Patents

Literature

46results about How to "Widely promoted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

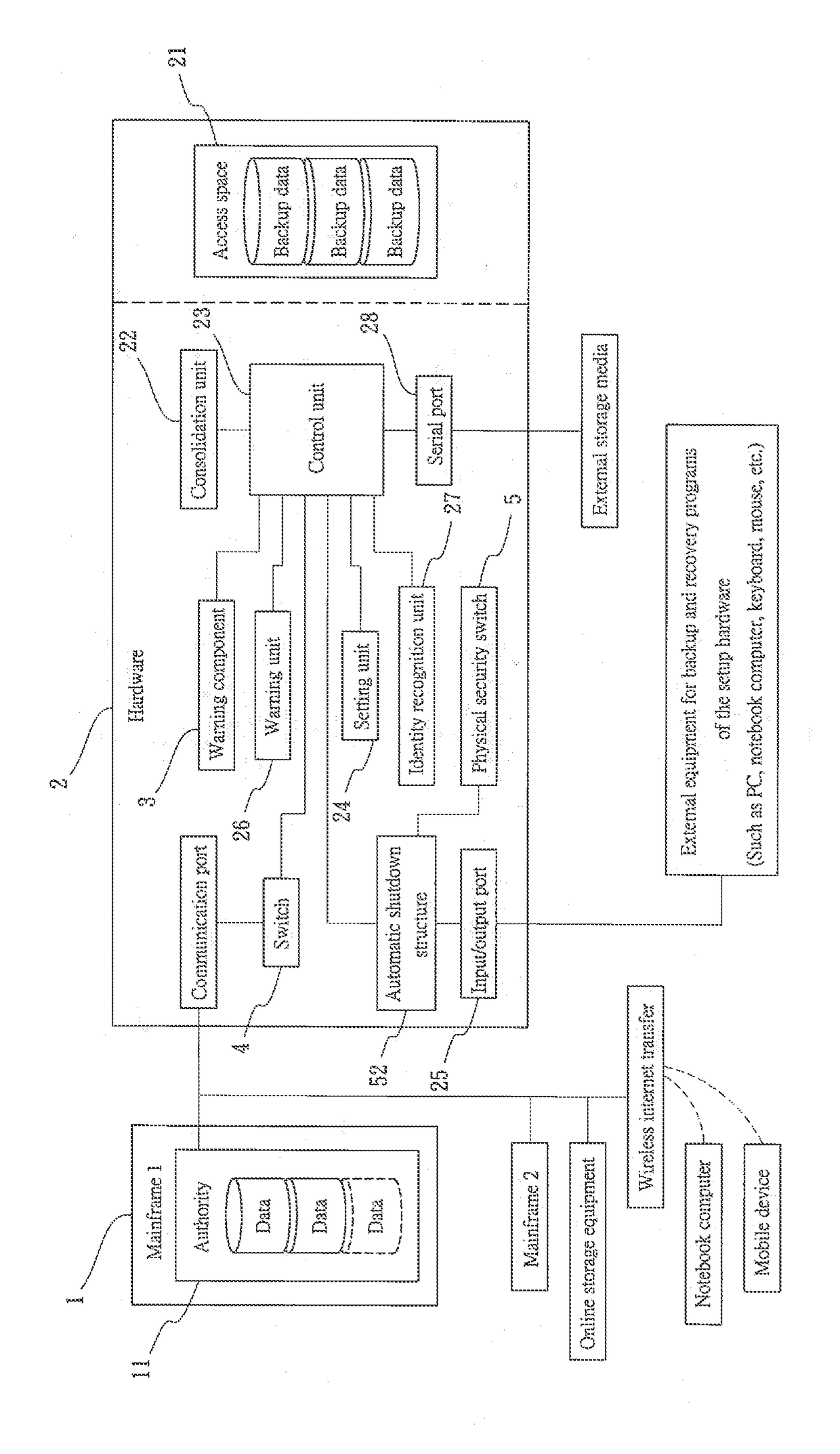

Active network backup device

InactiveUS20180375826A1Widely promotedEasily causes data corruption or blackmailInput/output to record carriersTransmissionRansomwareSoftware

An active network backup device includes at least a mainframe and a hardware. The mainframe and other network devices cannot log in, create settings and access data of the hardware. Hence, the hardware can practically prevent and block viruses, ransomware and attacks by hackers; moreover, the device has a physical security switch design for switching on and off a port to ensure personal operation of the administrator and prevent the hardware from being hacked by robot program. Most importantly, the hardware cannot execute destructive instructions and thereby viruses cannot be executed or run in the hardware, which also prevents accidental deletion due to setting errors, or any ransomware or malicious programs in the disguise of setting programs being downloaded and executed by careless users.

Owner:CHANG SHENG HSIUNG +1

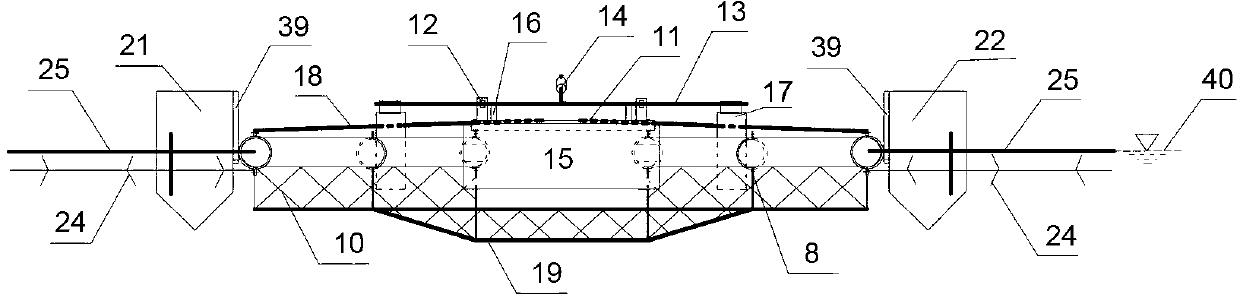

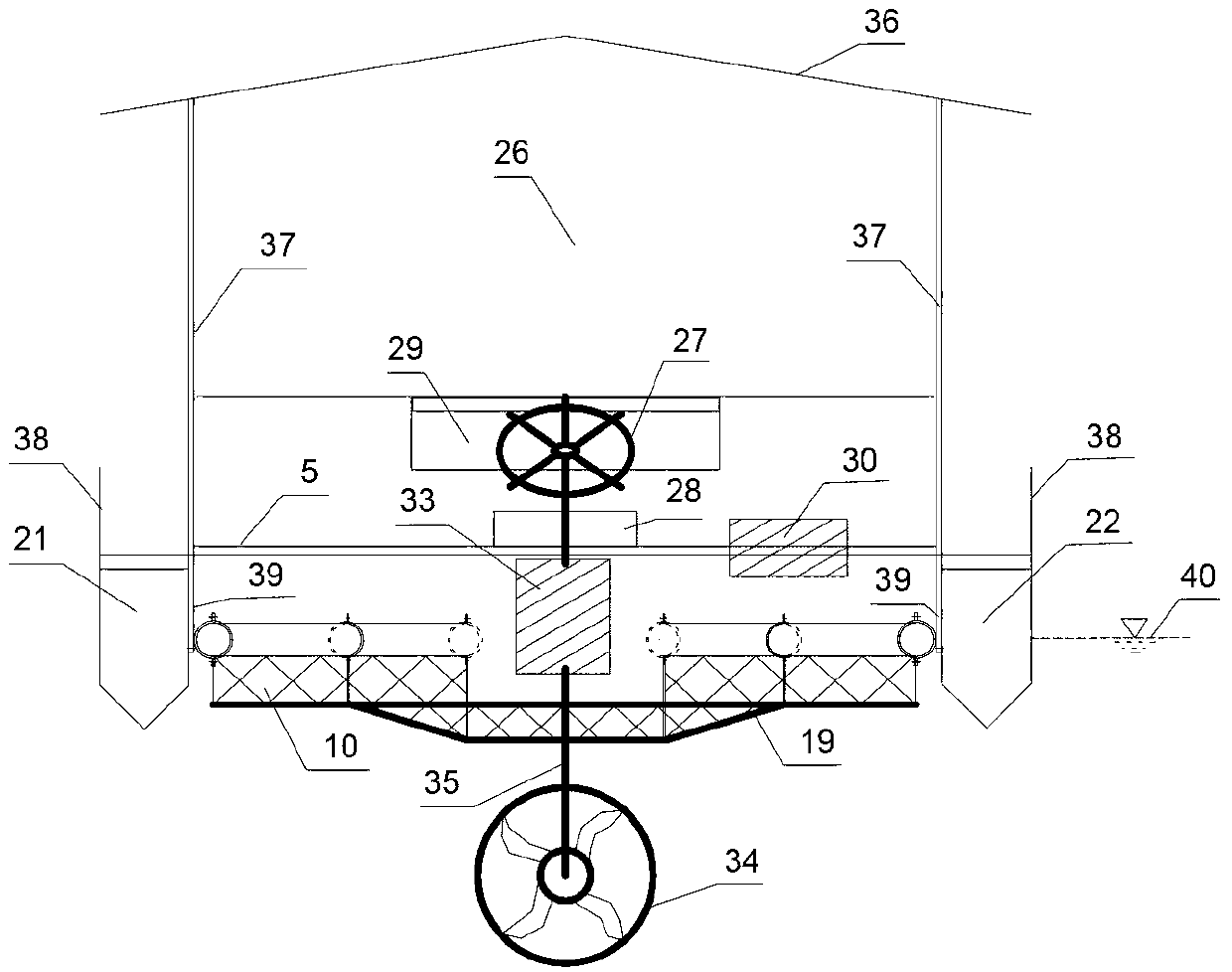

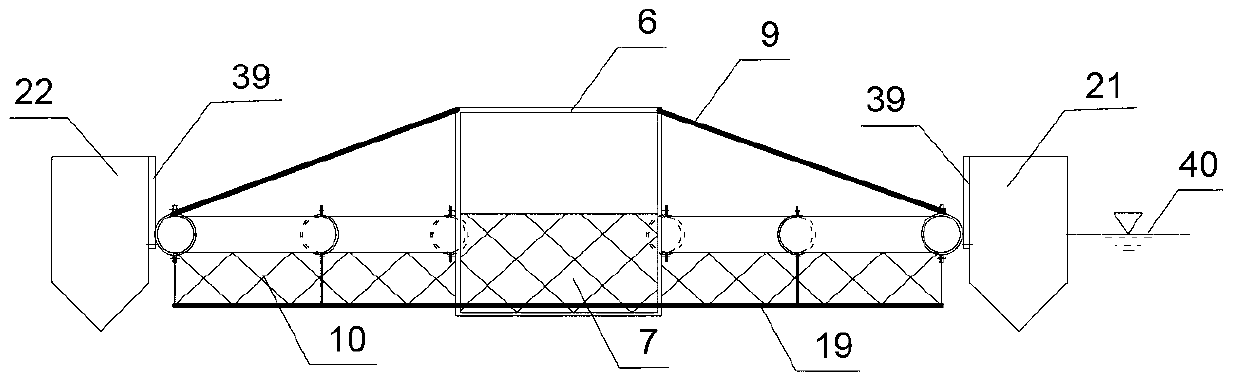

Automatic water floating object collecting device

ActiveCN103318382ARealize automatic collectionSimple structureWater cleaningWaterborne vesselsMarine engineeringPower equipment

The invention belongs to the technical field of water floating object collecting devices, and relates to an automatic water floating object collecting device. The main body structure of the automatic water floating object collecting device comprises a boat body, a bilateral wheel adjustable horn-shaped inlet section, a floating object inlet automatic door system, a ship power equipment operation system and a floating object outlet gate system. The bilateral wheel adjustable horn-shaped inlet section is arranged at the head end of the boat body, the floating object inlet automatic door system is arranged between the boat body and the bilateral wheel adjustable horn-shaped inlet section, the ship power equipment operation system is arranged in the middle section of the boat body, and the floating object outlet gate system is arranged on the tail portion of the boat body. The automatic water floating object collecting device is simple in structure, reliable in principle, high in operation reliability, simple and convenient to manage and maintain and low in cost, and does not need a machine driven system for collecting rubbish.

Owner:光大理工环境技术研究院(青岛)有限公司

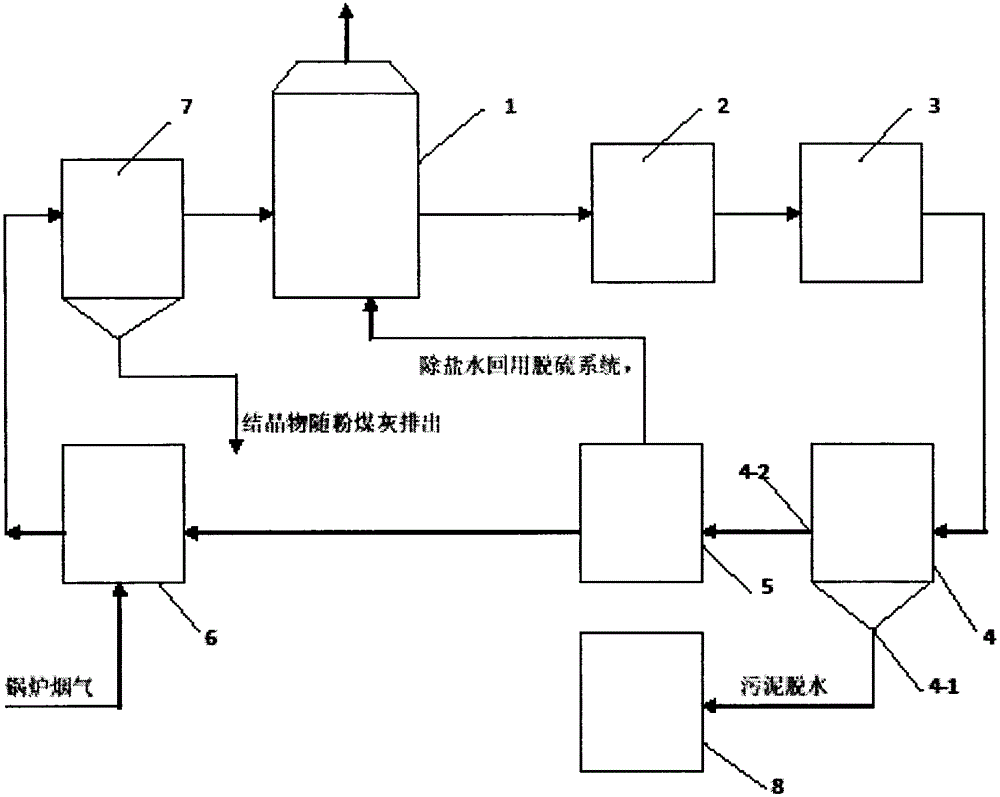

Wet desulfurization wastewater zero emission process and device thereof

InactiveCN104926008AAchieve reductionPracticalDispersed particle separationMultistage water/sewage treatmentWater vaporSludge

The invention discloses a wet desulfurization wastewater zero emission process and a device thereof; desulfurization wastewater behind a gypsum dewatering device is collected and enters a flocculation reactor, the desulfurization wastewater is softened, flocculated and clarified, and sludge is sent to a sludge processing device for dewatering; the clarified water after separation is desalted, the desalted water is reused in a desulfurization system, concentrated water is sent to an evaporation crystallization device, waste heat of a boiler flue gas is used for evaporation crystallization, and high-quality water steam is obtained after evaporation; an evaporated crystallized substance and the water steam are subjected to gas-solid separation, the high-quality water steam is sent into a desulfurization absorption tower for recycling, and the crystallized substance is discharged together with fly ash. The high-quality water steam can be completely recycled in the desulfurization adsorption tower; suspended solids, dissolved solids, heavy metals, high salt, and Ca<2+>, Mg<2+>, Cl<+> and F<-> ions and other substances are cured, separated and collected, the purpose of complete recycling of the desulfurization wastewater is achieved, and zero emissions of the desulfurization wastewater can be achieved. In addition, the method has no effect on other systems of a power plant, and has the advantages of high practicability, low investment, and wide popularization and use value.

Owner:王辛平

Pervious environment protection encarpus brick and method for producing the same

InactiveCN101586324AEfficient supplySolve problems such as floating dustSingle unit pavingsCeramic shaping apparatusBrickMaterials science

The present invention relates to a pervious environment protection encarpus brick and a method for producing the same, including a plus material and a bottom material, wherein the plus material is composed of emery sand, common silicates P.O42.5 grade cement, pigment and water, and the bottom material is composed of refined pisolite, common silicates P.O42.5 grade cement and water. The encarpus brick of the invention has an elegance and beautiful appearance, is ecological, environment protection, pervious, ventilated, radiating and skidproof, and may be used for laying for metro roads, large-sized parks, sports gymnasium, high-grade buildings, speedway service zone, plaza, shipside, parking grounds, district roads and the like, and is worthy to employ and popularize extensively.

