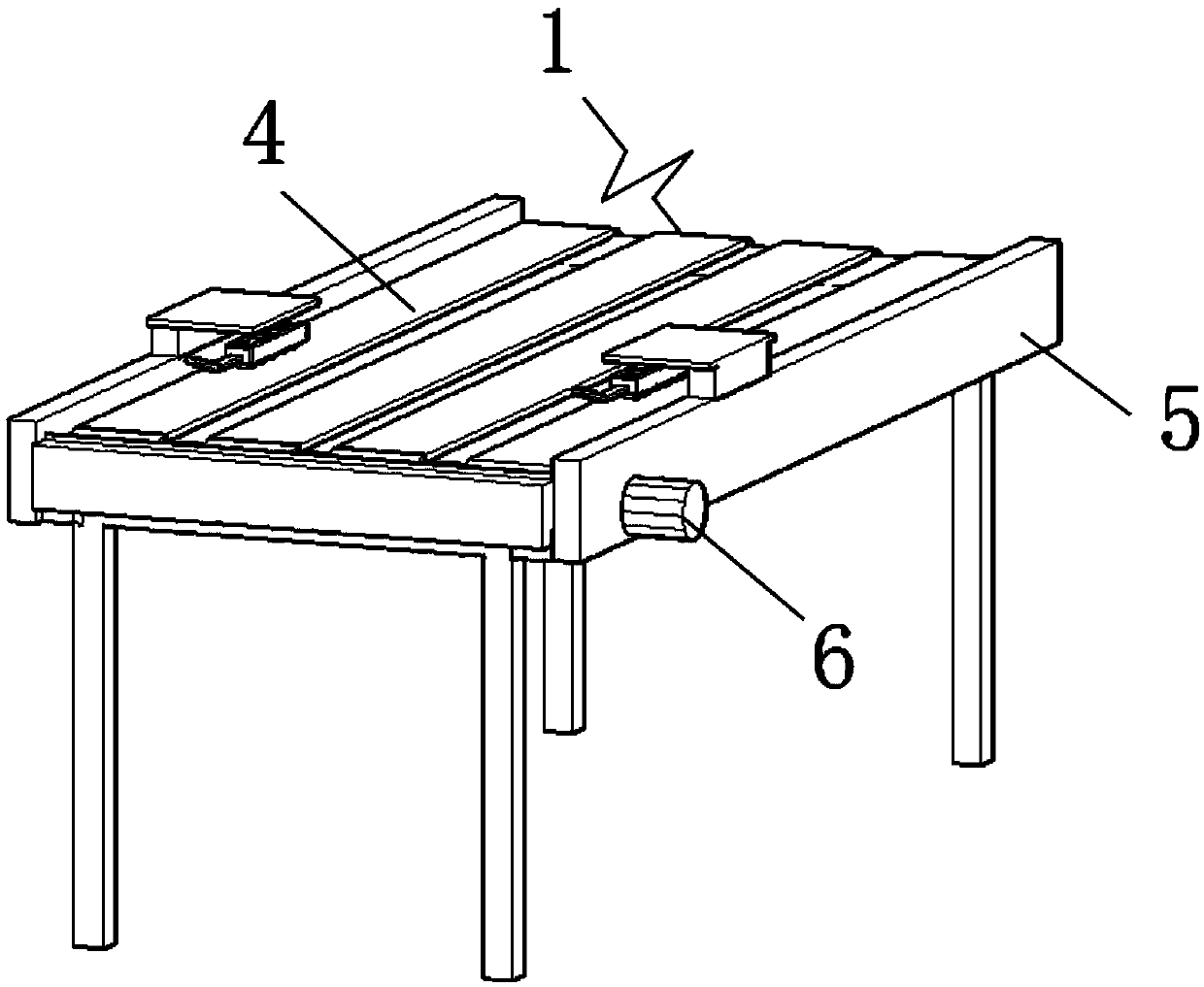

Automatic splicing device for long medium plate of multilayer wood-based panel

PendingCN109676711AReduce laborReduce outputOther plywood/veneer working apparatusWood veneer joiningGlue lineIndustrial engineering

