Standing and forming process of liquid-injected aluminum shell lithium ion battery

An ion battery, aluminum shell lithium technology, applied in the field of aluminum shell lithium ion battery after liquid injection, standing and forming process, to achieve the effect of reducing workshop dehumidification requirements, easy implementation and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

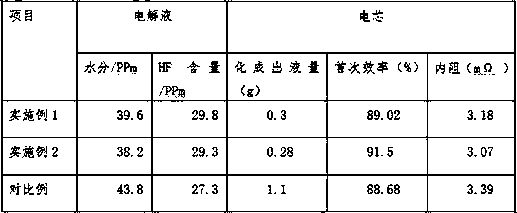

Embodiment 1

[0024] This embodiment is a 50Ah wound-type aluminum-cased lithium-ion battery. The cell is left to stand after liquid injection and the formation process is implemented according to the following steps:

[0025] 1. The battery is injected with electrolyte according to the normal amount;

[0026] 2. The same batch of batteries are connected in series after liquid injection;

[0027] 3. Put the cells connected in series into a closed box;

[0028] 4. Stand for 2 hours at normal temperature and pressure;

[0029] 5. Then vacuumize the airtight box to -0.08MPa;

[0030] 6. Stand in a vacuum state for 24 hours;

[0031] 7. Inject nitrogen into the airtight box to break the vacuum, and let it stand for 10 minutes under normal pressure;

[0032] 8. Transfer the battery cells that have been placed in parallel and are still in parallel to the formation box, and vacuumize -0.08MPa after the battery cells are connected;

[0033] 1.9. Carry out the chemical formation process accordi...

Embodiment 2

[0036] This embodiment is still a lithium-ion battery with a specification of 50Ah coiled aluminum case. After the battery cell is injected with liquid, it is left to stand and the formation process is implemented according to the following steps:

[0037] 1. The battery is injected with electrolyte according to the normal amount;

[0038] 2. The same batch of batteries are connected in series after liquid injection;

[0039] 3. Put the cells connected in series into a closed box;

[0040] 4. Stand for 1 hour at normal temperature and pressure;

[0041] 5. Then vacuumize the airtight box to -0.10MPa;

[0042] 6. Stand still for 20 hours in a vacuum state;

[0043] 7. Inject nitrogen into the airtight box to break the vacuum, and let it stand for 30 minutes under normal pressure;

[0044] 8. Transfer the battery cells that have been statically treated and are still in a parallel state to the formation box, and vacuumize -0.10MPa after the battery cells are connected;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com