Patents

Literature

73results about How to "Constitute reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite microbial fertilizer and preparation method thereof

InactiveCN104496577APromote absorptionRich strainsBio-organic fraction processingAnimal corpse fertilisersEnvironmental resistancePlant growth

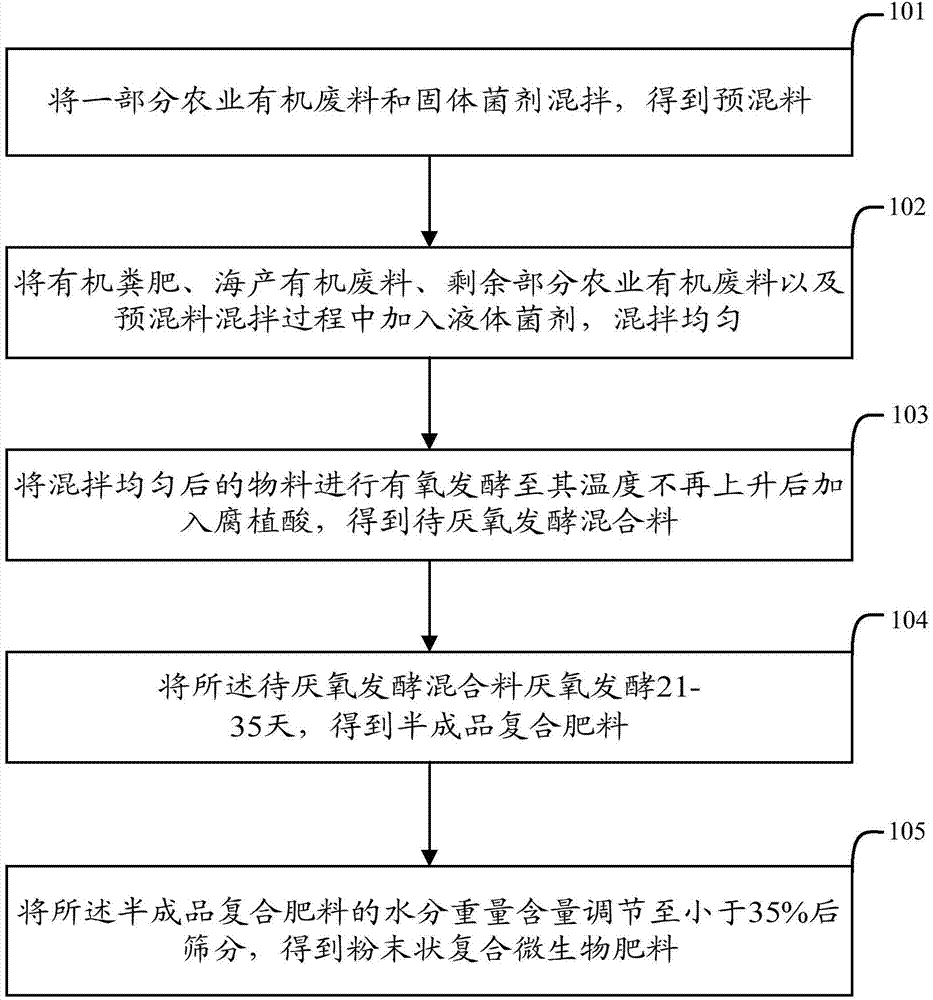

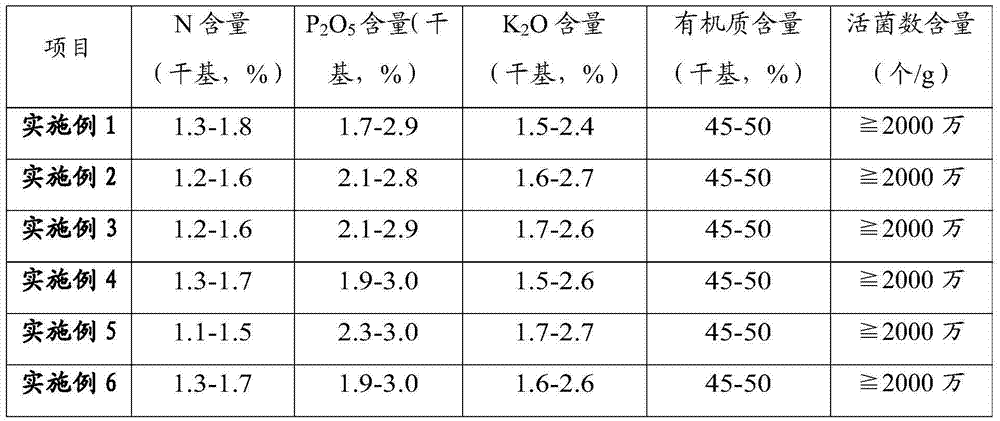

The invention provides a composite microbial fertilizer and a preparation method thereof, and belongs to the field of composite microbial fertilizers. The composite microbial fertilizer is prepared form the following raw materials in parts by weight: 4-6 parts of organic manure, 2-4 parts of humic acid, 0.7-3 parts of agriculture organic waste, 0.2-0.4 part of marine organic waste, 0.01-0.02 part of a liquid inoculant and 0.005-0.01 part of a solid inoculant. According to the composite microbial fertilizer, on one hand, comprehensive, balanced and easy-to-absorb nutrients are provided for crops, healthy growth of the crops is accelerated, and the produced fulvic acid can be used for adjusting the crop growth as a plant growth regulator, and on the other hand, a lot of beneficial microorganisms are generated. Due to balanced and sufficient fermentation substrates, the produced microorganisms are not easy to die; the composite microorganisms are large in viable number; the composite microbial fertilizer is significant in fertilizer efficiency, environmental friendly, and harmless after being applied; and due to large content of microorganisms and organic matters, the soil structure is also improved.

Owner:刘长生 +2

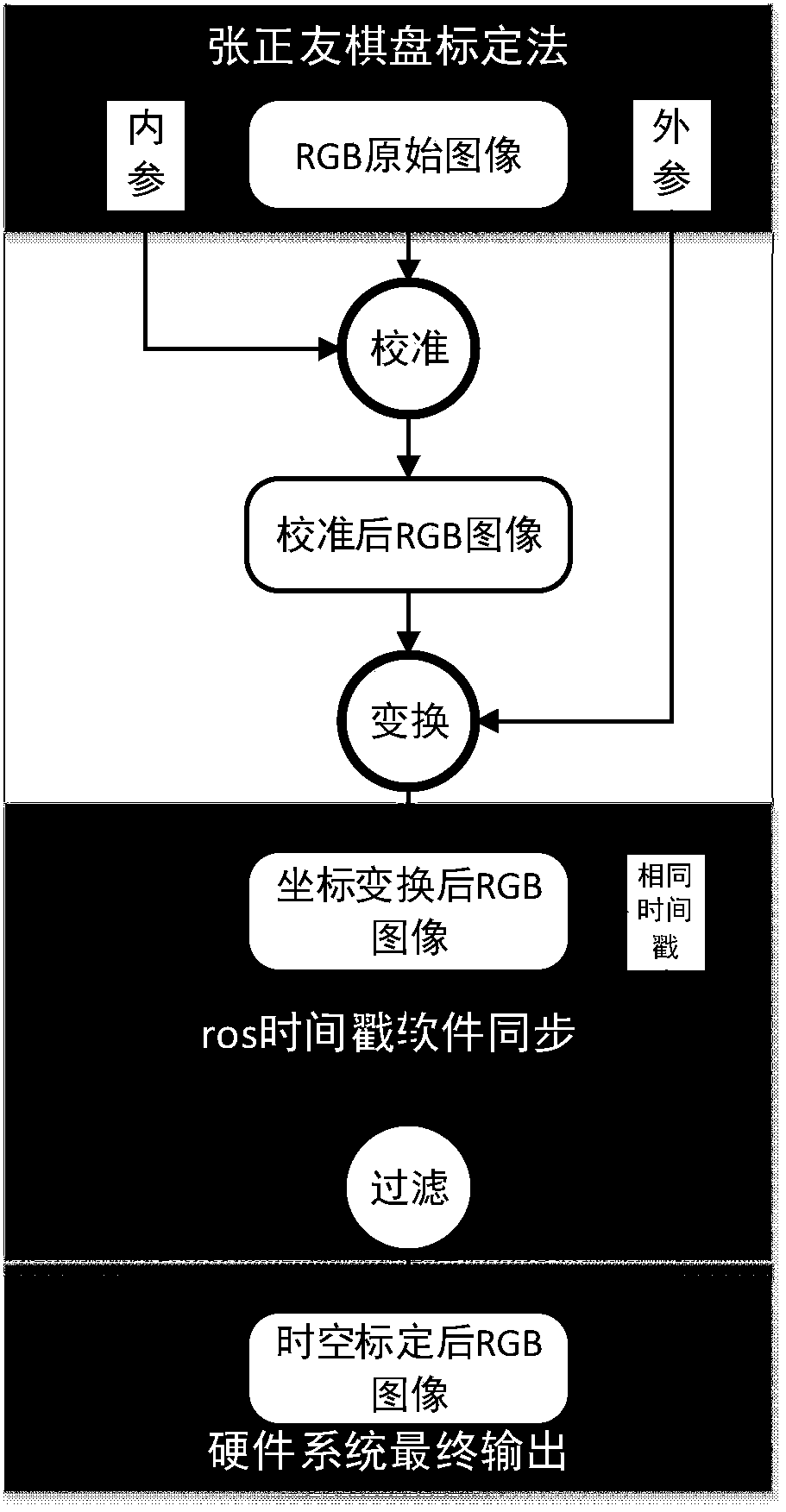

Video-based automatic identification system for abnormal conditions of fused magnesium furnace

InactiveCN107844770AConstitute reasonableSimple compositionProgramme controlTesting/monitoring control systemsFeature extractionComputer module

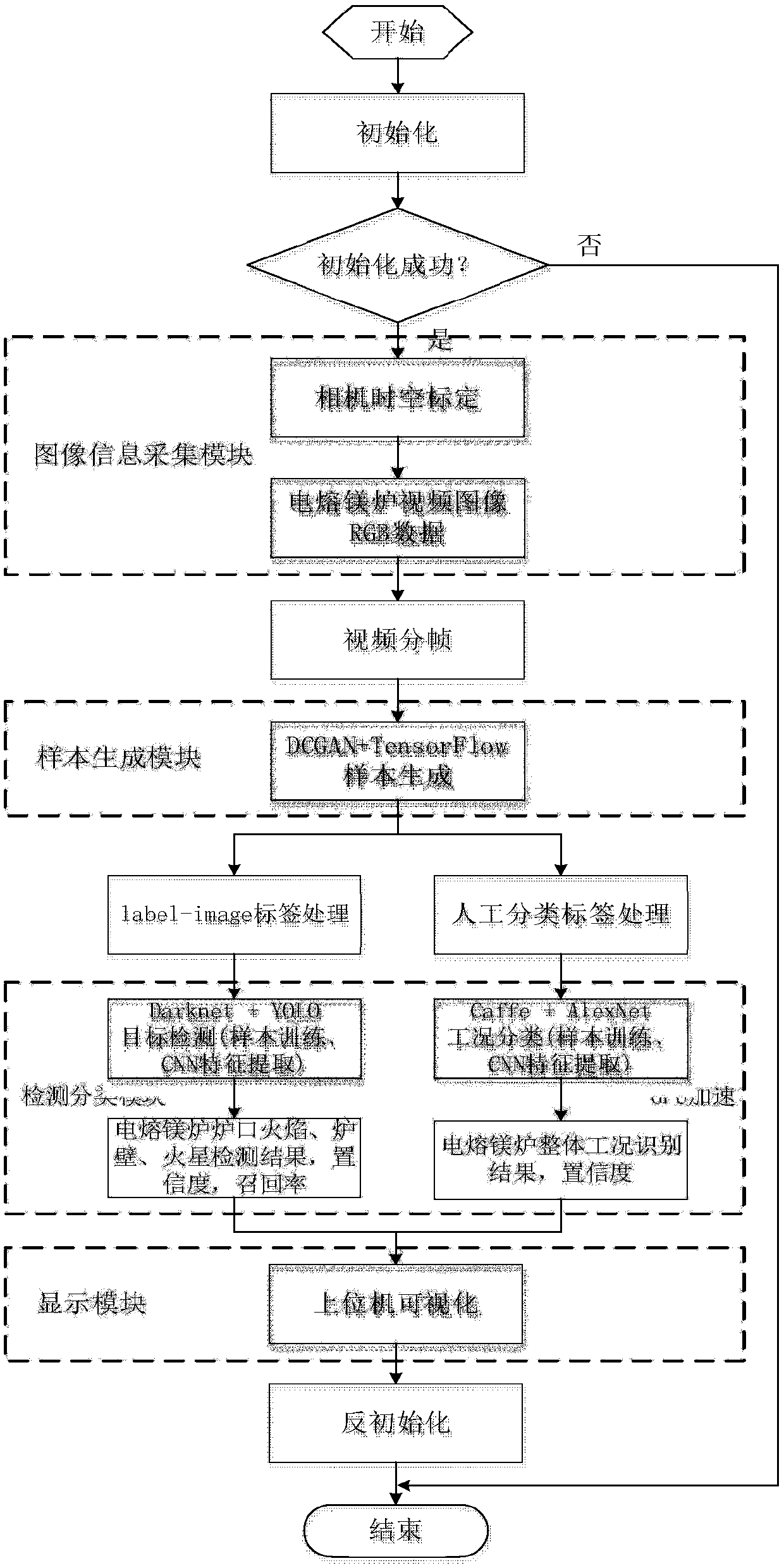

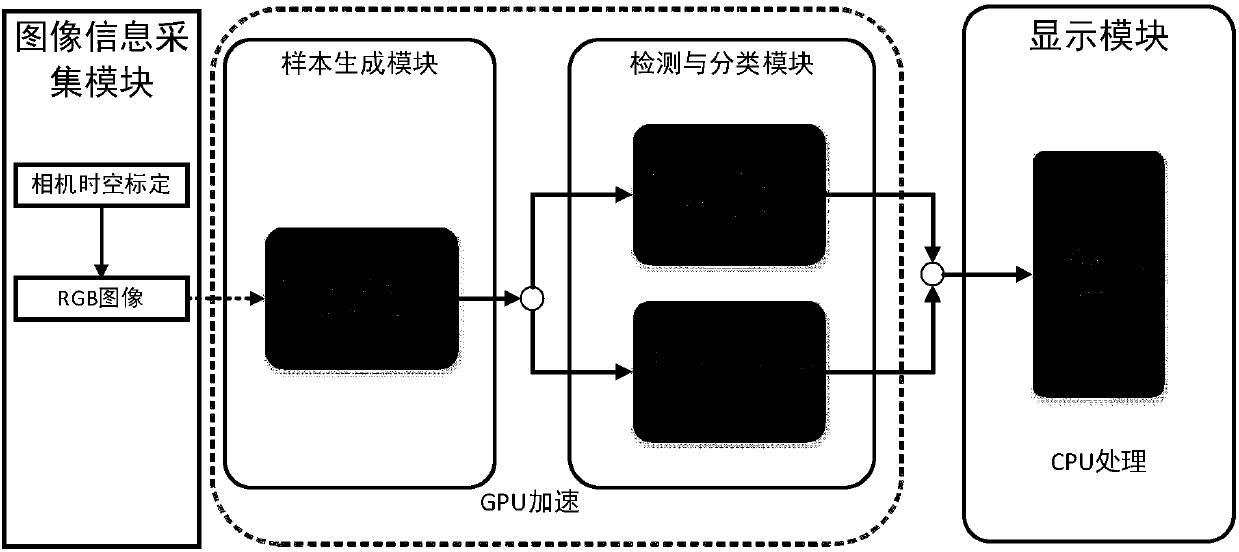

The invention relates to a video-based automatic identification system for abnormal conditions of a fused magnesium furnace. The method includes the steps of acquiring fused magnesia production fieldcondition information through an image information acquisition module and transmitting the information to a sample generation module; generating a training sample by the sample generation module, performing label processing and manual classification label processing on images through label-image software, and transmitting the processed video and image information to a detection and classificationmodule; performing, by the detection and classification module, feature extraction and processing on the video and image information through a corresponding algorithm to obtain an intelligent detection and classification model of the condition identification system; and displaying, by a display unit, the novel uses the test video and image information in a visualized manner by using the intelligent detection and classification model processed by the detection and classification module. The video-based automatic identification system of the invention has obviously improved identification effects as compared to a system using non-visual information alone such as the current and voltage, is reasonable in hardware device structure, convenient in operation, low in cost and high in the accuracyof discrimination and can replace manual routing inspection.

Owner:NORTHEASTERN UNIV

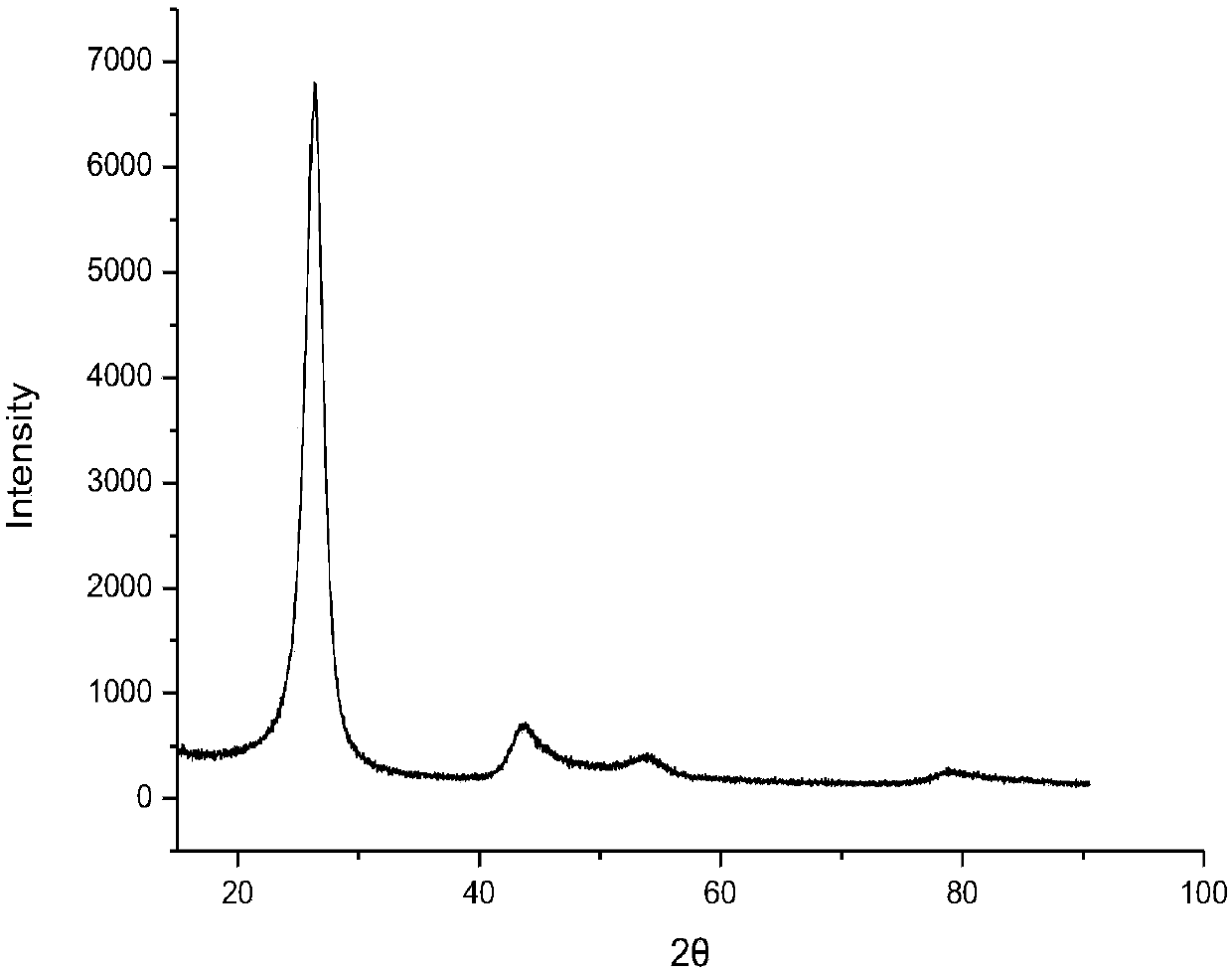

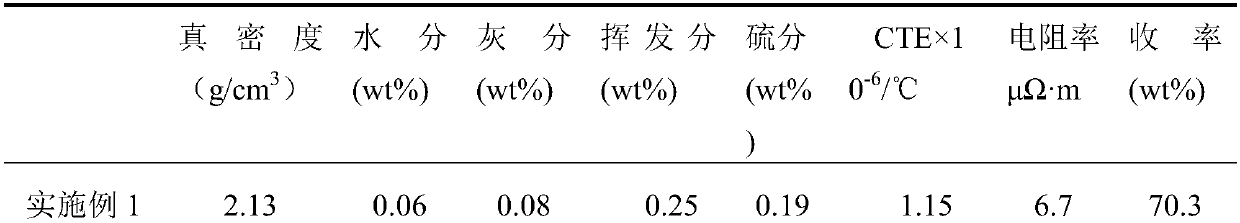

Process for producing needle coke from compounded and blended components such as washing oil, anthracene oil and asphalt in medium and low temperature coal tar as raw materials

InactiveCN107868671AEasy to handleStrong targetingCoking carbonaceous materialsTar working-up by solvent extractionCarbolineumCalcination

The invention provides a process for producing needle coke from compounded and blended components such as washing oil, anthracene oil and asphalt in medium and low temperature coal tar as raw materials. The process comprises the steps as follows: raw material pretreatment of the medium and low temperature coal tar, fraction cutting of the components such as the washing oil, the anthracene oil andthe asphalt in the medium and low temperature coal tar, blending of the compounding raw materials, and preparation of the needle coke with thermal polymerization and calcination processes. The ideal raw materials for the needle coke are prepared from fractions of the coal tar by compounding and blending, formation of a wide-area ordered fibrous structure from an intermediate phase can be greatly promoted in a thermal polymerization process by means of reasonable raw material components, and a needle coke product with excellent performance is obtained after calcination.

