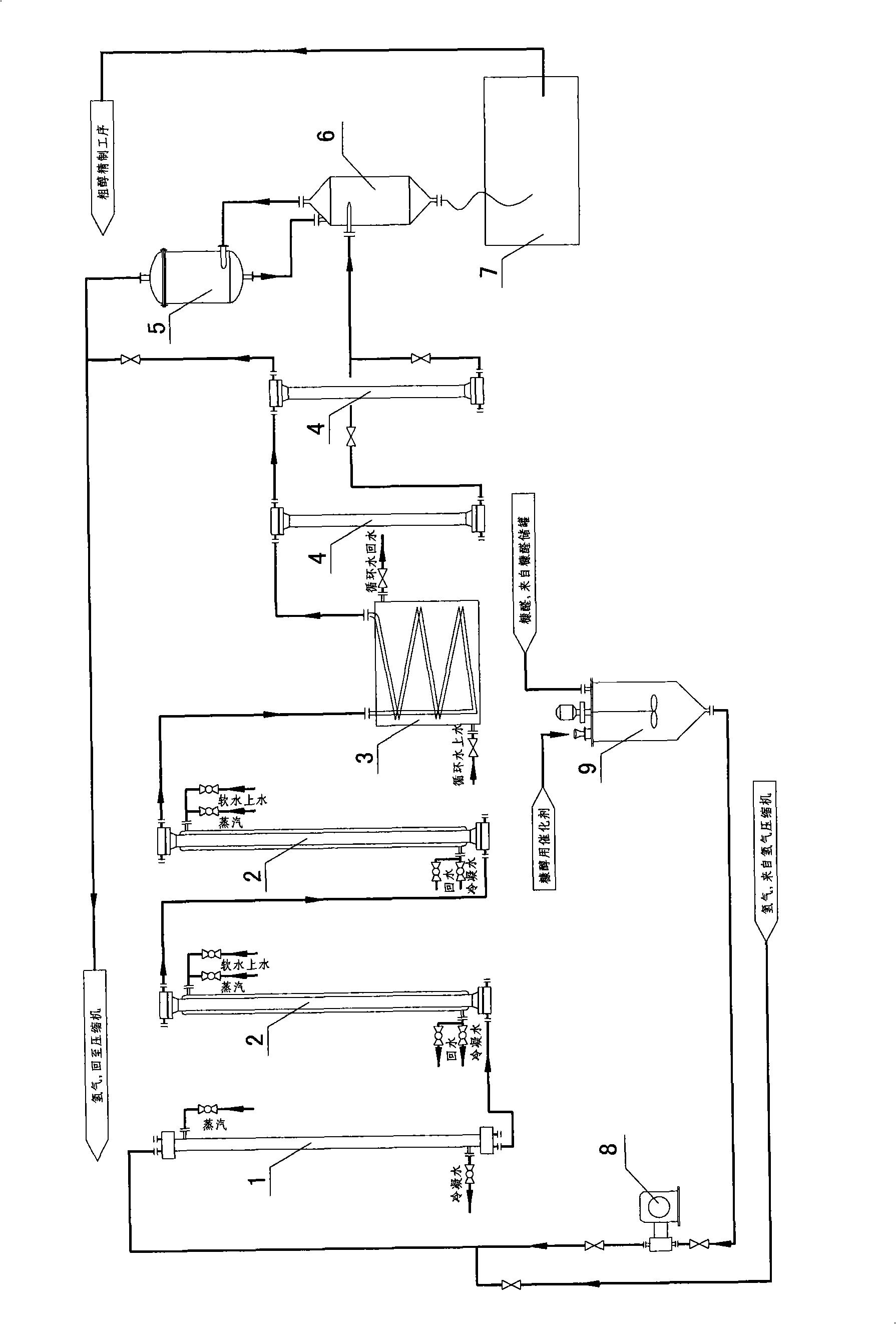

Method and system for preparing furfuryl alcohol by furfural liquid phase hydrogenation

A technology for hydrogen preparation and furfural liquid is applied in the field of furfural liquid-phase hydrogenation to prepare furfuryl alcohol, which can solve the problems of short residence time, short reaction time, small heat exchange area, etc. The effect of a large thermal area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

