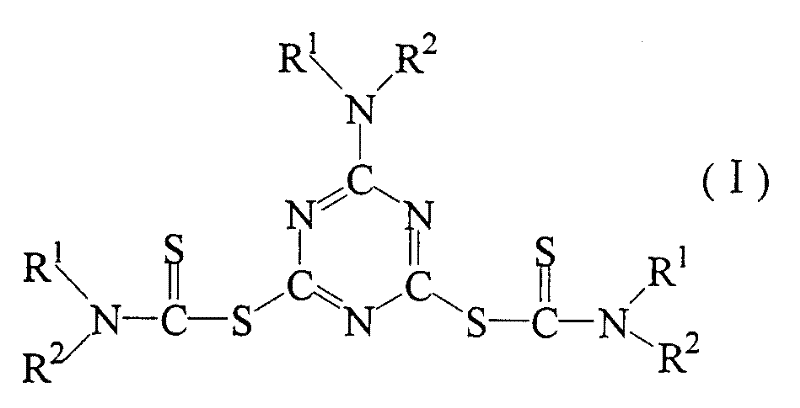

Dithioamino acid triazine derivative as additive for antioxidizing extreme pressure lubricating oil

A technology for lubricating oil additives and arginine triazine, which is applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of harsh synthesis process conditions, poor extreme pressure anti-oxidation performance, high production cost, etc., and achieve excellent extreme Anti-oxidation properties, low synthesis cost, and mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 16.12g (10% excess) sodium diethylamine thioformate and 50ml tetrahydrofuran, add them into a 250ml three-necked flask equipped with a thermometer, a stirring device, and a reflux condenser, and stir for 0.5hrs. Then weigh 4.0 g of cyanuric chloride and dissolve it with 50 ml of tetrahydrofuran. Then, under stirring, the tetrahydrofuran solution of cyanuric chloride was slowly added into the three-necked flask, the temperature was controlled at about 10°C, and the reaction was performed at a constant temperature for 2hrs. Then the temperature was slowly raised to reflux temperature, and the reaction was carried out at reflux for 3hrs. After the reaction was complete, the solution was concentrated. Then extract with benzene, wash with water several times at the same time, then dry overnight with anhydrous magnesium sulfate, after filtration, the filtrate is concentrated under reduced pressure to obtain crude product crystals, and the crude product is recrystallize...

Embodiment 2

[0020] Weigh 0.132mol (10% excess) dibutylamine sodium thioformate and 100ml acetone, add them into a 250ml three-necked flask equipped with a thermometer, a stirring device, and a reflux condenser, and stir for 0.5hrs. Then weigh 0.04mol of cyanuric chloride and dissolve it with 50ml of acetone. Then, under stirring, the acetone solution of cyanuric chloride was slowly added into the three-necked flask, the temperature was controlled at about 10°C, and the reaction was performed at a constant temperature for 3hrs. Then slowly heat up to reflux temperature, reflux reaction 3.5hrs. After the reaction was complete, the solution was concentrated. Then extract with benzene, wash with water several times at the same time, then dry overnight with anhydrous magnesium sulfate, filter, the filtrate is evaporated under reduced pressure to remove the solvent benzene, and obtain the brownish yellow crude product, and the pure compound can be obtained through the column: 2,6-bis( N,N-dib...

Embodiment 3

[0022] Weigh 0.132mol (10% excess) dioctylamine sodium thioformate and 100ml acetone, add them into a 250ml three-necked flask equipped with a thermometer, a stirring device, and a reflux condenser, and stir for 0.5hrs. Then weigh 0.04mol of cyanuric chloride and dissolve it with 50ml of acetone. Then, under stirring, the acetone solution of cyanuric chloride was slowly added into the three-necked flask, the temperature was controlled at about 10°C, and the reaction was performed at a constant temperature for 3hrs. Then slowly heat up to reflux temperature, reflux reaction 3.5hrs. After the reaction was complete, the solution was concentrated. Then extract with benzene, wash with water several times at the same time, then dry overnight with anhydrous magnesium sulfate, filter, the filtrate is evaporated under reduced pressure to remove the solvent benzene, and obtain the brownish yellow crude product, and the pure compound can be obtained through the column: 2,6-bis( N,N-dio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com