Owner:广州市坚基环保数码彩砖有限公司

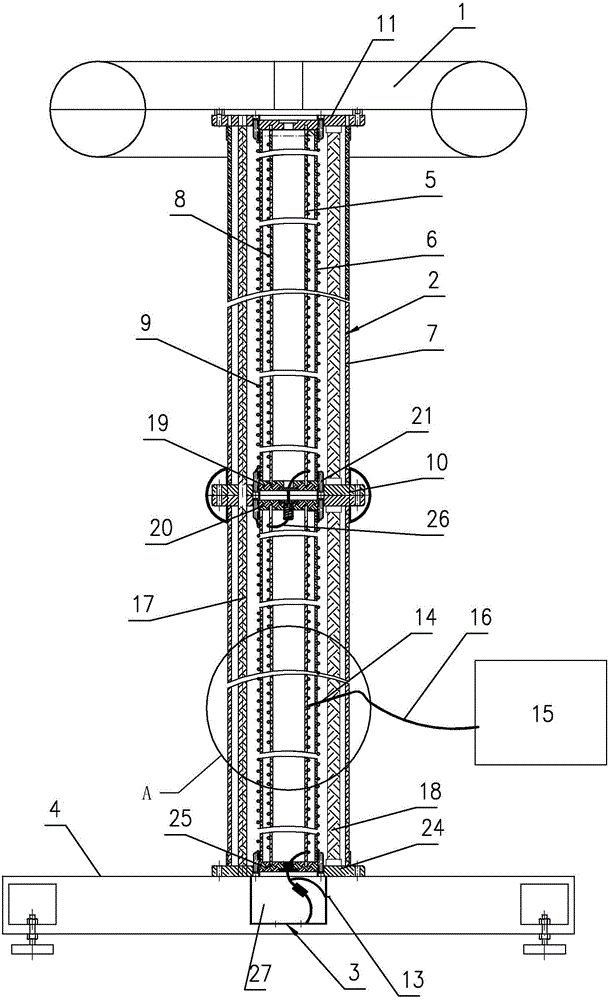

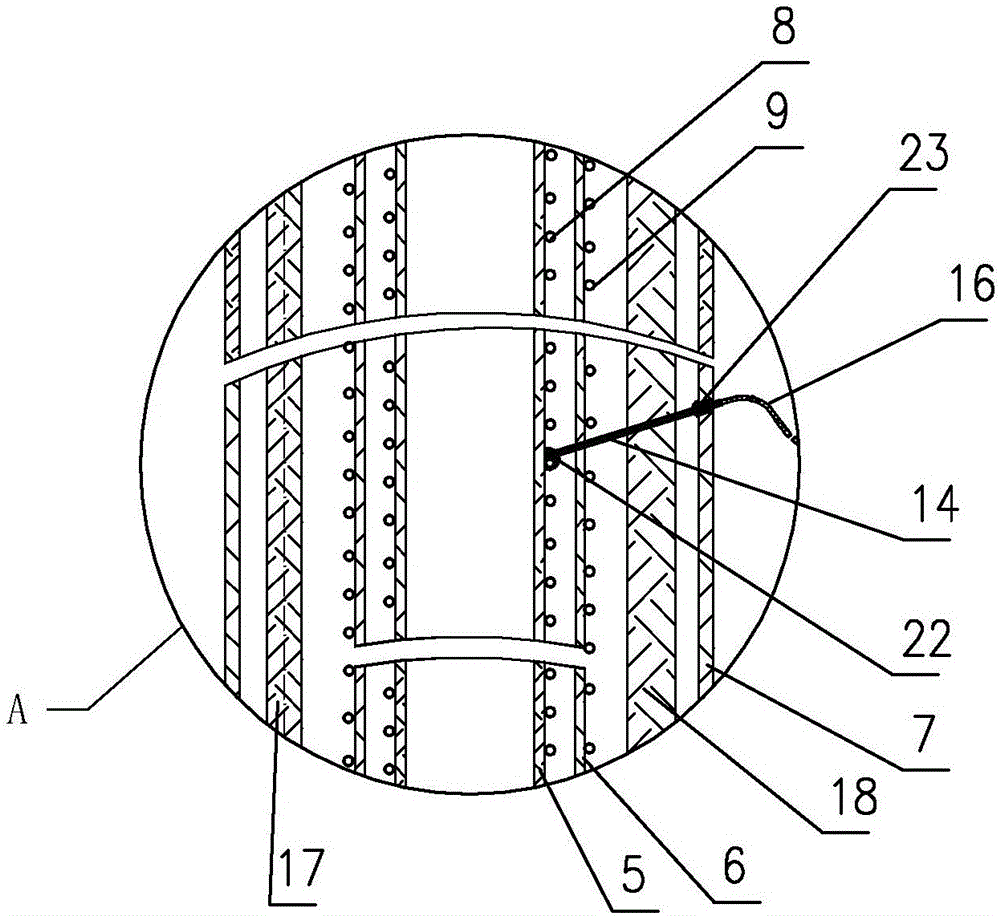

Self-calibration high precision AC-DC voltage divider

ActiveCN105092927AImprove the accuracy of the voltage divider ratioGuaranteed accuracyVoltage dividersLow voltageEngineering

The invention discloses a self-calibration high precision AC-DC voltage divider. The self-calibration high precision AC-DC voltage divider comprises a grading ring, a high voltage arm unit, a low voltage arm resistor and a foundation, wherein the high voltage arm unit comprises an inner insulation supporting cylinder, an outer insulation supporting cylinder, an outer insulation cylinder, a film type voltage division resistor arranged on an outer wall of the inner insulation supporting cylinder, and a film type clamping resistor arranged on an outer wall of the outer insulation supporting cylinder which are sequentially embedded from inside to outside, a temperature measurement probe and an AC-DC calibration instrument are further included, the temperature measurement probe is one, is fixed on the film type voltage division resistor and penetrates out of the outer insulation cylinder through a connection wire to connect with the AC-DC calibration instrument, sealing treatment on the portion of the connection wire penetrating through the outer insulation cylinder is carried out, temperature of the film type voltage division resistor is transmitted by the temperature measurement probe to the AC-DC calibration instrument in real time, and the real-time temperature of the film type voltage division resistor and the standard temperature coefficient curve of the film type voltage division resistor are contrasted by through the AC-DC calibration instrument so as to carry out self-calibration on a voltage division ratio to be a standard voltage division ratio. According to the self-calibration high precision AC-DC voltage divider, voltage division ratio precision is improved, and measurement result accuracy is guaranteed.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

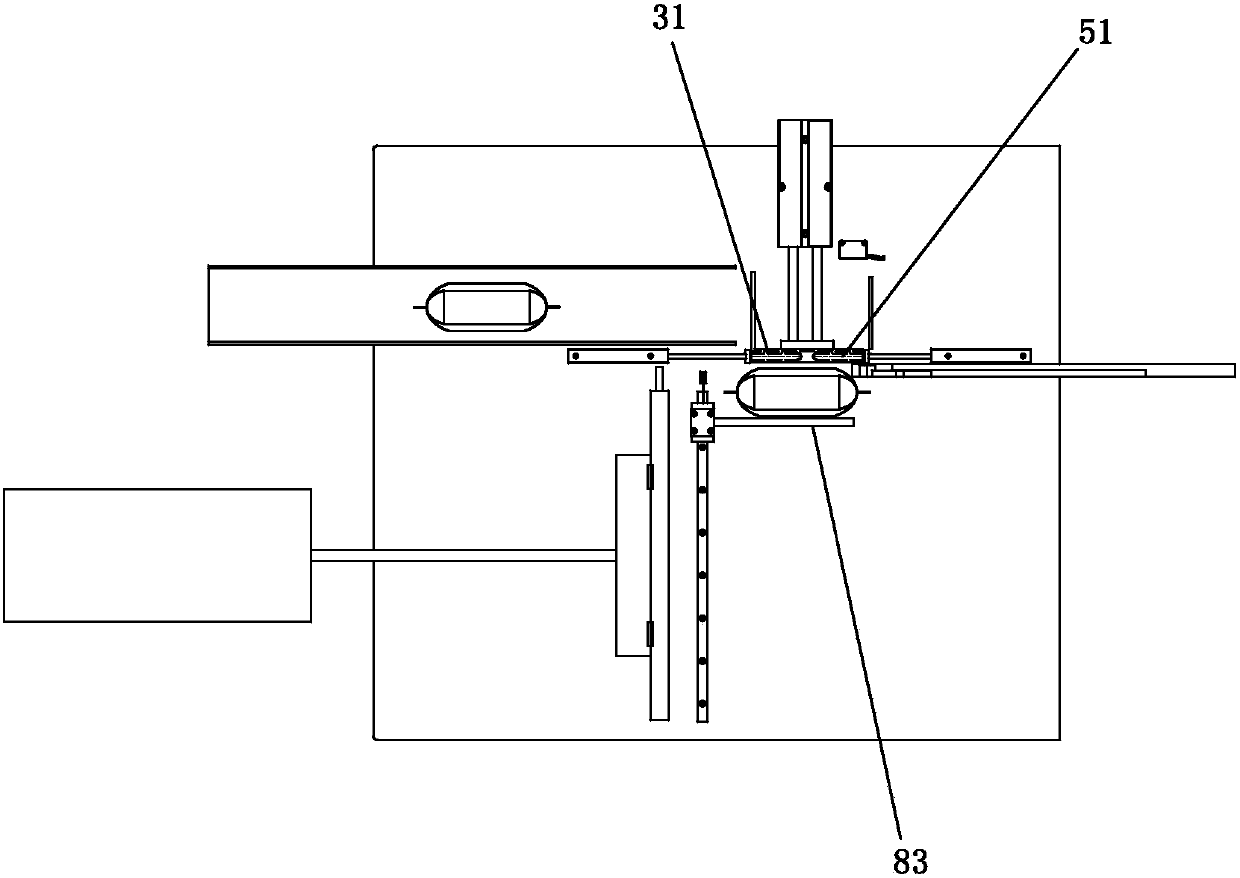

Automatic signal bag packaged product arrangement and combination device

The invention discloses an automatic signal bag packaged product arrangement and combination device which comprises an electric control device, a first bag pushing mechanism and a second bag pushing mechanism, wherein the first bag pushing mechanism is composed of a first pushing passage, a first pushing mechanism and a bag falling preventing mechanism; the second bag pushing mechanism is composedof a second pushing passage and a second pushing mechanism; the bag falling preventing mechanism is mounted on one side edge of the first pushing passage in the pushing direction of the first pushingmechanism; the electric control device controls a single bag to be conveyed to the inlet of the first pushing passage one by one, and then, the first pushing mechanism sequentially pushes each singlebag to the inlet of the second pushing passage until the quantity requirement of each row is met; the second pushing mechanism pushes the signal bags of each row until the quantity requirement of each column is met; the latter half part of the second pushing passage is positioned in a bag making forming mechanism; and the bag making forming mechanism wraps the single bags after arrangement and combination and seals and cuts the single bags to form middle bags. The automatic signal bag packaged product arrangement and combination device can realize automatic arrangement and combination of allspecifications of a softer signal bag packaged product with an irregular shape, reduces the labor cost and improves the working efficiency.

Owner:广州紫怡机电有限公司 +1

Silver aluminum slurry for electromagnetic shielding and preparation method thereof

InactiveCN101950597ASaving silver raw materialsImprove economyConductive layers on insulating-supportsMagnetic/electric field screeningElectromagnetic shieldingSlurry

The invention discloses silver aluminum slurry for electromagnetic shielding and a preparation method thereof. By accounting in percentage by weight, the silver aluminum slurry comprises 50-80 wt% of metal powder, 20-40 wt% of organic carrier, 5-10 wt% of dispersing agent, 2-12 wt% of defoamer and 3-10 wt% of surfactant, wherein the metal powder is composed of flaky silver powder and aluminite powder at the weight ratio of 20:80-80-20. The silver aluminum slurry for electromagnetic shielding replaces pure silver slurry by silver aluminum slurry, obtains the effect of the silver aluminum slurry serving as electromagnetic shielding material by a cheaper price, saves silver raw material, can be used in occasions with harsh environment requirements, such as civil electronic components, precise instruments and the like, and obtains favourable economic effect.

Owner:IRICO

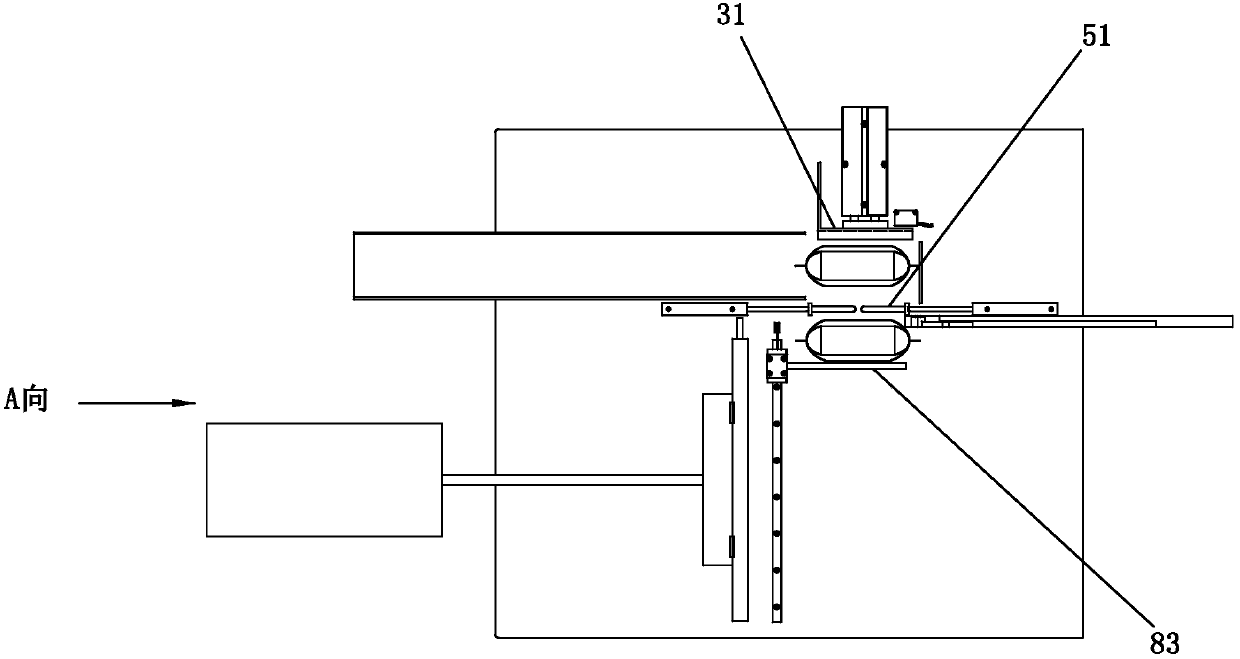

Test sleeve for GIS terminal test device

ActiveCN104698356AThe electric field distribution is the sameImprove accuracyTesting dielectric strengthEngineeringHigh pressure

The invention provides a test sleeve for a GIS terminal test device, and aims at testing a GIS terminal. The sleeve comprises an insulation barrel body, a high pressure import mechanism, a grounding shielding electrode and a grounding flange; the grounding flange is connected with one end of the insulating barrel body; the high pressure import mechanism is connected with the other end of the insulating barrel body; the ground shielding electrode is arranged on the inner wall of the insulating barrel body and connected with the grounding flange; a testing cavity in which the GIS terminal extends is formed in one end of the insulating barrel body, connected with the grounding flange and toward the other end of the insulating barrel; when in work, the testing cavity forms a closed testing cavity. The sleeve is safe, reliable, small in size, simple in structure, and convenient to mount and use; the completion pressure test can be carried out for the GIS terminal and a cable circuit; the accuracy, efficiency and reliability of test can be effectively improved; the test sleeve is suitable for wide popularization and application.