Owner:SHAANXI YULIN ENERGY GRP CO LTD +1

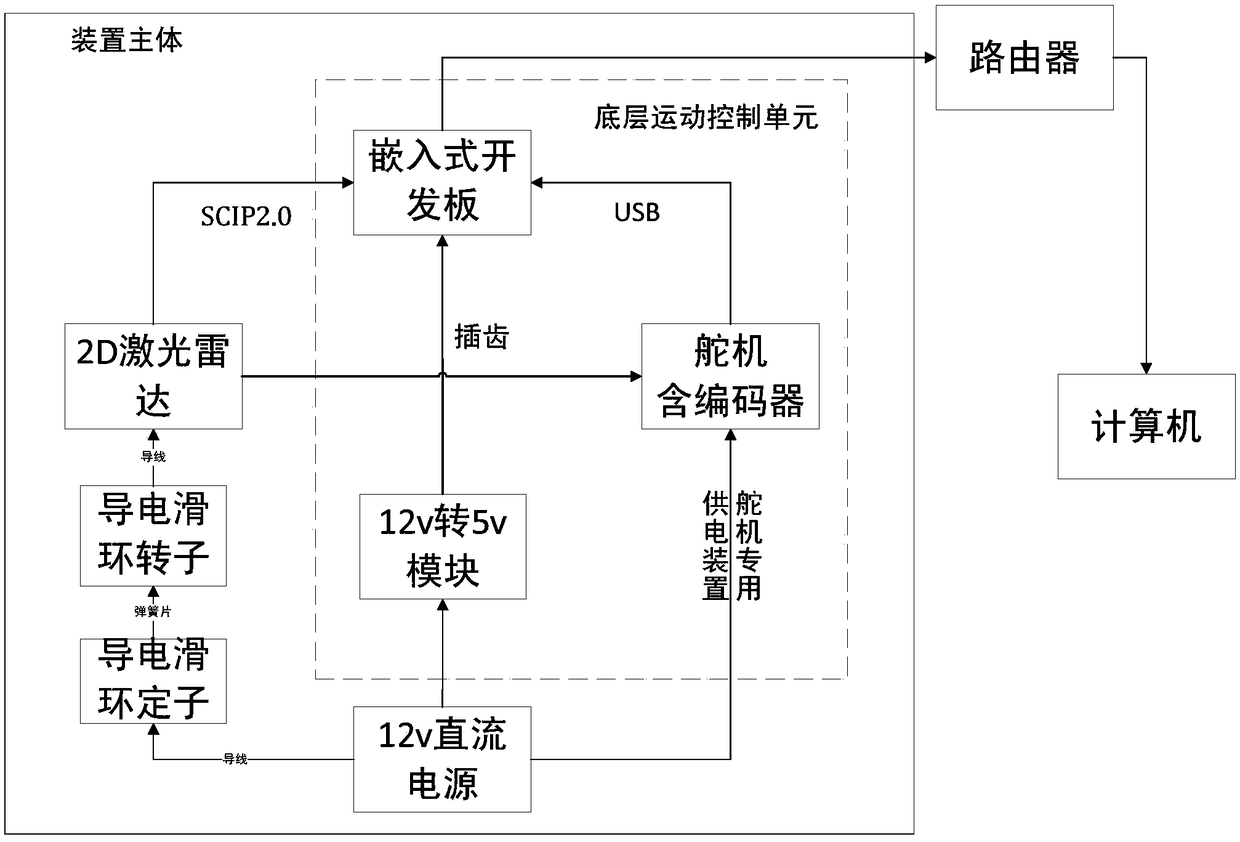

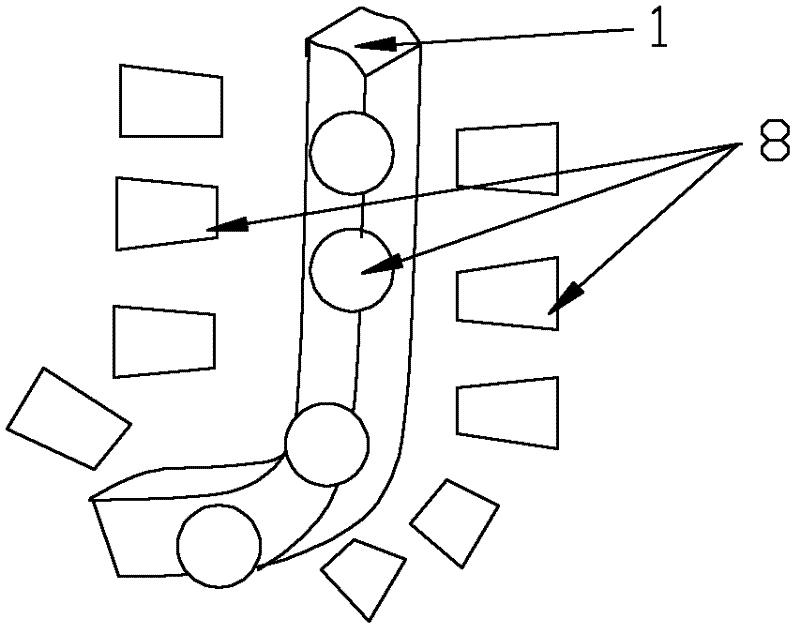

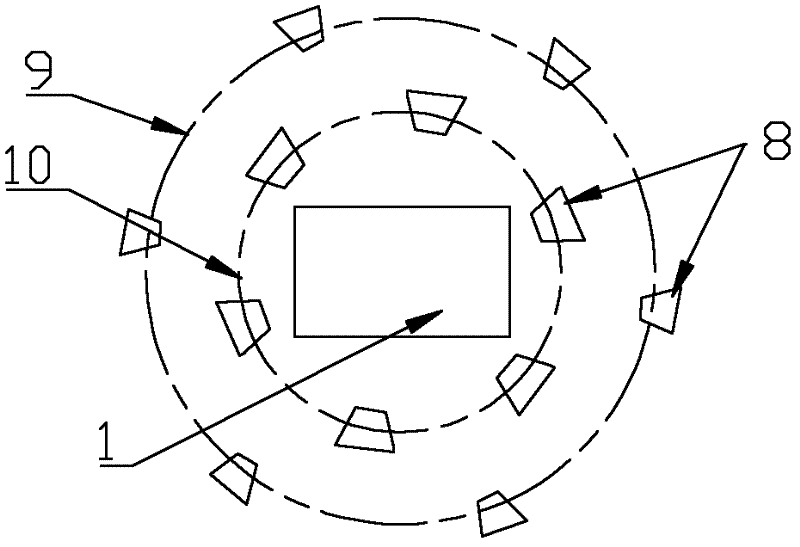

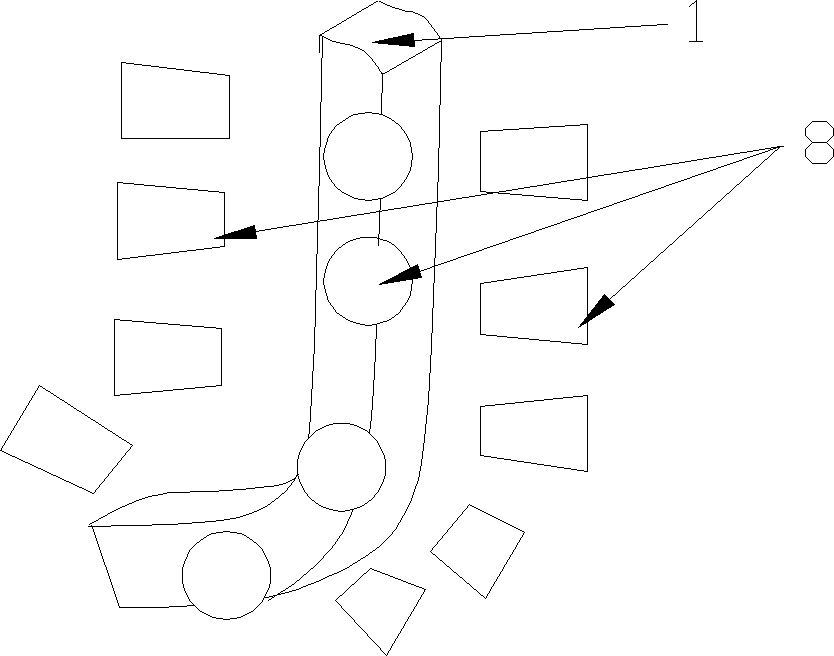

Three-dimensional laser SLAM system based on 2D laser radar and control method thereof

ActiveCN109358342ASave spaceEliminate the effects ofElectromagnetic wave reradiationRadarEngineering

The invention provides a three-dimensional laser SLAM system based on a 2D laser radar and a control method thereof. The system specifically comprises: a device body, a router, and a computer. The device body comprises: an embedded development board, a DC power supply, a 2D laser radar, a steering gear and a conductive slip ring. The system theory of the invention is combined with reality, and thecomposition is reasonable, concise and convenient. The invention can quickly establish and realize three-dimensional map and positioning, and has low cost, simple operation and convenient use. The entire system can be used not only in a handheld mode but also on a mobile robot. In the indoor and outdoor environment, the invention not only can establish a three-dimensional reconstruction map in real time, but also can calculate the position of a sensor by the SLAM algorithm to realize the real-time positioning function. Compared with the three-dimensional laser radar, the invention has large field of view, 360 degrees without dead angle, and is more suitable for construction in indoor environment, and the cost is lower. In addition, the entire system is also easy to operate and is not affected by ambient light.

Owner:NORTHEASTERN UNIV

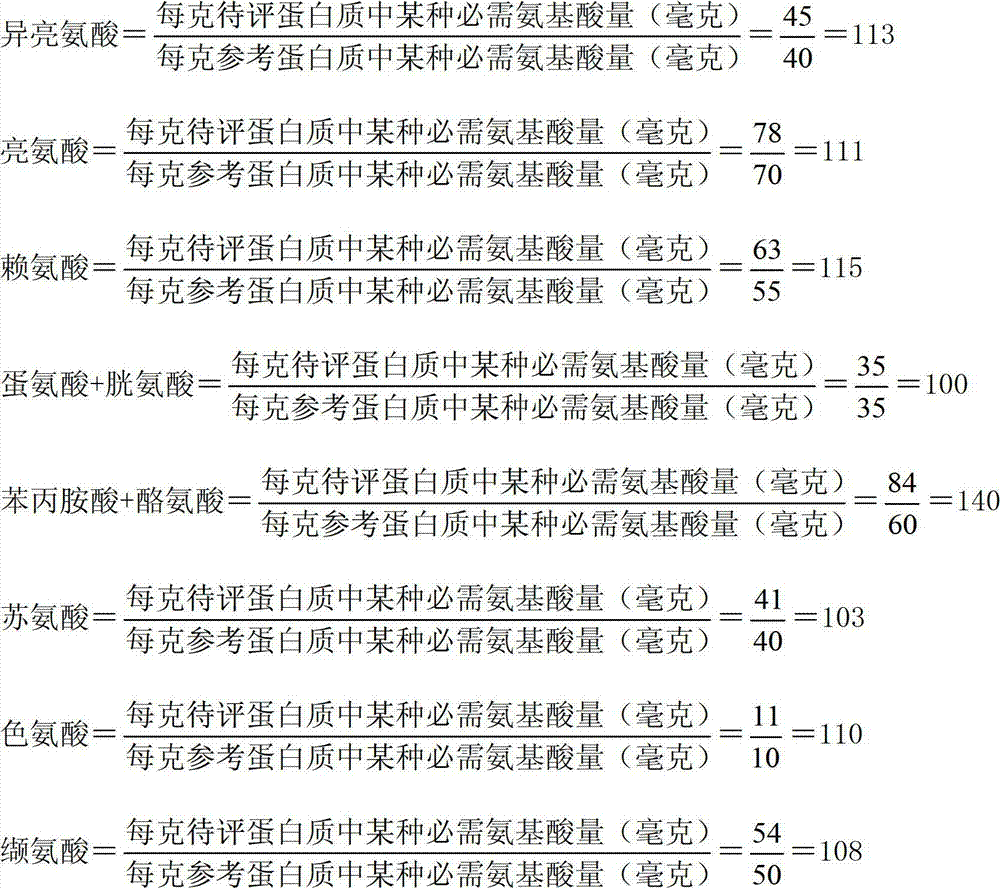

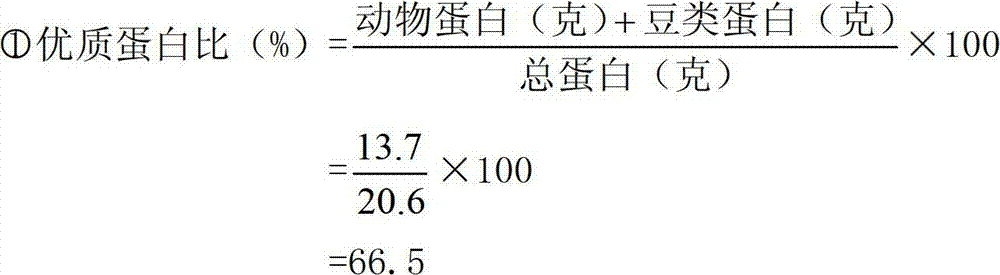

Preparation method of composite protein powder with high amino acid grade

InactiveCN109673814AFull and efficient useTake advantage ofLactobacillusMicroorganism/unicellular-algae proteins working-upAmino acid scoreYeast

The invention provides a preparation method of composite protein powder with a high amino acid grade. The preparation method specifically comprises the following steps: performing micronization treatment on raw material protein by a colloid mill and / or a high-pressure homogenizer, heating the raw material protein to denature the protein, performing countercurrent ultrasonic assisted enzymatic hydrolysis through single protease or multi-enzyme combination, performing individual or joint fermentation of yeast, lactic acid bacteria and bacillus subtilis to remove stinking and peculiar smell, performing ultrafiltration and ion exchange resin desalting, evaluating and supplementing essential amino acids, performing enzymatic polymerization and reconstitution reaction, and performing drying or performing drying and mixing to obtain a high-quality protein product with a reasonable proportion of the essential amino acids and an amino acid grade being 95 or above. The obtained composite proteinpowder has the high essential amino acid grade, belongs to high-quality protein, is easy to digest and absorb, has low sodium content, is suitable for people who need the high-quality protein, elderly people with a low protein digestion function, and persons under rehabilitation; the protein powder with low contents of sodium, potassium and phosphorus is suitable for people suffering from chronickidney disease (CKD) and the like; the product also has the effects of resisting oxidation, lowering blood cholesterol, strengthening the body and enhancing immunity.

Owner:刘良忠

Production method for trepang beverage enhancing immunity

ActiveCN104068418AAbundant resourcesImprove use valueFood homogenisationFood ingredient functionsGingerolSea cucumber

The invention relates to a production method for a trepang beverage enhancing immunity. The production method is characterized in that fresh trepangs are used as raw materials to be processed into trepang pulp, and fig powder, Chinese flowering quince powder, glossy ganoderma powder and fresh ginger powder are matched; and processing steps of mixing, homogenizing, ultrasonic processing, filtering, homogenizing, degassing, filling and sealing, microwave disinfecting and packing are performed on the raw materials to prepare the trepang beverage. The formula of the trepang beverage is scientific, the mouth feel of the trepang beverage is good, the trepang beverage is easy for a human body to absorb, the nutrient efficacy of the trepangs is promoted, the disadvantages of the traditional trepang beverage are eliminated, the trepang beverage has an obvious nourishing effect for the human body, and the nourishing effect of the trepang beverage for aged and feeble people, people after illness, people after operation and women after parturition is more obvious, so that the trepang beverage is a high-efficient trepang beverage for enhancing immunity.

