Process for producing needle coke from compounded and blended components such as washing oil, anthracene oil and asphalt in medium and low temperature coal tar as raw materials

A technology of low-temperature coal tar and needle coke, which is applied in tar processing through selective solvent extraction, petroleum industry, coking carbonaceous materials, etc. Deal with the burden and difficulty, etc., to achieve the effect of simple and efficient raw material processing, excellent product performance, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

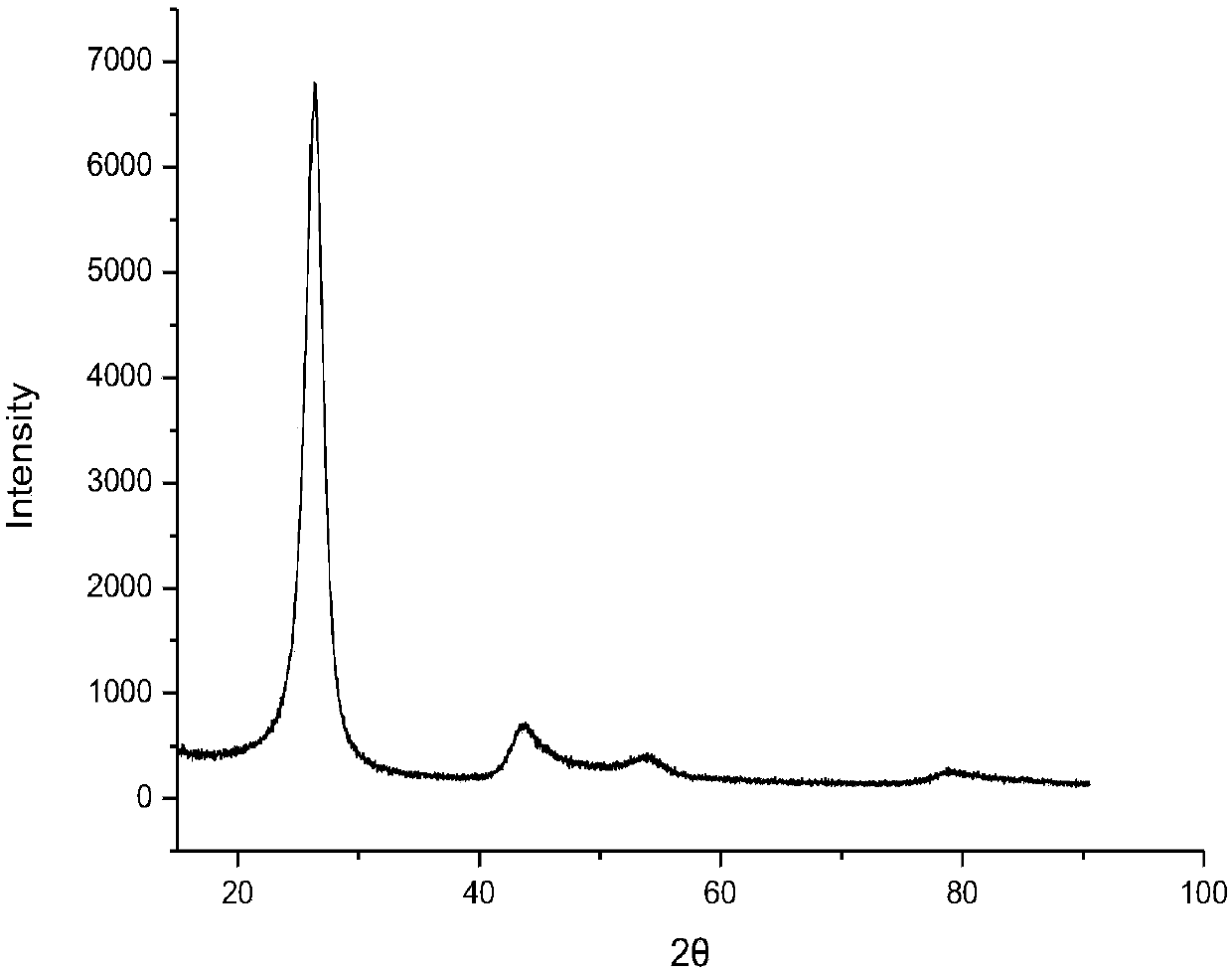

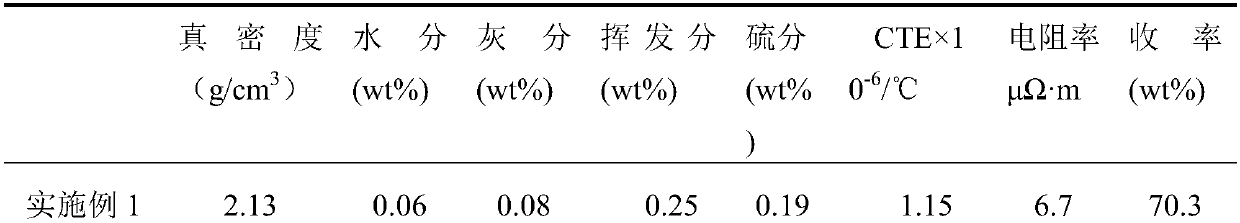

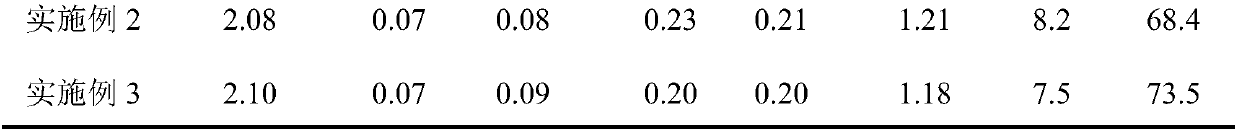

[0024] In this example, the process of producing needle coke with medium-low temperature coal tar medium wash oil, anthracene oil and asphalt components compounded as raw materials is specifically realized by the following steps:

[0025] 1000g of medium and low temperature coal tar is prepared with 1200g of toluene and 800g of n-heptane as a solvent extractant, and the coal tar is extracted for 6 hours at 75°C. The mixture is separated by distillation, and the solid insolubles are removed by physical separation. Cut 982g of refined medium-low temperature coal tar into vacuum fractions to obtain wash oil, anthracene oil and asphalt components of 148g, 196g, and 392g respectively, and prepare raw materials with mass m wash oil:m anthracene oil:m asphalt=1:1.5:6.5 , 542g of needle coke raw materials were blended with 60g of washing oil, 90g of anthracene oil, and 392g of pitch. The QI content of the pitch product was 0.096wt%, and the content of 3-4 ring aromatic hydrocarbons acc...

Embodiment 2