Owner:GUANGDONG WEIHENG POWER TRANSMISSION & DISTRIBUTION ENG +1

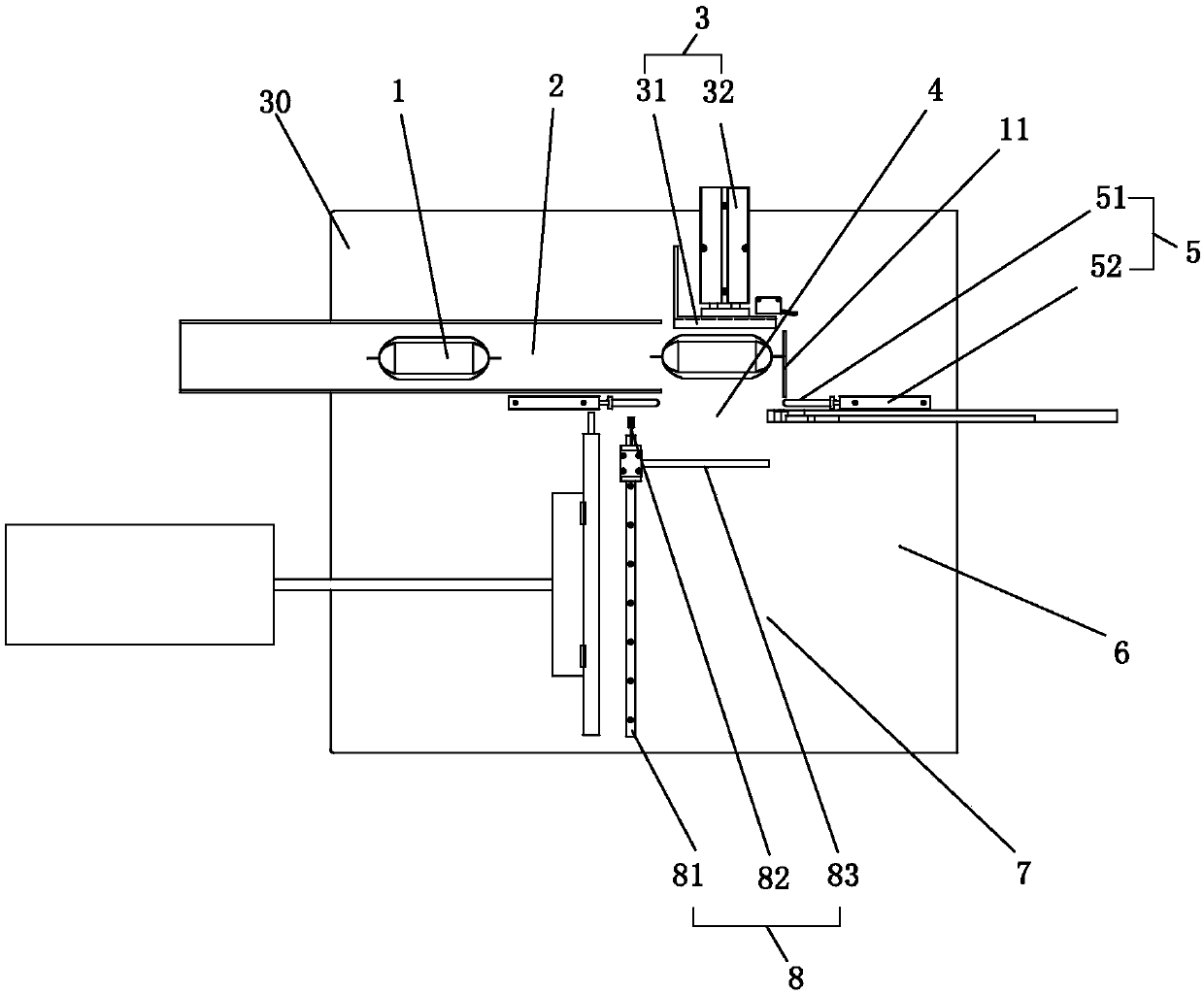

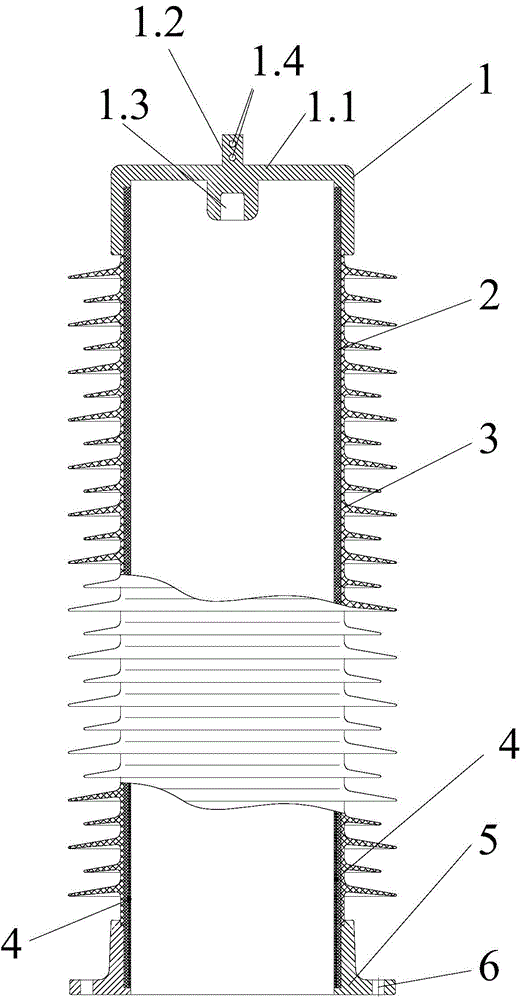

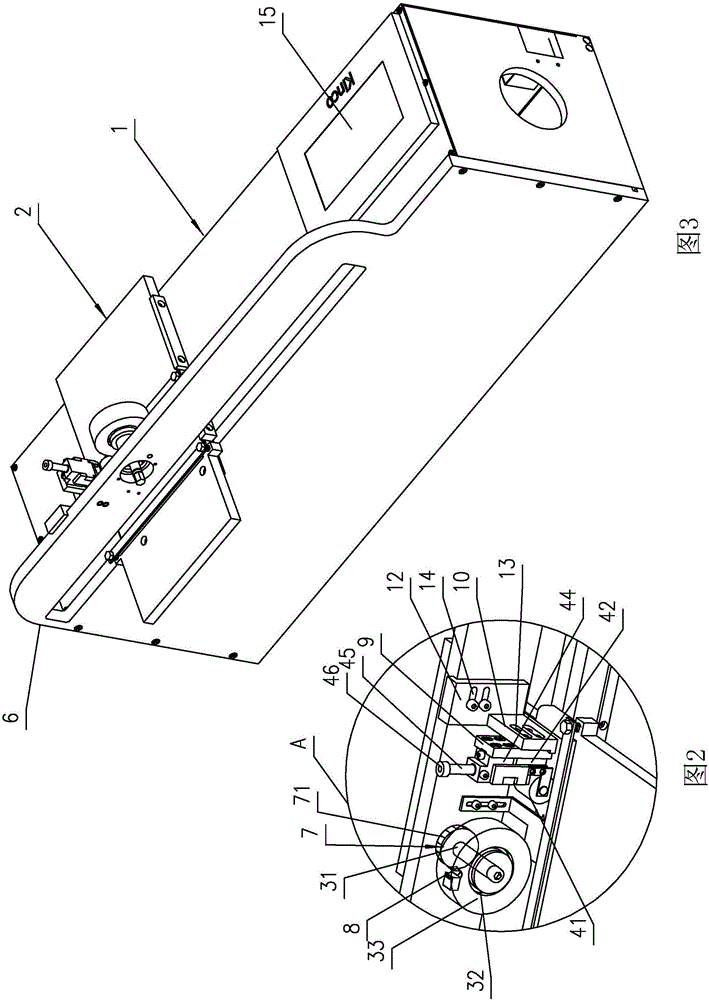

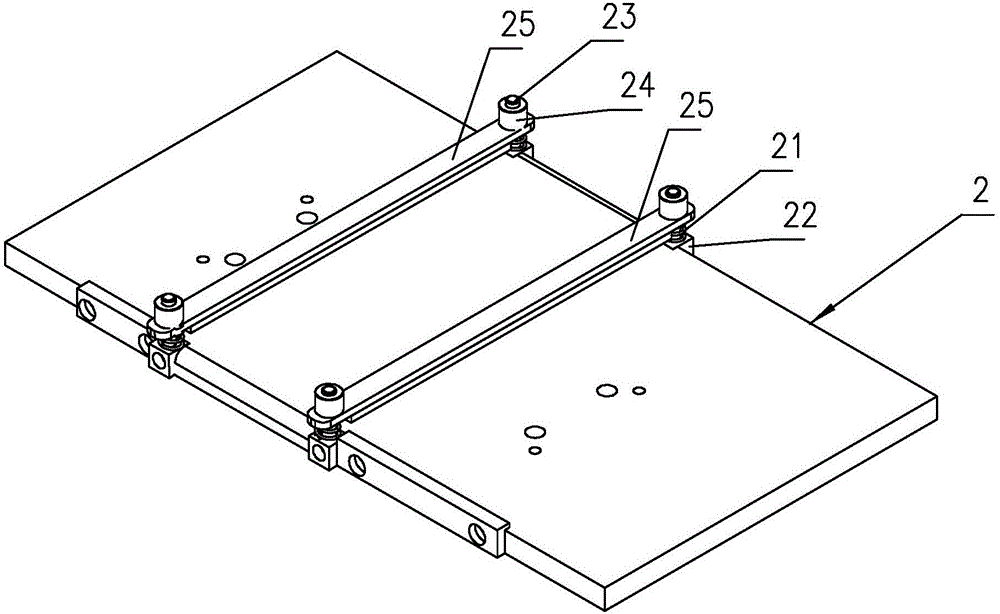

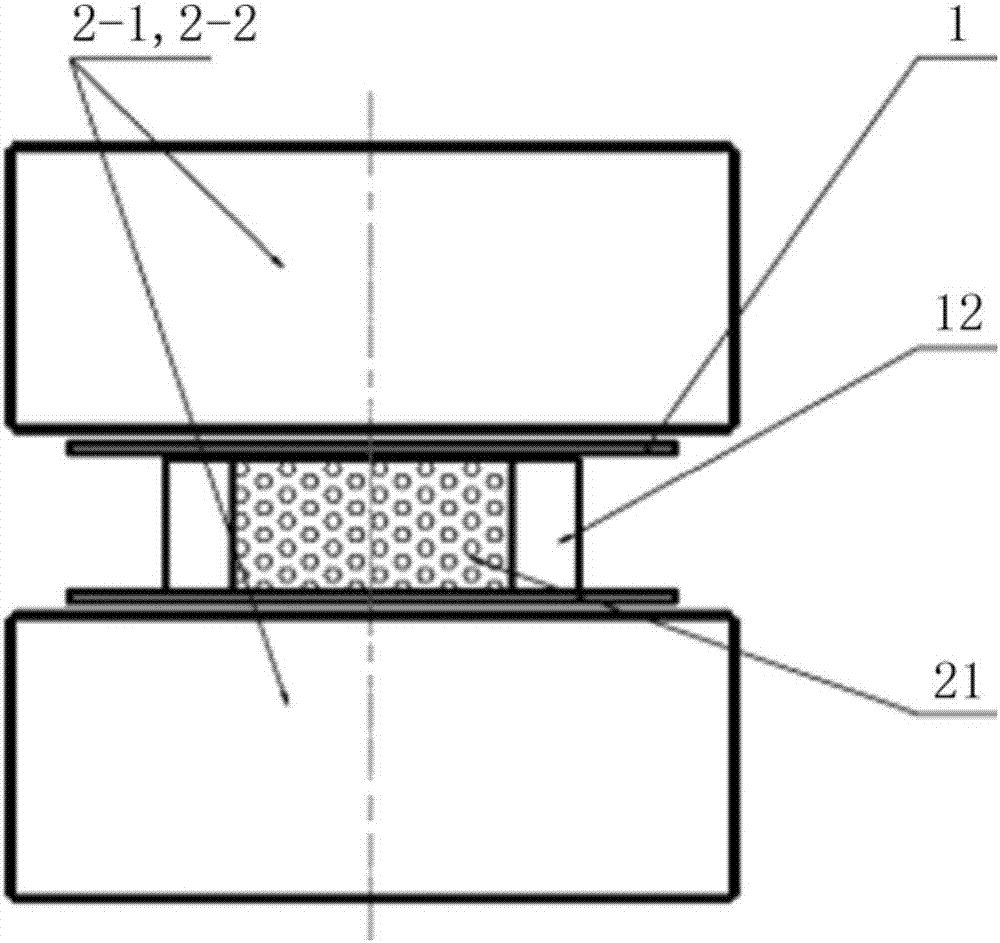

Full-automatic crystalline silicon solar cell quality testing machine

ActiveCN106328553ANo pollutionQuality assuranceSemiconductor/solid-state device testing/measurementSilicon solar cellElectric control

The invention discloses a full-automatic crystalline silicon solar cell quality testing machine. The full-automatic crystalline silicon solar cell quality testing machine includes a machine table, an electric control device, a driving mechanism, a detection table, an adhesive tape fixing device, an adhesive tape pressing wheel mechanism and a cutter; the top surface of the machine stage is provided with a mounting plate; an elongated through hole is formed in the mounting plate; the detection table passes through the elongated through hole; an elongated hole is formed in the top surface of the machine table; the driving mechanism is connected with the bottom surface of the detection table through the elongated hole so as to drive the detection table to move on the machine table; the adhesive tape fixing device, the cutter and the adhesive tape pressing wheel mechanism are all fixed on the mounting plate; the adhesive tape fixing device is mainly composed of a rotation shaft and a rotation wheel; the adhesive tape pressing wheel mechanism comprises a lifting pressing wheel; a gap is left between the pressing wheel and the detection table; the height of the gap is adjustable; and the cutter is located between the rotation wheel and the pressing wheel. With the full-automatic crystalline silicon solar cell quality testing machine of the invention adopted, automatic detection of the printing effect of silicon wafer grid lines to be detected can be realized; detection results are accurate; detection efficiency can be improved; time and effort can be saved; and the quality of silicon wafers can be ensured.

Owner:JA SOLAR

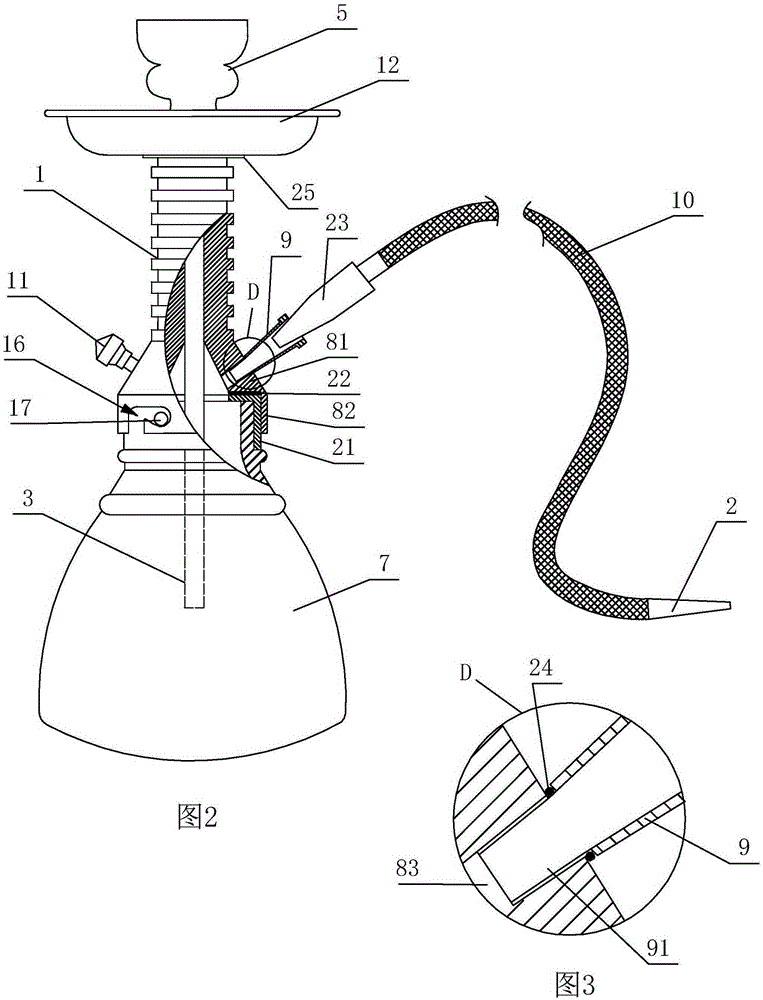

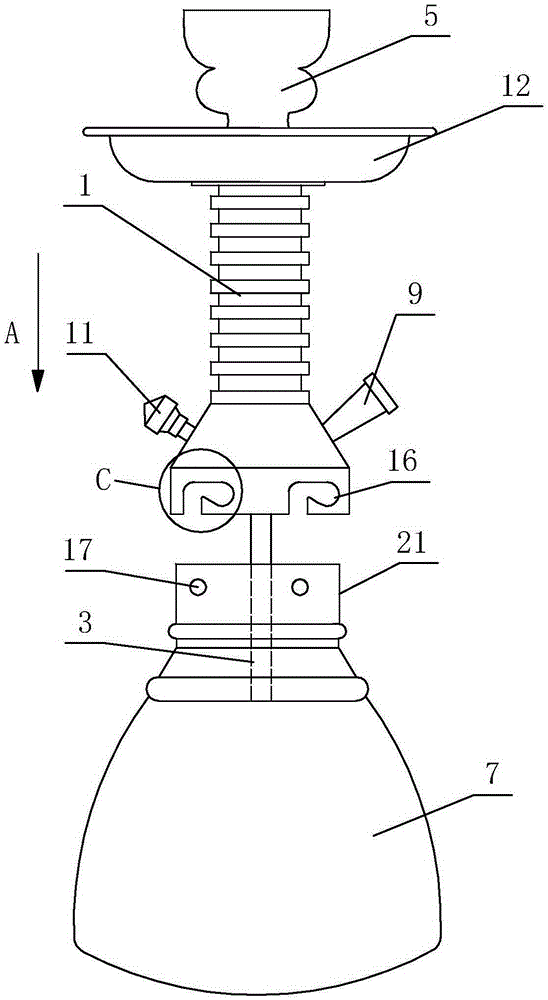

Improved type water tobacco pipe

The invention discloses an improved type water tobacco pipe which includes a tobacco pipe bowl seat, a tobacco pipe bowl, a tobacco pipe with a tobacco tube arranged therein, a water container, a hose and a tobacco holder, wherein the cavity of the tobacco pipe and the opening of the water container are connected with each other through at least one pair of buckle hole and buckle post; the buckle hole is formed in the side wall of the cavity; the buckle post is arranged on the outer wall of the opening of the water container and extends outwards; the buckle hole is mainly composed of a notch-shaped inlet and a bayonet; the inlet is communicated with the bayonet through a communicating hole matched with the buckle post cross section; the center of the bayonet is lower than that of the communicating hole, so that the buckle post can enter to the position corresponding to the communicating hole through the inlet; the tobacco pipe rotates relatively to the water container to enable the buckle post to enter the bayonet via the communicating hole and to be buckled, so as to connect the tobacco pipe and the water container, or reverse operations are carried out to enable the buckle post and the buckle hole to be separated to separate the tobacco pipe and the water container. According to the invention, the buckle post is buckled in the bayonet and is not easy to pull away, so that the water container can be effectively prevented from falling off and being damaged; when the tobacco pipe and the water container are separated, the operation is stable, and the charcoal and tobacco shred are not easy to fall off.

Owner:GUANGZHOU ZHAOYING HARDWARE

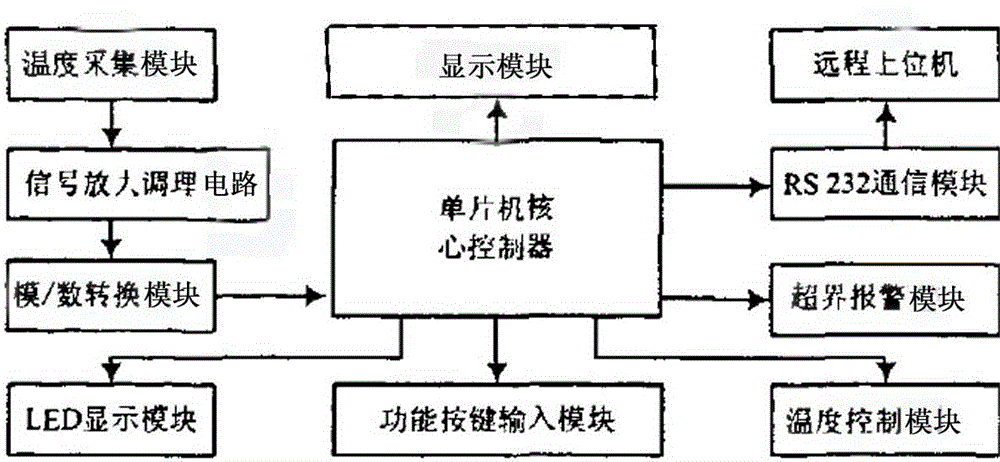

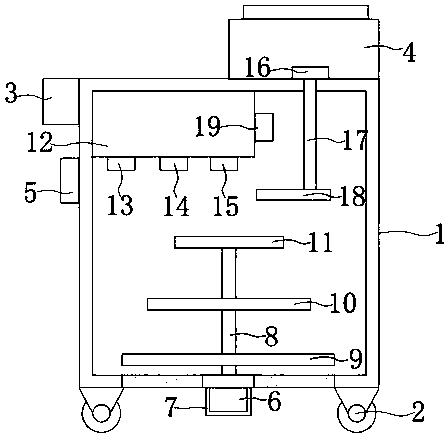

Constant-temperature control system

InactiveCN104656702ARich human-computer interaction environmentFriendly human-computer interaction environmentTemperatue controlMicrocontrollerEngineering

The invention relates to the technical field of modern electronic application, in particular to a constant-temperature control system. The constant-temperature control system comprises a single chip microcomputer controller, a temperature acquisition circuit, a signal amplifying and conditioning circuit, an analog / digital conversion module, an LED display module, a function press key input module, a temperature control module, a communication module and a display module, wherein the LED display module, the function press key input module, the temperature control module, the communication module and the display module are connected with the single chip microcomputer controller respectively; the temperature acquisition circuit, the signal amplifying and conditioning circuit and the analog / digital conversion module are connected in sequence, and the analog / digital conversion module is connected with the single chip microcomputer controller; the single chip microcomputer controller is connected with a remote upper computer through the communication module. The constant-temperature control system which has high temperature change curve visibility and the remote controllability is very suitable for the industrial remote management requirements. The constant-temperature control system is low in cost and good in expansibility; the portability of the system is improved. Water temperature can be constantly controlled within the range of 40-90 DEG C, the control error is smaller than 0.5 DEG C, the static error is smaller than 0.2 DEG C, and the constant-temperature control system can be widely applied and moved in the industry.