Owner:威海紫光科技园有限公司

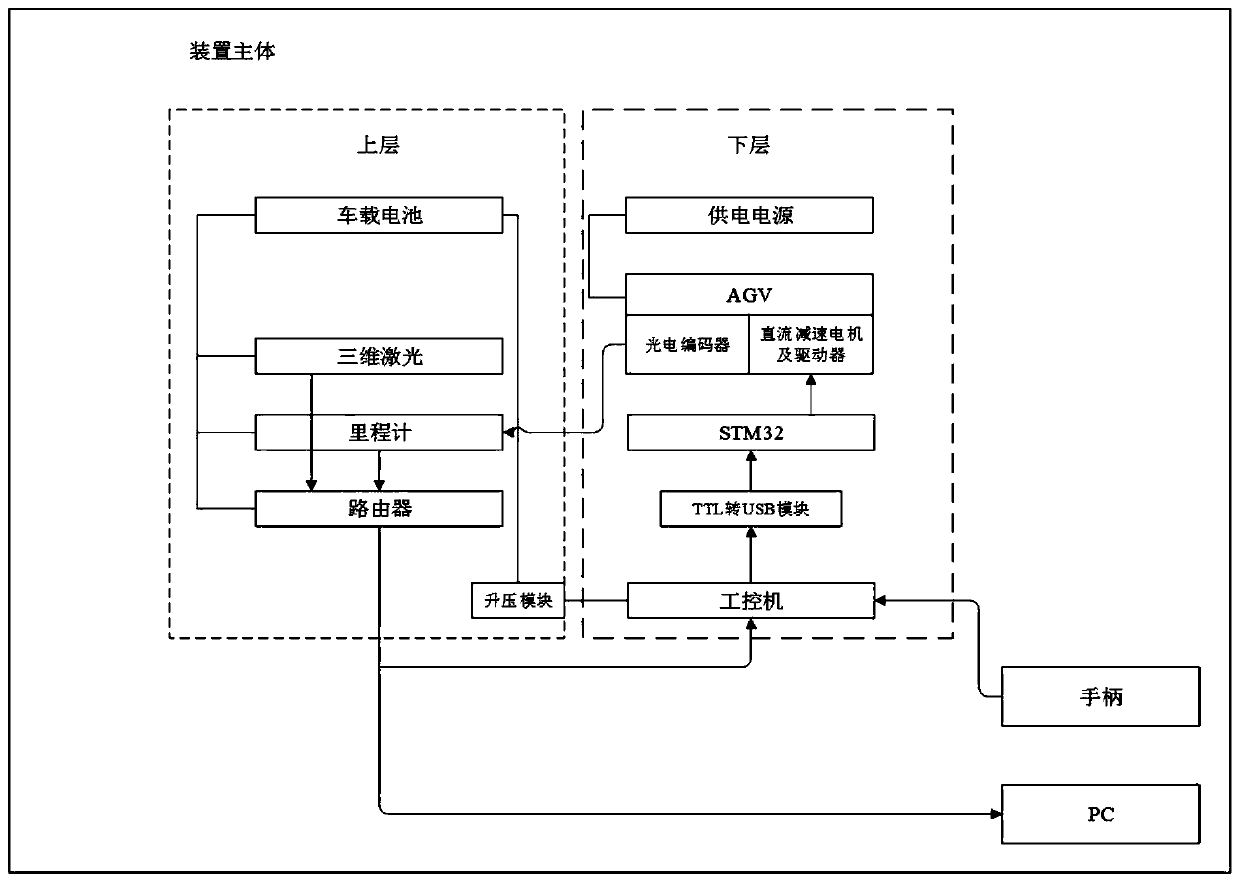

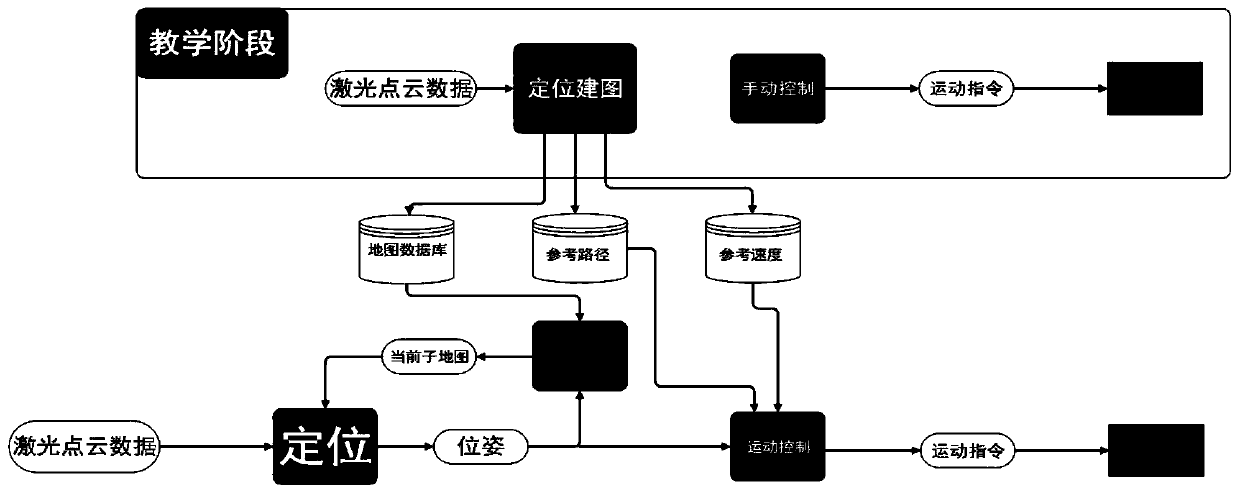

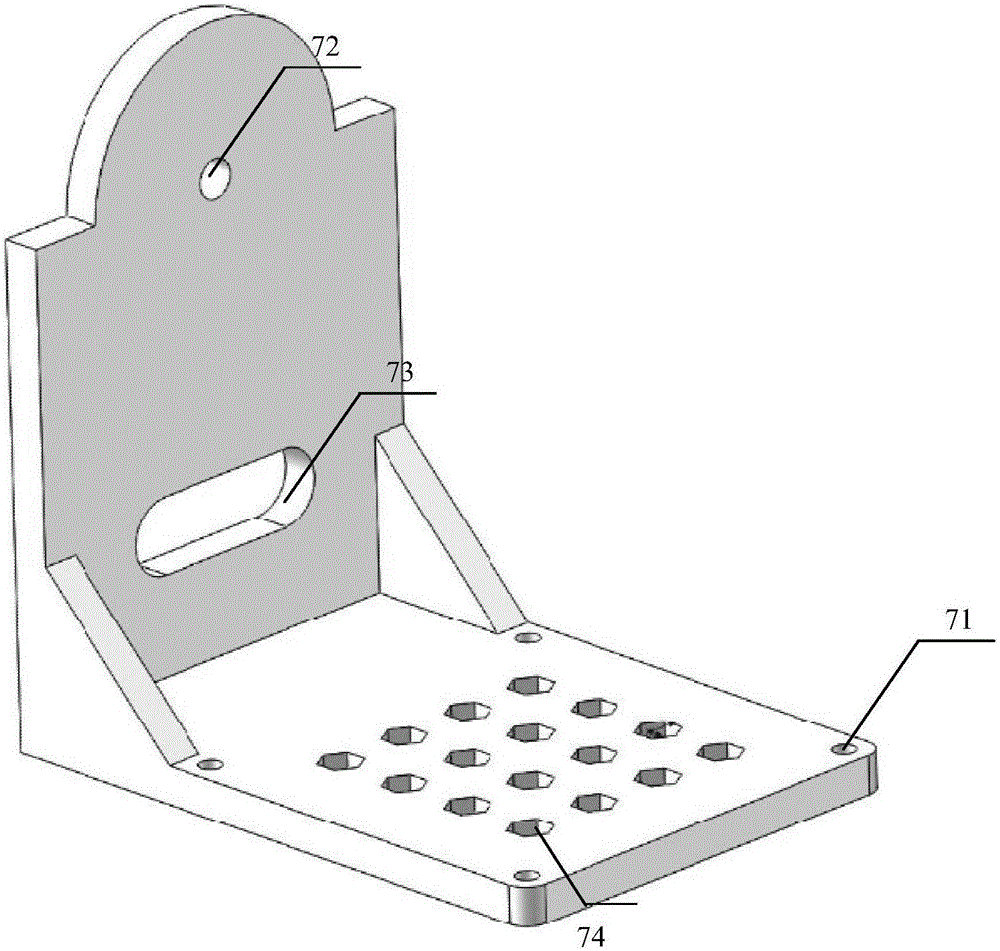

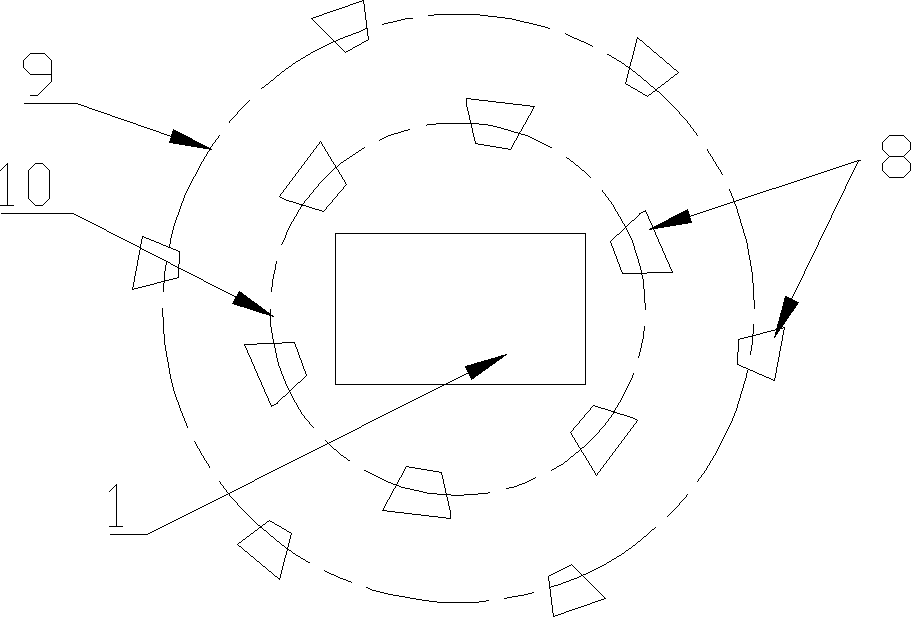

Mobile robot positioning navigation system and method based on teaching multi-sensor

InactiveCN110058594AEfficient use ofConstitute reasonablePosition/course control in two dimensionsVehiclesPoint cloudSimulation

The invention discloses a mobile robot positioning navigation system and method based on a teaching multi-sensor. The system comprises an upper navigation module, a lower motion control module, a handle and a computer; the handle provides an enabling effect of trolley motion control; the computer is used for monitoring and debugging a robot; the lower motion control module is used for realizing the motion control of a trolley platform, displaying trolley state information, and reading and transmitting encoder data; and the upper navigation module is used for acquiring point cloud data and speed data. The mobile robot positioning navigation system based on the teaching multi-sensor provided by the invention has the advantages that the structure is reasonable and concise, the method is convenient and fast, indoor AGV (Automated Guided Vehicle) navigation can be carried out quickly through the method, a non-specialized person is easy to use the method, the operation is simple, and the useis convenient. The calculation efficiency of the method of the system is high, and paths of any shape can be independently learned and traversed, and meanwhile, the speed and direction can be corrected according to three-dimensional laser data and position information provided by speedometer information.

Owner:NORTHEASTERN UNIV

Rice dumpling with reasonable food structure, reasonable energy and reasonable amino acid composition and rich in VA, calcium, iron, zinc and selenium

The invention discloses a rice dumpling with a reasonable food structure, reasonable energy and reasonable amino acid composition and rich in VA, calcium, iron, zinc and selenium. To realize the purpose above, the technical scheme provided by the invention is as follows: preparing following basic raw materials (are included in a basic recipe) in parts by weight: 15.0 parts of egg yolk, 7.0 parts of oyster, 6.5 parts of dry mussel, 2.5 parts of chicken liver, 15.3 parts of small fragrant dried bean curd, 20.0 parts of mung bean, 18.0 parts of indica sticky rice, 30.0 parts of black sticky rice, 10.0 parts of black rice, 1.0 part of konjac flavor powder, 27.3 parts of fresh chestnut, 7.0 parts of dehydration caraway, 4.0 parts of white granulated sugar, 0.5 part of chicken powder, 3.0 partsof fine salt, 8.0 parts of peanut oil and 4.0 parts of fructo-oligose. Raw materials (with functions of complementing yin deficiency, yang deficiency, tonifying Qi, enriching blood, helping digest and the like), such as 3.0 parts of tremella and 3.0 parts of dried lily bulb, or 3.0 parts of dried nut and 3.0 parts of barberry wolfberry fruit, or 3.0 parts of dried red dates and 3.0 parts of driedChinese yam, or 3.0 parts of longan pulp and 3.0 parts of black sesame, or 3.0 parts of poria cocos and 3.0 parts of pearl barley, or 3.0 parts of dried hawthorns and 3.0 parts of frutus amoni can berespectively added based on different dietary therapy functions.

Owner:唐山市华玉食品有限公司

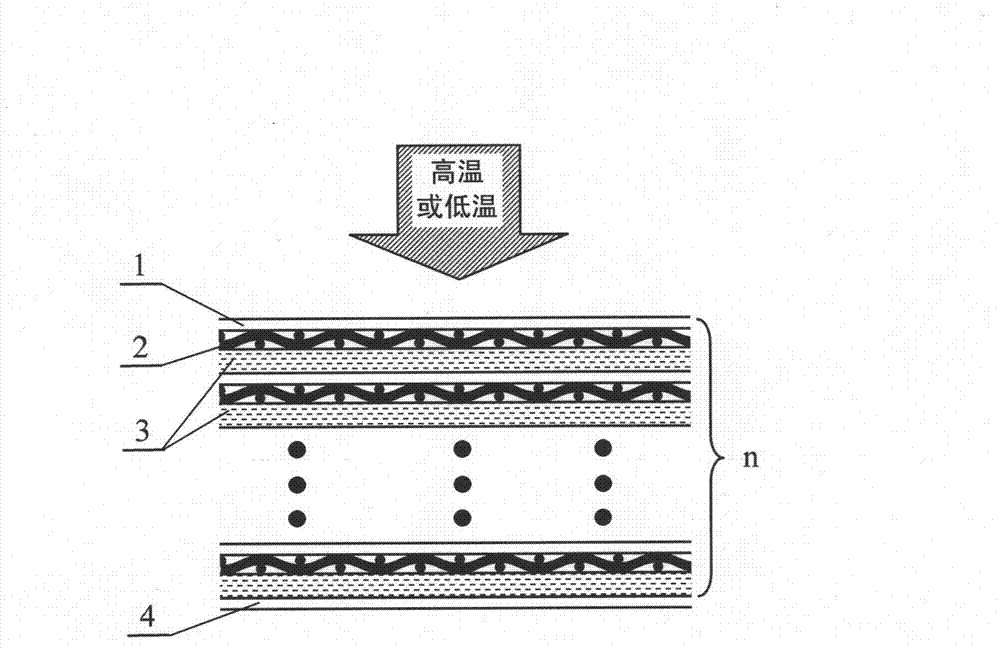

Enhanced heat-insulation composite film spaced by metal wire grating and application thereof

The invention relates to an enhanced heat-insulation composite film spaced by a metal wire grating and application thereof. The enhanced heat-insulation composite film consists of 3-20 layers of sandwich metal-plated high-polymer composite films which are spaced by parallel or orthorhombic metal wire gratings on fiber meshes. The enhanced heat-insulation composite film is characterized in that one side of the enhanced heat-insulation composite film can bear the effect of high temperature and low temperature within negative 250DEG C to 250DEG C, the other side of the enhanced heat-insulation composite film is kept to be at 5-40DEG C normal temperature, the enhanced heat-insulation composite film is a multilayer composite material which can realize rapid and even heat distribution, heat insulation and warmth keeping, the natural thickness is 4-20mm, the actual compact thickness is 1-8mm, the weight per square meter is 40-800g / m<2>, and the enhanced heat-insulation composite film is a fully-closed bonded or sewn heat-insulation, warmth-keeping soft enhanced heat-insulation composite film. The enhanced heat-insulation composite film can be solely used or can be combined with other materials and be used for human body protection and environmental heat insulation of high-temperature and low-temperature occasions such as firefighting, military, exploration and industry.

