Injection moulding method of composite material mainly containing stone and injection moulding equipment

A composite material and injection molding technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of difficult production of products with complex structures and special surface treatments, the inability to replace plastic products on a large scale, and the inability to apply high-quality products, etc. Achieve huge economic and social benefits, low cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

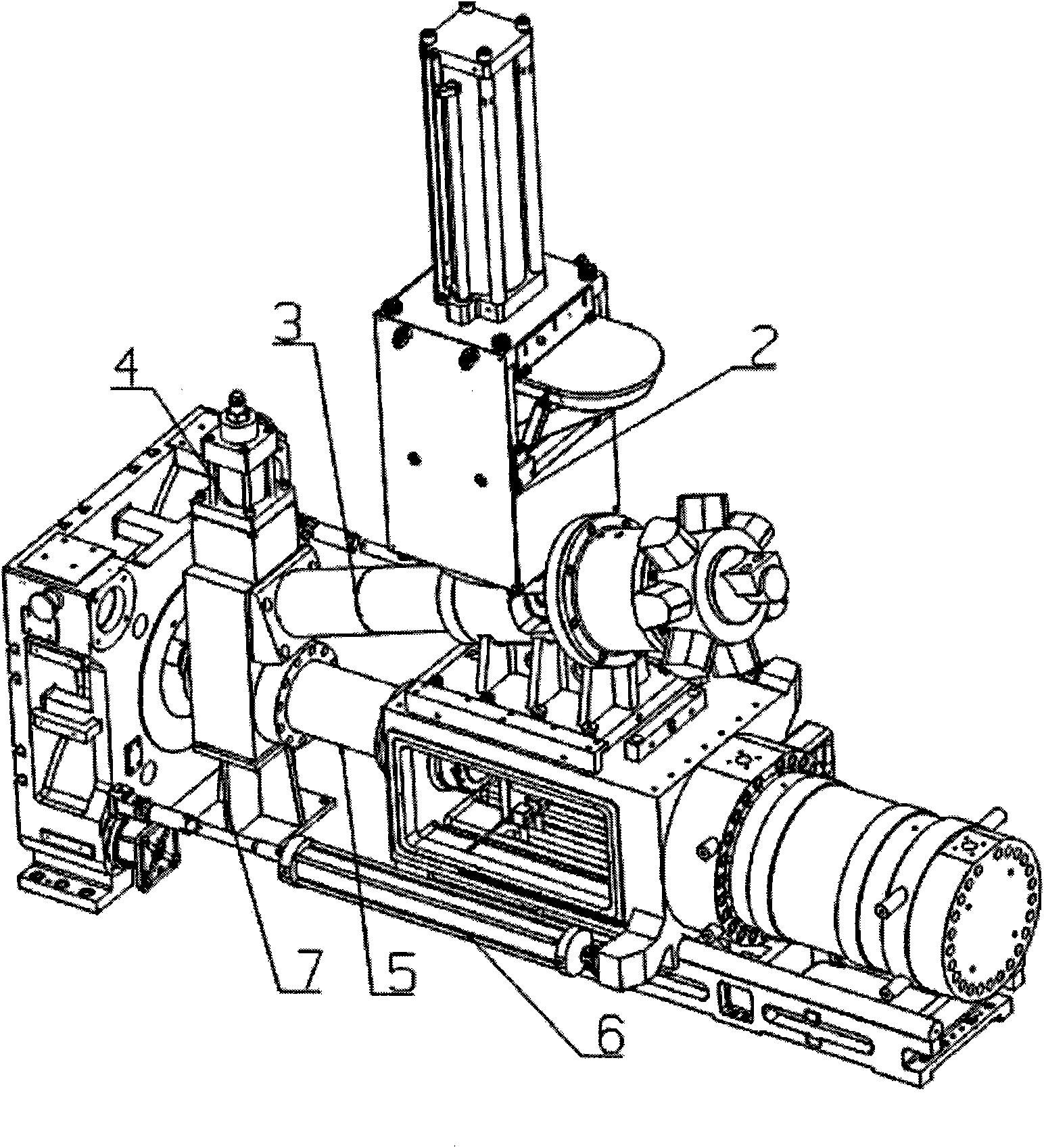

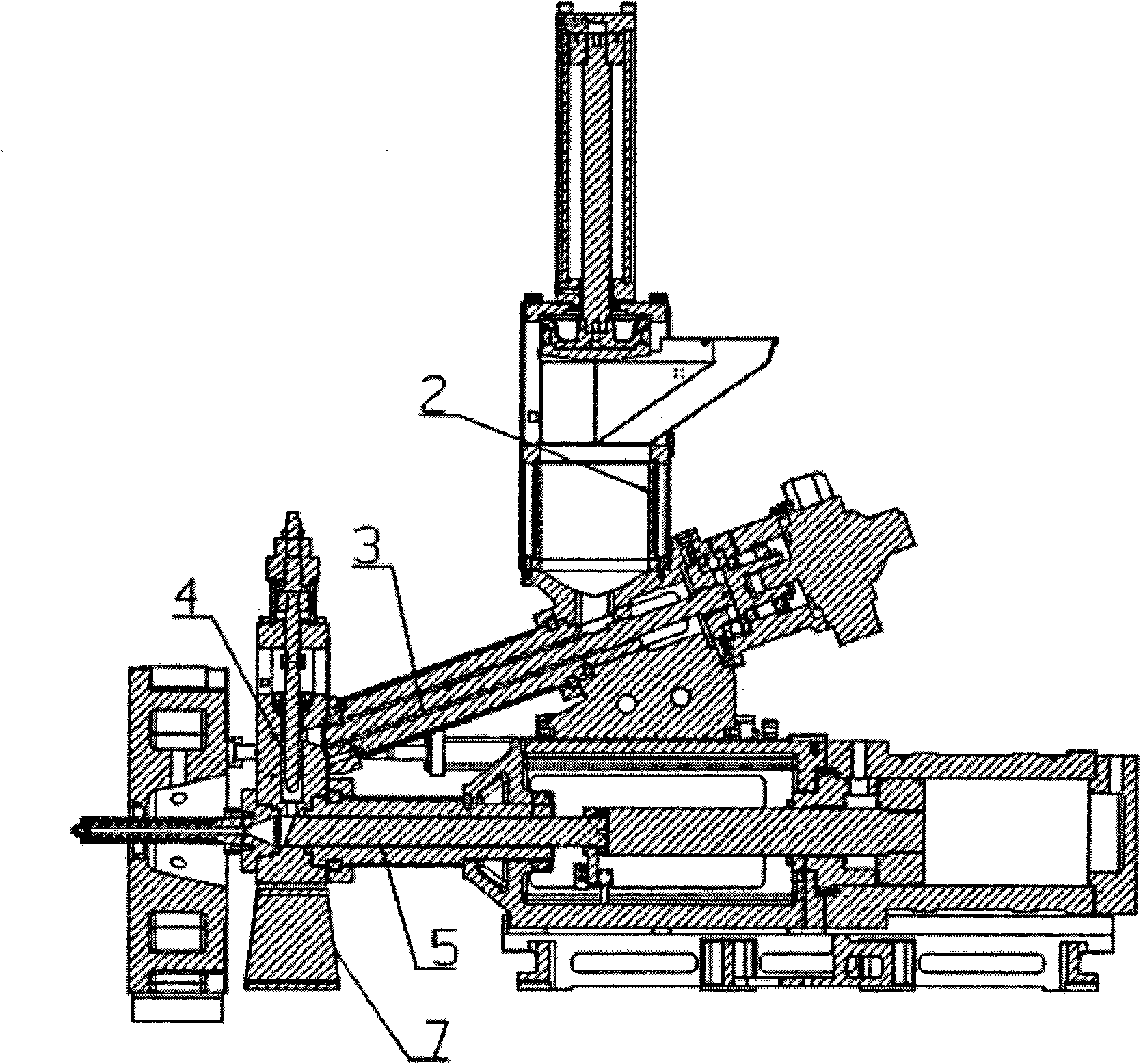

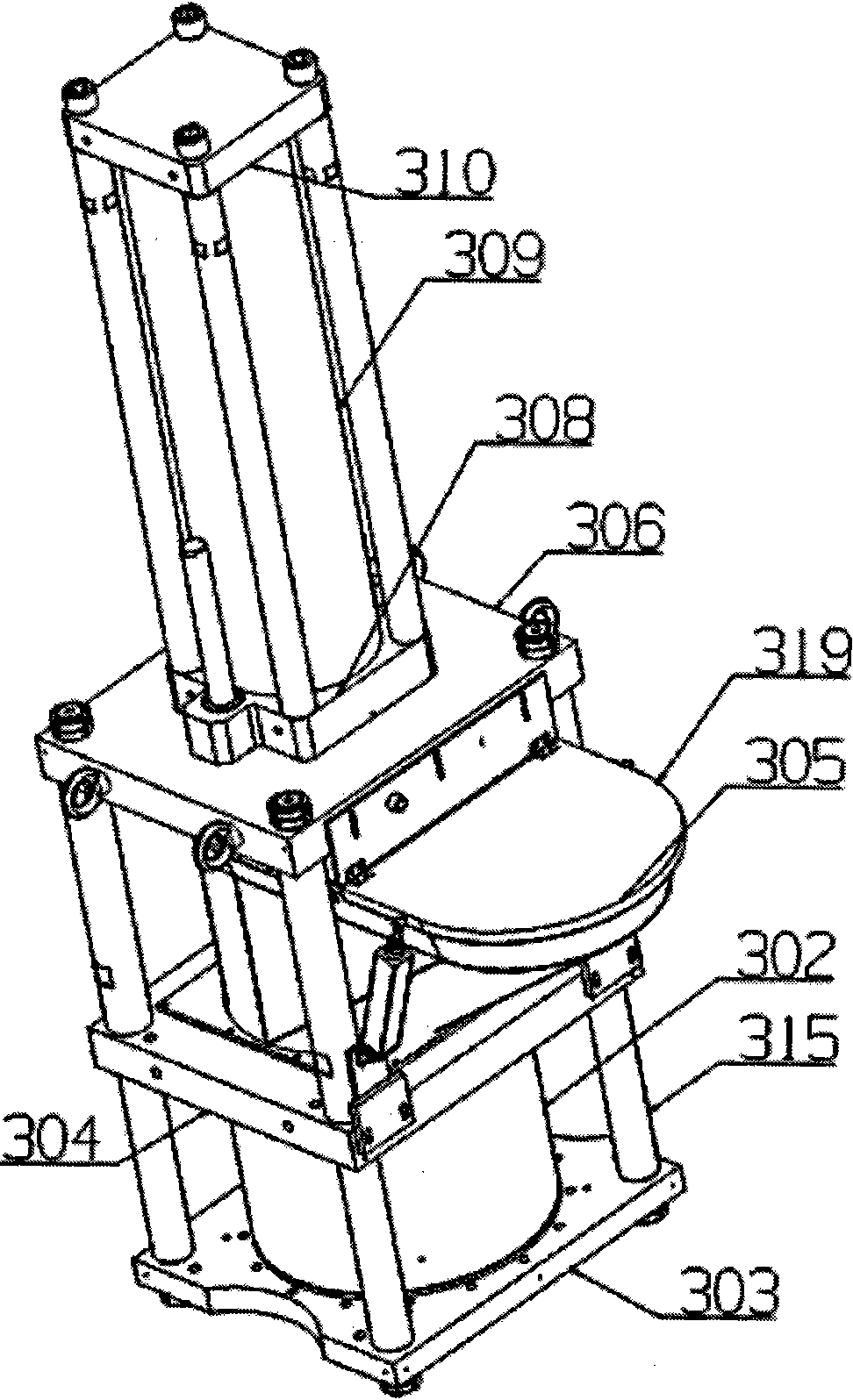

[0084] Injection Molding of Automotive Light Reflectors Using Stone-Based Composite Materials

[0085] Put the prepared raw materials into the storage barrel of the injection molding equipment, and the pressing piston drives the pressing head to press the raw materials into the pre-molding machine barrel. The temperature of the pre-molding barrel is set at 25°C, and then the raw material is forwarded into the injection barrel through the rotation of the pre-molding screw, and the pre-molding screw moves backward while rotating. The injection is carried out under the condition of 