Fully automatic twisted-pair wire processing equipment

A processing equipment and twisted pair technology, which is applied in the field of fully automatic twisted pair processing equipment, can solve problems such as low quality consistency, low production efficiency, and long turnaround time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

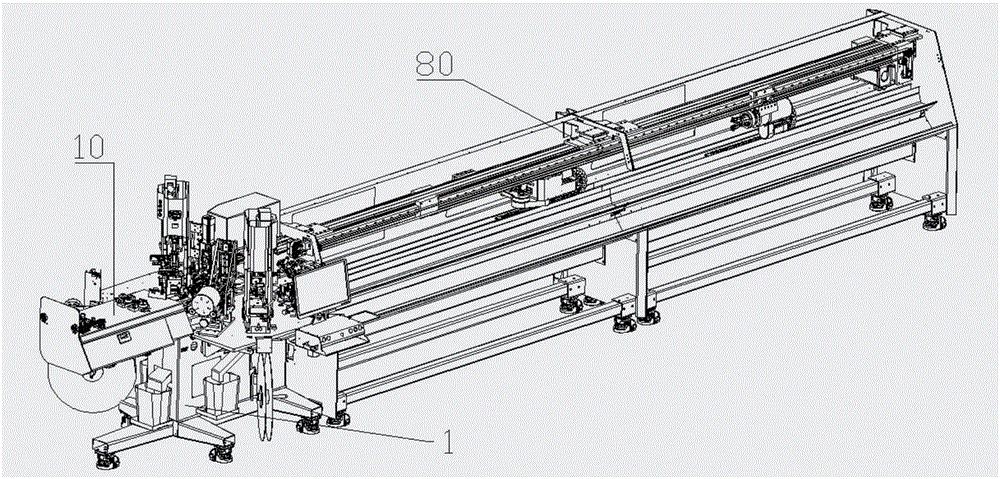

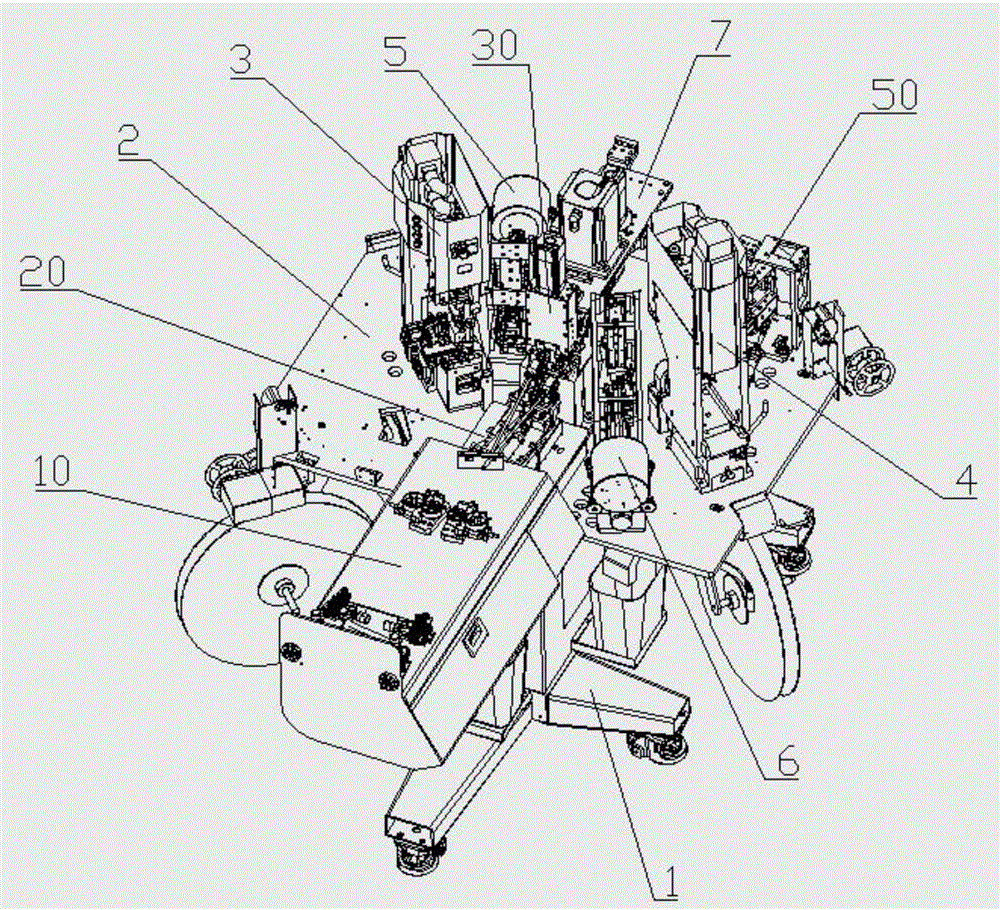

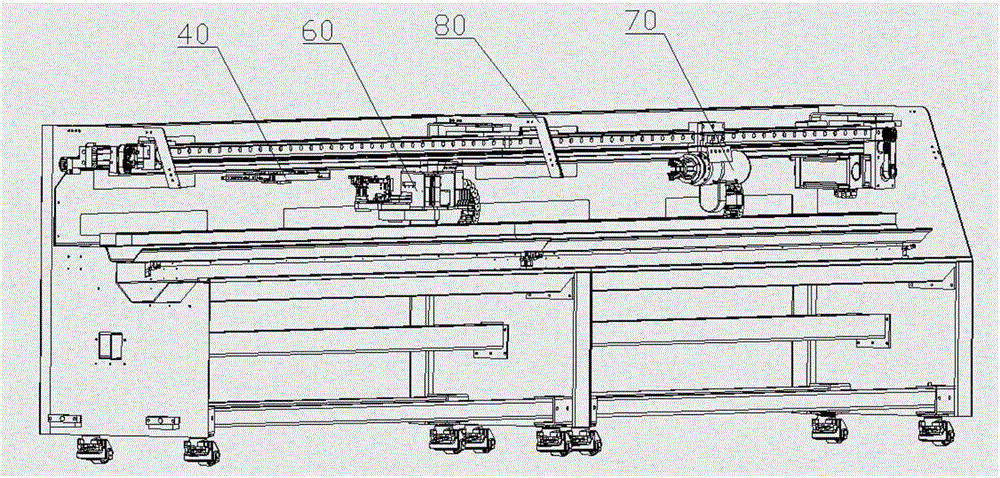

[0063] Such as Figure 1-23 As shown, a fully automatic twisted pair processing equipment includes a main frame 1, a workbench 2 is installed on the main frame 1, and a straightening module 10 is installed on the left side of the workbench 2 on the main frame 1; On the workbench 2, where the straightening module 10 is located on the same straight line, the front-end rotating arm 20, the double-line cutting module 30 and the rear-end rotating arm 7 are sequentially installed from left to right. The front of the double-wire cutting module 30 is sequentially installed with a threading bolt module 6, a crimping module 4, and a front-end transfer twisted wire module 50 from left to right; The crimping module 4 and the threading module 6 are installed in sequence from left to right in the rear; a rear frame 80 is installed on the right side of the workbench 2 on the main frame 1, and the rear frame 80 is sequentially arranged from left to right A pull wire module (40), a rear trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com