The invention discloses an automatic splicing device for a long medium plate of a multilayer wood-based panel. The automatic splicing device comprises a rear conveyor device, a processing device and asingle-plate conveyor device, and the rear conveyor device is fixedly connected one end of the processing device; the single-board conveyor device is fixedly connected with the other end of the processing device, and the rear conveyor device is internally provided with a first fixing bracket fixedly; the first fixing bracket is internally provided with a belt rotatably, and the inner top end of the processing device is fixedly provided with a guard plate; the guard plate is internally provided with a butt conveyor device fixedly, and one end of the guard plate is movably provided with a fixedlength cutter; and the other end of the guard plate is movably provided with edge lifting cutters, and the bottom end of the butt conveyor device is rotatably provided with glue line pressing coolingwheels of which the lower ends are fixedly provided with heating butt blocks. According to the automatic splicing device, the production efficiency can be improved, and labors are saved; and the costis saved, and the product quality is improved.

Owner:福建新顺兴装饰材料有限公司

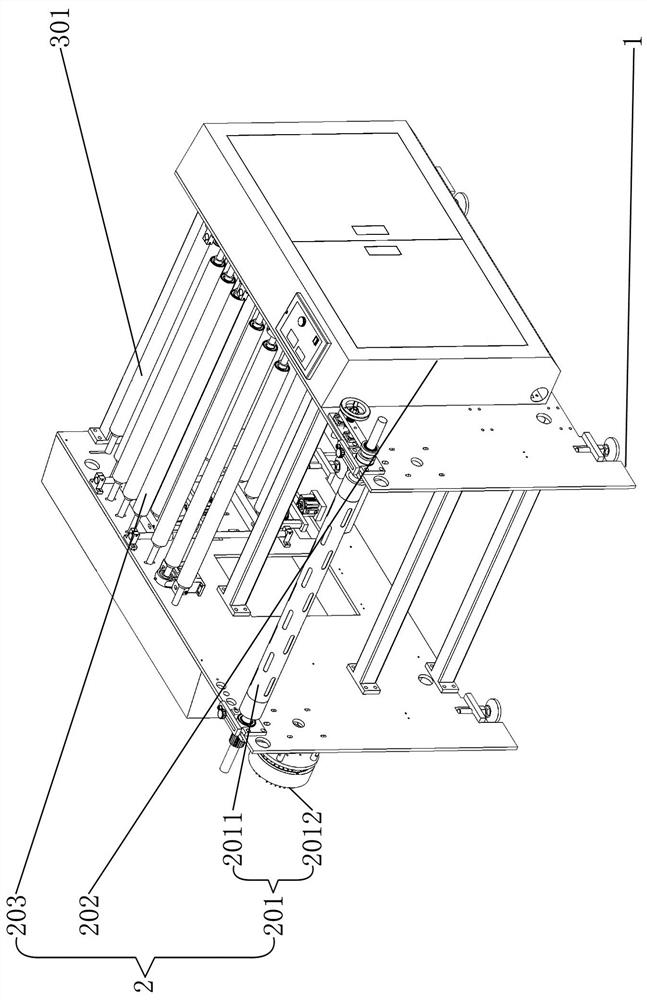

Industrial continuous production equipment and method for black phosphorus

ActiveCN109650359AFlexible setting of reaction temperatureFlexible time settingPhosphorus preparationBlack phosphorusPropeller

The invention discloses industrial continuous production equipment for black phosphorus. The equipment includes a heat-resistant screw conversion reactor, a charging pipe, a discharging pipe, a propeller blade, a motor and a heating device. The charging pipe is arranged on one end of the heat-resistant screw conversion reactor. The discharging pipe is arranged below the other end. The propeller blade in the heat-resistant screw conversion reactor is mounting on a rotating shaft. The two ends of the rotating shaft are connected to the heat-resistant screw conversion reactor through shaft sleeves. The motor is arranged on one of the heat-resistant screw conversion reactor and connected to the rotating shaft. The heating device is arranged outside the heat-resistant screw conversion reactor and the charging pipe. The outside of the heat-resistant screw conversion reactor is wrapped in the heating device. The heat-resistant screw conversion reactor includes multiple heating areas. An inertgas input pipe is arranged on the discharging pipe. According to the invention, the production process flow is optimized, the production cost is low, the operation is simple and safe, the automationdegree is high, and continuous production can be carried out under atmospheric pressure.