Owner:DONGHUA UNIV

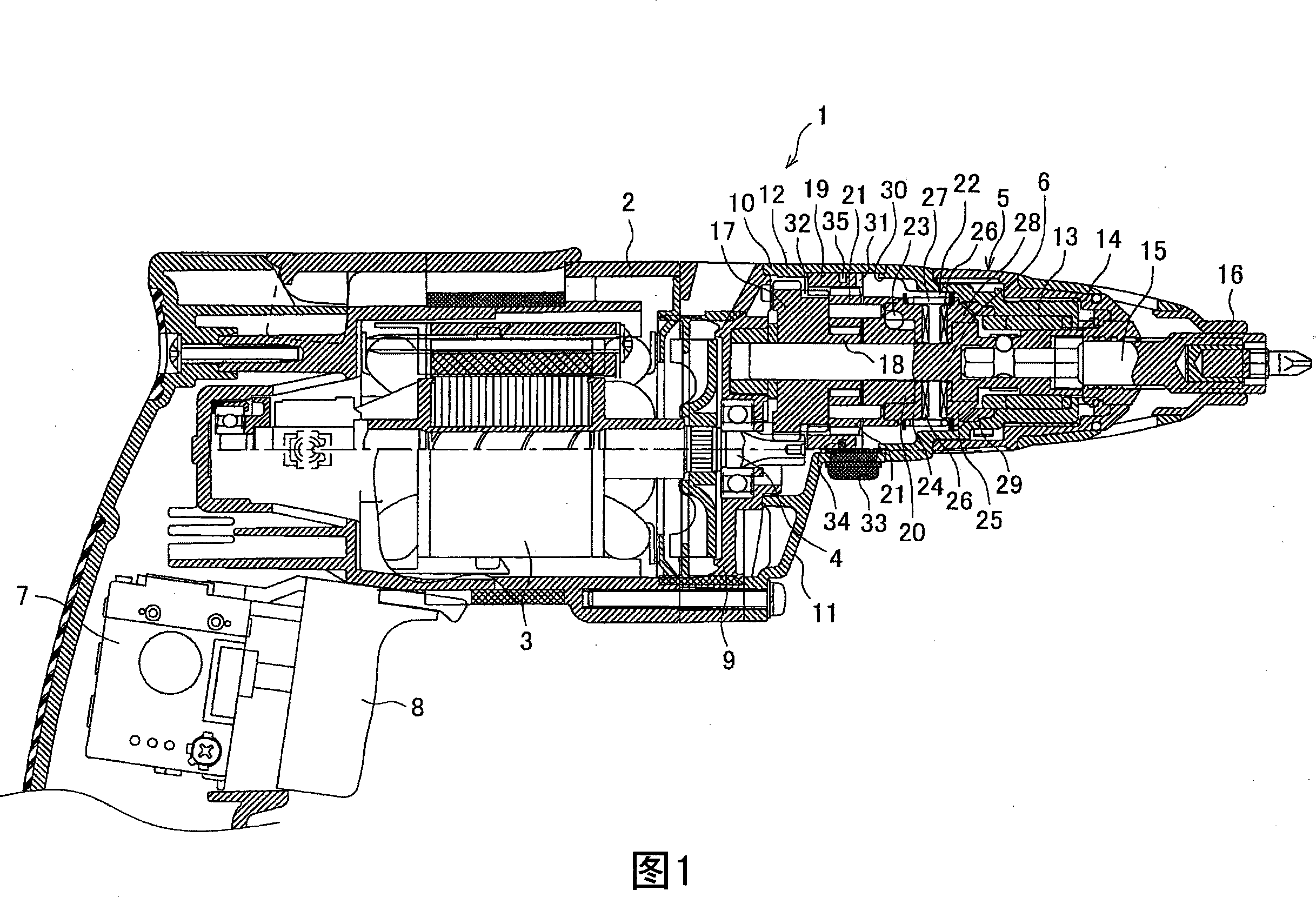

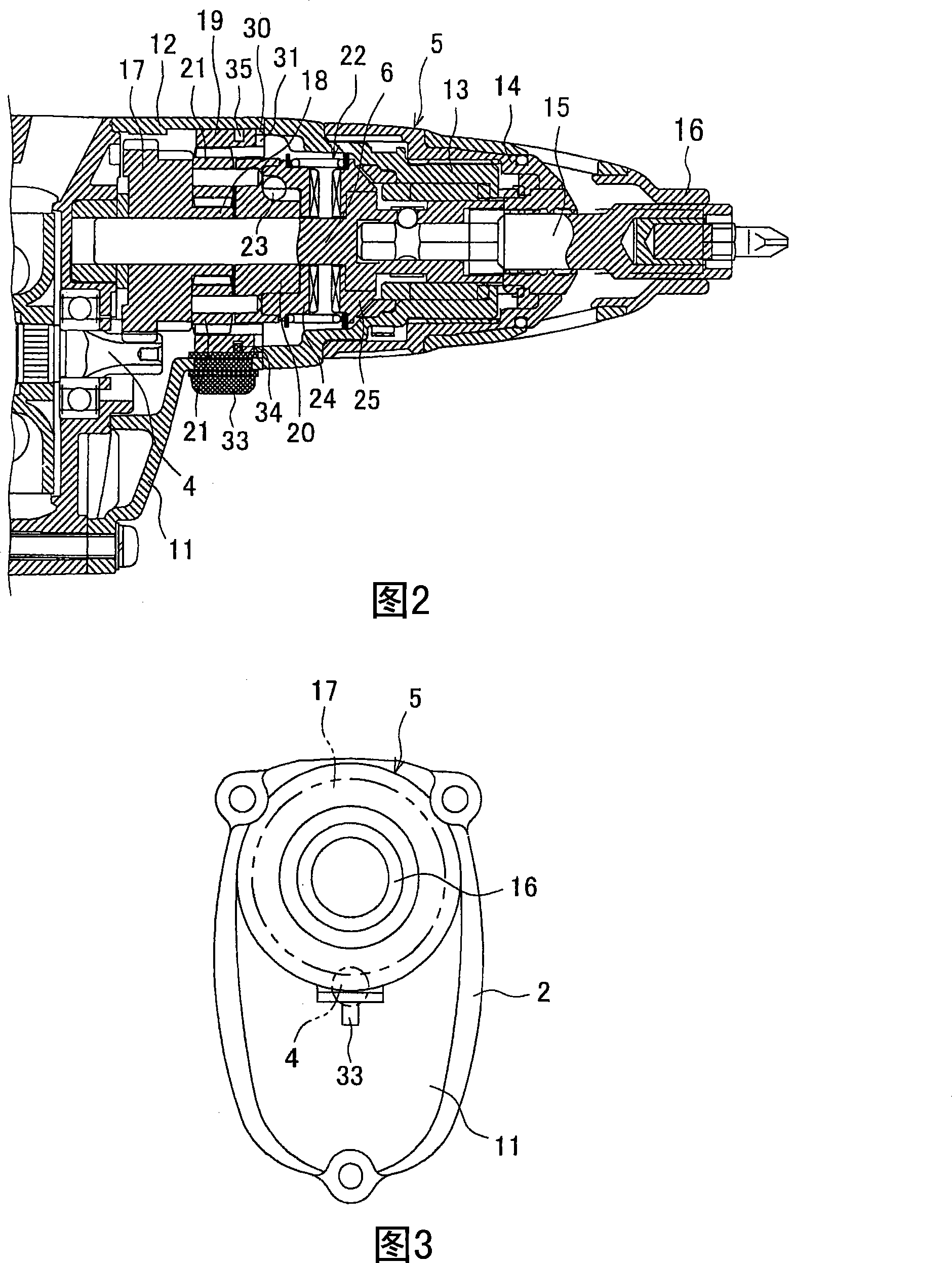

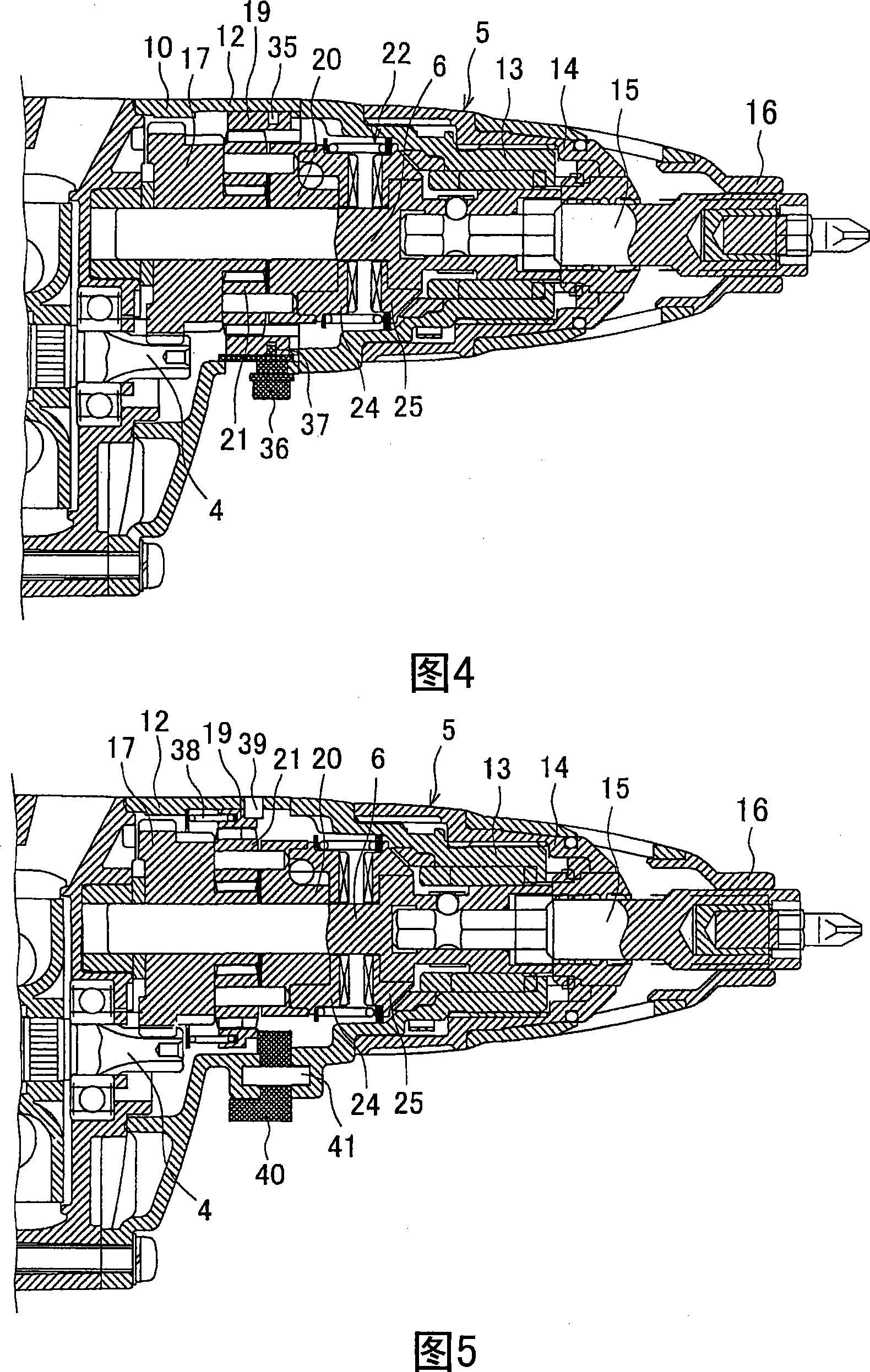

Screwdriver

InactiveCN101200056AAchieve compactnessGood workabilityPortable power-driven toolsPower driven toolsClutchGear wheel

The present invention provides a screw driver, realising compaction of the case and proceeding deceleration and two stage speed change at the same time. A planetary gear frame (20) is between a second gear (17) and a clutch mechanism (22), the planetary gear frame (20) has a planetary gear revolving motion in the inner gear (19) around a rotary center of the output (18) of the second gear (17), in another aspect, the inner gear is set by rotating in the front case (5) and moving between the back position and the front position, in the back position, the inner gear (19) is clamped with the output (19) to directly connect the second gear (17) and the planetary gear frame (20), in the front position, the inner gear (19) is separated with the output (18), and clamped with the clamping part (30), to limit rotation, a gear shift button (33) is set in the front and the back for switching the inner gear on the front case.

Owner:MAKITA CORP

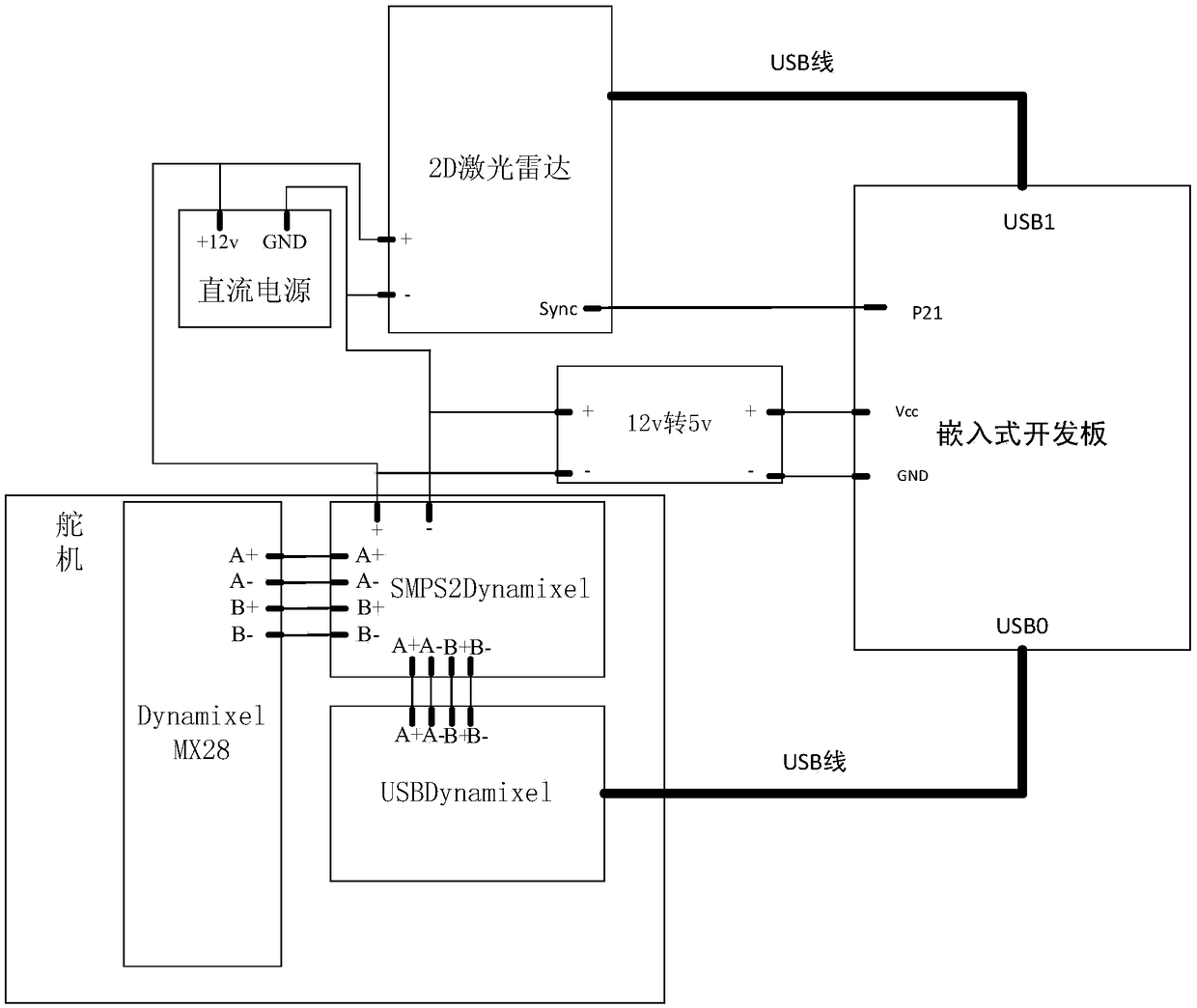

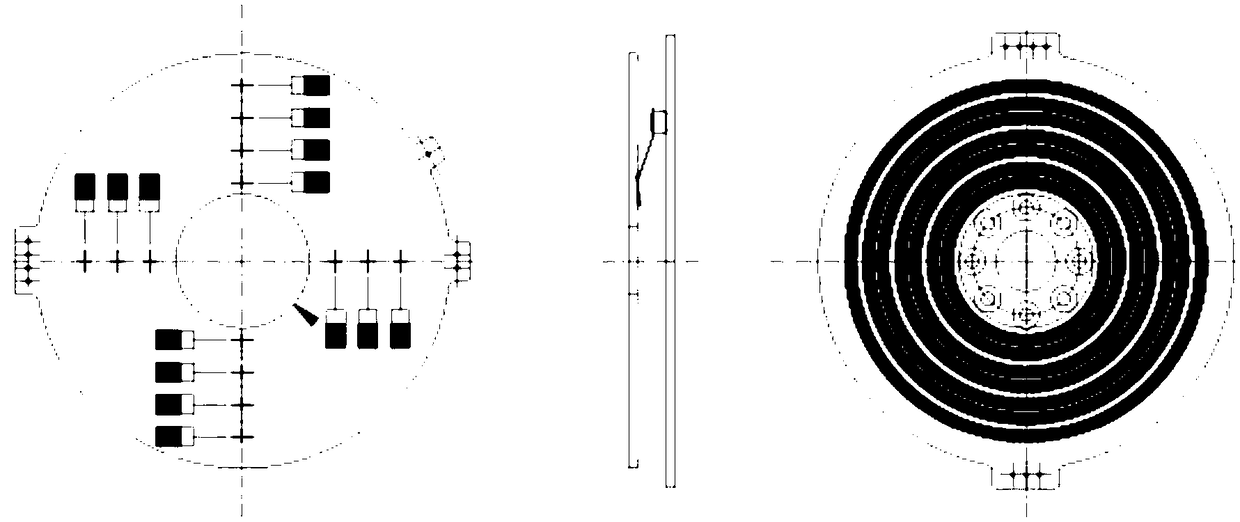

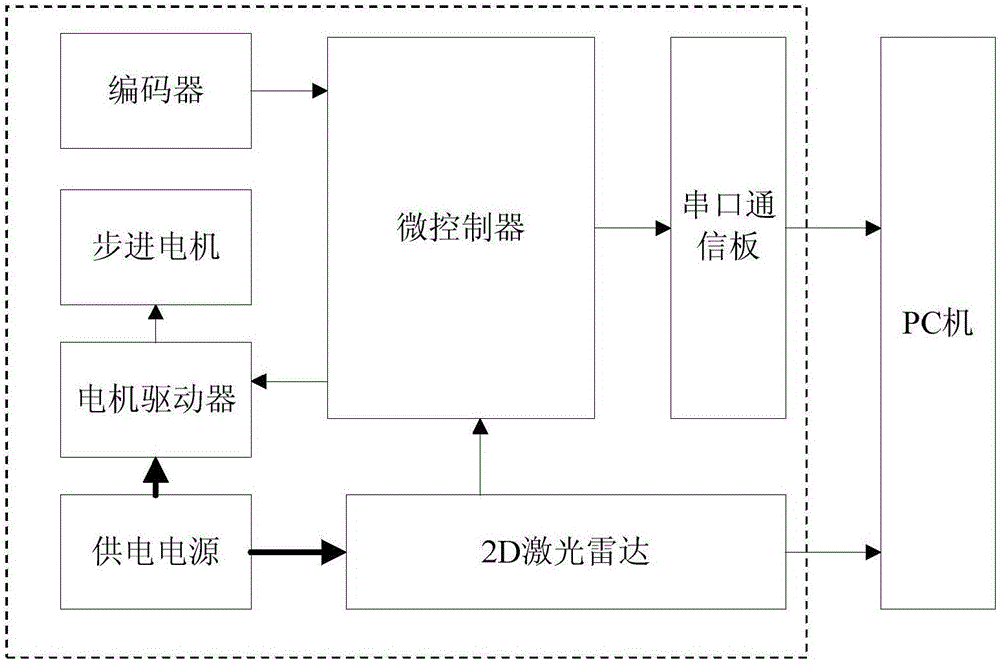

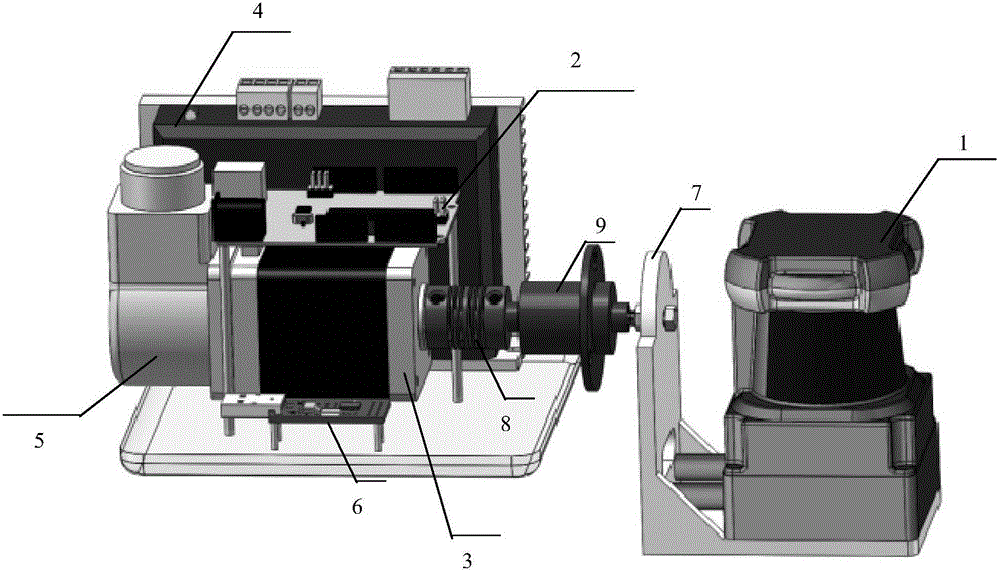

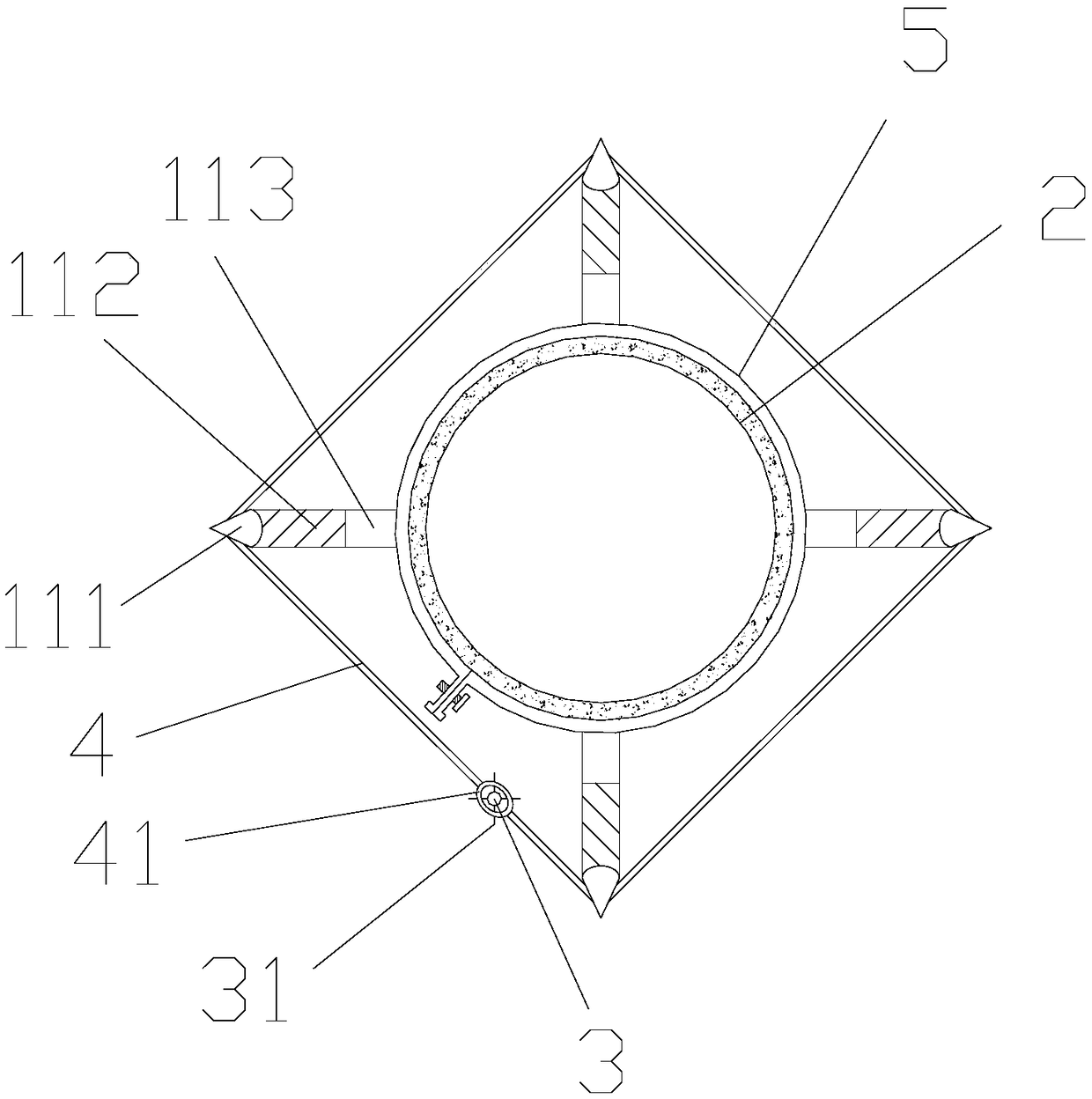

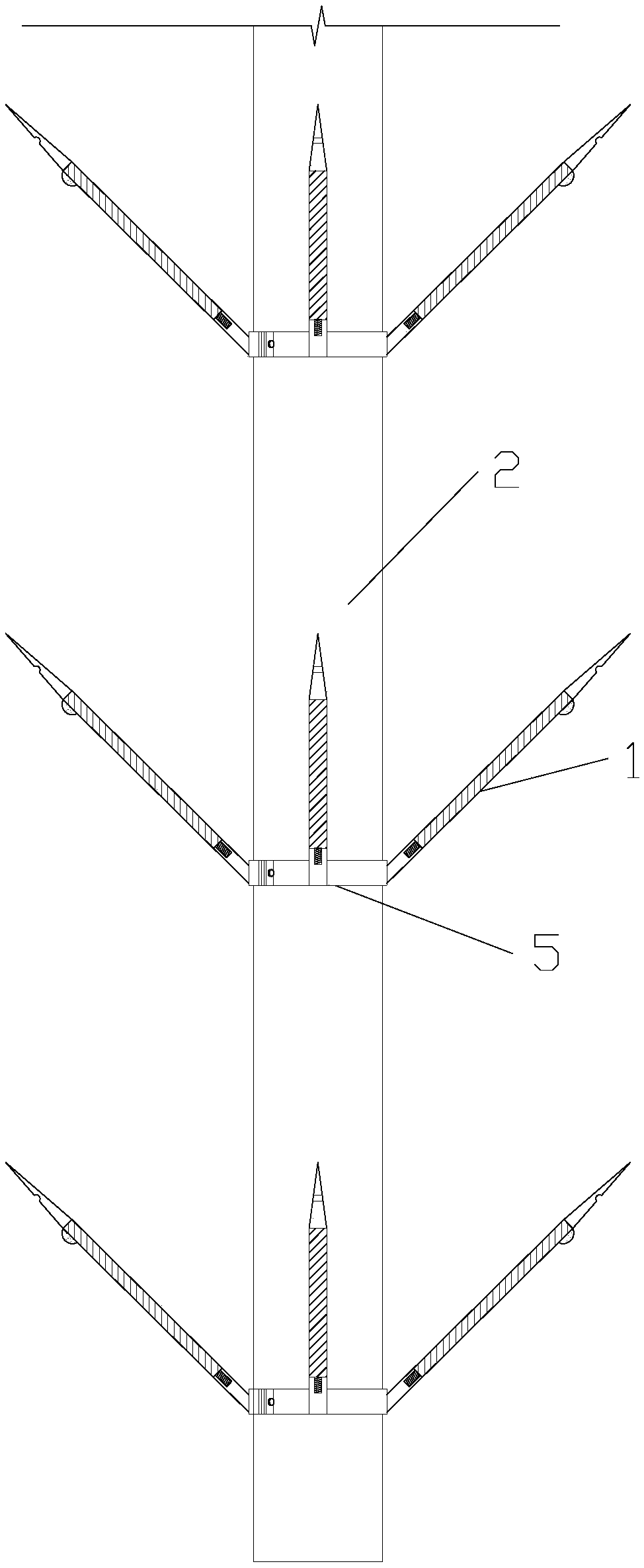

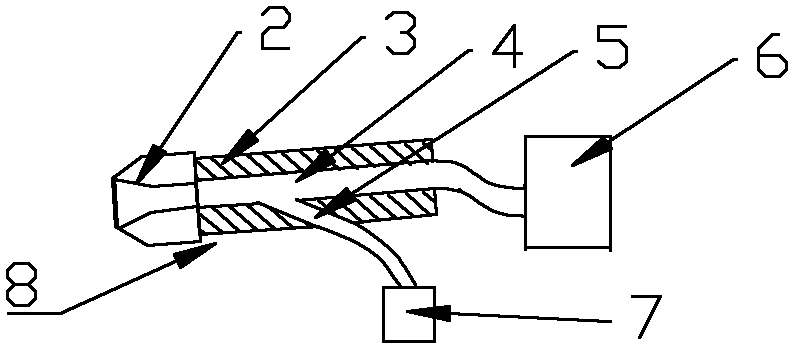

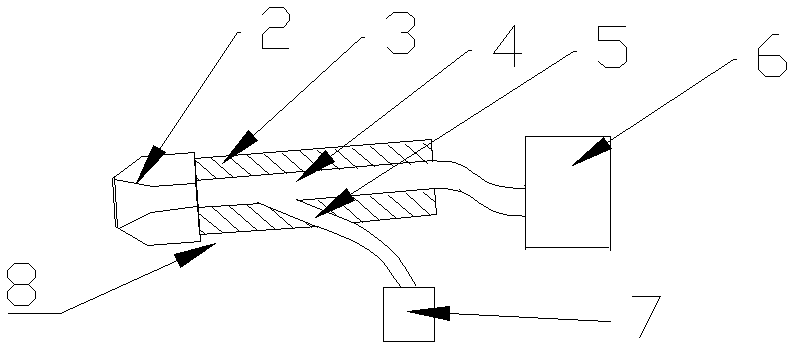

Portable three-dimensional scanning device based on 2D laser radar

InactiveCN105866793AConstitute reasonableSimple compositionElectromagnetic wave reradiationMicrocontrollerRadar

