Horizontal die casting machine for amorphous alloy

A horizontal die-casting machine and amorphous alloy technology, which is applied in the field of die-casting machines, can solve the problems of damaged molds, good product quality, and easy pinching of molds by molten debris, so as to achieve extended service life, good structural stability, Quality and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

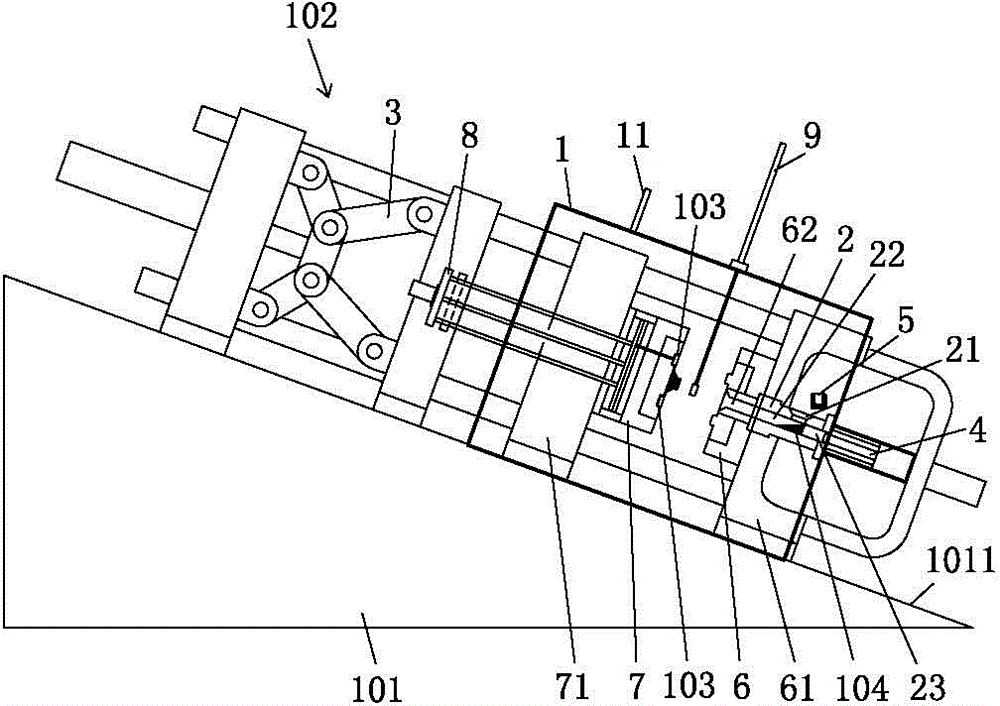

[0049] See figure 1 . The horizontal die-casting machine for amorphous alloys in this embodiment includes a frame 101, and a die-casting machine main body 102 arranged on the frame 101. The die-casting machine main body 102 is set at an acute angle to the horizontal plane; in this embodiment, the die-casting machine The acute angle formed between the main body 102 and the horizontal plane is 10 degrees.

[0050]The main body 102 of the die-casting machine includes a vacuum chamber 1, a heating and melting device arranged in the vacuum chamber 1, a die-casting storage cylinder 2 for receiving the molten soup 104 poured from the heating and melting device, and a die-casting storage cylinder 2 for accessing the molten soup 104 poured from the die-casting storage cylinder 2. The mold mechanism of the molten soup 104; the main body 102 of the die-casting machine also includes a driving mechanism 3 connected with the mold mechanism, and an injection mechanism 4 connected with t...

Embodiment 2

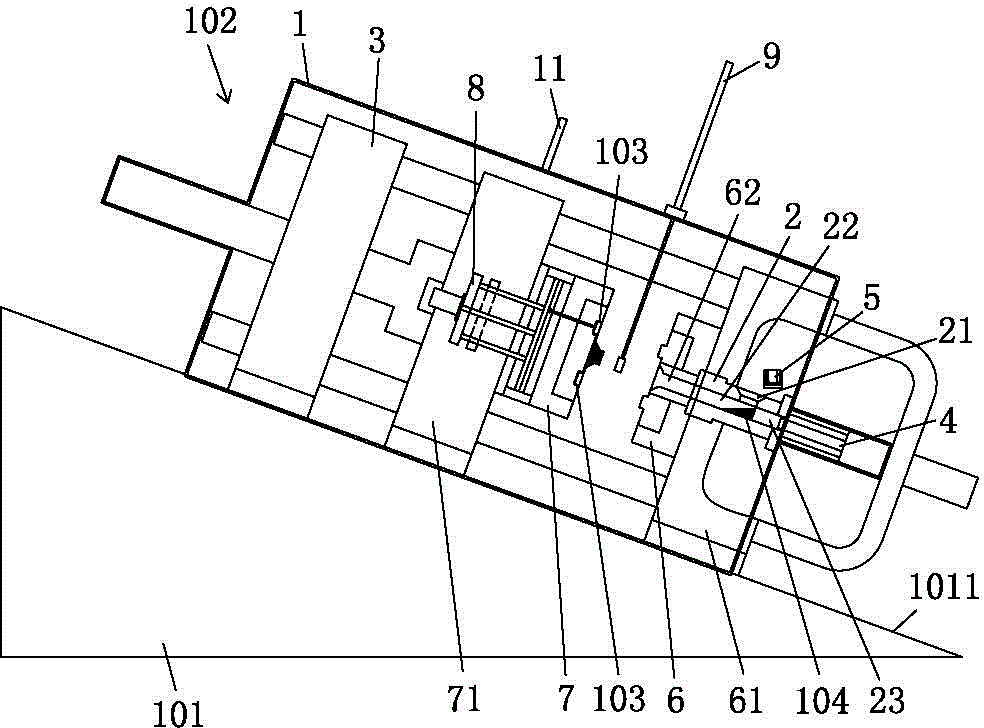

[0062] See figure 2 . Embodiment 2 of the horizontal die-casting machine for amorphous alloys of the present invention, the difference between this embodiment and Embodiment 1 is that the drive mechanism 3 is arranged in the vacuum chamber 1, and according to the needs of actual production, the amorphous alloy can be made The horizontal die-casting machine for alloys is designed as a small machine, which can save energy and reduce production costs. Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0064] Embodiment 3 of the horizontal die-casting machine for amorphous alloys of the present invention, the difference between this embodiment and Embodiment 1 is that in this embodiment, the acute angle formed between the main body 102 of the die-casting machine and the horizontal plane is 3 degrees . Since the acute angle formed between the main body 102 of the die-casting machine and the horizontal plane is 3 degrees, the acute angle formed between the die-casting storage cylinder 2 and the horizontal plane is also 3 degrees, which enables the die-casting storage cylinder 2 to store the actual production needs. The molten soup, and can facilitate the injection mechanism 4 to inject the molten soup of the die-casting storage cylinder 2 into the mold mechanism. Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com