Owner:BLACK P2 USA INC

Sulbenicillin sodium and sulbenicillin sodium used for injection

InactiveCN102161667BReduce contentReduce pollutionAntibacterial agentsPowder deliverySulbenicillinPhenylacetic acid

The invention provides a synthesis method of sulbenicillin sodium and sulbenicillin sodium used for injection, which comprises the concrete steps of: using 6-APA and BSA to synthesize an organic salt, and dissolving the organic salt into dichloromethane; using a sulphur phenylacetic acid triethylamine salt and pivaloyl chloride to make mixed anhydride; carrying out anhydrous condensation on the sulphur phenylacetic acid triethylamine salt and the pivaloyl chloride in the dichloromethane; and then forming a sodium salt, free-drying and obtaining a finished product. The new technical process isstable and feasible, better and stable in product quality and strong in operability of production, and reduces the environmental pollution.

Owner:辽宁科泰生物基因制药股份有限公司

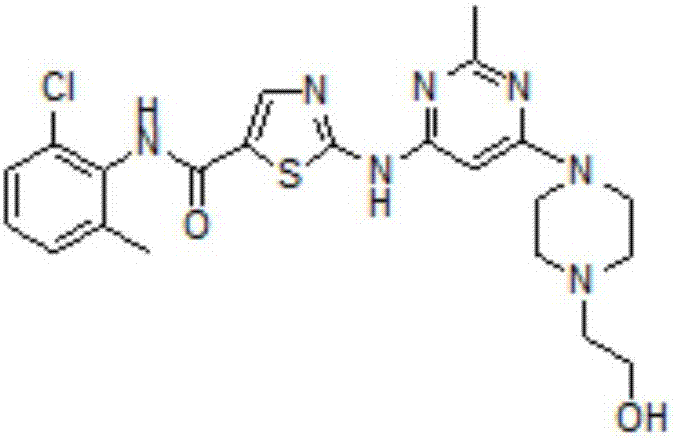

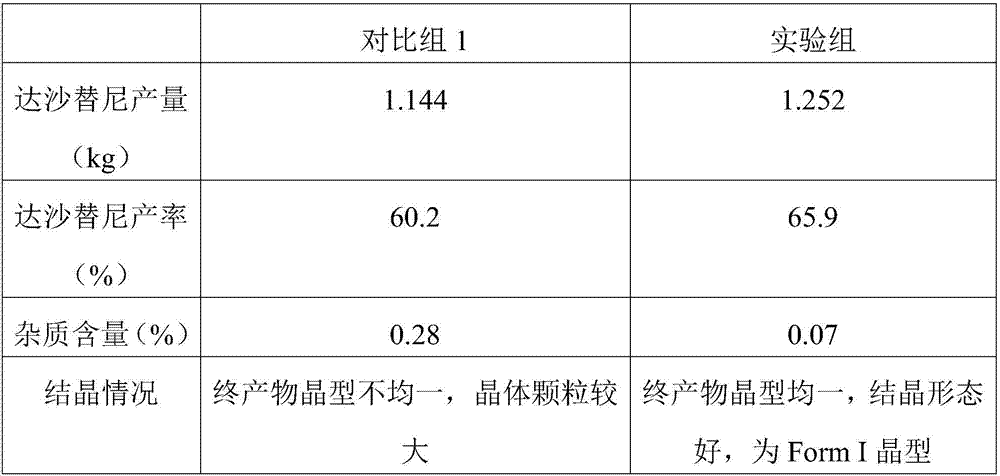

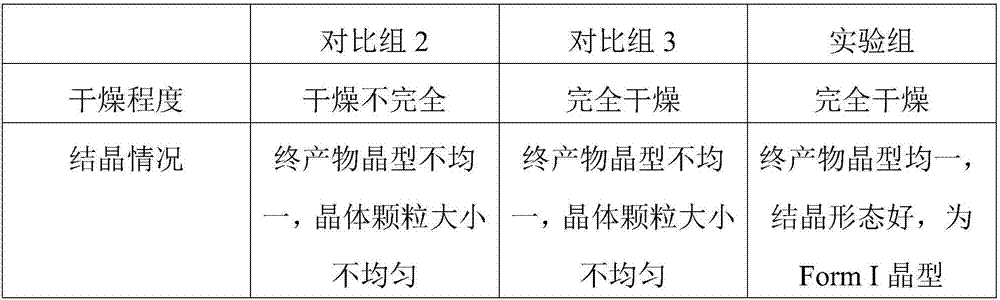

Preparation method of dasatinib

The invention discloses a preparation method of dasatinib. The preparation method comprises the following steps: (1) preparing N-(2-chloro-6-methyl-phenyl)-2-[(6-chloro-2-methyl-4-pyrimidyl)amino]-5-thiazole carboxamides; (2) preparing a dasatinib crude product; (3) refining the dasatinib: adding the dasatinib crude product and absolute methanol into a reaction kettle, stirring, performing nitrogen displacement, heating to refluxing while stirring, cooling, adding a seed crystal, stirring materials uniformly, cooling to 5 to 10 DEG in a uniform-speed cooling way, stirring at a constant temperature, filtering the materials, leaching an obtained filter cake with a proper amount of methanol, and drying the filter cake in a gradient heating way to a constant weight to obtain a dasatinib product. The preparation method has the advantages of simple process, high product yield and high product purity; the prepared Dasatinib product of a Form I crystal form has high stability, and the bioavailability of the product is equivalent to an existing T1H1-7 crystal form product.

Owner:JINAN LIMIN PHARMA

Method of cleaning molten steel with multi-foam screen of continuously casted tundish

The invention relates to a method of cleaning molten steel with a multi-foam screen of a continuously casted tundish. The method adopts the technical scheme that 2-4 permeable bricks (4) are arranged between an water inlet (1) and a water outlet (3) at the bottom (5) of the tundish (2), the distance between the permeable bricks (4) is 50-500mm, and the distance from the center of the permeable brick (4) adjacent to the water outlet to the center of the water outlet (3) is 300 