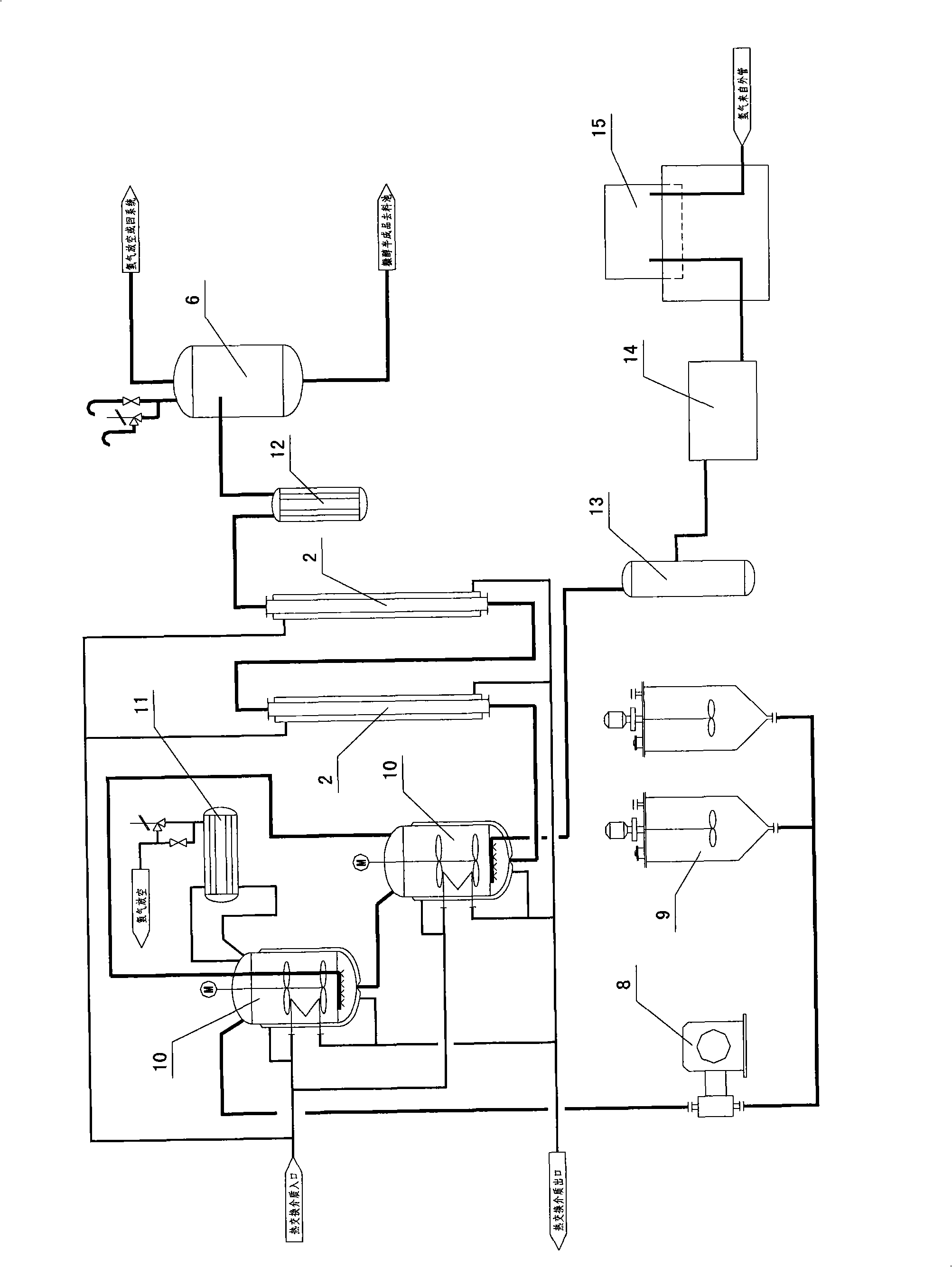

[0085] like figure 2 The process flow shown uses a fully mixed flow reactor connected in series with a plug flow reactor. Furfural, catalyst and co-catalyst are mixed evenly in the catalyst stirring tank 9 in proportion, and then transported into the fully mixed flow reactor 10 with a high-pressure metering pump 8 . The hydrogen is compressed by the hydrogen compressor 14 and delivered to the high-pressure hydrogen buffer tank, and the compressed hydrogen is sent from the bottom of the fully mixed-flow reactor 10 to the fully-mixed-flow reactor 10 by the high-pressure hydrogen buffer tank. The hydrogen and furfural are fully contacted and reacted in the fully mixed flow reactor 10, and the reacted materials are sent to the plug flow reactor 2 through the liquid level regulating valve to continue the reaction, and the unreacted hydrogen is released from the upper part of the fully mixed flow reactor 10. The liquid taken out is condensed by the vent condenser 11 and then retur...

