Gas-liquid separation and purification system for pyrolysis gas of agriculture and forestry biomass materials

A biomass material and pyrolysis gas technology, which is applied in the field of gas-liquid separation and purification system for pyrolysis gas of agricultural and forestry biomass materials, can solve the problems of high moisture content, poor condensation effect, low cooling uniformity, etc., and achieve continuous Uninterrupted air supply, improved condensation effect, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

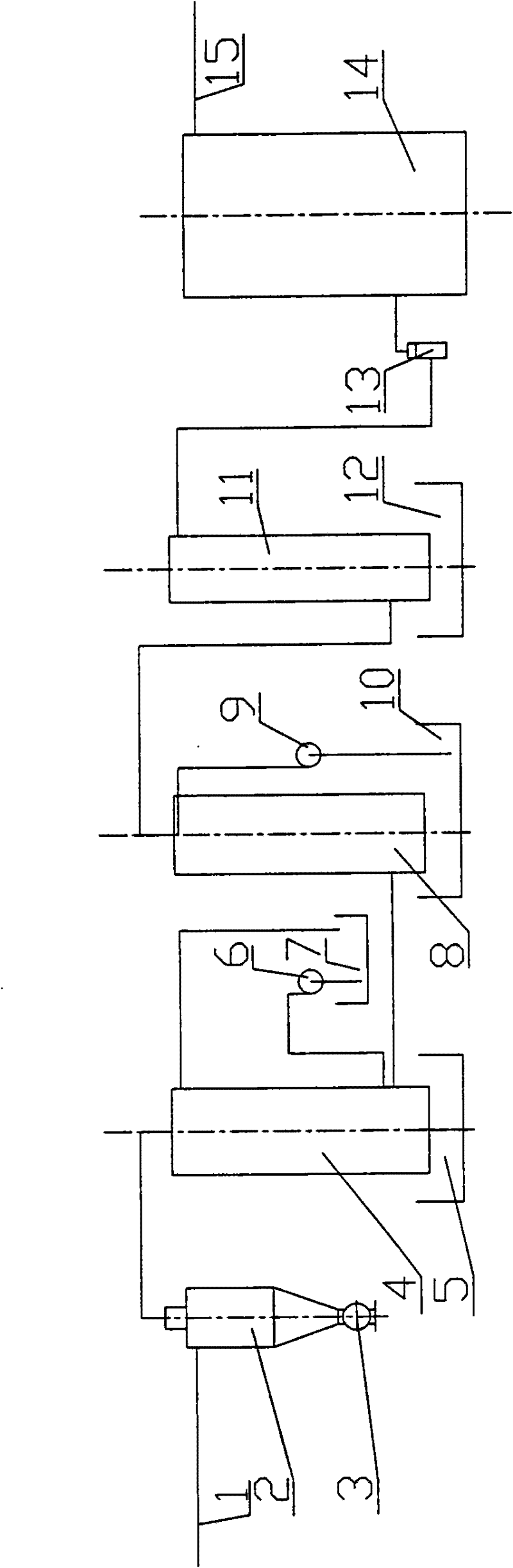

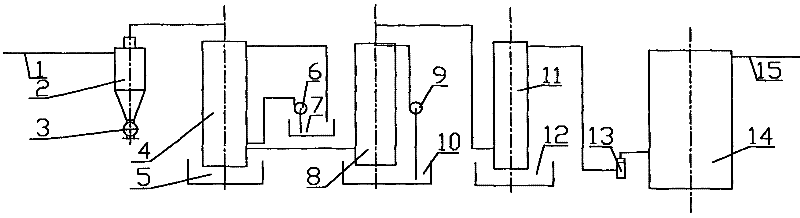

[0008] With reference to the accompanying drawings, its structure is to comprise gas input pipe 1, cyclone separator 2, needle tube condenser 4, vinegar liquid collecting tank 5, spray device 8, electrostatic decoker 11 and gas storage tank 14, wherein gas input pipe 1 is connected to the inlet of the cyclone separator 2, the outlet of the cyclone separator 2 is connected to the inlet of the needle tube condenser 4, the outlet of the needle tube condenser 4 is connected to the inlet of the spray device 8, and the outlet of the spray device 8 is connected to into the inlet of the electrostatic decoker 11, the outlet of the electrostatic decoker 11 is connected to the gas storage tank 14, and the outlet of the gas storage tank 14 is connected to the clean combustible gas output pipe 15.

[0009] The bottom of the cyclone separator 2 is provided with a star discharge valve 3; the cyclone separator 2 (existing) separates the solids in the gas.

[0010] The gas input pipe 1, the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com