Owner:范云泽

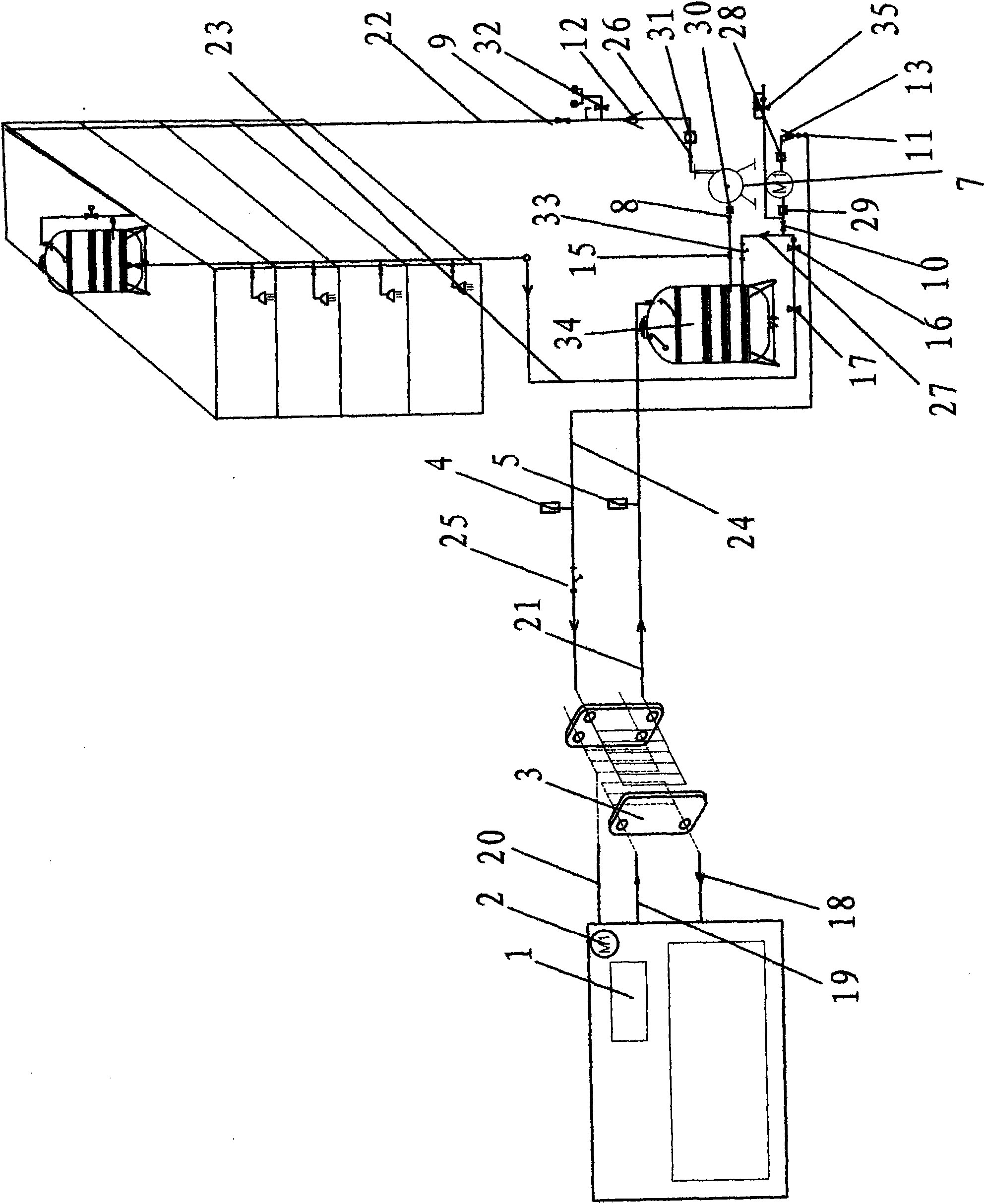

Waste heat recycling system of air compressor

InactiveCN101526076AConstitute scienceConstitute reasonablePositive displacement pump componentsPositive-displacement liquid enginesWater storageGas compressor

The invention relates to a waste heat recycling system of an air compressor, consisting of a heat exchanger, a pipeline, a water pump, a valve, a water storage device, a ball cock and a thermometer. The heated radiating circular medium in a radiator of the air compressor is connected with a heat source inlet of the heat exchanger by the pipeline; a heat source outlet of the heat exchanger is connected with a reflux port of the radiator of the air compressor by the pipeline; a cold water outlet of the heat exchanger is in series connected with the thermometer and then connected with a water inlet of the water storage device; the water storage device is provided with two water outlets; one water outlet is connected with a water inlet of the water pump by the valve; a water outlet of the water pump is sequentially connected with a check valve and the valve; and the valve is connected with a user by the pipeline. The invention has the advantages of scientific and reasonable system construction, and the like, not only can achieve heat recovery, but also has high recovery efficiency, can save large amount of heat sources, and has considerable economic benefits and wide popularization and application values.

Owner:东莞市中日盛达压缩机有限公司

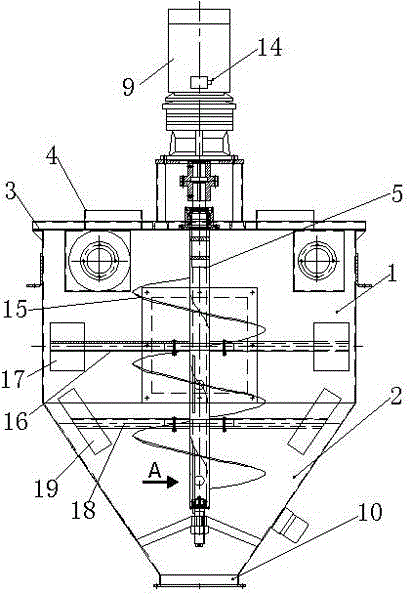

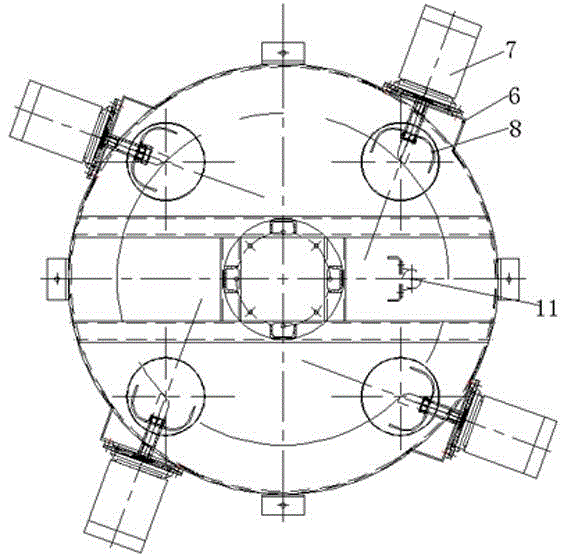

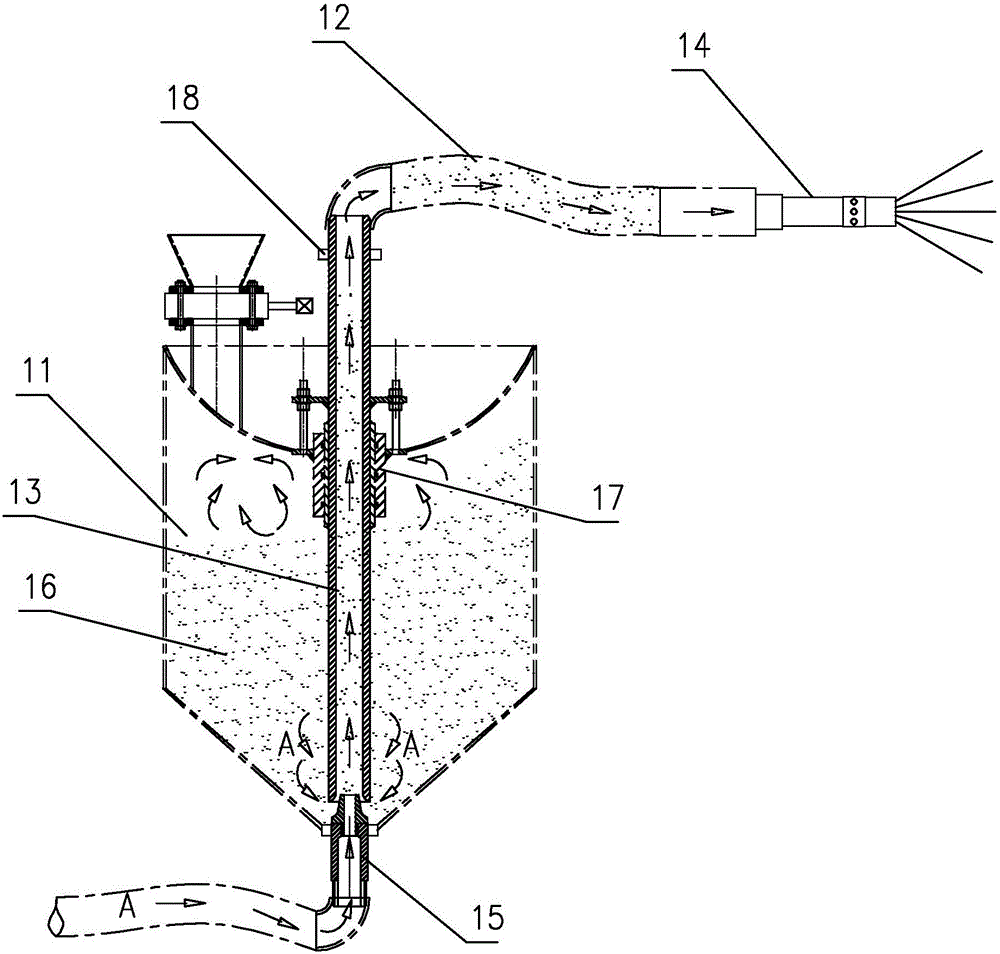

Powdered material homogenizing device

InactiveCN103331819AImprove mixing and homogenization effectImprove product qualityCement mixing apparatusMechanical engineeringFly ash

The invention relates to a powdered material homogenizing device, comprising an upper round bucket and a lower conical bucket connected with the lower end of the upper round bucket, wherein the upper end of the upper round bucket is connected with a cover plate, and at least two feed ports are uniformly distributed in the upper end surface of the cover plate along the circumferential direction. The powdered material homogenizing device is characterized in that a material stirring mechanism is respectively arranged on the circumferential wall of the upper round bucket, corresponding to each feed port; and a stirrer is longitudinally arranged in inner cavities of the upper round bucket and the lower conical bucket. The powdered material homogenizing device is compact in structure, can effectively promote the stirring and homogenizing effects of a powdered material, is particularly suitable for stirring and homogenizing materials including cement, fly ash, mineral powder, powdered additives and the like of large-scale commercial concrete mixing stations to ensure that the production quality and production process of commercial concrete are stable, and has wide popularization and application prospects.

Owner:XINJIANG KELI MACHINERY EQUIP

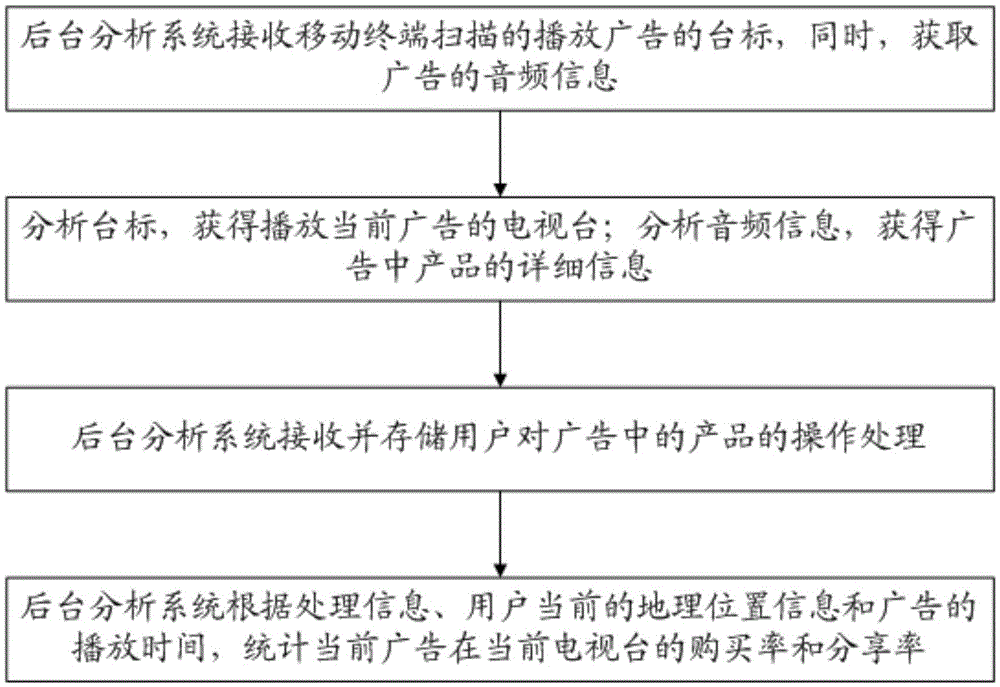

Advertisement monitoring method based on image analysis method

InactiveCN105574746AReal-time monitoring of delivery effectsWidespread publicityAdvertisementsMicrobloggingImaging analysis

The invention discloses an advertisement monitoring method based on an image analysis method and relates to the data analysis field. The method comprises steps that a background analysis system receives an advertisement playing station caption scanned by a mobile terminal, and the audio information of the advertisement is acquired; the station caption is analyzed, and a TV station playing the advertisement presently is acquired; the audio information is analyzed, and the detailed information of products in the advertisement is acquired; operation processing on the products in the advertisement carried out by a user is received and stored by the background analysis system; statistics of the purchase rate and the sharing rate of the advertisement at the present TV station is carried out by the background analysis system according to the processing information, the present geographical position information of the user and the advertisement playing time. Through the method, the advertisement products can be purchased by customers or shared to social network platforms such as the WeChat and Twitter, moreover, real-time business advertising effect monitoring is realized.

Owner:叶澎涛

Preparation method of hyaluronic acid-chitosan biomembrane

The invention provides a preparation method of a hyaluronic acid-chitosan biomembrane, wherein the biomembrane, which contains hyaluronic acid and carboxymethyl shitosan, is prepared by the crosslinking reaction of hyaluronic acid, carboxymethyl shitosan and polyvinyl alcohol in the presence of a crosslinking agent. The hyaluronic acid-chitosan biomembrane of the invention has good biological compatibility and longer half-life, and is favorable to improve the success rate of the glaucoma filtration operation and widely popularize the non - penetrating trabecular operation.

Owner:上海建华精细生物制品有限公司

Lilium brownii var.viridulum filial generation bulb expanding, developing and rooting method

ActiveCN106665364APromote rootingSatisfy industrializationHorticulture methodsPlant tissue cultureLilium columbianumSeedling

The invention provides a lilium brownii var.viridulum filial generation bulb expanding, developing and rooting method which comprises the following steps: 1, saving lilium brownii var.viridulum filial generation embryonic plants to make seedlings; 2, performing clumpy bud multiplication and quickly multiplying the seedling amount to make clump seedling; 3, performing bulblet induction and cultivating differentiated bulbs; 4, expanding and rooting bulblet, cultivating larger bulbs, rooting the larger bulbs and using the larger bulbs as a breeding original material for production to be directly transplanted into fields to be planted. By means of optimizing influence factors of quick expansion and rooting cultivation of hybrid lily bulbs, technical support is provided for large-scale production of lilium brownii var.viridulum filial generation test-tube plantlets; furthermore, technical assurance is provided for large-scale production of edible lilium brownii var.viridulum filial generation test-tube plantlets, and requirements of market for edible lily new hybrid varieties are met; thus, lilium brownii var.viridulum planting cost is reduced.

