Waste heat recycling system of air compressor

A technology of waste heat recovery and air compressors, which is applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of energy waste and heat energy not being reused, and achieve considerable economic benefits, widely popularized and utilized The effect of value and system composition science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

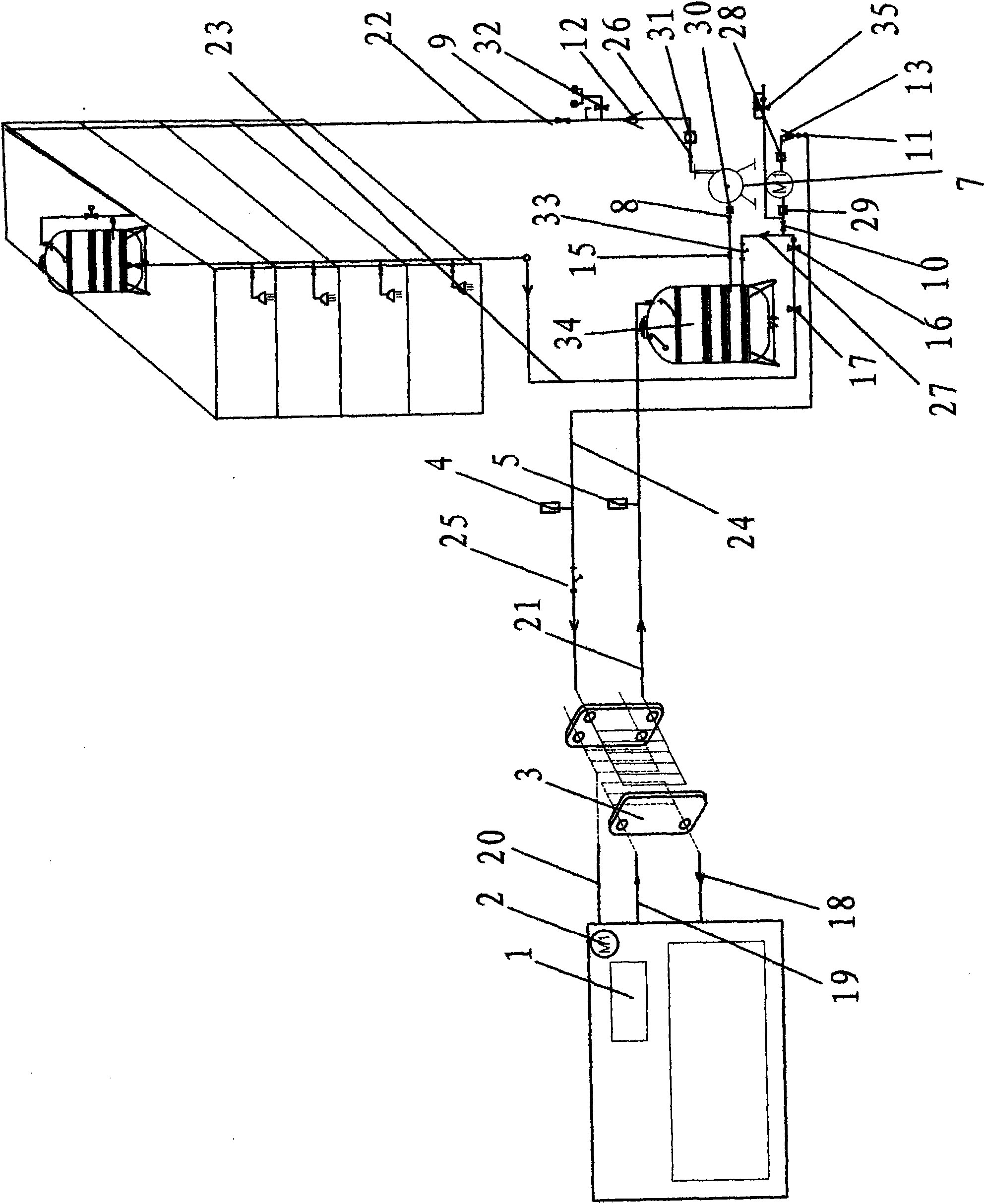

[0014] The water pump 2 is a 0.75KW pipeline pump, the pipeline 20 is a thermal PPR pipe with a diameter of 20mm, the heat exchanger 3 is an oil-gas heat exchanger, the thermometers 4 and 5 are ordinary threaded interface thermometers, and the valves 8, 9, 10, 11 and 27 are diameter 50mm gate valves, check valves 12, 13, 31 are 50mm diameter check valves, water pump 14 is a 3KW pipeline pump, solenoid valves 15, 16, 17 are stainless steel solenoid valves with a diameter of 50mm, pipelines 18 and 19 are thermal PPR pipes with a diameter of 20mm, Pipelines 21, 22, 23, and 24 are thermal PPR pipes with a diameter of 50 mm, Y-type filters 25 and 37 are Y-type filters with a diameter of 50 mm, float valve 26 is a copper port float valve with a diameter of 50 mm, and the drain valve 282932 is a drain valve with a diameter of 50 mm, 33343536 It is a 50mm rubber soft joint.

[0015] In the embodiment, both ends of the water pump are connected with soft joints in order to reduce noise....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com