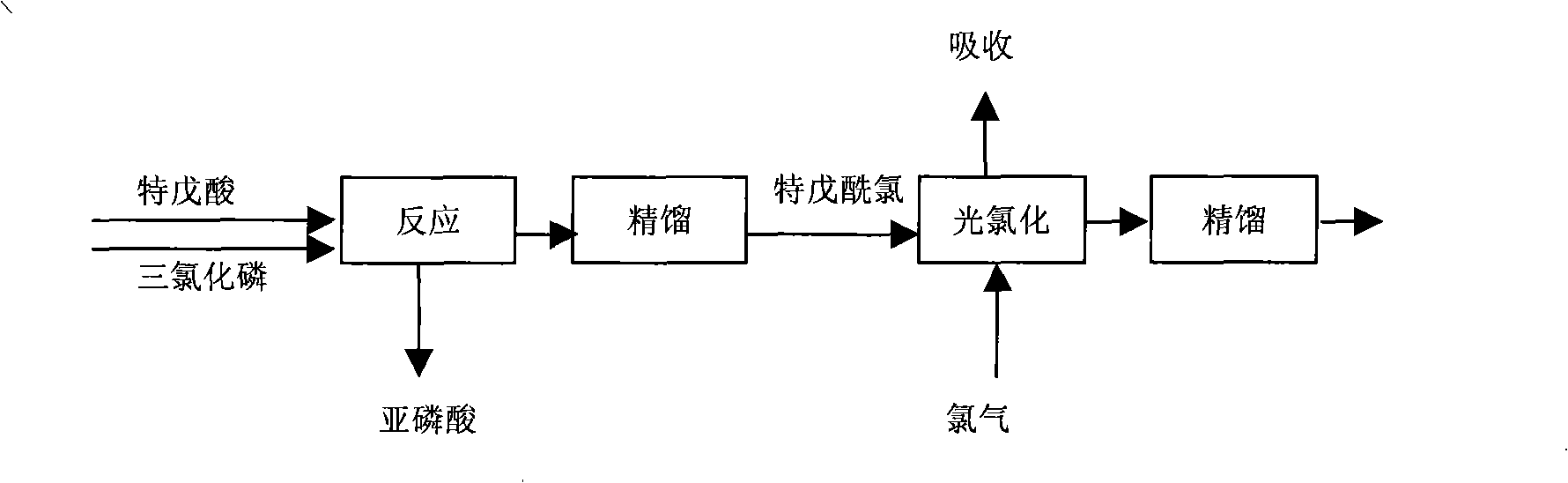

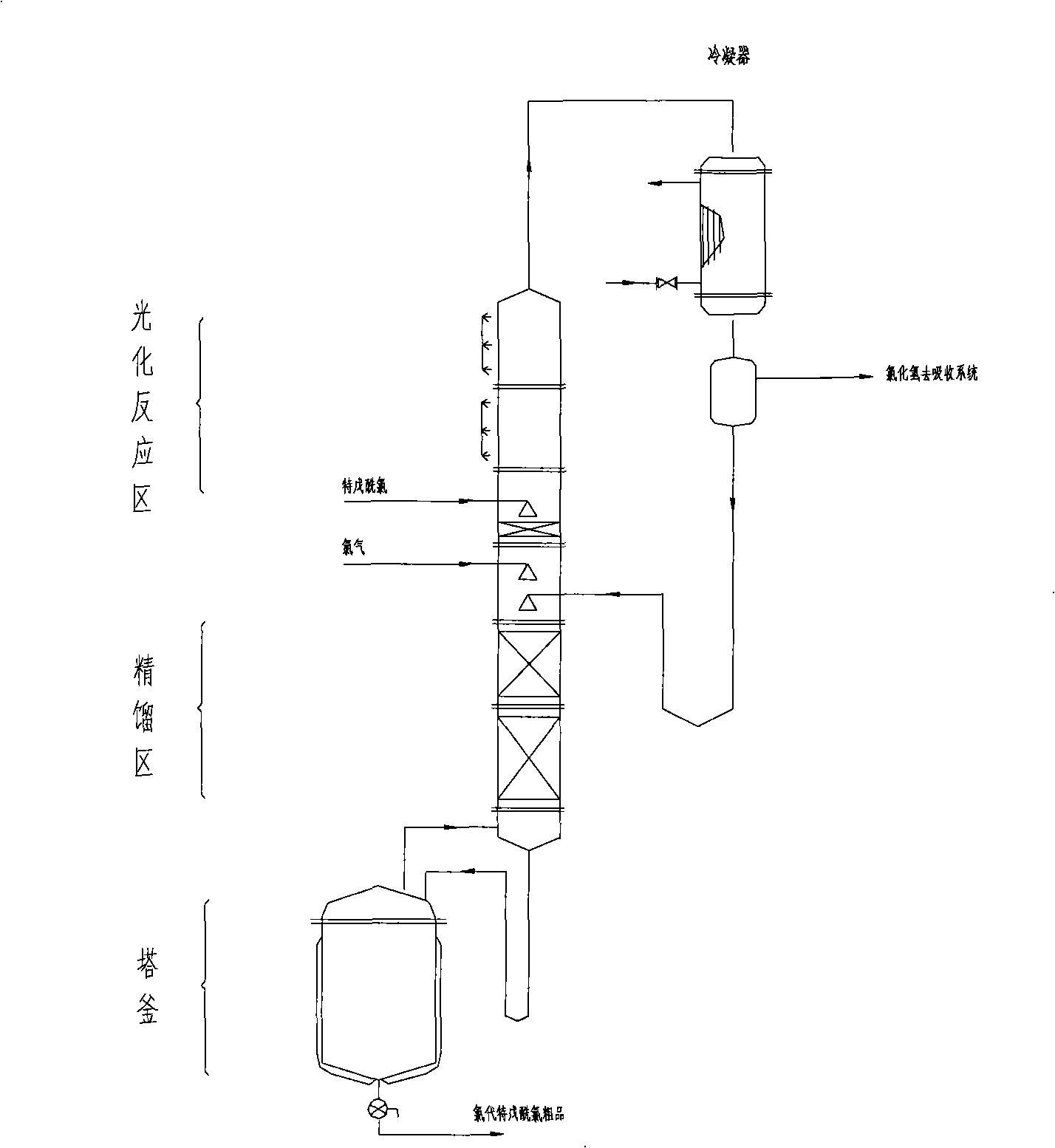

Process for preparing chloro-pivalyl chloride

A technology for chloropivaloyl chloride and crude chloropivaloyl chloride, which is applied in carboxylate preparation, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as non-industrial production methods, and achieve low cost and easy The effect of control and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Industrial example: an example of producing 1 ton of chlorpivaloyl chloride with a content above 99.5%.

[0028] 1, in reaction step (1), the pivaloyl chloride (claiming trimethylacetyl chloride again, structural formula is (CH 3 ) 3 CCOCl) molecular formula is C 5 h 9 ClO, molecular weight 120.5)

[0029] Raw materials used (1) pivalic acid, content > 98% (2) phosphorus trichloride, content 98%

[0030] at 2m 3 Drop into 937kg pivalic acid and 405kg phosphorus trichloride in the reactor. Slowly raise the temperature under stirring for 2 hours, rise to 55 ° C, continue to keep warm and stir for 2 hours, let stand to separate the upper layer clear night, rectify, collect the fraction at 104-105 ° C, and obtain 1050 kg of fine pivaloyl chloride, with a content of 99.5%. The rate is above 92%.

[0031] 2. In the reaction step (2), the final product 3-chloro-2,2-dimethylpropionyl chloride (also known as chloropivaloyl chloride, structural formula ClCH 2 (CH 3 ) 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com