Owner:YICHUN UNIVERSITY

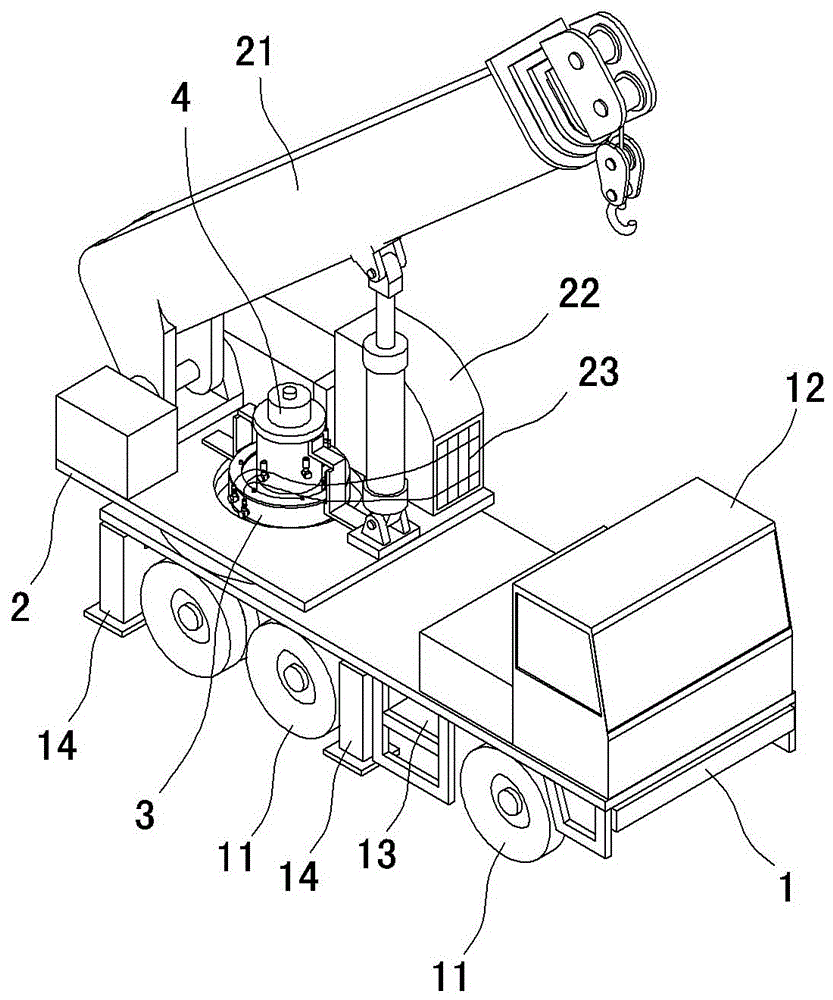

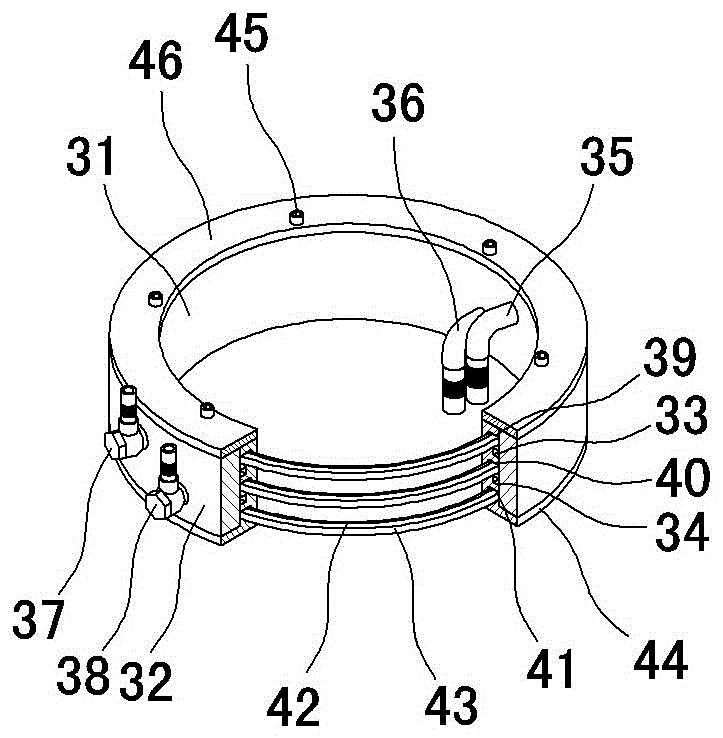

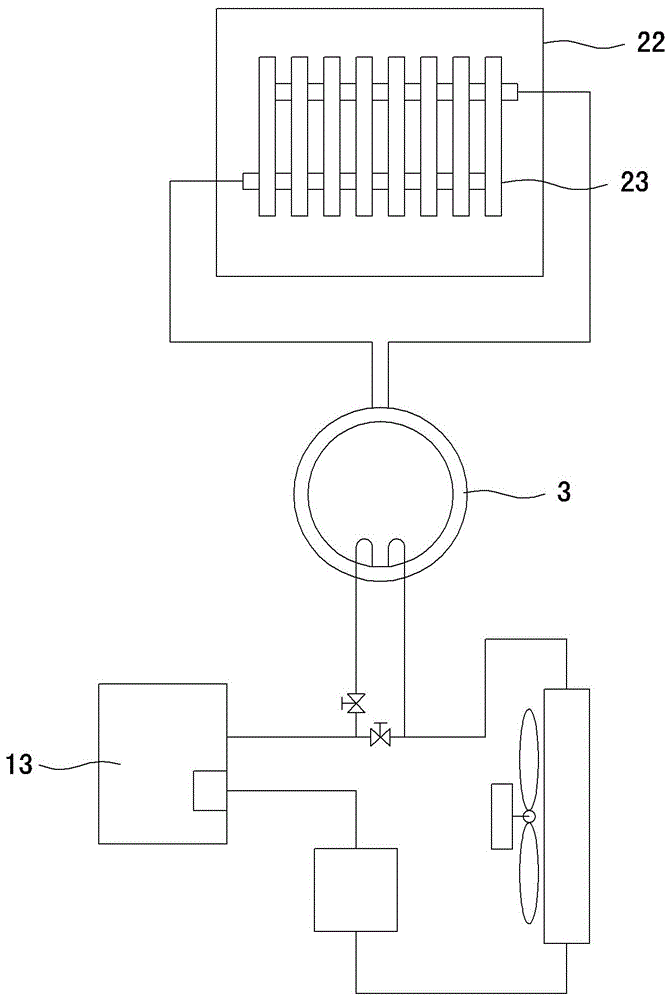

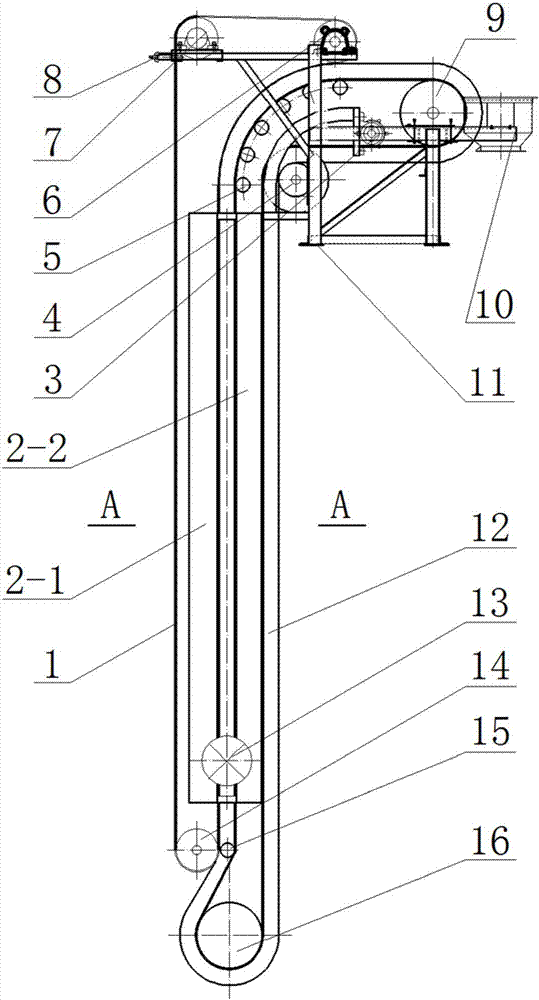

An autocrane heating a lifting control room by utilizing cooling water of a lower-vehicle engine

InactiveCN106167232AReduce winter operating costsImprove cooling efficiencyLoad-engaging elementsCranesControl roomEngineering

The invention relates to an autocrane heating a lifting control room by utilizing cooling water of a lower-vehicle engine. A revolution water feeder (3) is disposed between a lower vehicle (1) and an upper vehicle (2) and includes a fixed body (31) and a revolution body (32) which are in rotation matching. A first annular water path (33) and a second annular water path (34) are disposed between the fixed body (31) and the revolution body (32). The fixed body (31) is provided with a first pipe joint (35) and a second pipe joint (36) which are separately in series connection in a cooling water circulating pipeline of an engine (13). A heat dissipation finned radiator (23) is disposed in the lifting control room (22). The revolution body (32) is provided with a third pipe joint (37) and a fourth pipe joint (38) respectively communicating with the heat dissipation finned radiator (23). The cooling water of the lower-vehicle engine is utilized to heat the lifting control room of the upper vehicle, and therefore consumption of a large amount of fuel for heating lifting control rooms of autocranes having medium and small sizes in winter is not required, the running cost of the autocrane in winter in reduced, and energy conservation and emission reduction are facilitated.

Owner:刘长富

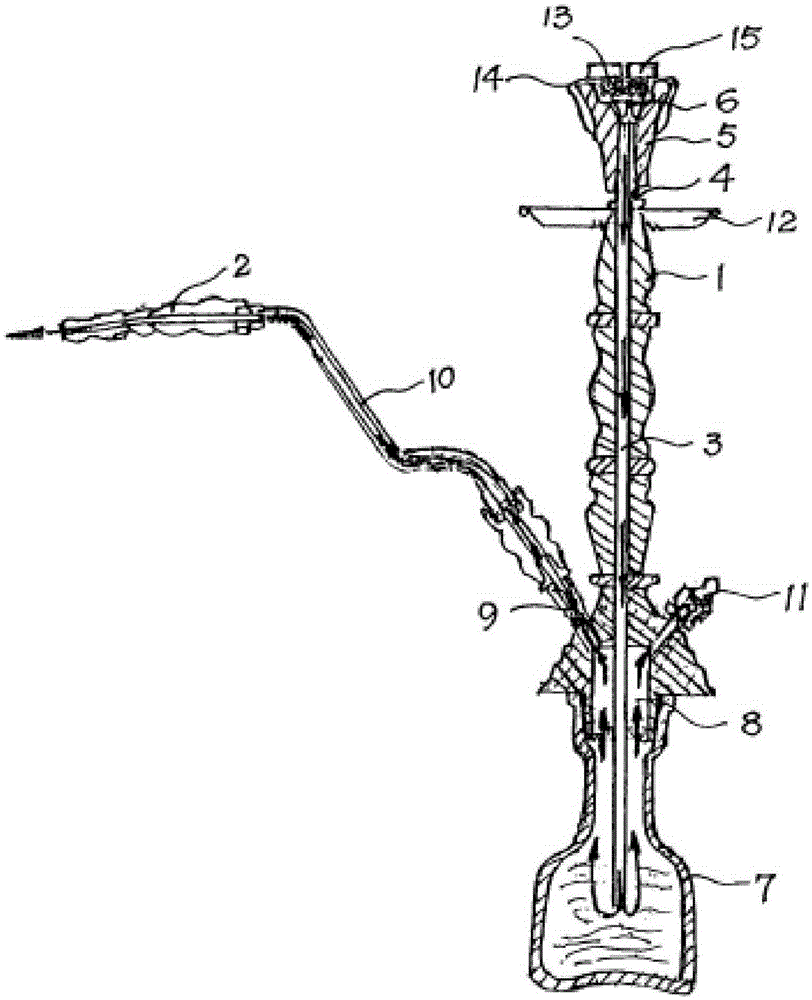

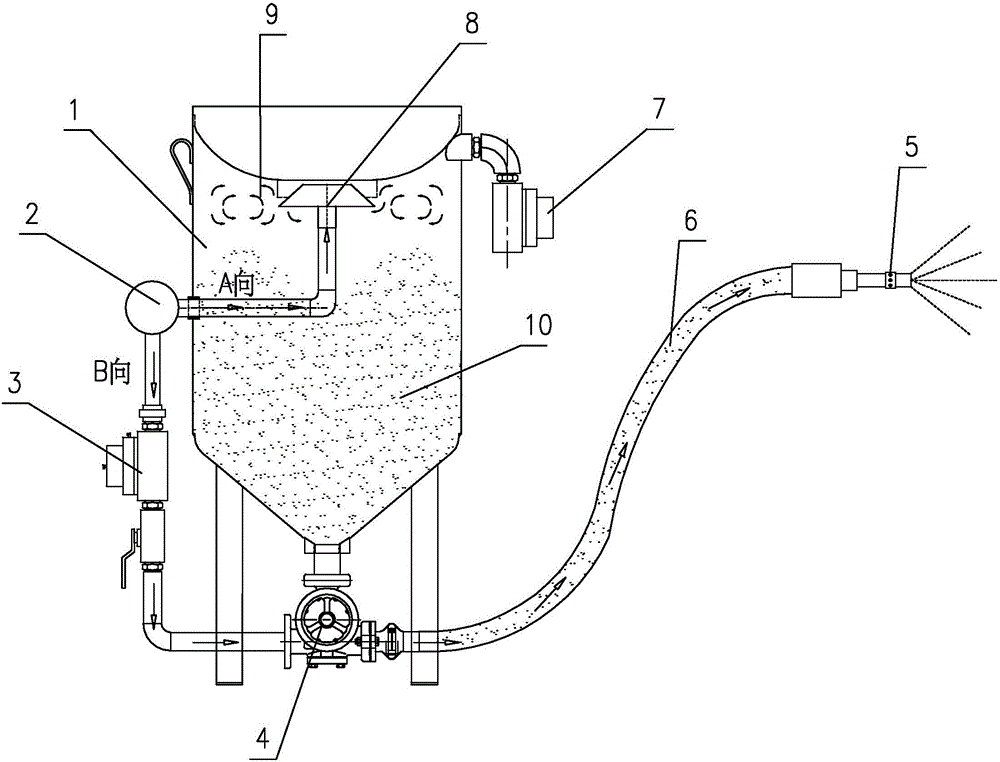

Pressure sand blasting device for micro-powder sand

InactiveCN105881225ASolve a series of problems caused by the phenomenon of tower bridge with fine powder sand materialSimple structureBlast gunsAbrasive feedersSiphonSand blasting

The invention discloses a pressure sand blasting device for micro-powder sand. The pressure sand blasting device comprises a pressure tank containing sand and a sand blasting pipe. The pressure sand blasting device for the micro-powder sand further comprises a siphon vertically arranged in the pressure tank. The siphon upwards penetrates the pressure tank to be connected with the sand blasting pipe and downwards stretches to the bottom of the pressure tank. A jet flow air nozzle used for jetting compressed gas is arranged at the bottom of the pressure tank. The jet flow air nozzle stretches in a lower siphon opening of the siphon, and a gap exists between the jet flow air nozzle and the lower siphon opening of the siphon. Compressed gas is jet into the siphon through the jet flow air nozzle, and therefore jet flow dynamic pressure is formed at the lower siphon opening of the siphon so as to drive the sand in the pressure tank to enter the siphon and be jet out upwards through the sand blasting pipe. According to the pressure sand blasting device for micro-powder sand, an existing sand outlet valve assembly is replaced with the siphon, the structure is simplified, the manufacturing cost is greatly reduced, manufacturing and maintaining are convenient, sand discharging is continuous and stable, and the working efficiency is improved; and in addition, the sand inlet amount can be conveniently adjusted, and the production cost is reduced.

Owner:GUANGZHOU CITY CONSTR COLLEGE

Method for detecting flour for preparing fresh and wet flour products

ActiveCN104359736AWidely promotedMeet market demandMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationStandard samplesChemistry

The invention discloses a method for detecting flour for preparing fresh and wet flour products. The method for detecting the flour for preparing the fresh and wet flour products comprises the following steps: preparing a soak solution, preparing a standard sample, preparing a sample to be tested, treating the sample to be tested, treating the standard sample, calibrating the standard sample, calibrating the sampled to be tested, and determining the acceptable products. According to the detection method, the strong basicity of Na2CO3 is utilized, and the natural oxidation process of the flour products within 8 hours can be simulated within 20 minutes, so that the color change degree of the flour products within 8 hours in the flour preparation process can be reflected; the method is suitable for detecting the flour used for preparing fresh and wet noodles, wonton and boiled dumplings, and is capable of detecting whether the flour is qualified or not within a short time, thus being in accordance with the demand of the market and being widely popularized.

Owner:安徽侯王面业有限公司

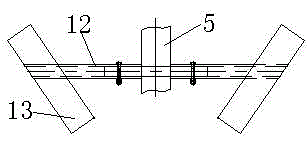

Automatic material taking device for vertical air cushion clamping conveyer

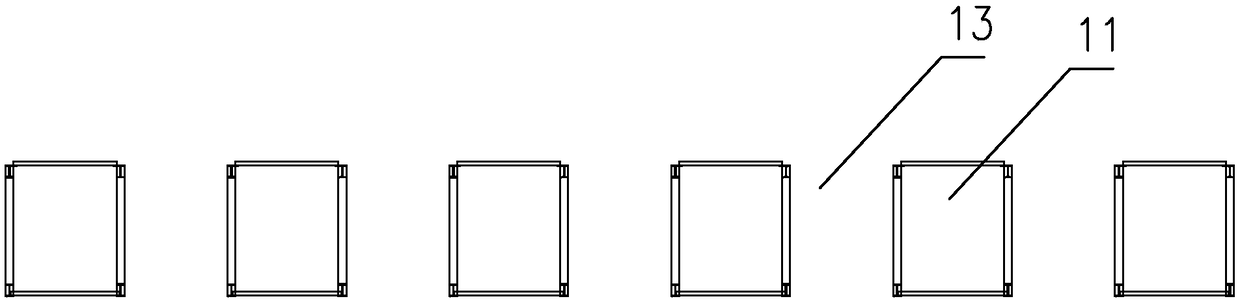

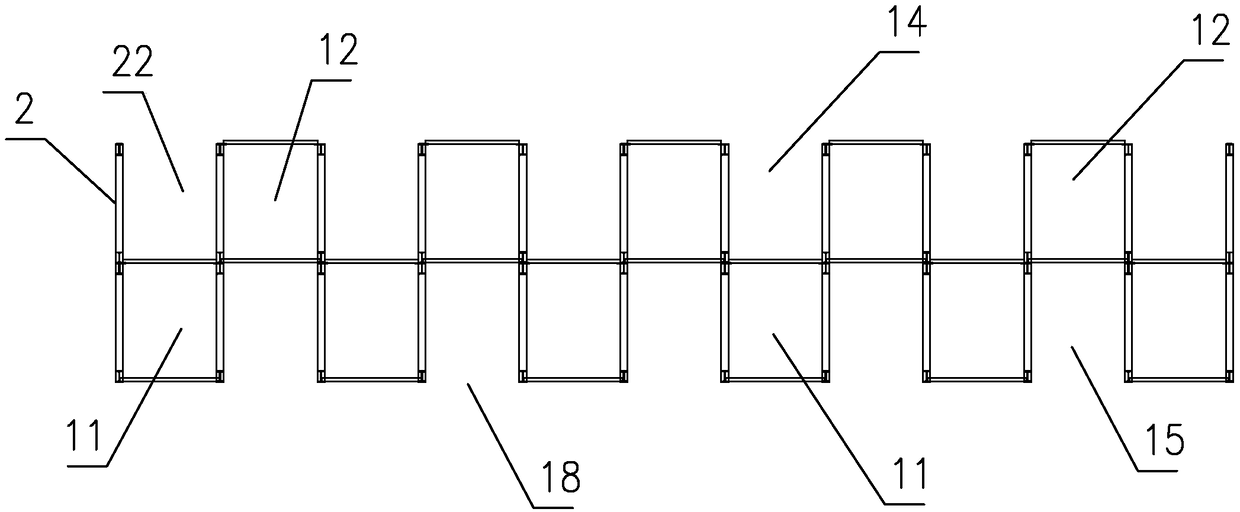

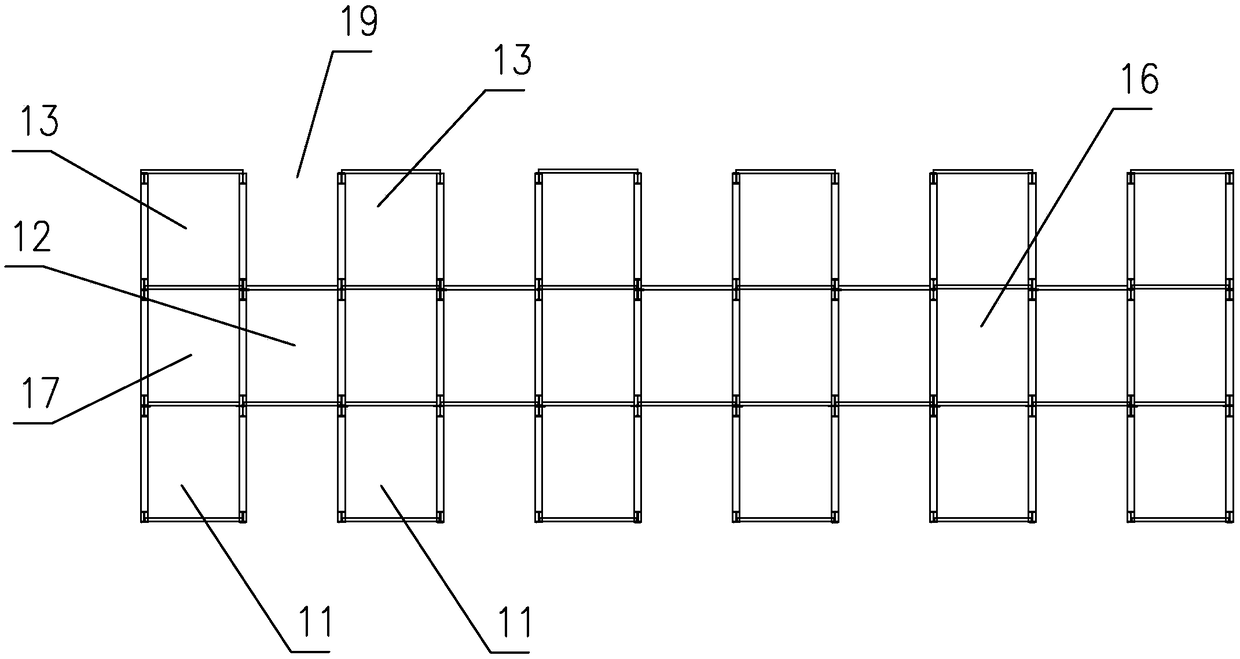

PendingCN107215613ASimple structureImprove performanceConveyorsPackagingWave shapeProviding material

The invention relates to an automatic material taking device for a vertical air cushion clamping conveyer. The automatic material taking device for the vertical air cushion clamping conveyer comprises a vertical lifting section, the vertical lifting section includes a wave-shaped edge blocking conveying belt (12) and a covering belt (1), a material taking roller (16) is arranged at the bottom of the vertical lifting section, the wave-shaped edge blocking conveying belt (12) is wound on the material taking roller (16), and a redirection roller (14) and a compression roller (15) which are used for mounting and compressing the covering belt (1) are arranged above the material taking roller (16). Compared with the prior art, the automatic material taking device for the vertical air cushion clamping conveyer has the beneficial effects that a passive material bearing device in an existing air cushion conveyer is improved into an automatic material taking device, automatic material taking and conveying are achieved, meanwhile, other material taking equipment for providing materials is not needed to be configured independently, so that the application range of existing vertical air cushion conveyers is further widened. The automatic material taking device for the vertical air cushion clamping conveyer is simple in structure, reliable in property and high in conveying efficiency, can save energy and is environmentally friendly.