The invention provides a portable three-dimensional scanning device based on a 2D laser radar. The portable three-dimensional scanning device based on the 2D laser radar comprises the 2D laser radar, a microcontroller, a stepping motor, a motor driver, an encoder, a serial port communication board, a power supply, a conductive slip ring and a PC, wherein an output end of the encoder and a synchronous signal end of the 2D laser radar are connected with a data input end of the microcontroller; a data output end of the microcontroller is connected with an input end of the serial port communication board; a control end of the microcontroller is connected with an input end of the motor driver; an output end of the motor driver is connected with an input end of the stepping motor; a data output end of the serial port communication board is connected with the PC through a USB concentrator; a data output end of the 2D laser radar is connected with the PC through the conductive slip ring and the USB concentrator; and a power end of the motor driver and a power end of the 2D laser radar are connected with the power supply. The portable three-dimensional scanning device based on the 2D laser radar is reasonable and simple in composition and speedy and convenient to use, can perform three-dimensional scanning quickly, and is low in cost, simple to operate and convenient to use.

Owner:NORTHEASTERN UNIV

Preparation method of solid beverage for maintaining men's health

The invention discloses a preparation method of a solid beverage for maintaining men's health. The method is characterized by making fresh sea cucumber and fresh oyster meat into small molecular sea cucumber oyster powder, then compounding the small molecular sea cucumber oyster powder with a Chinese yam extract, a Gorgon fruit extract, a cinnamon extract, a raspberry extract, a ginkgo biloba extract, malt powder, tomato powder, ginseng powder, a cordyceps militaris extract, broken pine pollen, stevia rebaudiana powder and zinc gluconate, and conducting ultrafine mixing, granulation and packaging, thus obtaining a solid beverage. The invention is guided by the "kidney tonifying oriented" traditional Chinese medicinal theory, and adopts kidney vigorousness and failure as the main line to discuss the beverage for maintaining men's health and the preparation method thereof. A small molecular sea cucumber oyster hydrolysis product extracted by a modern biological technology is organically combined with nutritional and health care components, the health efficacy of each component is optimized, at the same time multiple demands of men's health are covered, and the effects of enhancing male vitality, resisting oxidation, preventing aging, protecting vascular endothelial cell and delaying cell senescence.

Owner:WEIHAI XINYI BIOLOGICAL TECH

No-sucrose moon cake containing soy protein and manufacturing method thereof

InactiveCN101669537AGood for healthReasonable formulaDough treatmentBakery productsAlkaline waterSucrose

The invention relates to a no-sucrose moon cake containing soy protein and a manufacturing method thereof. The no-sugar moon cake comprises the following raw materials based on parts by weight: cladding: 25-45 parts of plain flour, 5-25 parts of soy protein, 5-20 parts of vegetable oil, 25-45 parts of no-sugar syrup and 0.2-0.8 portion of alkaline water; and fillings: 60 parts-90 parts of merchantno-sugar cantonese moon cake fillings, 5-25 parts of soy protein, 2-15 parts of vegetable oil and 3-18 parts of no-sugar syrup. The manufacturing method of the moon cake comprises the following steps: first, emulsifying oil, syrup and alkaline water needed in the cladding, then adding the emulsified oil, syrup and alkaline water into flour and soy protein which are mixed evenly, kneading the mixture into dough, and fermenting 20-30 minutes for spare; weighing all the ingredients of the fillings based on parts by weight, and fully and evenly stirring for spare; firstly manufacturing moon cakeembryo according to the ratio of the cladding and the fillings of 3:7, 2:8 or 1:9, and pressing and forming; brushing egg liquid, with the baking temperature of 170-220 DEG C; and finally heat-sealingand packaging. The invention adds the optimal soy protein into the formula of the moon cake, does not add sucrose, and manufactures a moon cake which is more beneficial to body health, leads people not only to inherit the traditional custom, but also supplement nutrition when people eat the moon cake.

Owner:天津实发冠华生物科技有限公司

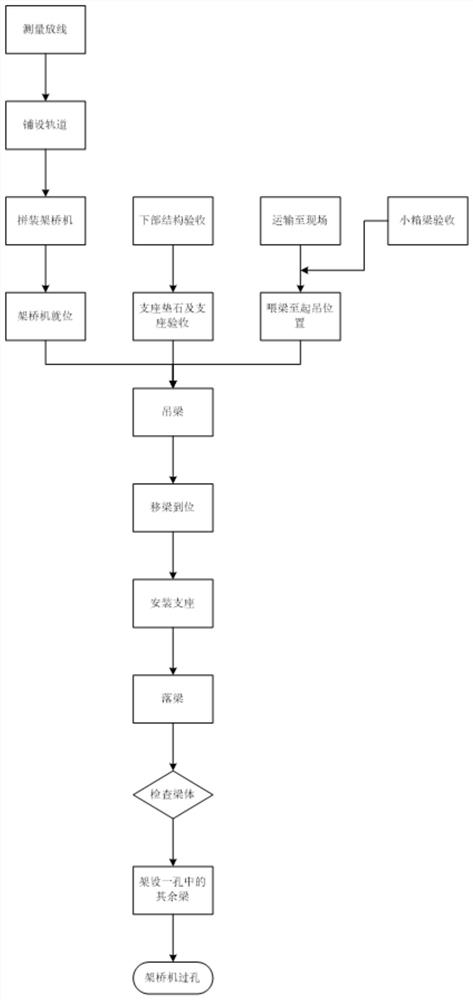

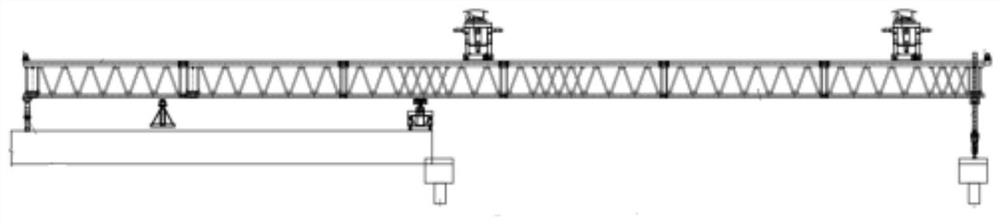

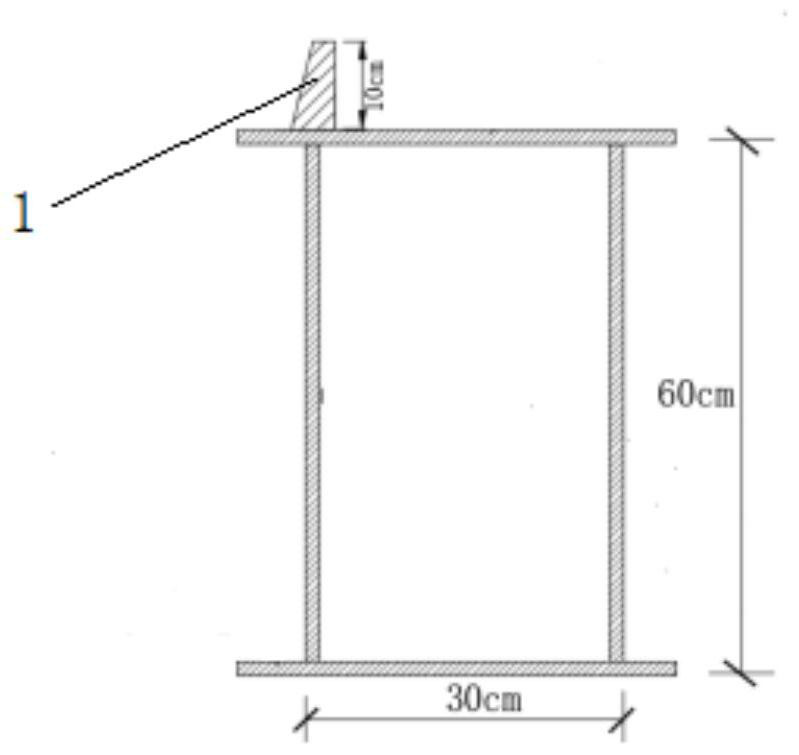

Construction method for prefabricated box girder support in complex city environment

PendingCN113957793AEasy to transportSimple structureBridge erection/assemblyBridge engineeringArchitectural engineering

The invention discloses a construction method for a prefabricated box girder support in a complex city environment, and belongs to the technical field of bridge engineering, and the construction method comprises the following steps: S1, carrying out surveying and setting out; S2, laying tracks, and assembling a bridge girder erection machine; S3, enabling the bridge girder erection machine to erect the box girder in a high-low mode; S4, mounting a support; S5, fixing the box girder; S6, carrying out bridge deck girder feeding and box girder erection of the bridge girder erection machine; and S7, performing crossing of the bridge girder erection machine. The truss double-beam bridge girder erection machine is adopted, a main truss of the bridge girder erection machine adopts standing rod pieces, transportation is convenient, the assembling and disassembling speed is high, the cost is saved, the machining period is shortened, high-low hoisting construction is adopted, a girder lifting station is not arranged, box girders are transported to the erection position through an offline transport vehicle, and the bridge girder erection machine directly lifts and erects the girders; a girder is lifted in the middle of an erection pier position, the mode that the front portion is high and the rear portion is low is adopted, box girders are lifted and longitudinally moved through a crane carriage, 1-2 spans are installed through a crane before a bridge girder erection machine is installed, and installation of the bridge girder erection machine is facilitated.

Owner:中能建建筑集团有限公司

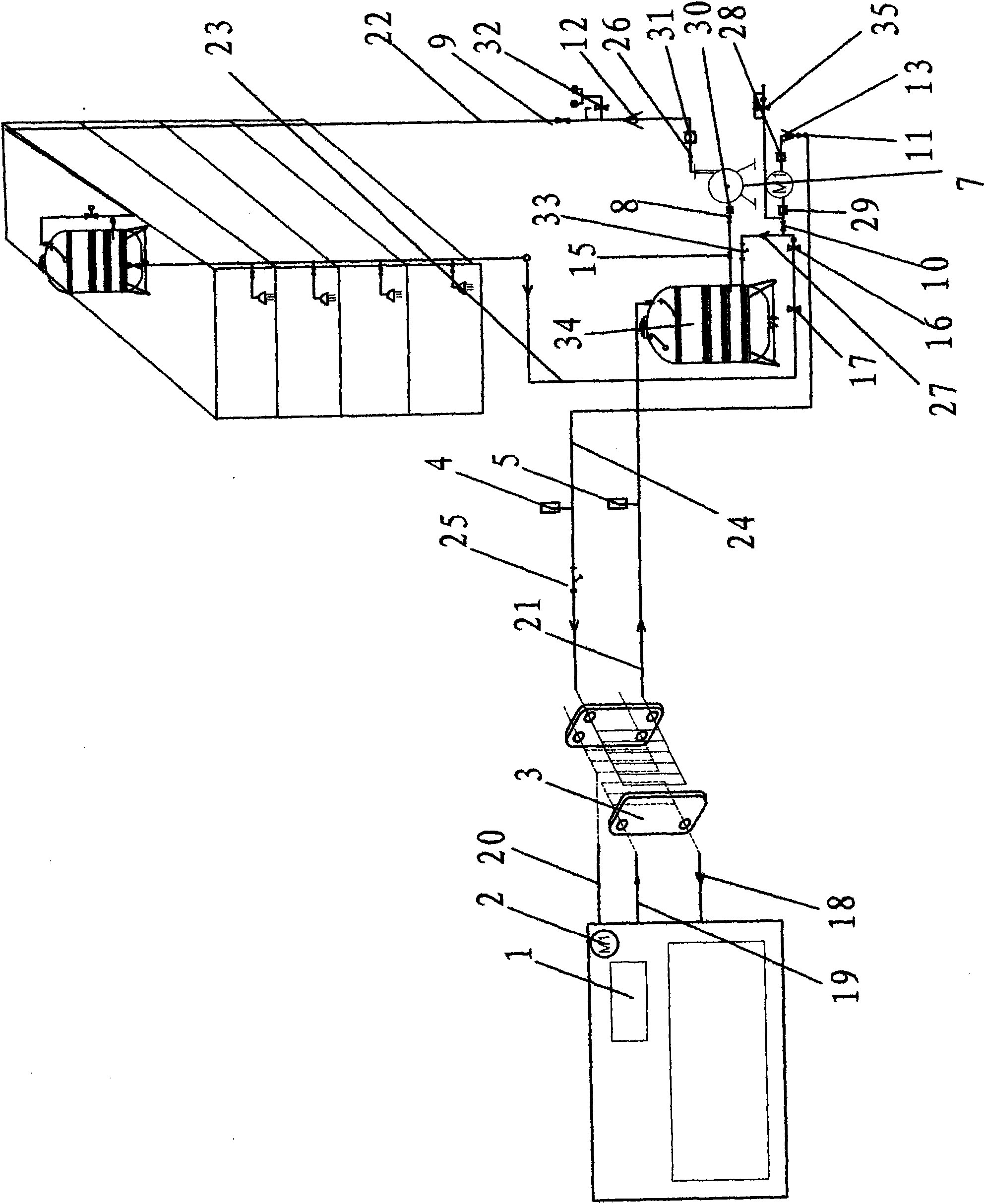

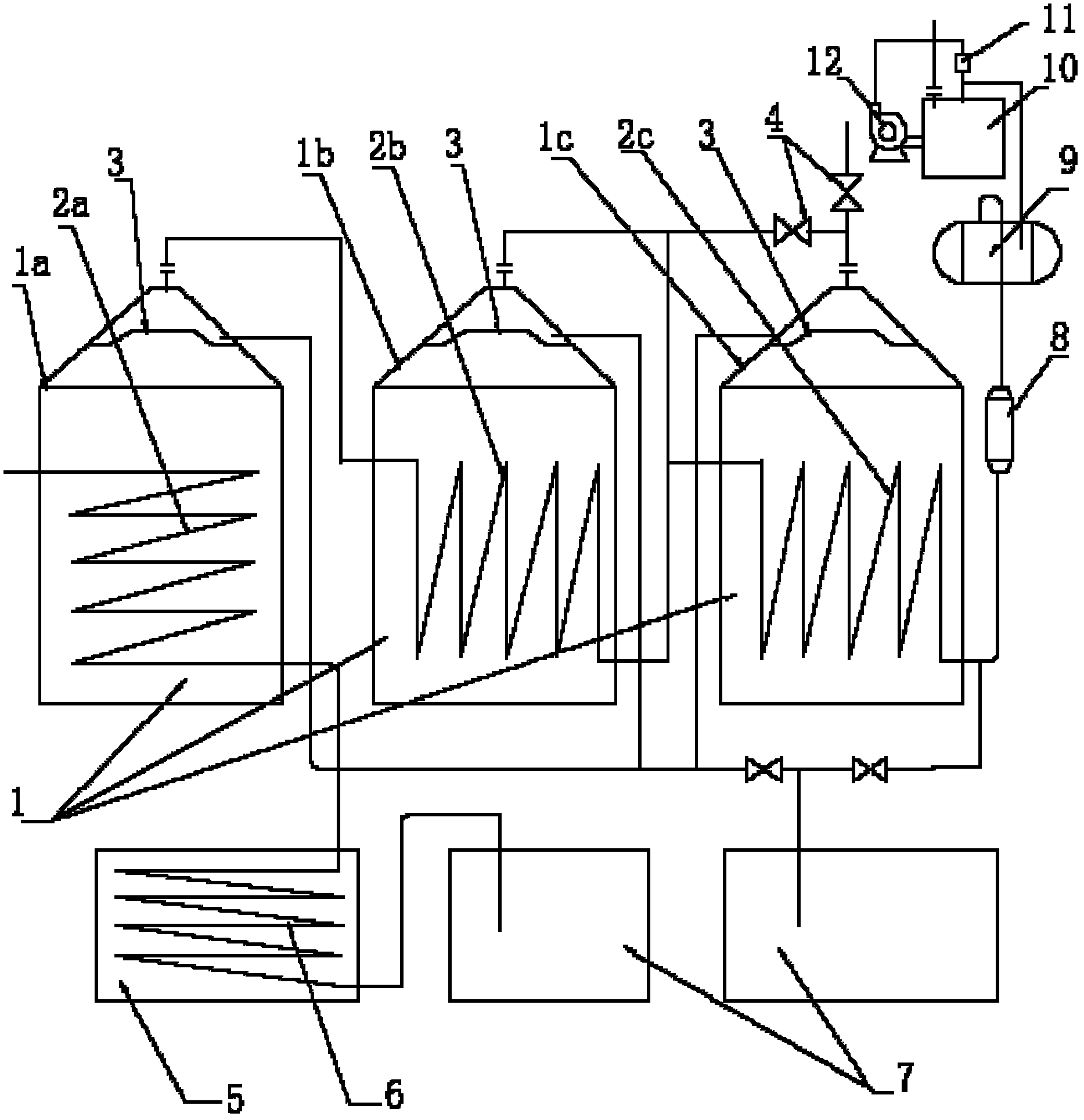

Waste heat recycling system of air compressor

InactiveCN101526076AConstitute scienceConstitute reasonablePositive displacement pump componentsPositive-displacement liquid enginesWater storageGas compressor

The invention relates to a waste heat recycling system of an air compressor, consisting of a heat exchanger, a pipeline, a water pump, a valve, a water storage device, a ball cock and a thermometer. The heated radiating circular medium in a radiator of the air compressor is connected with a heat source inlet of the heat exchanger by the pipeline; a heat source outlet of the heat exchanger is connected with a reflux port of the radiator of the air compressor by the pipeline; a cold water outlet of the heat exchanger is in series connected with the thermometer and then connected with a water inlet of the water storage device; the water storage device is provided with two water outlets; one water outlet is connected with a water inlet of the water pump by the valve; a water outlet of the water pump is sequentially connected with a check valve and the valve; and the valve is connected with a user by the pipeline. The invention has the advantages of scientific and reasonable system construction, and the like, not only can achieve heat recovery, but also has high recovery efficiency, can save large amount of heat sources, and has considerable economic benefits and wide popularization and application values.