to 600mm; before the tundish is cast, argon is introduced to the permeable bricks (4), the flow quantity of argon is 5-10Nl / min, and the pressure is 0.02-0.05MPa; during the tundish casting, the flow quantity of argon is 7-20Nl / min, and the pressure is 0.08-0.15MPa; and the permeable bricks (4) are inclined or plane, and the permeable bricks (4) can be a diffusion type permeable bricks, permeable bricks with through holes, or combination type permeable bricks. The method provided by the invention has the characteristics that the investment is low, the method is simple to operate, and the method can efficiently eliminate foreign gases and a large amount of small non-metal inclusions. Moreover, the method can efficiently reduce the consumption of fireproof materials and pollution, produce no rolling slags in the smelting process, and make the temperature uniform and stable.

Owner:WUHAN UNIV OF SCI & TECH

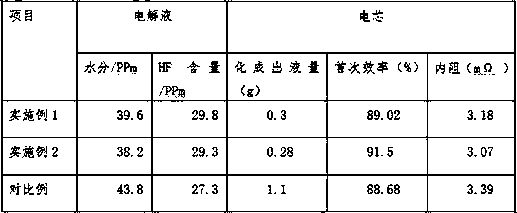

Standing and forming process of liquid-injected aluminum shell lithium ion battery

InactiveCN109742314ALow environmental requirementsSimple processFinal product manufactureSecondary cells charging/dischargingElectrical batteryNitrogen

The invention discloses a standing and forming process of a liquid-injected aluminum shell lithium ion battery. The process is carried out according to the following steps of injecting liquid into battery cores in a normal amount; after liquid is injected into the same batch of battery cores, connecting the battery cores in series; placing the battery cores connected in series in a closed box; performing standing on the battery cores for 1-2 hours under normal temperature and normal pressure conditions; then vacuumizing the closed box; performing standing on the closed box for 20-24 hours in avacuum state; injecting nitrogen into the closed box to break the vacuum, performing standing on the closed box at normal pressure for at least 10 min; transferring the battery cores which are stillin parallel after the standing treatment to a forming box; vacuumizing the forming box after the battery cores are connected; performing a forming process according to conventional indexes in the vacuum state; after forming is completed, sealing an aluminum shell battery core opening by using a steel ball. According to the standing and forming process of the liquid-injected aluminum shell lithiumion battery disclosed by the invention, standing is performed under the vacuum condition, on the one hand, the electrolyte in the battery cores is not directly in contact with air in the workshop, andthe HF acid is not generated; on the other hand, internally installed polar plates of the battery cores are sufficiently soaked by the electrolyte so that the quality of the produced battery is goodand stable.