Owner:SUZHOU NIUKU CONVEYING MACHINERY CO LTD

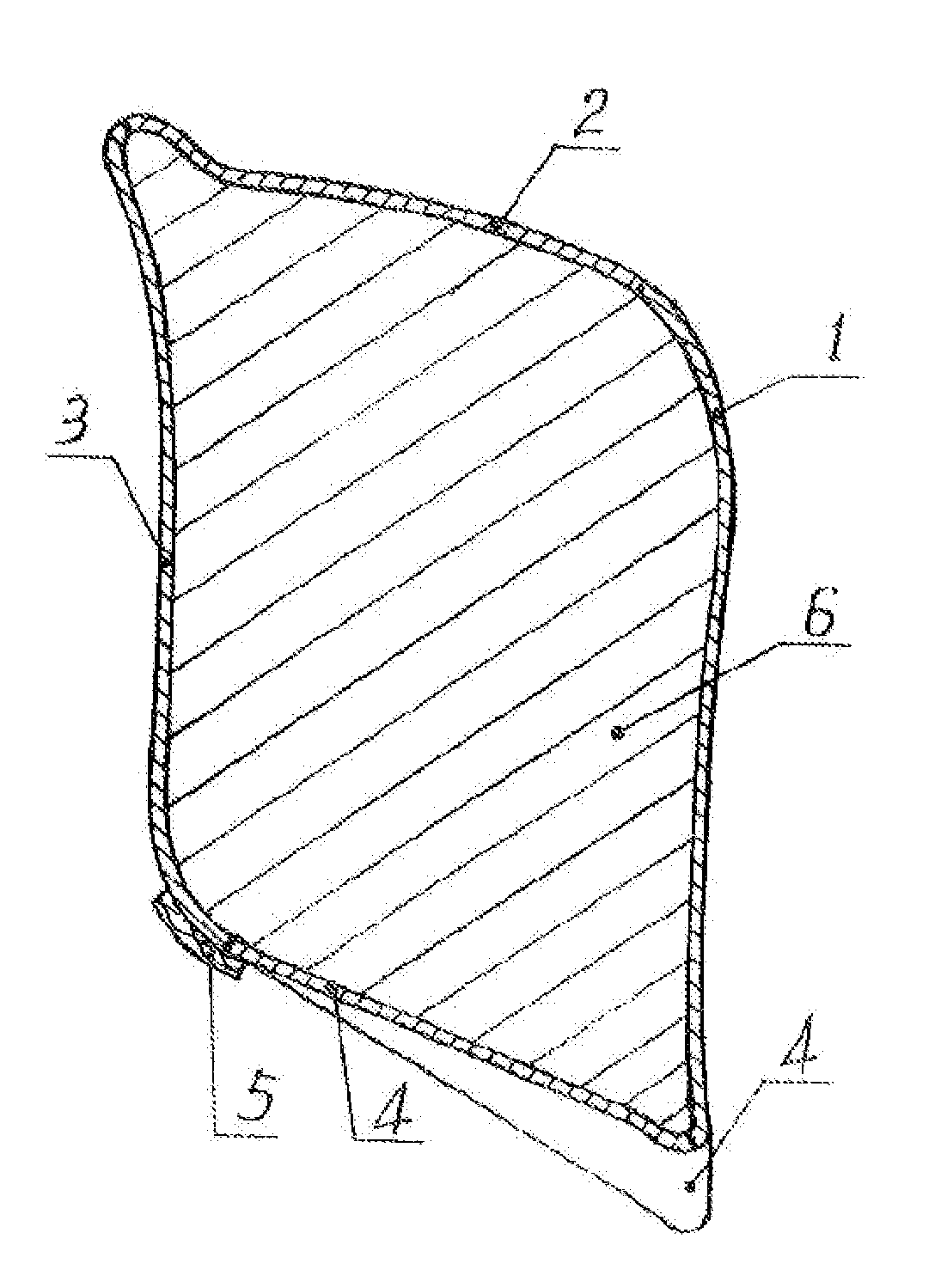

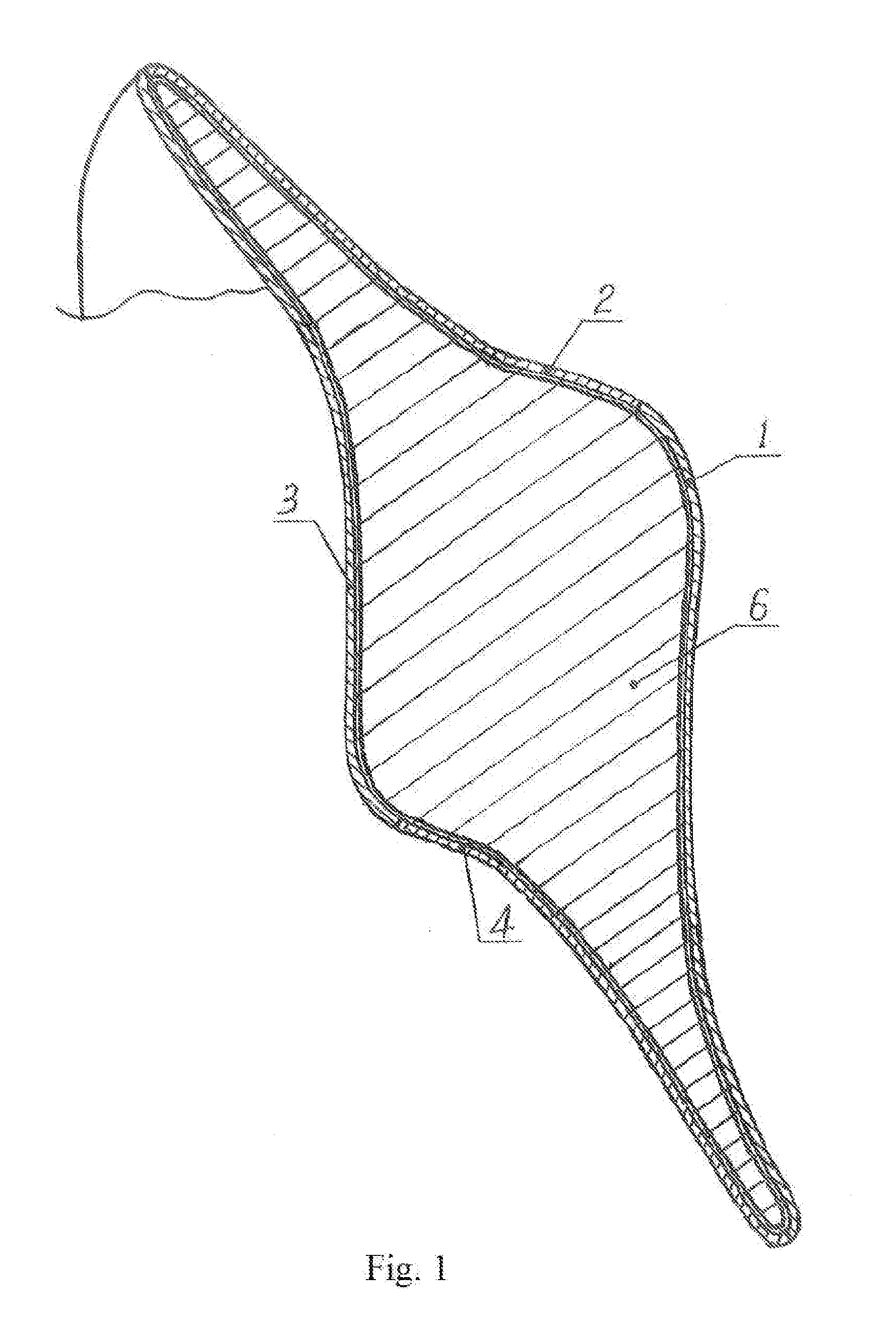

Automobile neck pillow

InactiveUS20130038111A1Improve air qualityFeel comfortableVehicle seatsOperating chairsOxygen ionsEngineering

An automobile neck pillow relates to an automobile seat articles technology field, which adopts a key technology truly adapted to human mechanical physiological curves and makes a multiple choice about materials of a core body and an elongated housing and a scientific measurement about shapes and sizes thereof to make the core body and the elongated housing match with each other, wherein the core body is soaked in medical liquids of health care to provide health care and healing to the neck, the core body is attached with a bamboo charcoal fiber cushion, an infra-red cloth, or a negative oxygen ion cloth while integrally being sprayed with perfume, and a brace provided in the elongated housing is mounted between a seat and a head cushion by a longitudinal fixation, a transverse fixation, a combination of longitudinal and transverse fixation, a head-sleeving fixation, or an integral fixation with the head cushion.