Owner:东莞市中日盛达压缩机有限公司

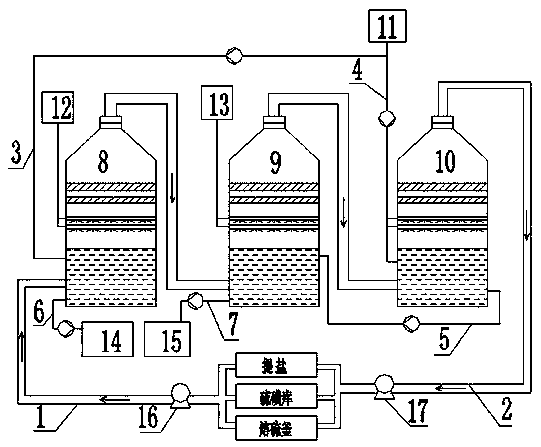

Mother liquor evaporation system

InactiveCN102489028ASimple system configurationIncrease productivityMultiple-effect evaporationAluminium oxides/hydroxidesMother liquorMulti effect

The present invention discloses a mother liquor evaporation system with good evaporation effect, high production efficiency and low energy consumption. The mother liquor evaporation system comprises evaporators which are composed of a tank and a heat exchanger provided in the tank, an evaporation system is composed of the evaporators, the evaporation system is a multi-effect evaporation system constituted by a plurality of evaporators, in the evaporators of the multi-effect evaporation system, an outlet of the tank of the front evaporator tank is connected to an inlet of the heat exchanger of the rear evaporator; steam passes through the heat exchanger, the one effect evaporator introduces steam for once, the subsequent evaporators successively introduce secondary steam which can be taken as a heat exchange medium.

Owner:赵晨

Sea cucumber compressed tablet candy capable of enhancing immunity with high efficiency

InactiveCN104686768AAbundant resourcesImprove use valueConfectionerySweetmeatsBiologically active substancesSuperfine grinding

The invention relates to a sea cucumber compressed tablet candy capable of enhancing immunity with high efficiency, which is characterized in that fresh sea cucumber is taken as a raw material for processing to obtain sea cucumber freeze-drying powder, a fig extract product, a grosvenor momordica fruit extract product, Chinese yam powder, pawpaw powder and ginger powder are cooperated, and steps of mixing, superfine grinding, soft material preparation, granulation, tabletting, examination and packaging are carried out to obtain the product. According to the invention, precious resource such as sea cucumber is organically combined with a modern biology technology, sea cucumber nutrition efficacy is lifted and developed, so that the compressed tablet candy has the advantages of abundant nutrition component and biologically-active substance, easy absorption by human body, convenient eating and carrying, good mouthfeel, immunity enhancement with high efficiency.

Owner:WEIHAI XINYI BIOLOGICAL TECH

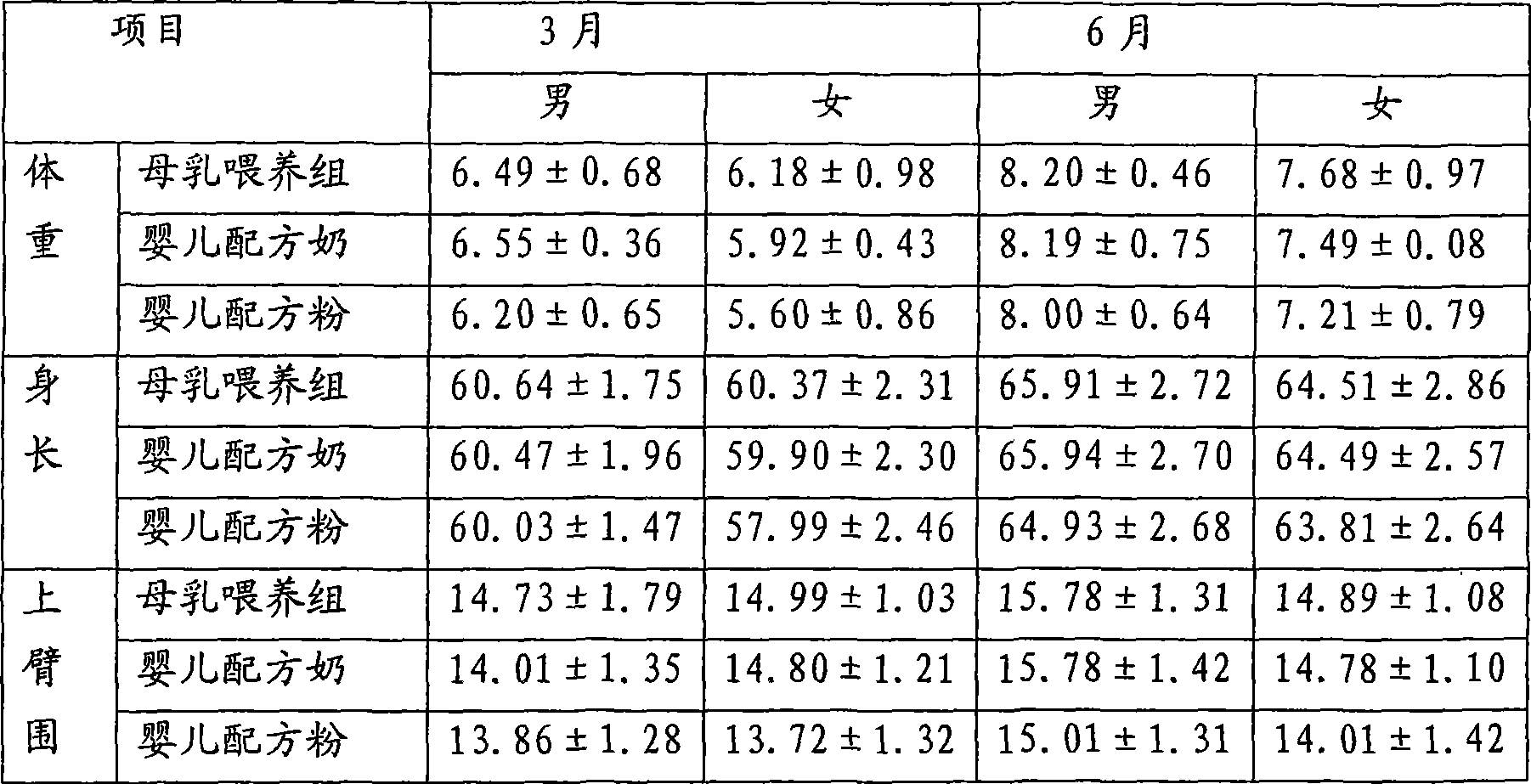

Liquid milk with additive arachidonic acid suitable for baby of 0 to 6 months old

InactiveCN101427797AConstitute reasonableImprove bioavailabilityMilk preparationFood preparationCow milkingAdditive ingredient

The invention relates to milk and a preparation method thereof, in particularl to infant liquid milk supplemented with arachidonic acid (AA) suitable for newborn to 6 months babies, which belongs to the technical field of dairy products. The ingredients (in weight ratios) of the infant liquid milk are as follows: 200Kg to 500Kg of cow milk, 1Kg to 10Kg of whey protein concentrate 34 (whey protein content of 33%), 20Kg to 100Kg of desalted whey powder D70 (whey protein content of 12%), 20Kg to 100Kg of vegetable fat powder, 1Kg to 10Kg of lactose, 100g to 500g of vitamin complex, 200g to 600g of complex minerals, 1Kg to 8Kg of stabilizers, 300Kg to 700Kg of water, and 0.1Kg to 1Kg of arachidonic acid (AA). The infant liquid milk has balanced nutrition and fine and smooth mouthfeel, is easy to absorb, and can meet the needs for normal growth and development of infants and simultaneously promote the intelligence development of infants.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

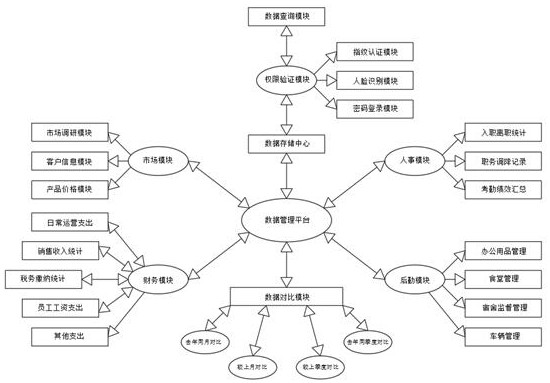

WEB-based enterprise data analysis system and analysis method thereof

PendingCN112418741AStable and safe to workConstitute reasonableFinanceDigital data authenticationBusiness enterpriseData acquisition

The invention discloses a WEB-based enterprise data analysis system and an analysis method thereof, the analysis system comprises an analysis system and an analysis method, the analysis system is mainly composed of a data management platform, a market module, a financial module, a personnel module, a logistics module, a data comparison module, a data storage center, an authority verification module and a data query module, the analysis method is mainly composed of market module analysis, financial module analysis, personnel module analysis, logistics module analysis, data comparative analysisand data storage and query. According to the WEB-based enterprise data analysis system and the WEB-based enterprise data analysis method, detailed data acquisition is performed on market areas, financial data, personnel mobilization and logistics of enterprise operation, and through comparison with past data, health conditions of enterprise development and problems needing to be improved are comprehensively analyzed, and enterprises can develop more stably and efficiently.

Owner:广西云牛动力网络科技有限公司

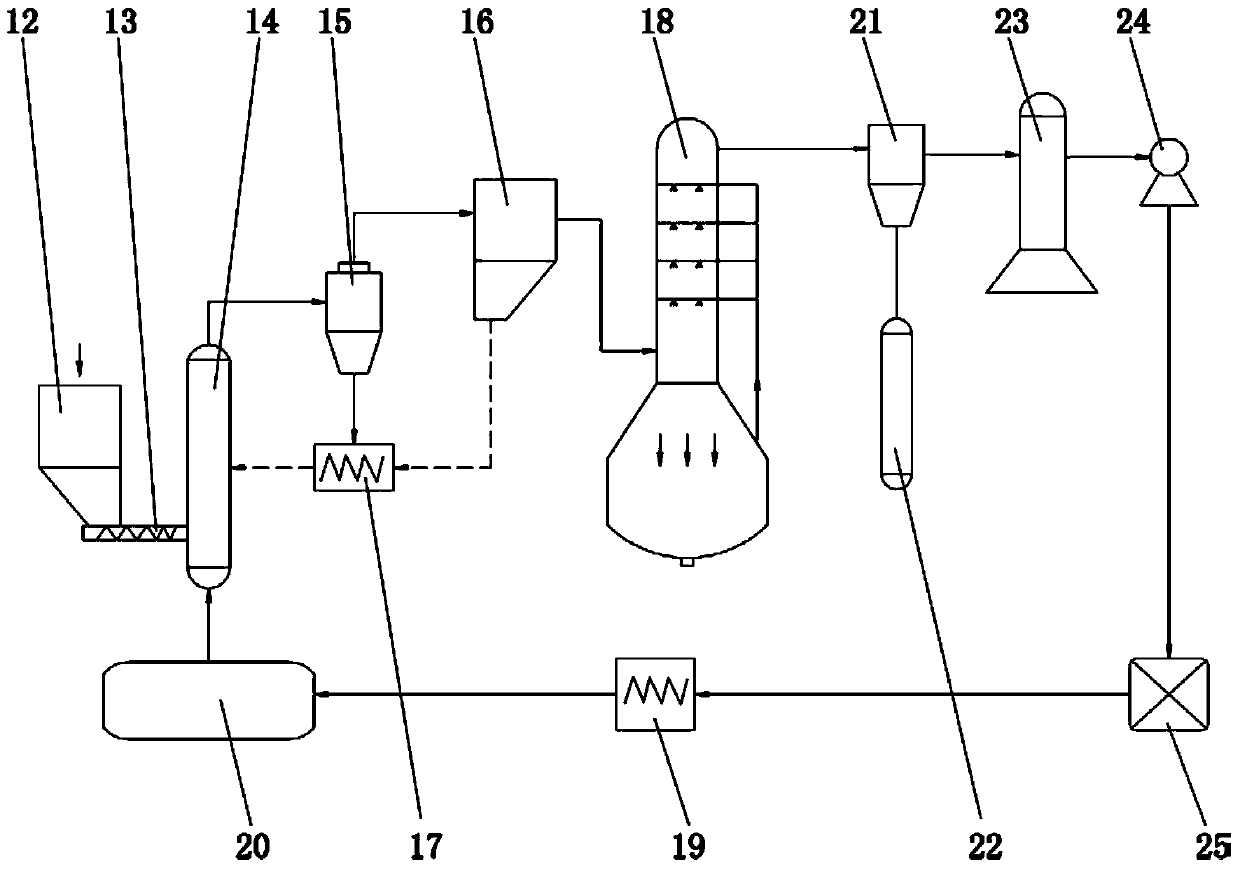

Ecological oil condensing tower and preparation system thereof

InactiveCN103463830AWith circulating cooling functionIncrease productivityVapor condensationLiquid hydrocarbon mixture productionTowerOil storage

The invention discloses an ecological oil condensing tower and a preparation system thereof. The condensing tower is composed of a tower body and a tower bottom, wherein the lower end of the tower body is provided with an air inlet and is connected with a gas-solid separator, and the upper end of the tower body is provided with an air outlet and is connected with an oil-gas separator; a plurality of spray pipes which are provided with spray heads and are horizontally arranged are penetrated in the wall body of the tower body; a pipeline is connected between the spray pipes of the tower body and the tower bottom. The condensing tower in the preparation system is integrated by the tower body and the tower bottom, and an oil storage tank and pipeline parts are omitted, so that the system is simpler and more reasonable in structure; the condensing tower does not depend on external circulation because of having a circulation cooling function, so that the production efficiency of ecological oil is increased.

Owner:GUANGZHOU DEVOTION THERMAL TECH

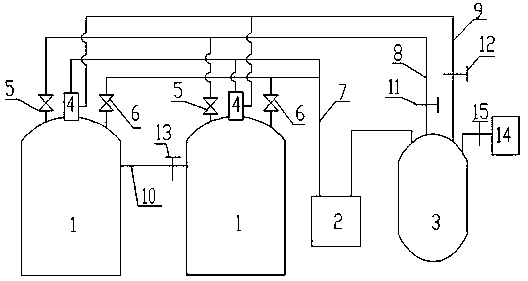

Pressure-maintaining and tail gas treating method and device for material tank of coking plant

PendingCN109185700AIncreased security measuresTo achieve the purpose of maintaining pressureFluid handledContainer discharging methodsProcess systemsGas compressor

The invention discloses a pressure-maintaining and tail gas treating method and device for a material tank of a coking plant. The pressure-maintaining and tail gas treating method is characterized inthat tail gas and nitrogen gas in the material storage tank are compressed and stored to a high-pressure gas tank through a gas compressor for later use; tail gas and nitrogen gas do not need to treatand emit; a material slot tank is equipped with a pressure sensor; operation is performed by detecting gas pressure in the material storage tank in real time; when gas pressure is too low, a pipelinefor connecting the high-pressure gas storage tank to the material slot tank supplements pressure to the material slot tank, so that the material slot tank is prevented from pressure loss; when pressure in the material slot tank is too great, the gas compressor is started, the material storage tank and gas compressor pipelines are opened for compressing tail gas and nitrogen gas in the material storage tank into the high-pressure gas storage tank to release pressure of the material slot tank, so that tail gas and nitrogen gas generated in the material slot tank are intensively collected and used, and are compressed, stored or replenished to the material slot tank through a sealed circulating hoop; pressure-maintaining gas is the same as gas in the material storage tank, and other media arenot introduced, so that the whole process system and device is reasonable in configuration; and resources of the coking plant are utilized to the greatest extent in case of not increasing energy consumption or slightly increasing energy consumption, so that energy is saved and consumption is reduced.

Owner:山东环达环保科技有限公司

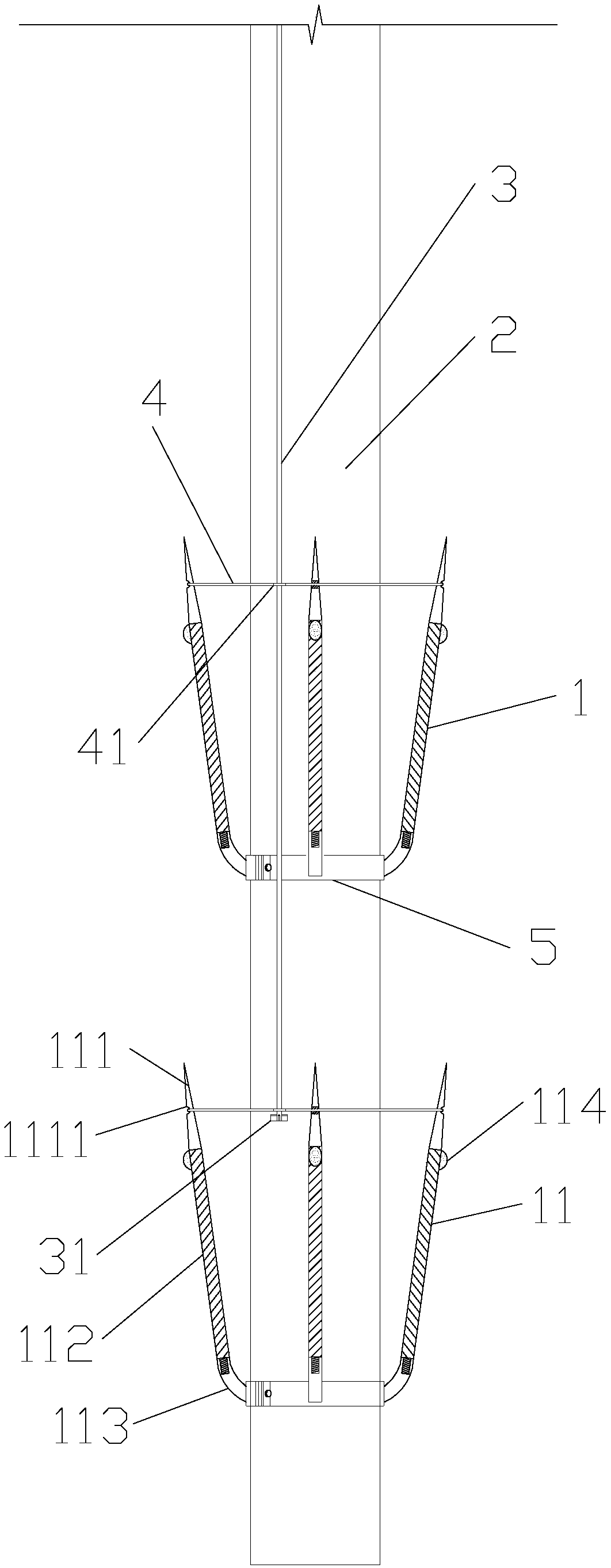

Sleeve valve pipe capable of resisting pulling force and floating force on hole protecting sleeve pipe

The invention discloses a sleeve valve pipe capable of resisting pulling force and floating force on a hole protecting sleeve pipe. The pipe comprises a PVC sleeve valve floral pipe, at least one pointed clamping strip set, elastic clamping strip binding rings and binding ring pulling ropes; pointed clamping strips comprise pointed head portions, middle strip-shaped portions and elastic strip-shaped tail portions; the pointed clamping strips are installed on the PVC sleeve valve floral pipe through the strip-shaped tail portions, and grooves away from the PVC sleeve valve floral pipe are formed in the pointed head portions; pulling rope penetrating rings are arranged on the clamping strip binding rings; the clamping strip binding rings are embedded in the grooves in the pointed head portions, and the pointed clamping strips are bound to the PVC sleeve valve floral pipe by utilizing the clamping strip binding rings, so that the included angle between the pointed clamping strips and thePVC sleeve valve floral pipe is 0-5 degrees; when the clamping strip binding rings fracture or are separated from the grooves in the pointed head portions, the included angle between the pointed clamping strips and the PVC sleeve valve floral pipe is 30-50 degrees. It can be prevented that the PVC sleeve valve floral pipe moves upward under the upward pulling and floating effects of the hole protecting sleeve pipe, the construction efficiency is improved, and the pouring quality is ensured.