Owner:JIANGSU FRONT NEW ENERGY +1

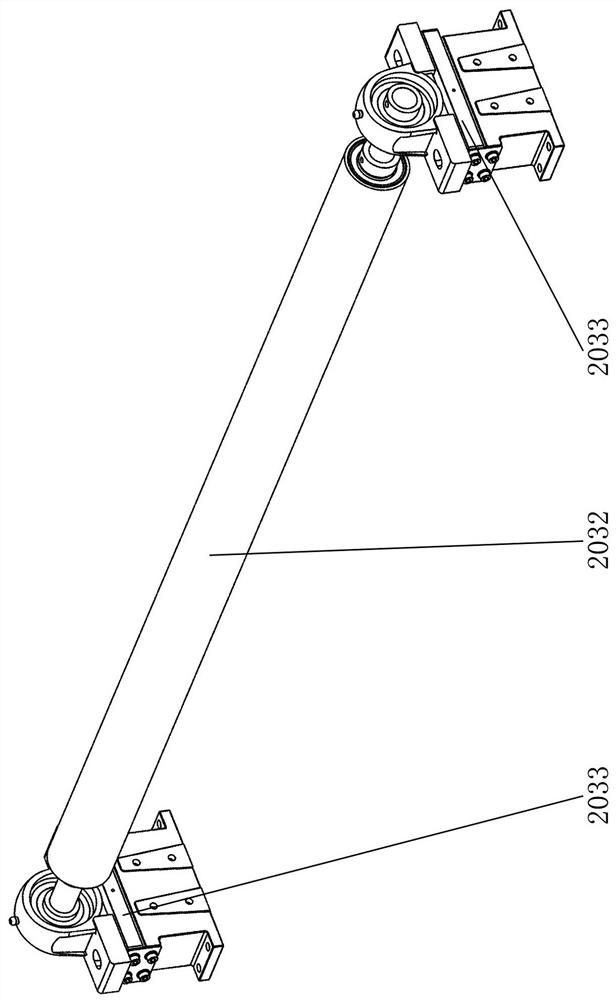

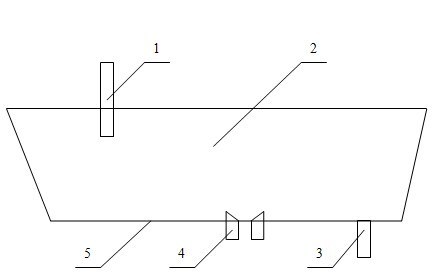

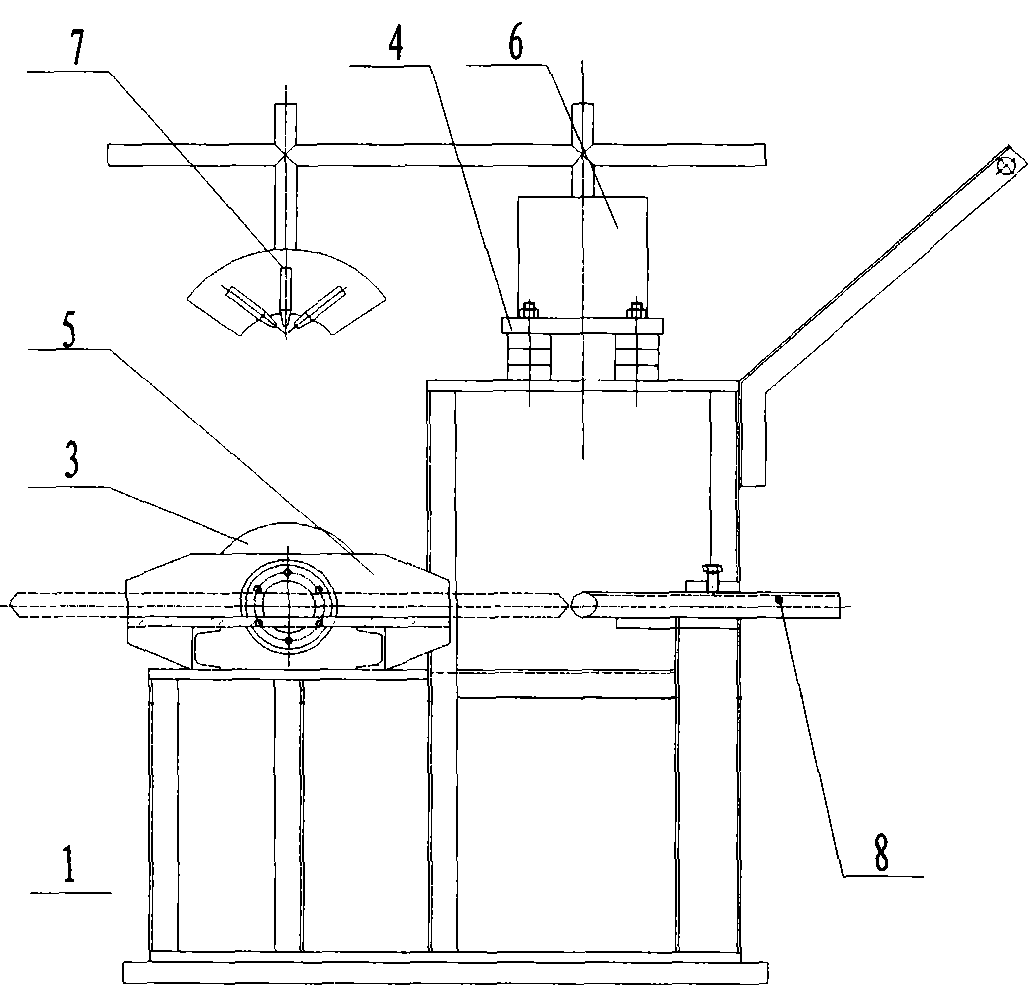

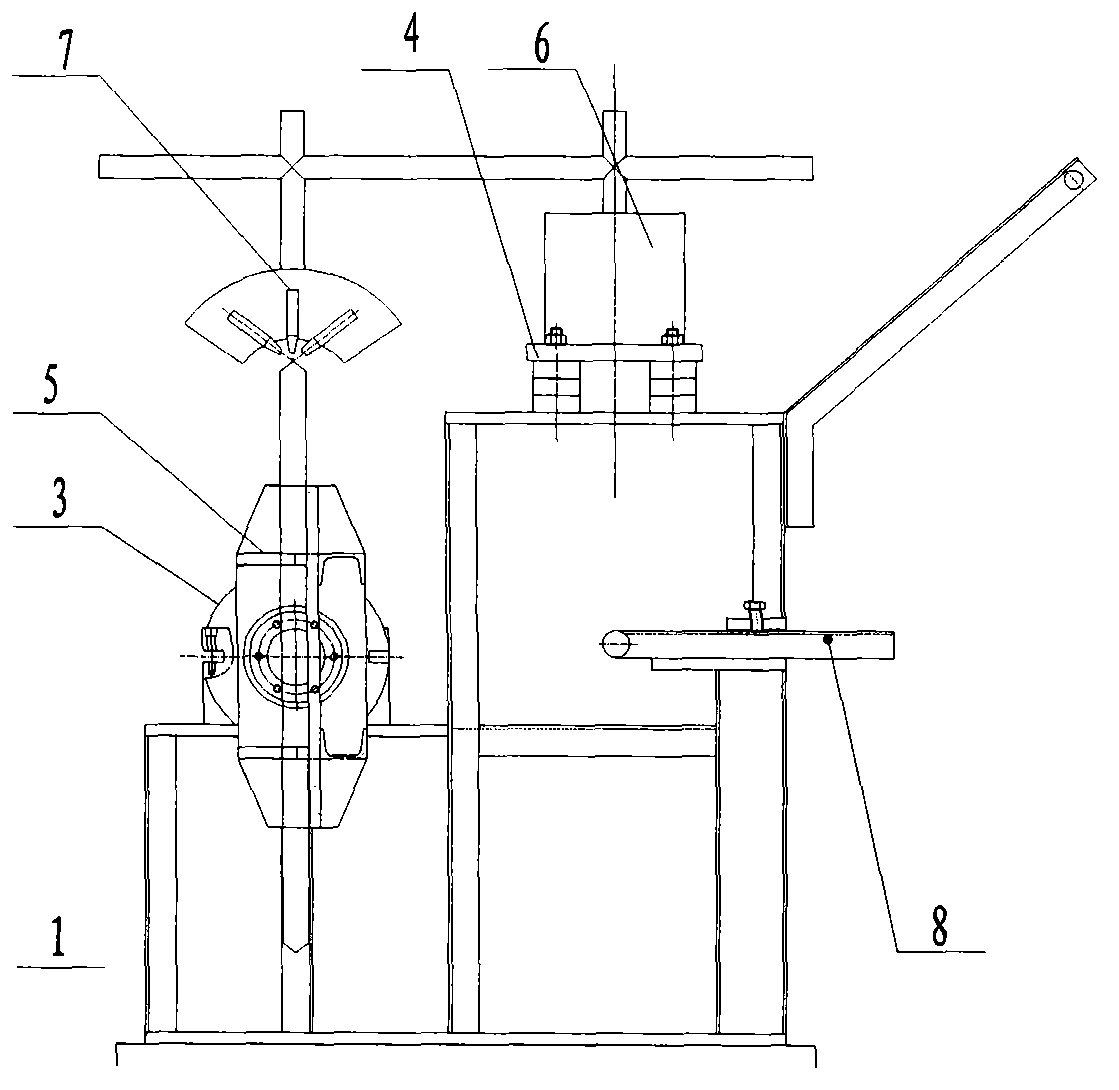

Middle plate bi-directional gas cutting chamfering equipment

The invention relates to coal machine equipment, in particular to middle plate bi-directional gas cutting chamfering equipment. A traditional method for chamfering a middle plate comprises the steps that the middle plate is horizontally placed on the ground, a semi-automatic flame cutting machine is used for cutting one corner of the middle plate every time in a gas cutting mode, the flame cutting machine needs to be aligned four times when the gas cutting is conducted on the four corners, and the middle plate needs to be turned over one time. The machining efficiency is low, the labor intensity of workers is large, the machining quality is not stable, and huge potential safety hazards exist in the process of turning over the middle plate. The middle plate bi-directional gas cutting chamfering equipment is composed of a support, an adjusting cushion plate, a rotary frame locating disc, a guide rail, a rotary frame, the semi-automatic flame cutting machine, three sets of cutting torches and a loading locating device. According to the middle plate bi-directional gas cutting chamfering equipment, the