Steel ball lapping liquid

A lapping and steel ball technology, applied in the field of steel ball lapping liquid, can solve the problems of high production cost of lubricating oil and mechanical oil, cleaning liquid polluting the environment, troublesome cleaning, etc., to shorten processing time, improve surface quality, and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

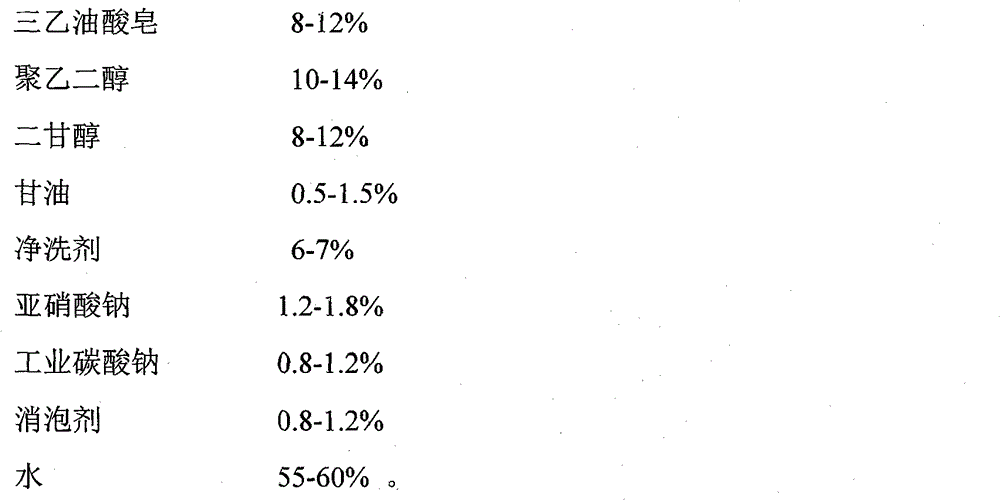

[0033] A steel ball polishing liquid is characterized in that the weight percent of each component of its constituent raw materials is:

[0034] Triethyl Oleate Soap 8-12%

[0035] Polyethylene glycol 10-14%

[0036] Diethylene glycol 8-12%

[0037] Glycerin 0.5-1.5%

[0038] Detergent 6-7%

[0039] Sodium nitrite 1.2-1.8%

[0040] Industrial sodium carbonate 0.8-1.2%

[0041] Defoamer 0.8-1.2%

[0042] Water 55-60%.

[0043] The steel ball polishing solution is characterized in that the weight percent of each component of its constituent raw materials is:

[0044] Triethyl Oleate Soap 10%

[0045] Polyethylene glycol 12%

[0046] Diethylene glycol 10%

[0047] Glycerin 1%

[0048] Detergent 5%

[0050] Industrial Sodium Carbonate 1%

[0051] Defoamer 1%

[0052] Water 58.5%.

[0053] Wherein, the defoamer is selected from one of silicone defoamers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com