Sleeve valve pipe capable of resisting pulling force and floating force on hole protecting sleeve pipe

A sleeve valve tube and sleeve technology, applied in the sleeve valve tube field, can solve the problems of large resistance and inability to effectively fix the PVC sleeve valve flower tube, etc., and achieve the effects of effective and reasonable composition, good promotion and application prospects, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

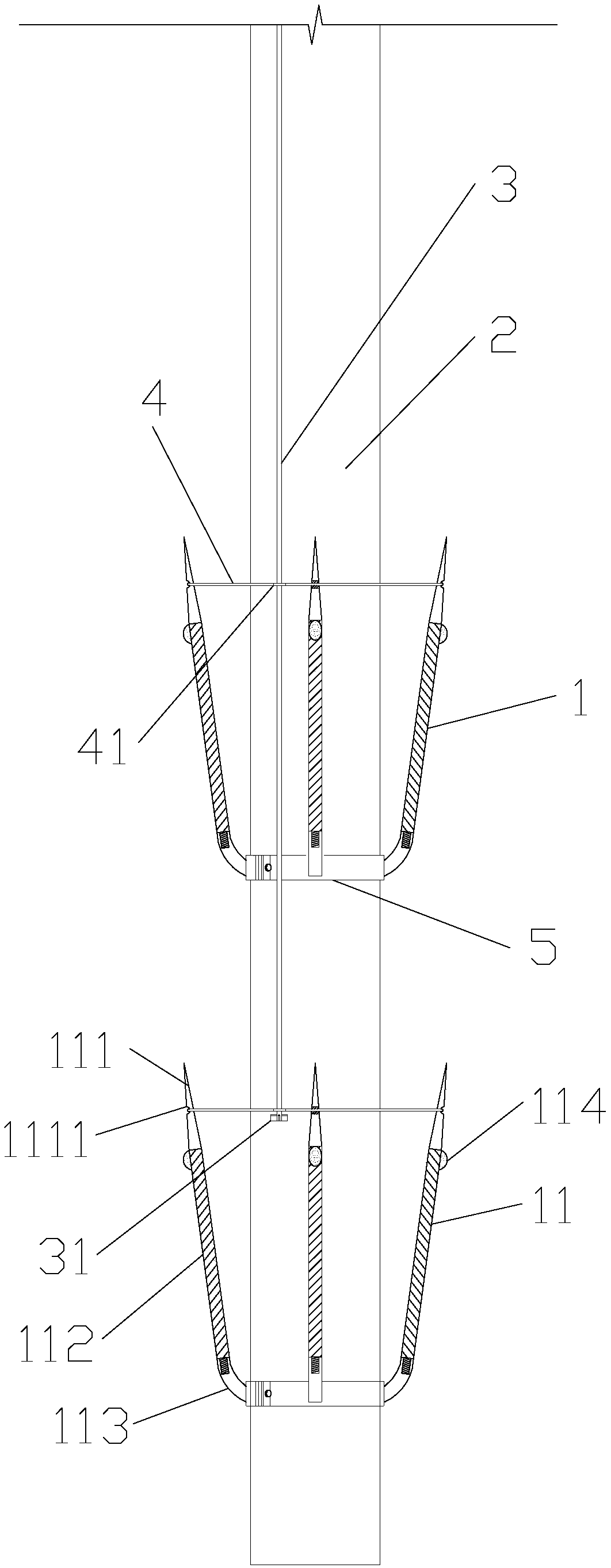

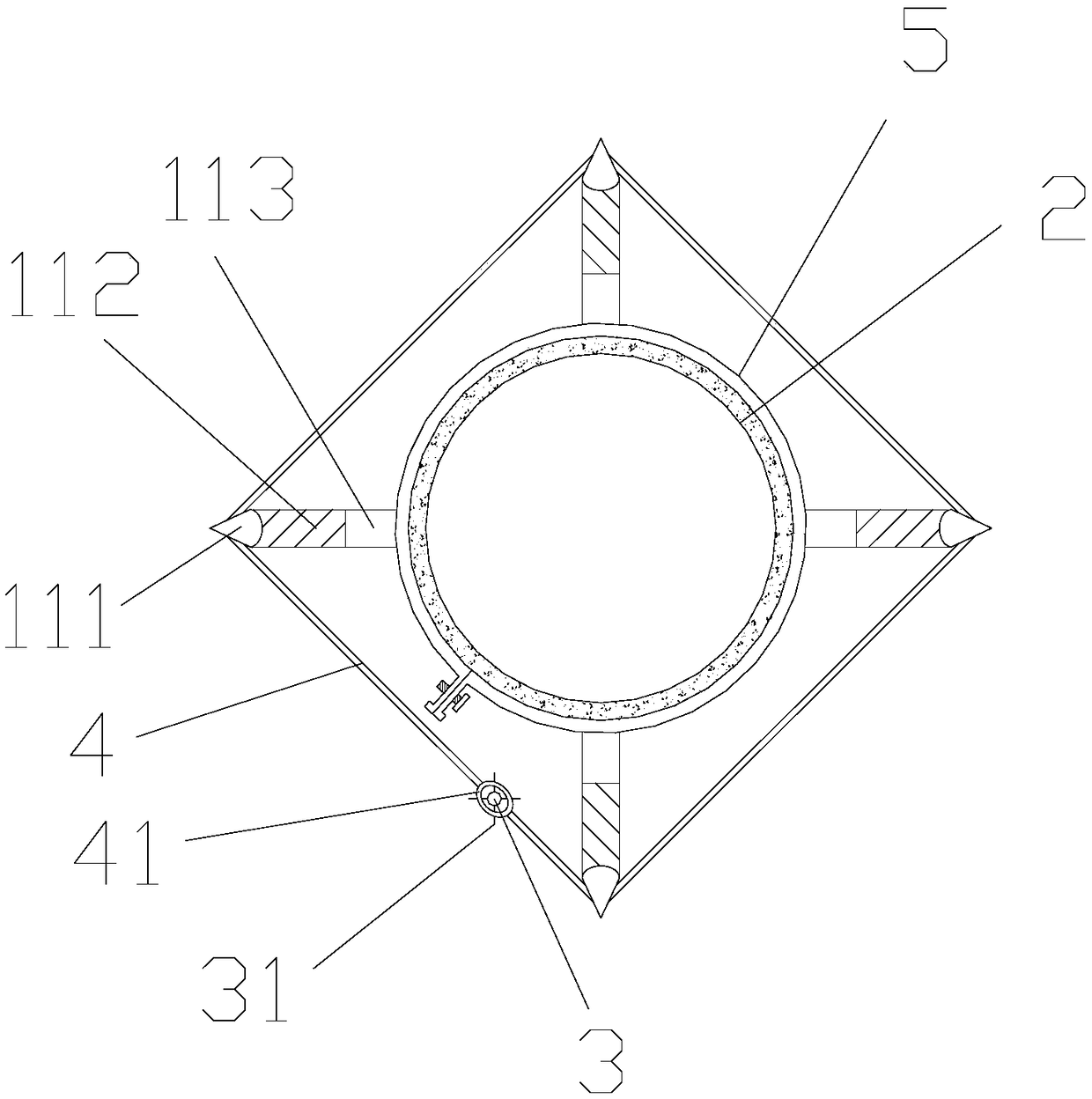

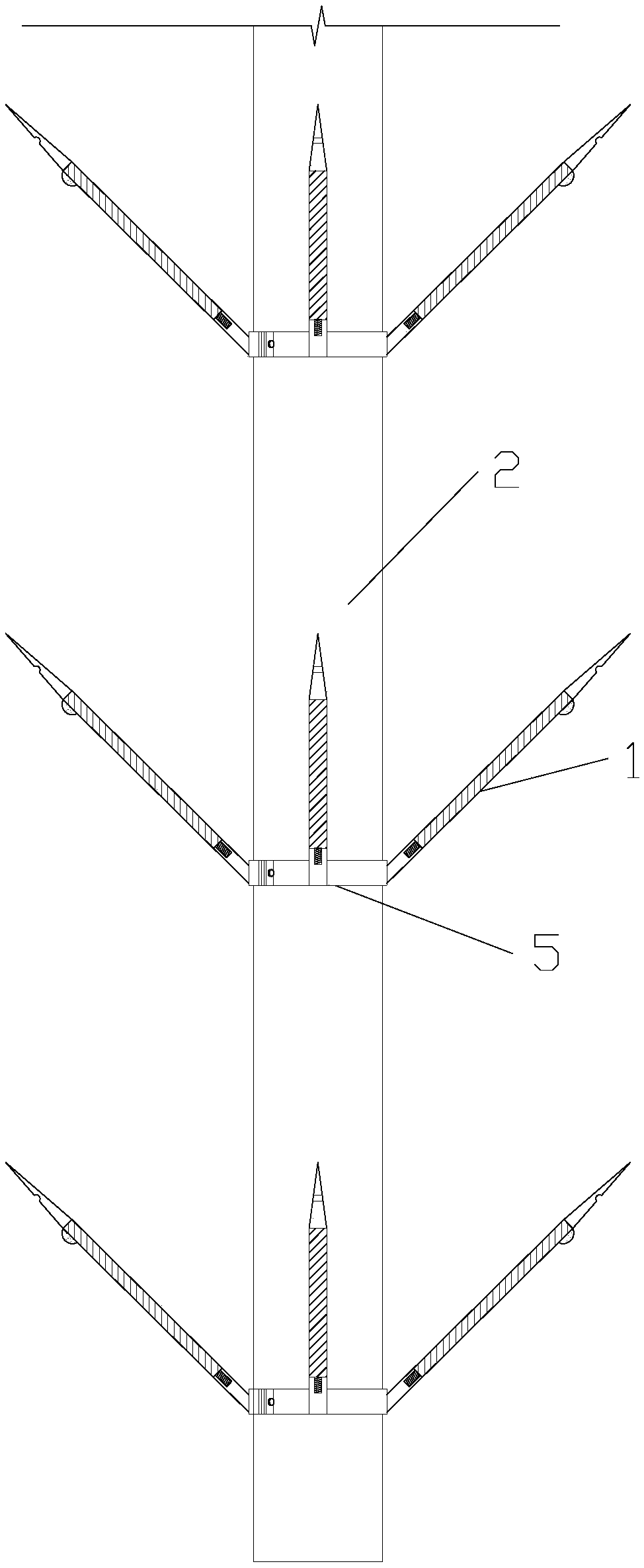

[0036] A sleeve valve tube that resists the pull-out and buoyancy forces of a grommet casing, see figure 1 , figure 2 , image 3 ,include:

[0037] PVC sleeve flower tube 2;

[0038] At least one set of pointed clips 1, said pointed clips 1 comprising a plurality of pointed clips 11 ( figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown in the case of installing four pointed clips 11); the pointed clip 11 includes a pointed head 111, a strip middle 112 and an elastic strip tail 113 connected in sequence; the pointed The clip 11 is installed on the PVC sleeve valve flower tube 2 through the strip tail 113; the pointed head 111 has a groove 1111 facing away from the PVC sleeve valve flower tube 2;

[0039] There is an elastic clip binding ring 4, which is provided with a drawstring threading ring 41 (see Image 6 , Figure 7 ); when the clip binding ring 4 is embedded in the groove 1111 of the pointed head 111, the clip binding ring 4 will tighten the pointed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com