Steel ball photosphere solution

A technology of light balls and steel balls, applied in the direction of lubricating compositions, etc., can solve the problems of cleaning liquid pollution, high cost, troublesome cleaning, etc., and achieve the effects of shortening processing time, good cleaning, and improving surface quality

Active Publication Date: 2013-07-10

安徽舒城云飞工贸有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Light ball liquid is used in many processes in the process of steel ball processing. The steel ball light ball liquid currently on the market is carefully prepared from raw materials such as fatty acid amide, high-grade lubricant, penetrant, anti-fungal agent and defoamer. , its appearance is a brown-red uniform transparent liquid, the cost is high, and it is troublesome to clean after it is applied to the steel ball, and the cleaning liquid will pollute the environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

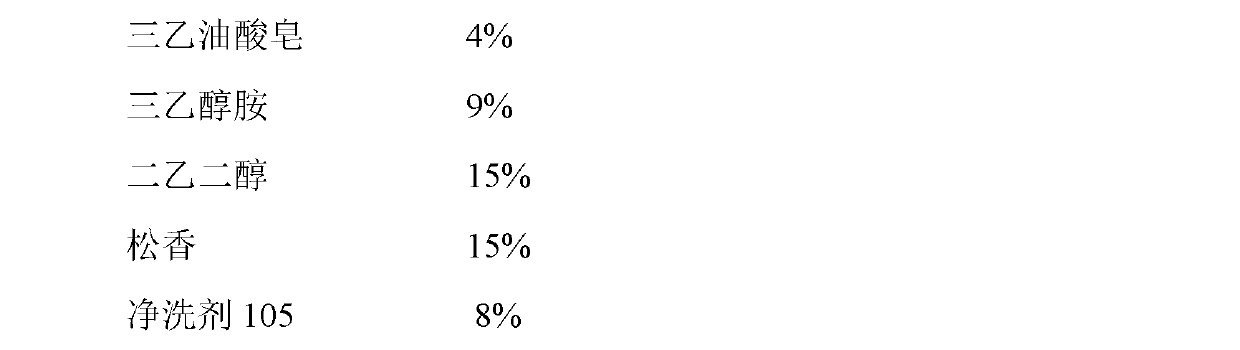

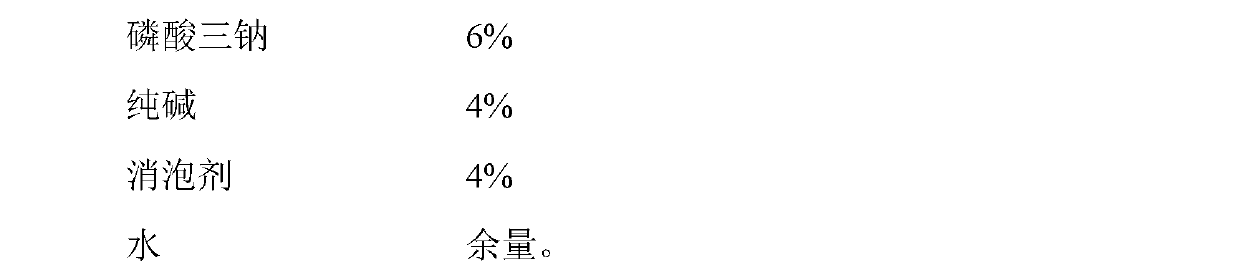

Embodiment 1

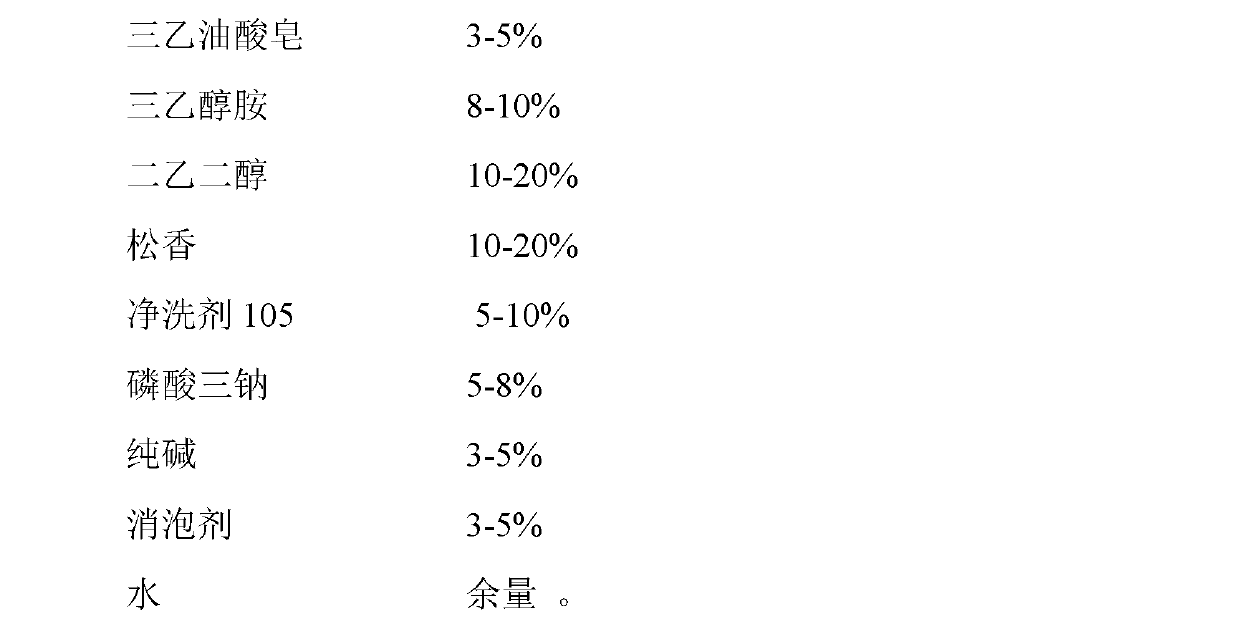

[0019] Steel ball photosphere liquid, the percentage by weight of each component of its composition raw material is:

[0020]

[0021]

[0022] Wherein, the defoamer is selected from one of silicone defoamers.

[0023] The performance data of the steel ball photosphere liquid that the present invention makes:

[0024]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses steel ball photosphere solution, which comprises the following components in percentage by weight: 3-5 percent of triethyl oleic soap, 8-10 percent of triethanolamine, 10-20 percent of diethylene glycol, 10-20 percent of colophony, 5-10 