[0027] 1000g of medium and low temperature coal tar is prepared with 1090g of furfural and 910g of n-hexane as a solvent extractant, and the coal tar is extracted at 60°C for 8 hours. The mixture is separated by distillation, and the solid insolubles are removed by physical separation. Cut 975g of refined medium-low temperature coal tar into vacuum fractions to obtain 142g, 208g and 405g of wash oil fractions at 230-300°C, anthracene oil fractions at 300-350°C and asphalt fractions at 350-450°C respectively. Oil: m anthracene oil: m asphalt=1:1:5.5 Ratio adjustment of raw materials, respectively with washing oil 74g, anthracene oil 74g, asphalt 405g allocation needle coke raw material 553g, make the pitch product QI content be 0.092wt%, 3~ The content of 4-ring aromatic hydrocarbons accounts for 68.3wt%. Put the blended raw materials in a 1L high-temperature and high-pressure reactor, vent the system, replace with nitrogen, raise the temperature to 400°C at a heating rate of 0...

Embodiment 3

[0029] Use 1929g of N-methylpyrrolidone and 1071g of cyclohexane as a solvent extractant for 1000g of medium-low temperature coal tar, extract the coal tar for 6 hours at 80°C, separate the extractant from the mixture by distillation, and remove the solid insolubles by physical separation. Cut 986g of refined medium-low temperature coal tar into vacuum fractions to obtain 132g, 215g and 418g of wash oil fractions at 230-300°C, anthracene oil fractions at 300-350°C, and asphalt fractions at 350-450°C, respectively. Oil: m anthracene oil: m pitch = 1: 1.5: 7.5 The ratio of the needle coke raw material deployment, respectively with 56g of washing oil, 84g of anthracene oil, pitch 418g deployment of needle coke raw material 558g, so that the QI content of the pitch product is 0.098wt% , the content of 3-4 ring aromatic hydrocarbons accounted for 70.2wt%. Put the blended raw materials in a 1L high-temperature and high-pressure reactor, vent the system, replace with nitrogen, raise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com