15-25mm / s, the raw material is injected into the mold through the mold gate, and the pressure is maintained for 3 seconds, the mold temperature is 160°C, and the material is cured in the mold for 65 seconds. Finally, the mold is opened to take out the product.

[0086] The above-mentioned product has been tested, and its bending strength is 130Mpa, tensile strength is 29Mpa, and impact strength is 29K...

Embodiment 2

[0087] Example 2: Using stone-based composite materials to injection mold the base of an electric iron

[0088] Put the prepared raw materials into the storage barrel of the injection molding equipment, and the pressing piston drives the pressing head to press the raw materials into the pre-molding machine barrel. The temperature of the pre-molding barrel is set at 17°C, and then the raw material is forwarded into the injection barrel through the rotation of the pre-molding screw, and the pre-molding screw moves backward while rotating. The injection pressure of the injection device is 42-52Mpa, and the injection speed The injection is carried out under the condition of 55-70mm / s, the raw material is injected into the mold through the mold gate, and the pressure is kept for 2 seconds, the mold temperature is 180°C, and the material is cured in the mold for 35 seconds. Finally, the mold is opened to take out the product.

[0089] The above-mentioned product has been tested, an...

Embodiment 3

[0090] Example 3: Using stone-based composite materials to injection mold the car cigarette lighter base

[0091] Put the prepared raw materials into the storage barrel of the injection molding equipment, and the pressing piston drives the pressing head to press the raw materials into the pre-molding machine barrel. The temperature of the pre-molding barrel is set at 25°C, and then the raw material is forwarded into the injection barrel through the rotation of the pre-molding screw, and the pre-molding screw moves backward while rotating. The injection is carried out under the condition of 8-15mm / s, the raw material is injected into the mold through the mold gate, there is no dwell time, the mold temperature is 175°C, and the material is cured in the mold for 147 seconds. Finally, the molded product is opened.

[0092] The above-mentioned product has been tested, and its bending strength is 129Mpa, its tensile strength is 28Mpa, and its impact strength is 27KJ / M2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com