Owner:CCFEB CIVIL ENG

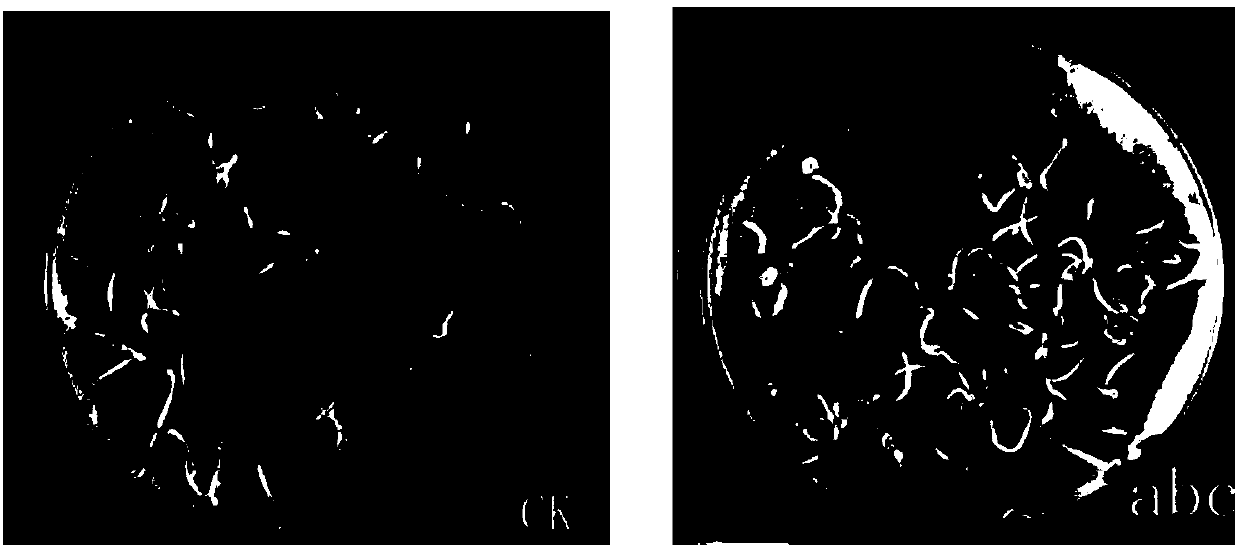

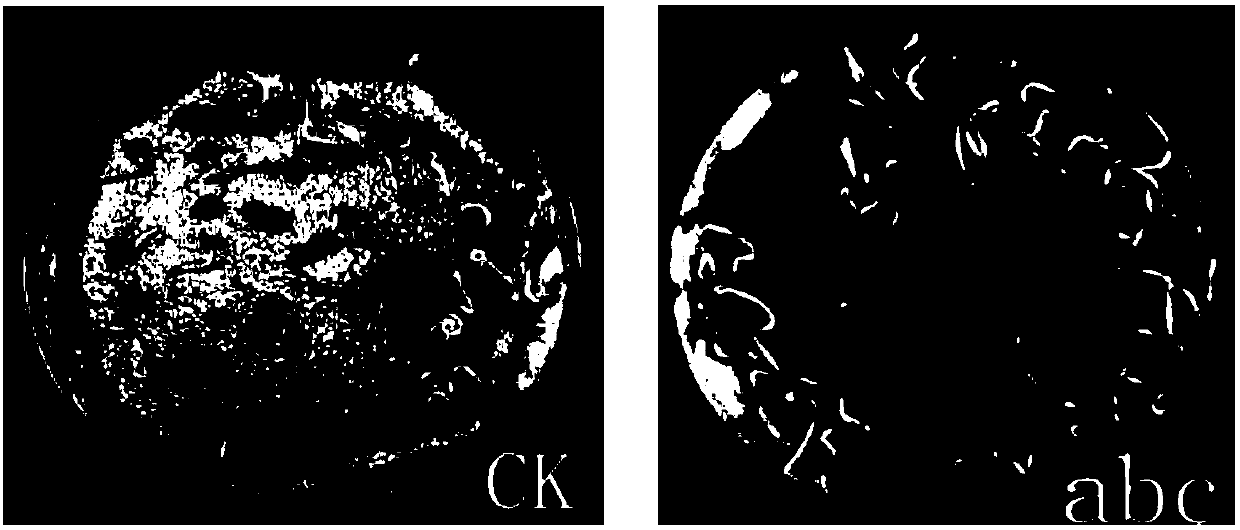

Compound initiator of tomato seeds

InactiveCN109673667ASolve the germination rateSolve the emergence speedBiocidePlant growth regulatorsVitalityGibberellin

The invention provides a compound initiator of tomato seeds. The compound initiator is prepared from the following components in proportion: 1.5-2.5 g / L of chitosan, 0.15-0.25 g / L of gibberellin and 5-15 g / L of sodium chloride. According to the compound tomato seed initiator, formulation composition is reasonable, characteristics and effects of all the raw materials are fully utilized, reasonableassembling is conducted to enable the compound initiator to play the best initiating effect, and the tomato seeds of different vitality can be initiated. Processing and making are easy, using is convenient, and an ideal product is provided for initiation of the tomato seeds.

Owner:NANJING AGRICULTURAL UNIVERSITY

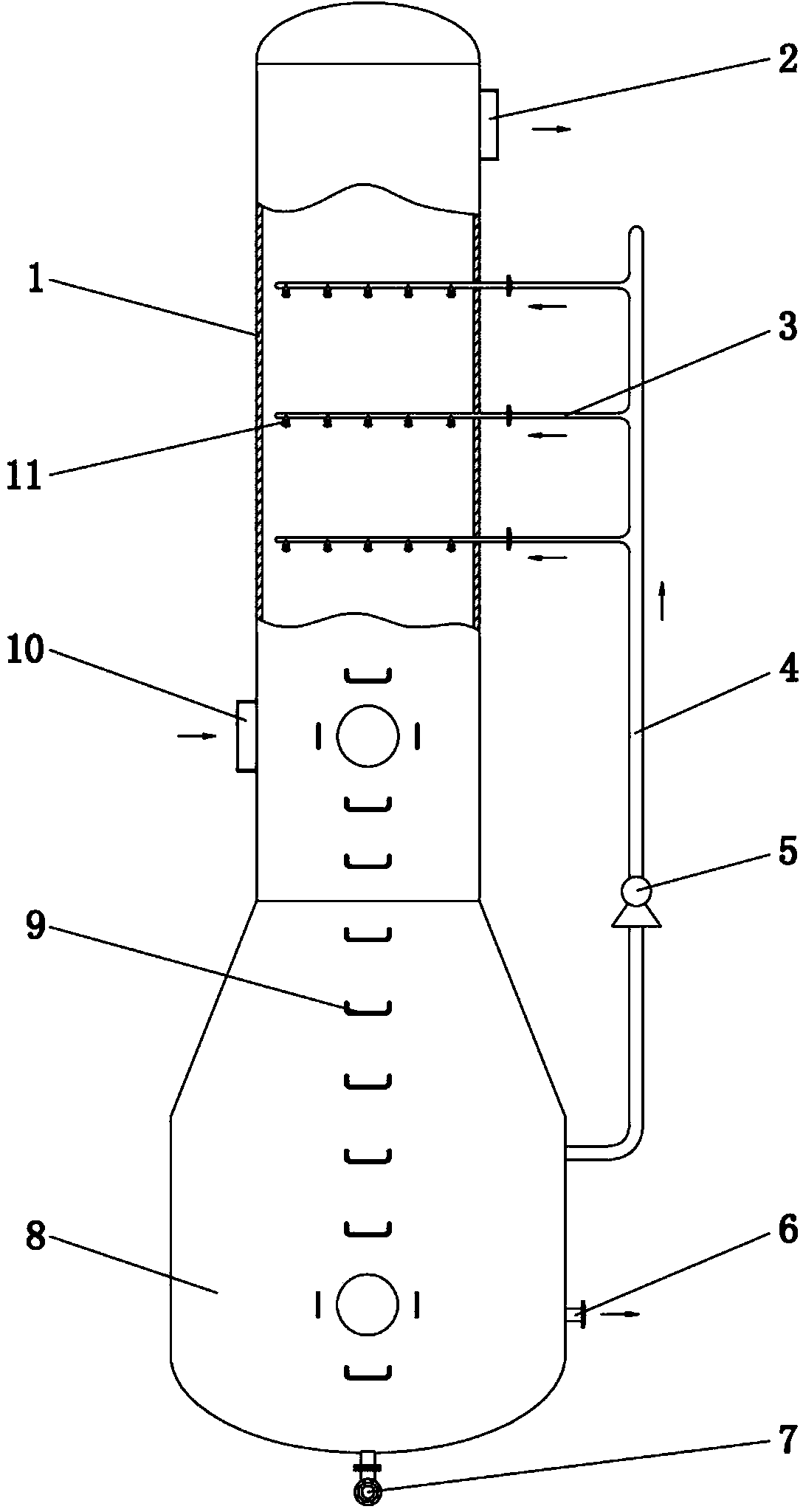

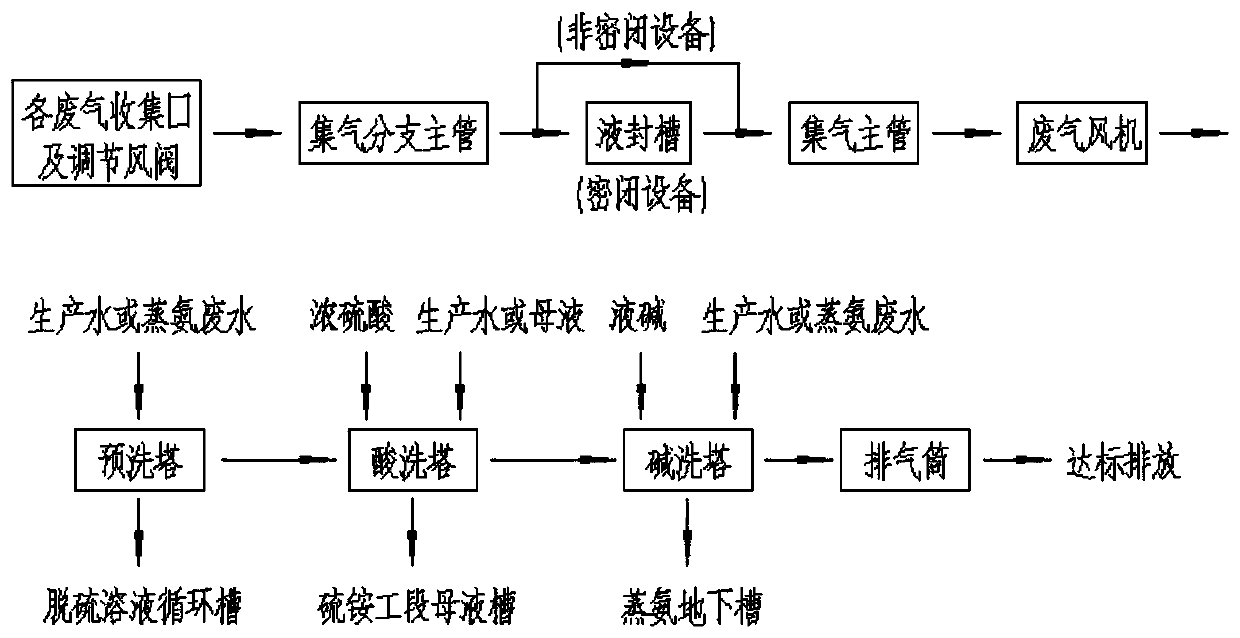

Tail gas treatment method and device for salt extraction facility, sulfur warehouse, and sulfur-melting kettle of coking plant

PendingCN109248555AMaximize utilizationConstitute reasonableDispersed particle separationSulfurEngineering

The invention discloses a tail gas treatment method for a salt extraction facility, a sulfur warehouse, and a sulfur-melting kettle of a coking plant, which comprises the following steps: collecting the waste gas generated in salt extraction production, the waste gas emitted from the materials of the sulfur warehouse, and the waste gas emitted from the sulfur-melting kettle in production of the coking plant by a collection device, introducing into the lower part of a closed pickling spray tower via a pipeline and a fan, pickling, introducing the pickled gas into the lower part of the closed alkali washing spray tower, alkali washing, introducing the gas subjected to alkali washing to the gas inlet of the lower part of a closed water washing spraying tower by the outlet of the upper part ofan alkali washing spray tower and pipelines, water washing, transporting back the gas subjected to water washing to the collection points of salt extraction, the sulfur warehouse, and the sulfur-melting kettle by the fan, and finally circulating the waste gas for returning and utilization, to achieve zero discharge of tail gas treatment. The entire process and device structure are reasonable, inthe case of energy saving, coking plant resources are utilized maximally, and tail gas generated by the salt extraction facility, the devices, the sulfur warehouses, and the sulfur-melting kettles iscollected and treated centrally, realizing circulation treatment and energy saving and consumption reduction, without discharging.

Owner:山东环达环保科技有限公司

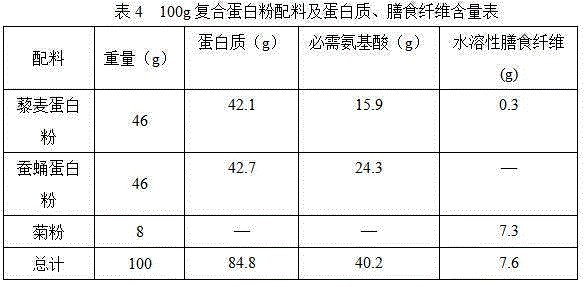

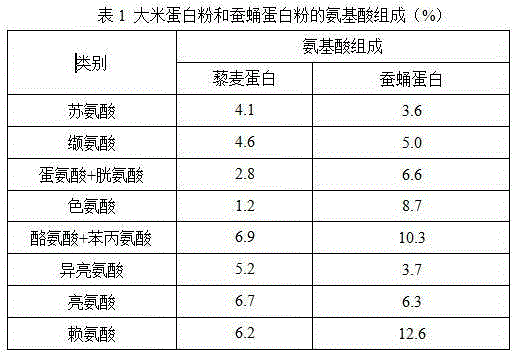

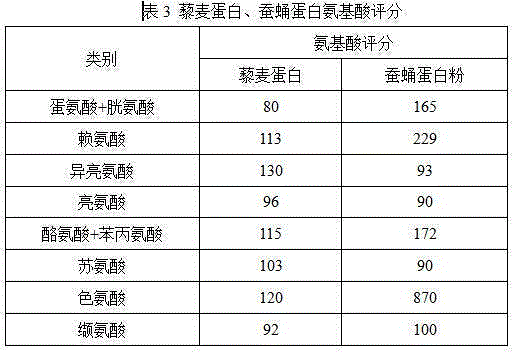

Compound protein powder rich in content of essential amino acids and reasonable in composition and preparation method of compound protein powder

InactiveCN105286022AConstitute reasonablePrevent obesityFood ingredientsUltrafiltrationAlpha-amylase

The invention relates to compound protein powder which is rich in the content of essential amino acids and reasonable in composition and a preparation method of the compound protein powder. The compound protein powder disclosed by the invention is prepared from the following components in parts by weight: 46-48 parts by weight of silkworm chrysalis protein powder, 46-48 parts by weight of quinoa protein powder and 4-8 parts by weight of inulin. The preparation method comprises the following steps of preparing the quinoa protein powder through the steps of soaking quinoa, grinding the soaked quinoa into quinoa pulp, performing enzymolysis through alpha-amylase and glucoamylase, and performing enzyme deactivation, extraction, centrifugation, ultrafiltration concentration, high-temperature instantaneous sterilization, spray drying and the like; and adding quantitative silkworm chrysalis protein powder and the inulin to the quinoa protein, and uniformly mixing the quinoa protein powder, the silkworm chrysalis protein powder and the inulin so as to obtain the compound protein powder. The compound protein powder is rich in the content of the essential amino acids and reasonable in the composition; besides, the compound protein powder contains water-soluble dietary fibers with various health-care effects, the sources of the raw materials of the compound protein powder are rich, and the compound protein powder is simple in technology, convenient to eat and suitable for production.

Owner:SHIYAN TIANXIANG BIOTECH CO LTD

Billet steel crystallization secondary cooling method and device

The invention discloses a billet steel crystallization secondary cooling method and a device, which have the advantages that the simplicity is realized, the implementation is easy, the composition is simple and reasonable, and the cooling effect is good. In the method, the multilayer covering spraying of gas-liquid mixing cooling media is carried out through a spraying device. The device comprises a spraying device in multilayer arrangement at the inner side and the outer side around the periphery of the billet steel crystallization cooling section, and the spraying device is respectively connected with an air supply source and a water supply source.

Owner:陈寅明

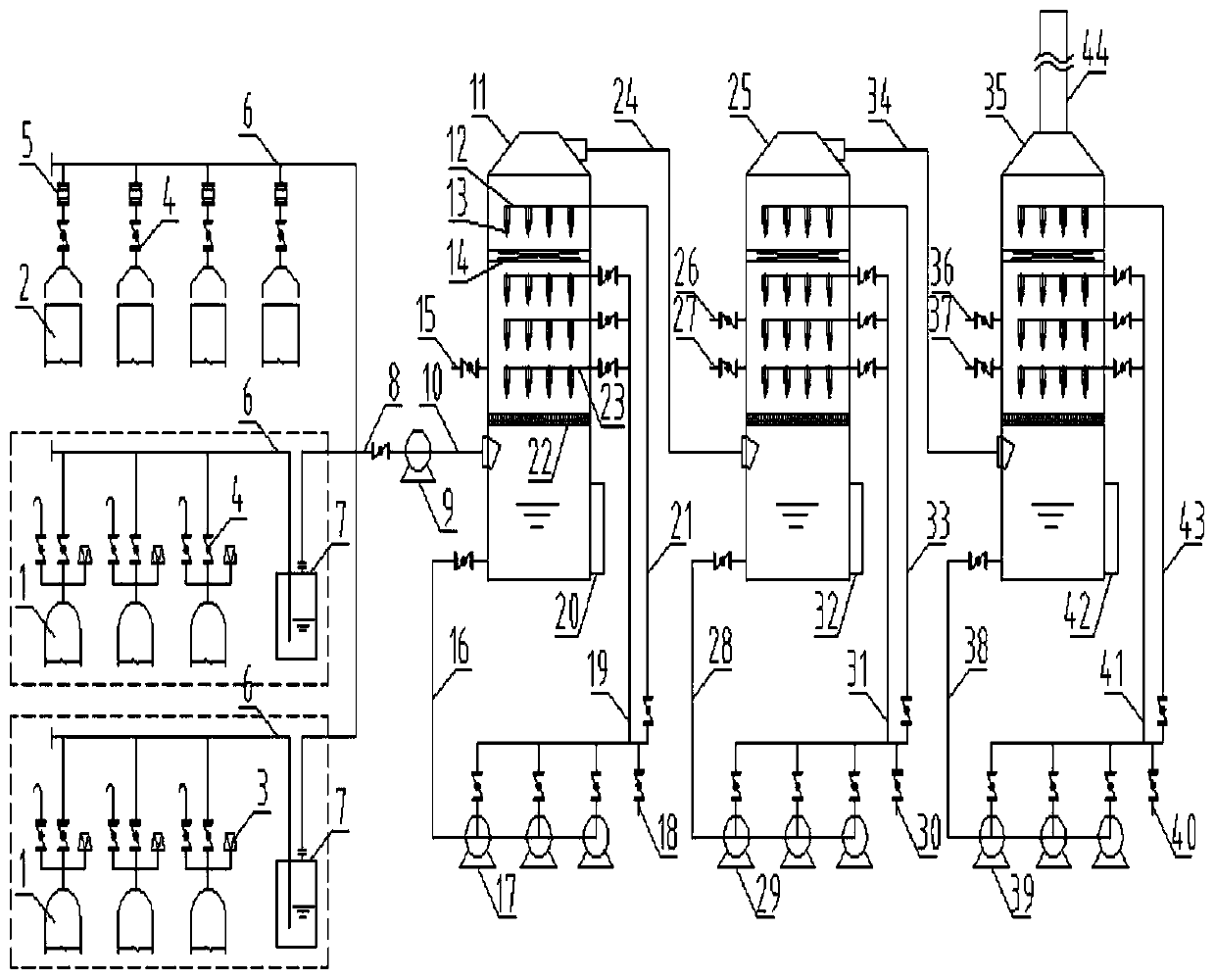

Device and method for treating waste gas of ammonium sulfate, desulfurization and salt extraction working sections of coking plant

InactiveCN110180351AReasonable process and device compositionReduce the amount of exhaust gas collectedGas treatmentDispersed particle separationAmmonium sulfateElectric energy

The invention discloses a device and method for treating waste gas of ammonium sulfate, desulfurization and salt extraction working sections of a coking plant. The device comprises closed equipment, wherein one side of the closed equipment is provided with non-closed equipment, all-weather fire-retardant breather valves, air regulating valves, fire arrestors, gas collection branch main pipes, liquid seal tanks, a gas collection main pipe I, a waste gas fan, a gas collection main pipe II, a prewashing tower, flushing layers, nozzles, demisters, prewashing tower production water, a prewashing tower circulating pump inlet pipe, prewashing tower circulating pumps, a prewashing tower drain pipe and a prewashing tower circulating pipe. The whole process and the device of the invention have a reasonable structure, reduce the waste gas collection amount of a waste gas discharge point, reduce the power of the waste gas fan and save electric energy. Meanwhile, coking plant resources are utilizedto the maximum extent under the condition of saving energy consumption, waste gas generated by production equipment such as grooves, tanks, and kettles of the sections of ammonium sulfate, desulfurization and salt extraction is collected and treated in a centralized manner, useful substances in the waste gas are recovered to the maximum extent while the waste gas is treated, and waste is turned into wealth while the waste gas reaches the emission standard.