Embodiment 2

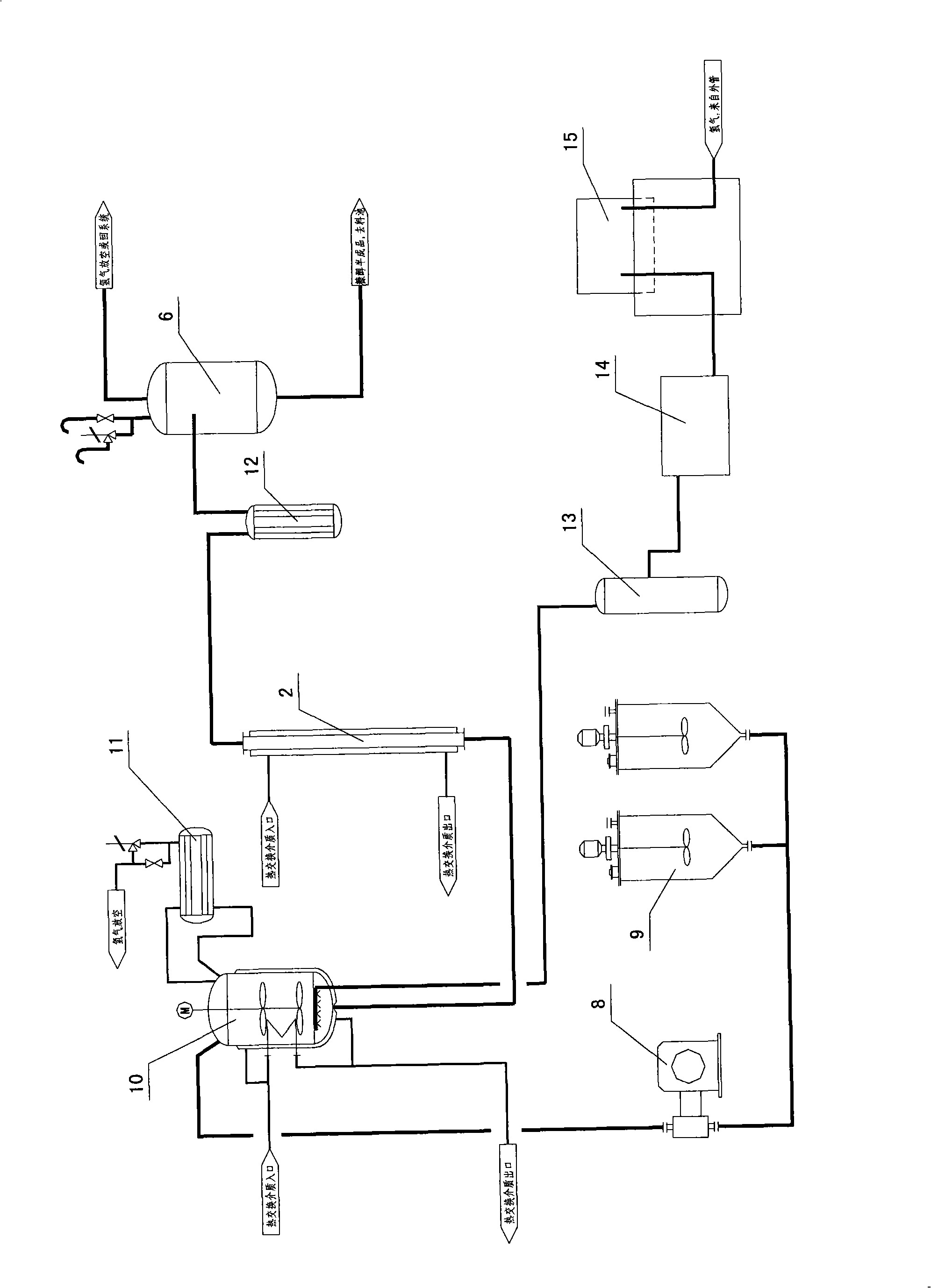

[0092] like image 3 The process flow shown uses a fully mixed flow reactor and three plug flow reactors used in series. Furfural, catalyst and co-catalyst are mixed evenly in the catalyst stirring tank 9 in proportion, and then transported into the fully mixed flow reactor 10 with a high-pressure metering pump 8 . The hydrogen is compressed by the hydrogen compressor 14 and delivered to the high-pressure hydrogen buffer tank, and the compressed hydrogen is sent from the bottom of the fully mixed-flow reactor 10 to the fully-mixed-flow reactor 10 by the high-pressure hydrogen buffer tank. Hydrogen and furfural are fully contacted and reacted in the fully mixed flow reactor 10, and the reacted materials are sent to three plug flow reactors 2 through liquid level regulating valves to continue the reaction. The liquid carried out at high temperature is condensed by the vent condenser 11 and then returned to the fully mixed flow reactor 10 for reaction, and the condensed hydrogen...

Embodiment 3

[0099] like Figure 4 The process flow shown uses two fully mixed flow reactors and two plug flow reactors used in series. Furfural, catalyst and co-catalyst are mixed evenly in the catalyst stirring tank 9 in proportion, and then transported into the fully mixed flow reactor 10 with a high-pressure metering pump 8 . The hydrogen is compressed by the hydrogen compressor 14 and delivered to the high-pressure hydrogen buffer tank, and the compressed hydrogen is sent from the bottom of the fully mixed-flow reactor 10 to the fully-mixed-flow reactor 10 by the high-pressure hydrogen buffer tank. The hydrogen and furfural are fully contacted and reacted in the fully mixed flow reactor 10, and the reacted materials are sent to the plug flow reactor 2 through the liquid level regulating valve to continue the reaction, and the unreacted hydrogen is released from the upper part of the fully mixed flow reactor 10. The liquid taken out is condensed by the vent condenser 11 and then retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com