Owner:HUANG LEI

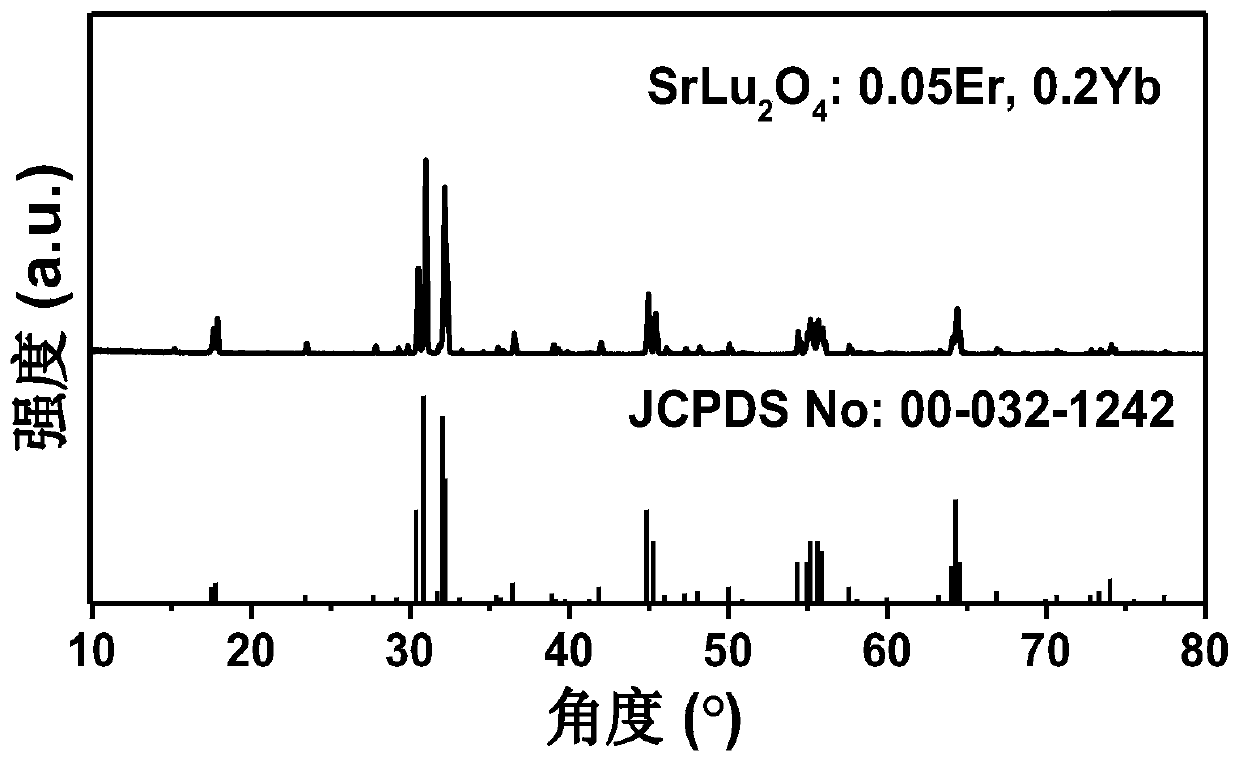

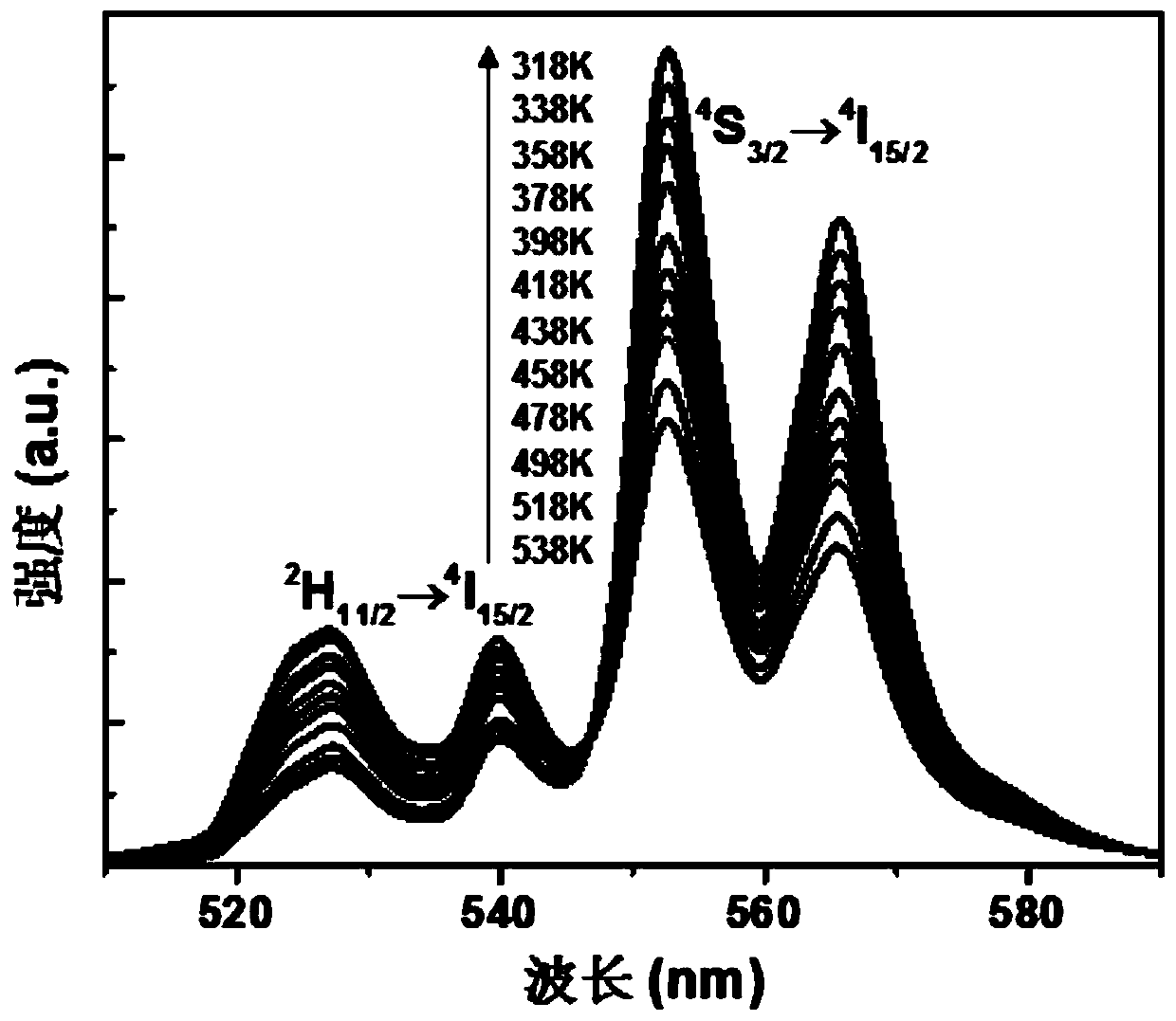

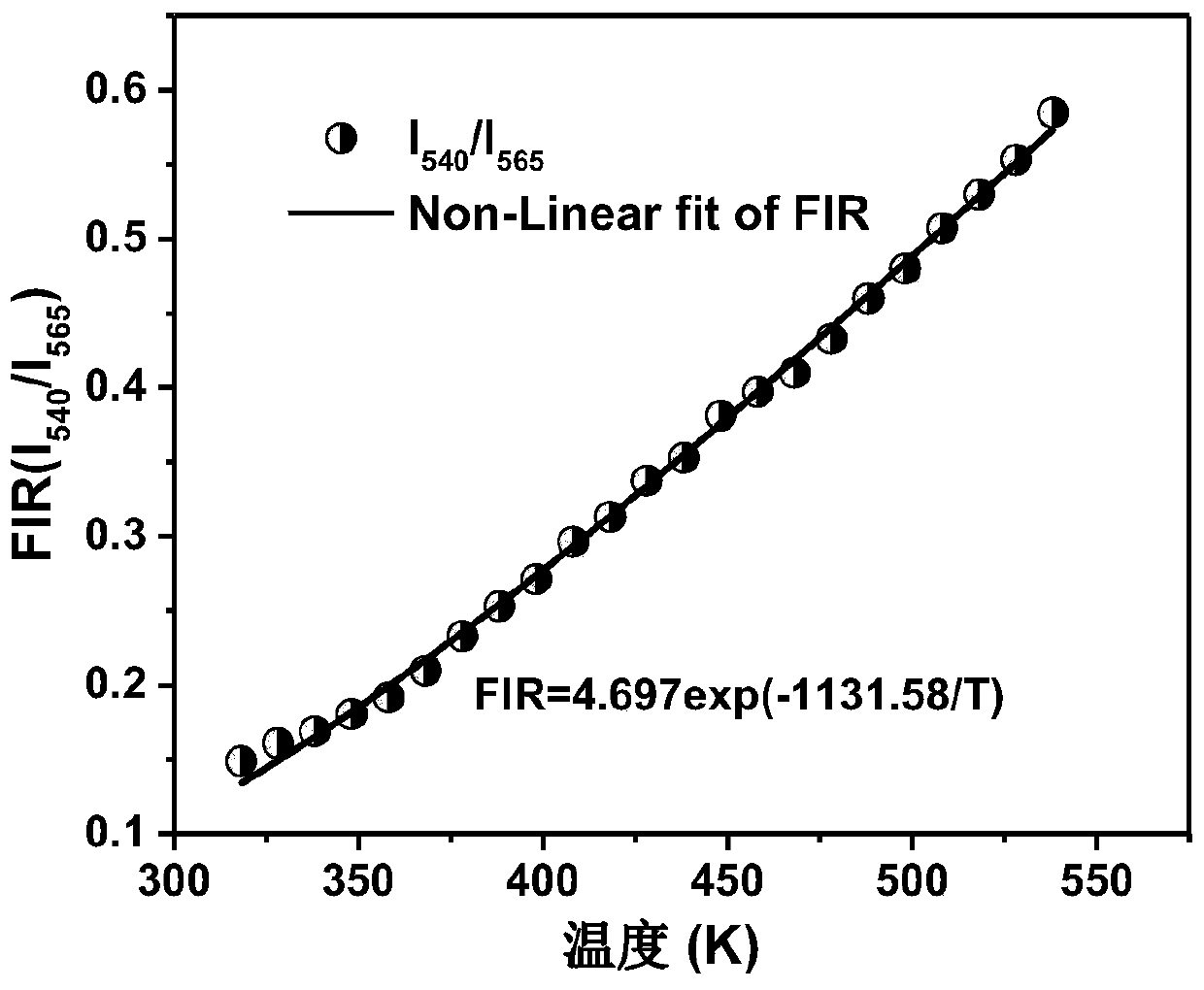

High-sensitivity up-conversion temperature measurement material as well as preparation method and application thereof

ActiveCN110330971ARealize non-contact measurementReduce dependenceThermometers using physical/chemical changesLuminescent compositionsRare earth ionsStructural formula

The invention discloses a high-sensitivity up-conversion temperature measurement material as well as a preparation method and application thereof. The general structural formula is MA2O4: xEr<3+> / yYb<3+>, wherein M is selected from Ca, Sr or Ba, and A is selected from La or Lu; x: y is equal to (1-15):20. The material adopts laser of 980nm as an excitation light source, and emits emission peaks ofthermally coupled energy levels at 540 nm and 552 nm respectively. By utilizing the fact that the number of particles on the thermally coupled energy levels of rare earth ions follows the Boltzmann distribution law, the layout of the number of particles and the temperature have a quantitative relationship, so that the measurement of actual temperature is realized. The method is extremely small inerror and high in sensitivity, effectively realizes fast response and real-time monitoring of subtle changes of the temperature, also has the advantages of simple preparation, ready availability of the raw materials, stability, reliability, low cost and the like, and is suitable for being widely applied and popularized.

Owner:CHONGQING UNIV OF TECH

Method for preparing pig corneal endothelium implant piece by adopting femtosecond laser technology for assistance

ActiveCN109363801AGood biocompatibilityReduce the difficulty of transplantationEye implantsLaser technologyCorneal surface

The invention discloses a method for preparing a pig corneal endothelium implant piece by adopting a femtosecond laser technology for assistance. The method comprises the following steps that S1, a pig cornea is pretreated; S2, after the pig cornea enters an interactive interface of a femtosecond laser machine, surgical parameters of femtosecond lasers are set according to a pig cornea thickness value measured before surgery, the lasers are precisely gathered on a set corneal surface and flattened, and laser blasting and gasified cutting are conducted to complete manufacturing of a corneal posterior lamellum implant piece which is a corneal endothelium piece with a posterior elastic layer, wherein the thickness is 100 microns, and the diameter is 8.5 mm; S3, decellularization operation isconducted through physical methods such as swelling, repeated freezing and thawing, shaking and air drying; S4, the pig corneal endothelium implant piece is prepared. The method adopts an instantaneous laser blasting technology so that precise corneal cutting can be completed, the immunogenicity of a pig corneal matrix piece is reduced, and the ultra-thin pig corneal endothelium implant piece withthe posterior elastic layer can also be prepared at the same time, so that transplantation difficulties caused by nonuniform thickness are greatly reduced.

Owner:黄国富 +1

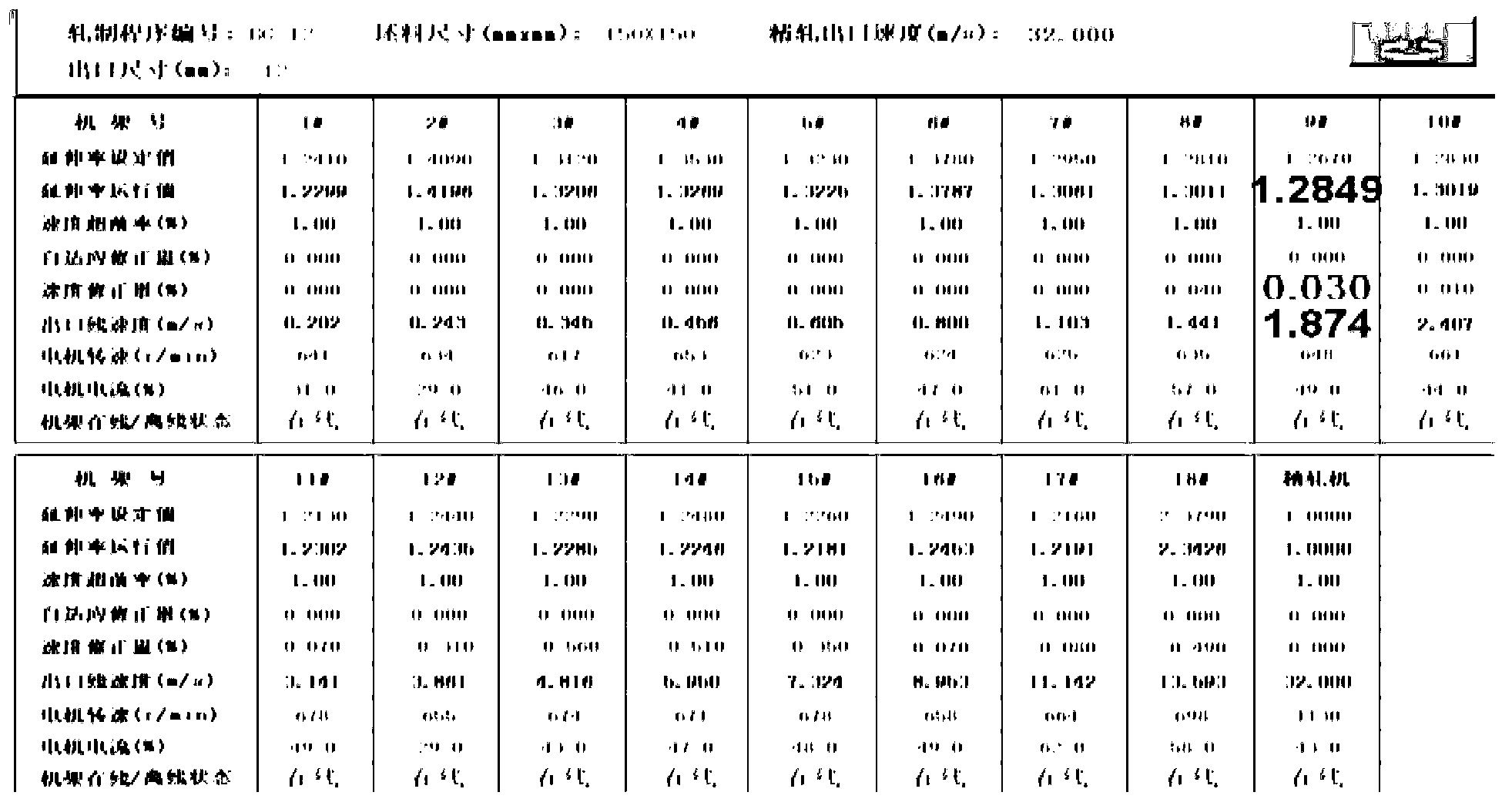

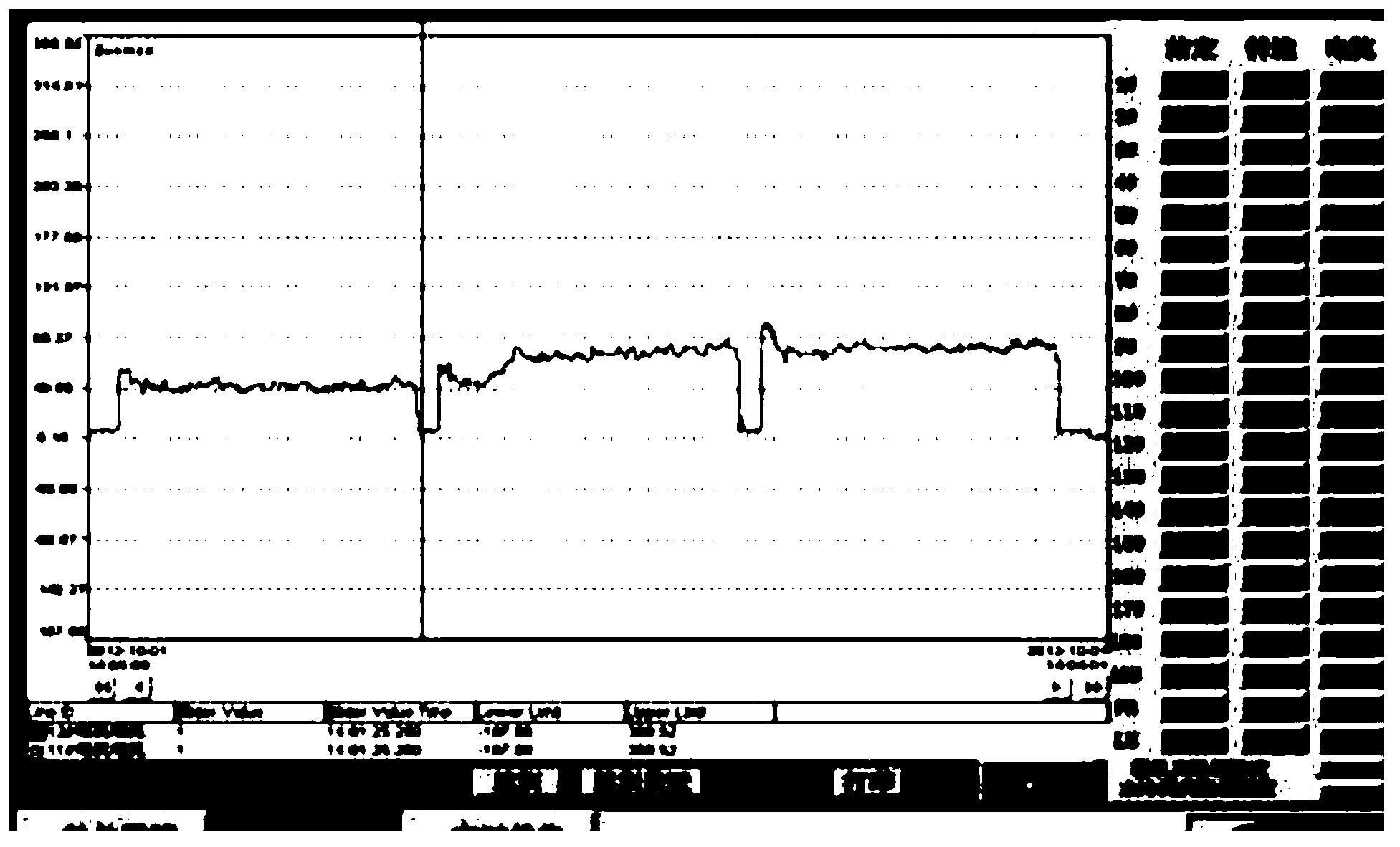

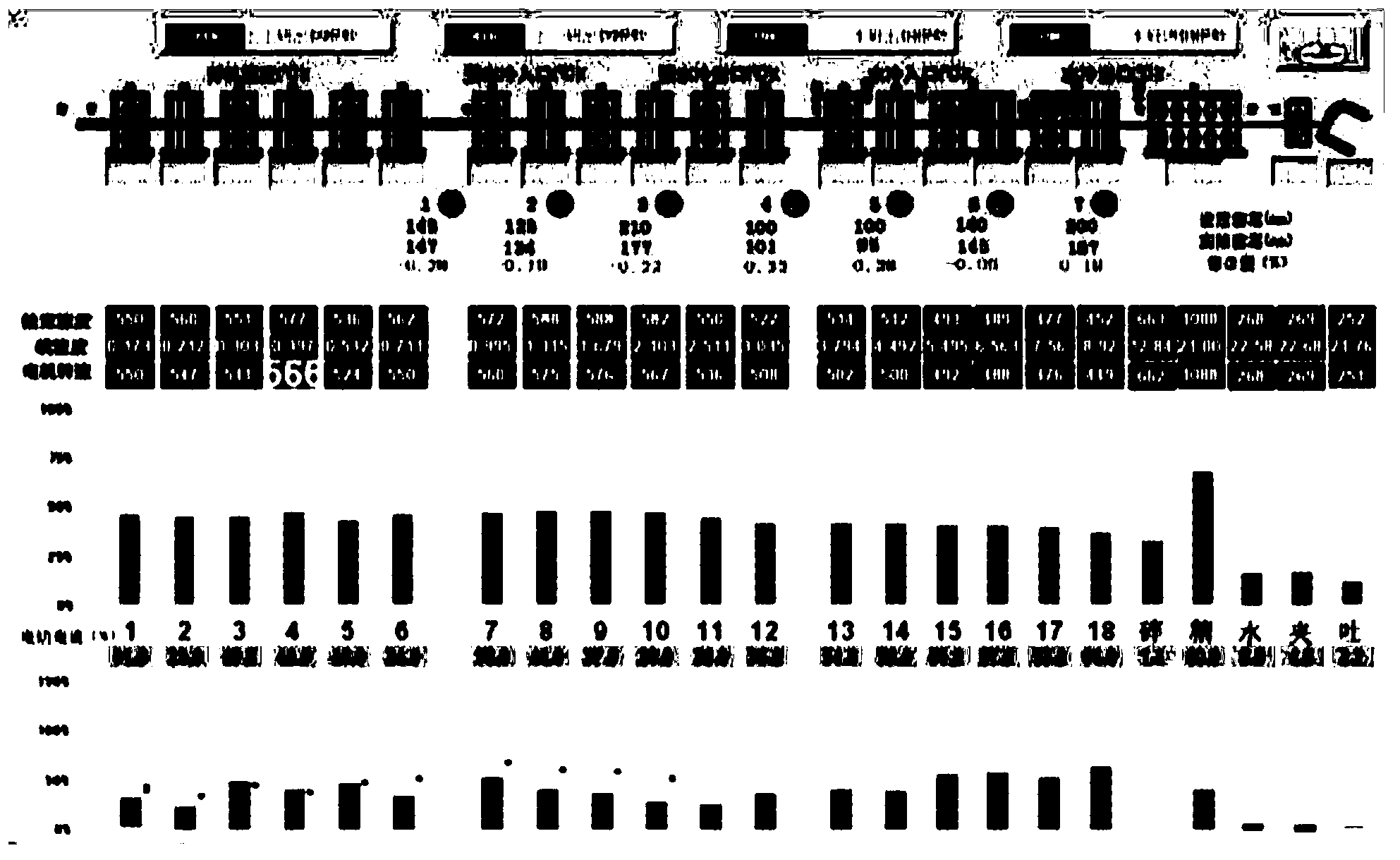

Method for judging whether rolling guide position of high-speed wire production line is damaged or not

InactiveCN103230947ASteel-holding accideCause massGuiding/positioning/aligning arrangementsMeasuring devicesProduction linePower flow

The invention discloses a method for judging whether a rolling guide position of a high-speed wire production line is damaged or not. The method is adopted to judge whether the guide position is about to be damaged or not according to change of load current of a rolling mill of a machine frame where the guide position is located and change of load current of rolling mills of adjacent machine frames. The method can be used for guiding steel rolling production and avoiding a stuck steel accident and a quality accident caused by the managed rolling guide position.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

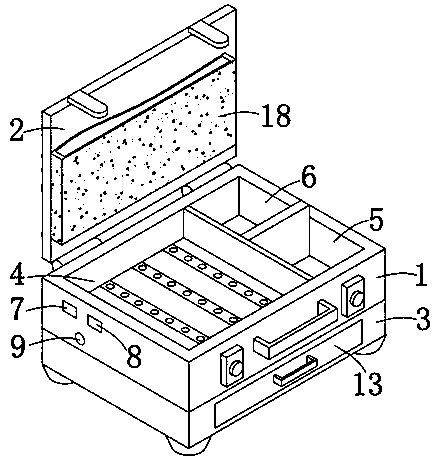

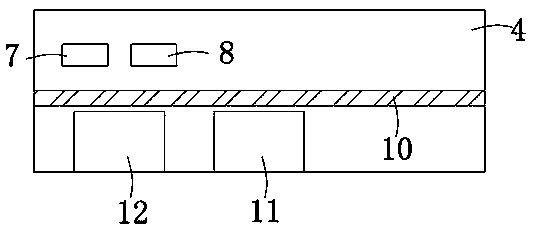

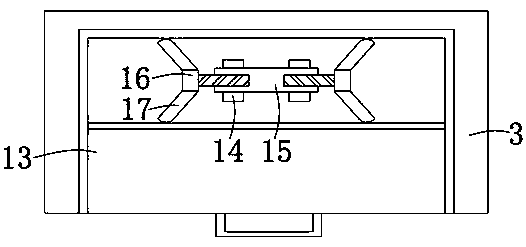

Portable multifunctional computer protection box

InactiveCN108968266AEasy to fixImprove cooling effectPursesLuggageInstrumentationComputer engineering

The invention discloses a portable multifunctional computer protection box. The portable multifunctional computer protection box comprises a protection box shell; an upper cover is movably connected to the outer side wall of the protection box shell through a hinge, and a tool box is fixedly connected to the bottom end of the protection box shell; a computer storage slot is formed in the protection box shell; a first accessory slot is formed in one side of the computer storage slot, and in the protection box shell through a separation plate; a second accessory slot is formed in the upper sideof the first accessory slot. The portable multifunctional computer protection box has the advantages that precise instruments for construction detection are put into a drawer in the tool box, and an inner threaded sleeve is rotated to reversely move bolts on two sides, so that the distance from the inner side wall of the tool box is conveniently adjusted through a clamping block, the detection instruments in different sizes are conveniently fastened, time and labor are saved, multifunction is realized, and the application range is wide; through a handle on the protection box shell, movement isfacilitated, convenience in use is improved, and widespread promotion and popularization are benefited.