Owner:优赛环保工程(天津)有限公司

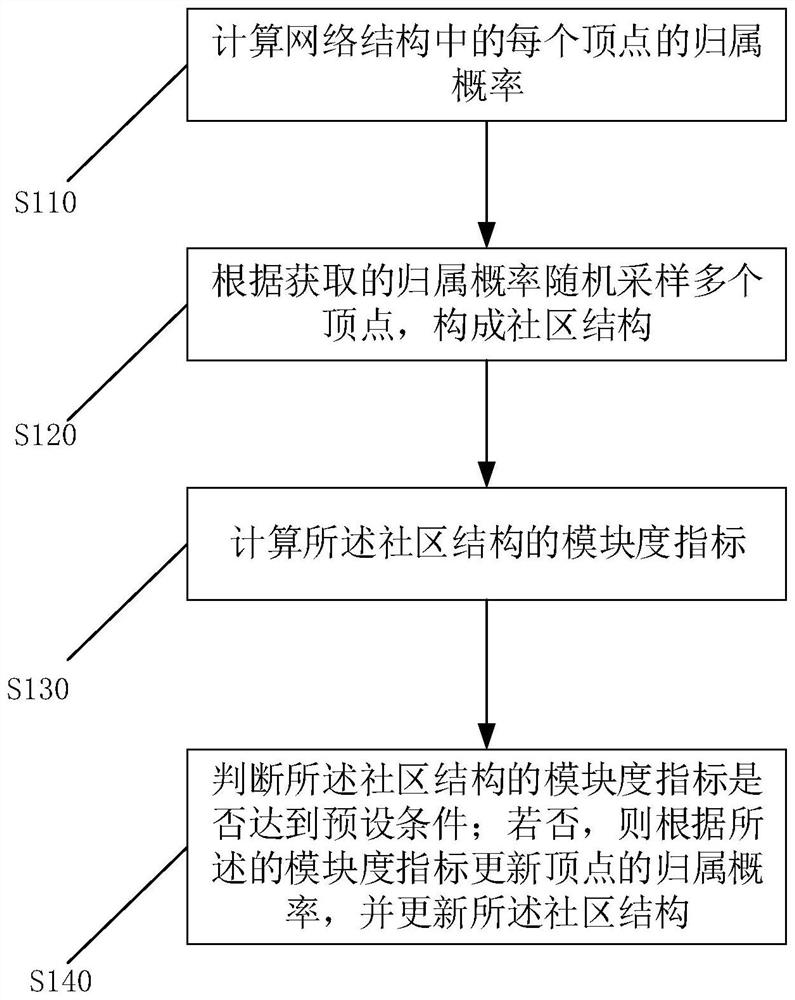

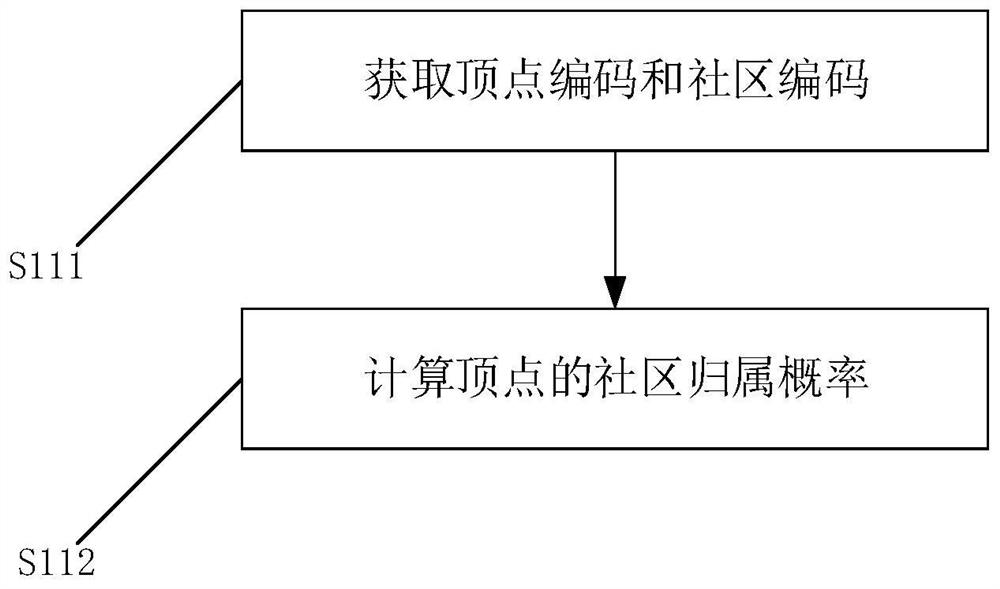

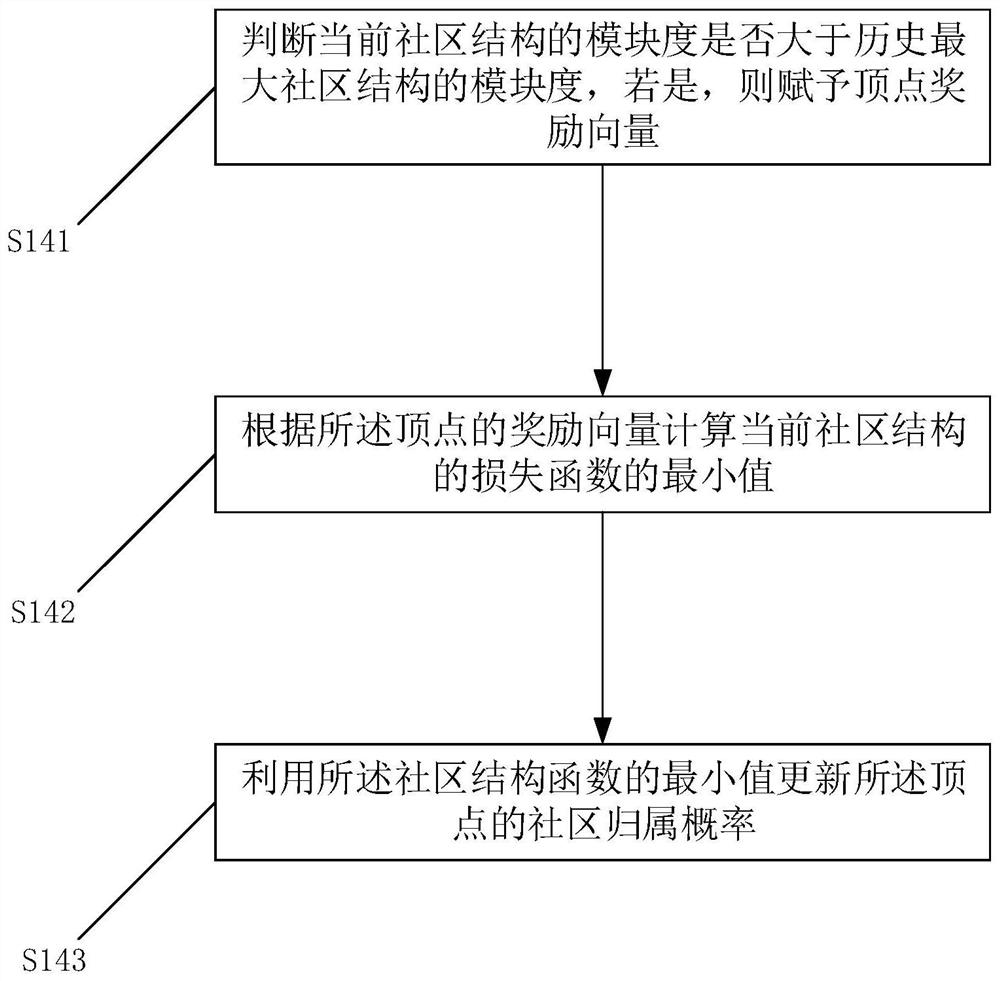

Community structure division method, device and equipment and computer readable medium

PendingCN111833199AEasy to understand implementationEasy to understandData processing applicationsAlgorithmTheoretical computer science

The invention provides a community structure division method, device and device, and a computer readable medium. The method comprises the steps of calculating an affiliation probability of each vertexin a network structure; randomly sampling a plurality of vertexes according to the obtained affiliation probability to form a community structure; calculating community structure modularity indexes;judging whether the modularity index of the community structure reaches a preset condition or not; if not, updating the affiliation probability of the vertex according to the modularity index, and updating the community structure; If so, outputting the current community structure. According to the embodiment of the invention, the community structure is determined according to the affiliation probability of the vertex, and the global community structure can be optimized step by step in an iterative computation updating mode, so that the composition of the vertex in the community structure is more reasonable, and the global community property can be better reflected.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

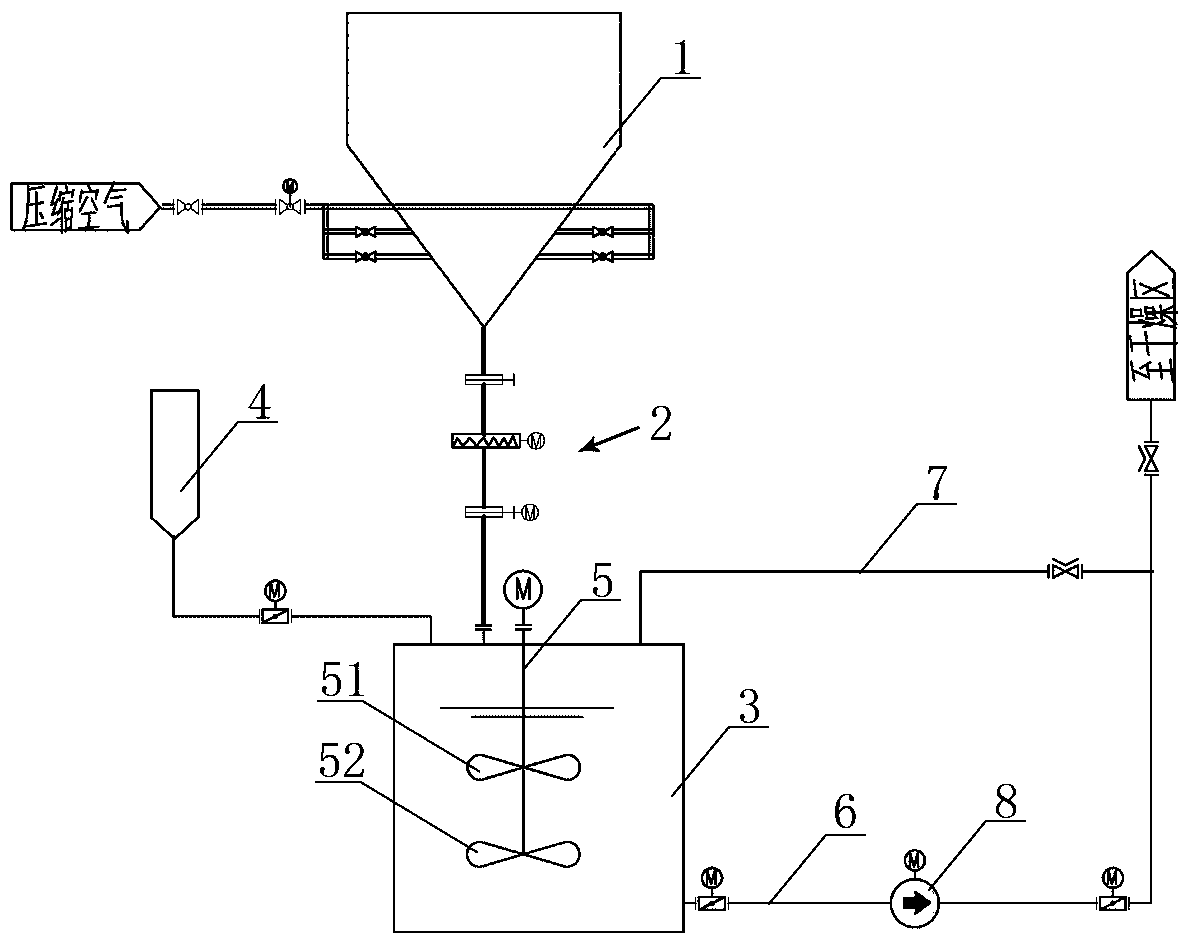

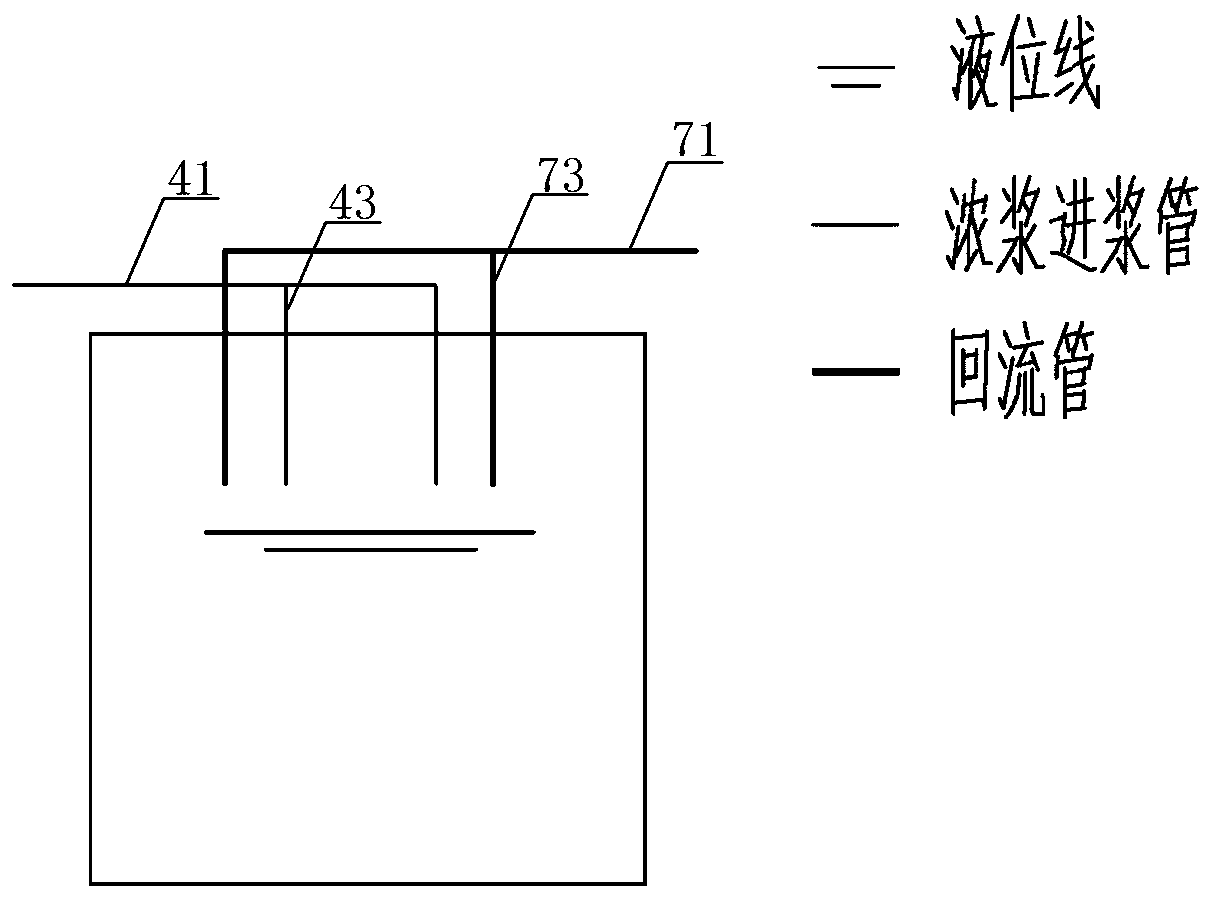

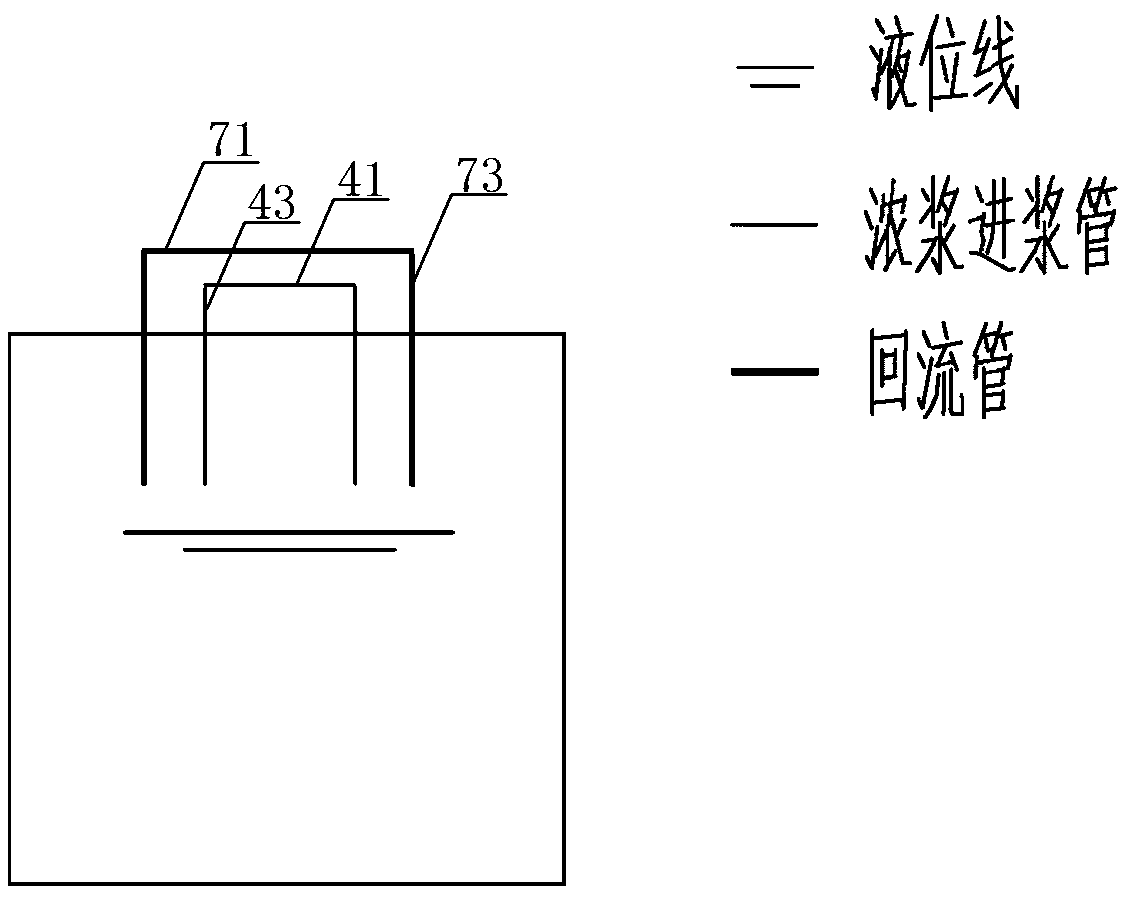

Slurry conditioning system of zero-wastewater-discharge device and operation method thereof

PendingCN109200871APrevent floatingDestroy surface tensionRotary stirring mixersTransportation and packagingWastewaterSystem stability

The invention discloses a slurry conditioning system of a zero-wastewater-discharge device and an operation method thereof. The slurry conditioning system comprises a slaked lime powder bin, a feedingsystem and a conditioning box sequentially communicating with each other from top to bottom, wherein the conditioning box communicates with a thick slurry feeding pipeline, a conditioned slurry outlet pipeline and a return pipeline; an agitator is arranged in the conditioning box; and a mixing pump is arranged on the conditioned slurry outlet pipeline. The invention provides an improved scheme for the slurry conditioning system of a device used for zero discharging of the wastewater of a thermal power generating unit; the improved slurry conditioning system can improve the sufficient dissolving of slaked lime in concentrated slurry and promote conditioning effect, and avoids vicious circulation caused by floating of the slaked lime on the surface of the concentrated slurry due to delayeddissolution of the slaked lime; at the same time, the slurry conditioning system also avoids influence on the operation stability of the system caused by deposition of the slaked lime on the bottom ofthe conditioning box due to excessive supply of slaked lime powder when the slaked lime powder is not sufficiently dissolved or not dissolved in time; and the slurry conditioning system greatly improves the sufficiency and timeliness of a conditioning reaction, is enhanced in system stability, reduces the consumption of the slaked lime powder, and can be extensively applied to thick slurry conditioning units in devices for zero discharging of the wastewater of thermal power generating units.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com