adjusting cushion plate, the loading locating device and the three sets of cutting torches are adjusted only when a first workpiece is machined, and later when the middle plate is replaced and after the two edges of the middle plate rotate to the top positions respectively, the two symmetrical edges of the middle plate can be chamfered in a bi-directional gas cutting mode only by starting the flame cutting machine. According to the middle plate bi-directional gas cutting chamfering equipment, the two edges of the middle plate are chamfered in the bi-directional gas cutting mode easily and conveniently, and the machining efficiency is high.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

Maojian black tea fermentation production process

InactiveCN109874885AGood quality and stableImprove ventilationPre-extraction tea treatmentBlack teaRelative humidity

The invention discloses a Maojian black tea fermentation production process. The process comprises the following steps: s1. picking fresh leaves of Maojian tea and picking gross tea; s2. moistening the standby gross tea with wet water; s3. performing inoculation of the dominant flora for fermentation and observing the fermentation effect; s4. determining a terminal point of fermentation and dryingthe fermented tea leaves; and s5. testing the fermented tea. The Maojian black tea fermentation production process optimizes the influence factors such as the fermentation temperature, the fermentation time, the relative humidity, the type of an additive, the amount of the dominant flora, and the like. At the same time, the ventilation conditions of a fermentation chamber are improved, and the Maojian black tea with good quality and stability can be obtained.

Owner:湖南省云上茶业有限公司

Automatic Glazing Machine

The invention discloses an automatic glazing machine. The automatic glazing machine comprises a rack, a control device, a rotation mechanism, a glazing mechanism, a transferring mechanism, an enamel pearl processing mechanism, a leftover material cleaning mechanism and an output mechanism, wherein the control device is arranged at the upper part of the rack; the rotation mechanism is arranged at the lower part of the rack; the rotation mechanism comprises a positive rotation mechanism and a reverse rotation mechanism; the rotation mechanism is arranged between the positive rotation mechanism and the reverse rotation mechanism; each of the positive rotation mechanism and the reverse rotation mechanism comprises a rotary plate, and a driving motor and a rotation wheel arranged under the rotary plate. The automatic glazing machine is high and stable in glazing quality and high in working efficiency.

Owner:景德镇艺廊陶瓷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com