percent of detergent105, 5-8 percent of trisodium phosphate, 3-5 percent of sodium carbonate, 3-5 percent of defoaming agent, 1-3 percent of raffinate of triethanolamine and 55-60 percent of water. The photosphere solution is oil-free, odourless and non-toxic, has good chemical stability, and is convenient and safe to use, and the environment pollution is reduced; and the photosphere solution is adopted in a steel ball processing process, so that the surface quality of the steel ball can be improved, and the working efficiency is improved.

Description

technical field [0001] The invention relates to the field of fine chemical industry, in particular to a steel ball photosphere liquid. Background technique [0002] Light ball liquid is used in many processes in the process of steel ball processing. The steel ball light ball liquid currently on the market is carefully prepared from raw materials such as fatty acid amide, high-grade lubricant, penetrant, anti-fungal agent and defoamer. , its appearance is a brown-red uniform transparent liquid, the cost is high, and it is troublesome to clean after it is applied to the steel ball, and the cleaning liquid will pollute the environment. Contents of the invention [0003] The invention discloses a photosphere liquid for steel balls. The photosphere liquid has good cleaning, lubricating, anti-extreme pressure and anti-rust properties, is convenient for cleaning, improves the surface quality of steel balls, and shortens the processing time of steel balls. [0004] To achieve the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10M173/02C23G1/19C23C22/62

Inventor 潘永复

Owner 安徽舒城云飞工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com