Owner:DEZHOU VOCATIONAL & TECHN COLLEGE

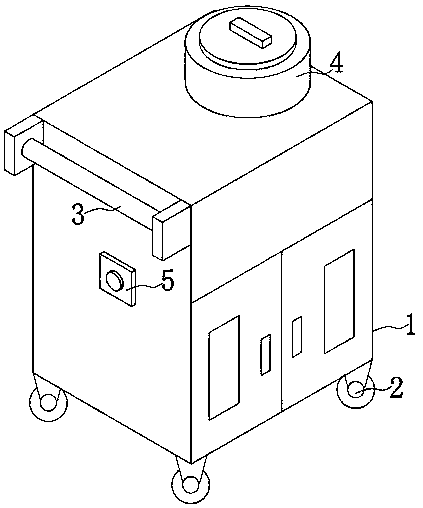

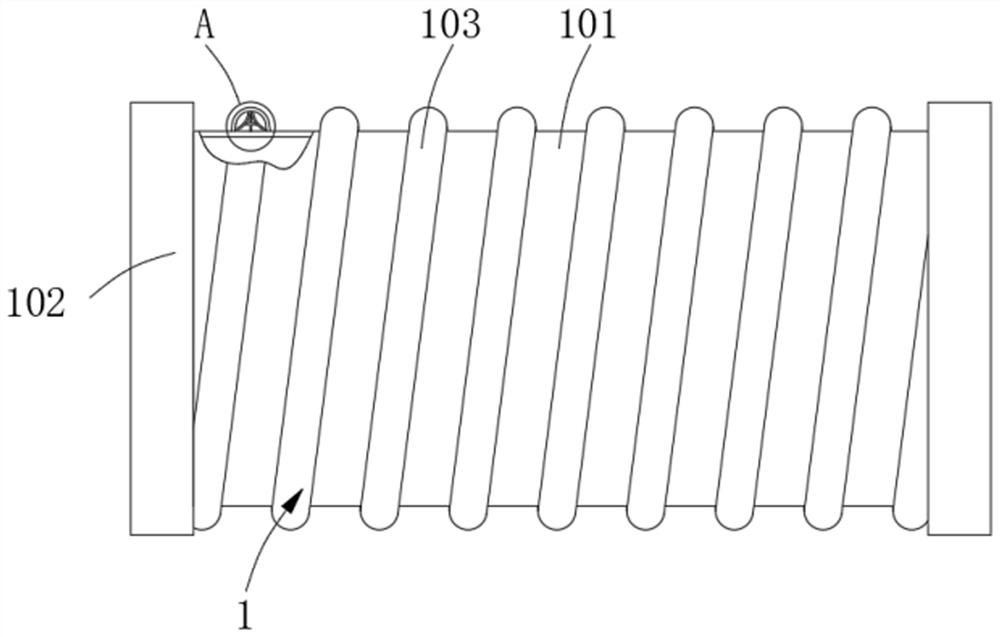

Vegetable cultivation box based on Internet of Things

InactiveCN110352748ASimple structureReasonable designTransmission systemsClimate change adaptationDrive shaftThe Internet

The invention discloses a vegetable cultivation box based on Internet of Things. The vegetable cultivation box comprises a cultivation box body, four sets of universal wheels are arranged symmetrically at the corner of the bottom end of the cultivation box body, a push rod handle is installed at the position of the top end of one side of the cultivation box body in a welded manner, a liquid storage tank is mounted at the upper end of the top of the cultivation box body, a wireless communicator is installed at the position of one side wall of the cultivation box body and the lower end of the push rod handle in an embedded manner, a drive motor is fixedly installed in the center of the bottom end of the cultivation box body, a universal driving shaft is fixedly connected to the output end ofthe top of the drive motor, and the top of the universal driving shaft penetrates the bottom end of the cultivation box body to extend to the interior of the cultivation box body. The vegetable cultivation box is precise in structure, reasonable in design, convenient to operate, capable of performing remote irrigation control of cultivated plants on the basis of the Internet of Thins, safe and stable and beneficial to wide promotion and popularization.

Owner:罗旭

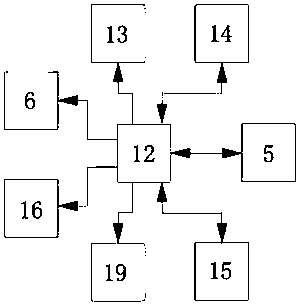

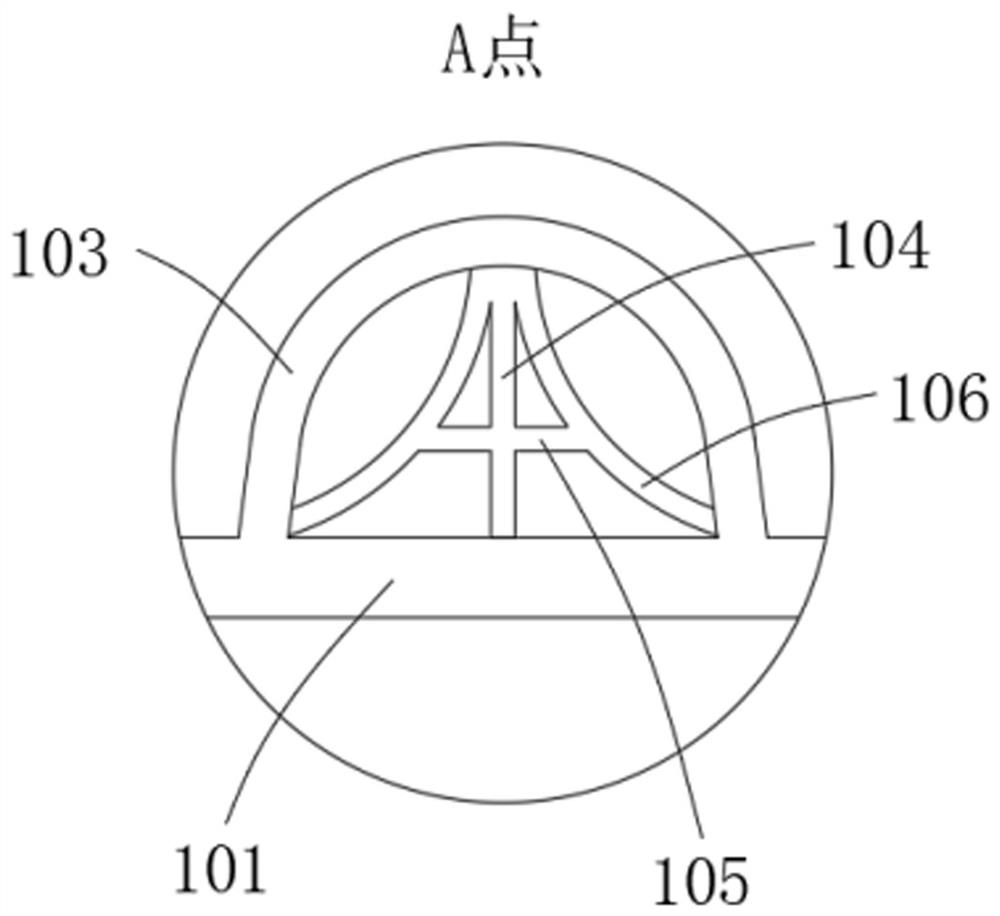

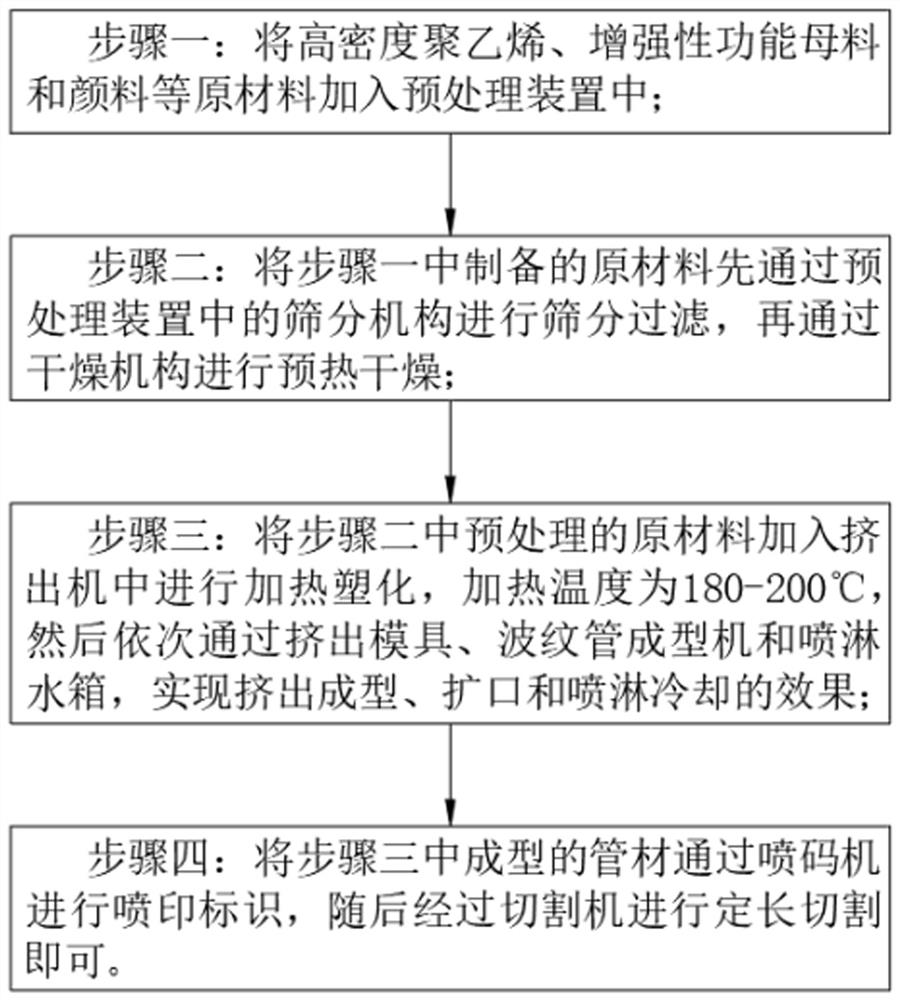

HDPE multi-rib reinforced winding corrugated pipe and production method and device

PendingCN114658928AStrong impact resistancePlay a supporting roleRigid pipesTubular articlesElectric machineryMaterials science

According to the HDPE multi-rib reinforced winding corrugated pipe disclosed by the invention, through cooperative use of the vertical ribs, the reinforcing ribs and the supporting ribs, when the surface of the winding pipe is subjected to pressure of a soil layer, the umbrella-shaped structures can play a role in supporting the winding pipe, so that the winding pipe is not liable to collapse and has the advantage of high impact resistance, and the ring stiffness of the winding corrugated pipe is effectively improved. According to the production method of the HDPE multi-rib reinforced winding corrugated pipe, the advantage of being easy and convenient to operate is achieved, the quality of the produced HDPE multi-rib reinforced winding corrugated pipe is high, and the percent of pass of products is greatly improved; according to the production device of the HDPE multi-rib reinforced winding corrugated pipe, the gear motor can be used for driving the movable plate, the stirring rod and the inclined rod to move synchronously, and the purposes of saving energy and electricity can be achieved without using a plurality of gear motors for driving; and meanwhile, in the process of screening the raw materials through the screening mechanism, the raw materials can make full contact with heat, and the drying effect is further improved.

Owner:HUNAN HENGYUAN NEW MATERIAL TECH DEV CO LTD

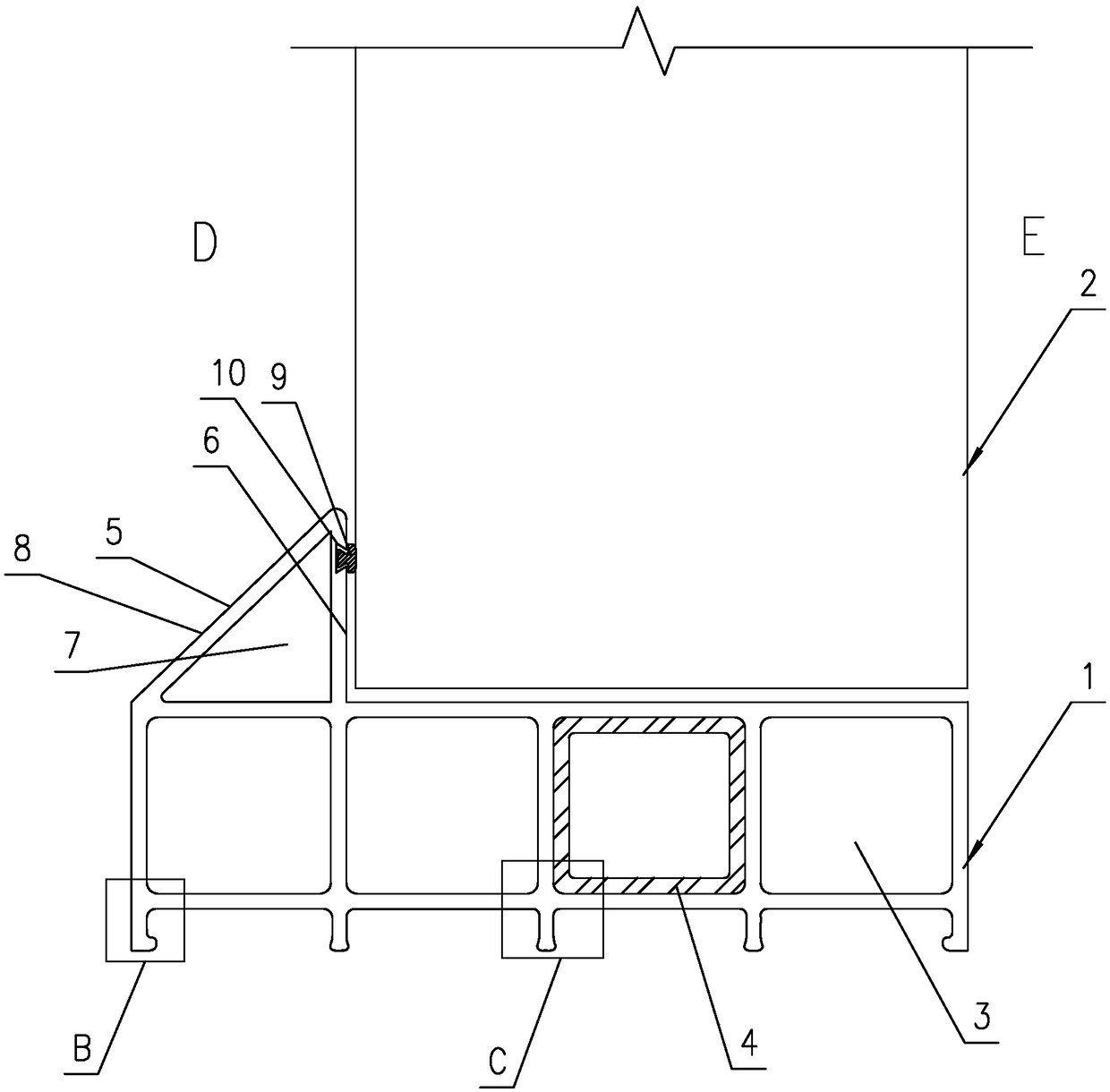

Window auxiliary frame for plastic or aluminum plastic co-extrusion door and window dry method installation

PendingCN108756601AGood energy saving effectSolve the problem of thermal insulationBase framesThermal insulationEngineering

The invention discloses a window auxiliary frame for plastic or aluminum plastic co-extrusion door and window dry method installation. The window auxiliary frame is a long block-shaped body made of anelastoplastic material and arranged in the width direction of an outer window in a full-length mode, that is, the long block-shaped body is arranged transversely. The upper surface of the window auxiliary frame is connected with a lower frame of the outer window, the window auxiliary frame is internally provided with a plurality of hollow cavities arranged side by side lengthways and penetratingthrough horizontally, a metal tube is tightly nested in part or all of the hollow cavities to form a core cavity body, and the core cavity body is a tight whole. The window auxiliary frame adopts a multi-cavity structure, greatly improves the thermal insulation performance, significantly enhances the energy saving ability of the outer window and a building and solves the thermal insulation problemof a traditional auxiliary frame. In addition, steel tubes are tightly nested in the hollow cavities, and sufficient strength is provided for the installation of the outer window. Moreover, the window auxiliary frame has simple structure, low manufacturing cost and high practicability, and is suitable for wide popularization and application.

Owner:广东建科节能环保科技有限公司 +1

Staggered type modular building structure and construction method thereof

PendingCN109281406AOverlap component reductionAvoid wastingBuilding constructionsFloor slabModular unit

The invention discloses a staggered type modular building structure and a construction method thereof. The staggered type modular building structure comprises a plurality of modular units, and the modular units are arranged in a plurality of layers in the vertical direction. The adjacent modular units are connected, and the modular units of the first layer are arranged at intervals, so that gaps are formed between the adjacent modular units. The modular units of the second layer and above are arranged in a staggered mode with the modular units of the adjacent layers, and single gables are arranged on the outer sides of the layers of an even number. The second layer modular units and the adjacent modular units of the same layer and of the upper and lower layers form internal spaces of the modular units, and external walls are additionally arranged on the front and rear sides to form a complete modular unit. Floor slabs are additionally arranged at the gaps of the first layer and the toplayer to form internal spaces of the modular units, and external walls are additionally arranged on the front and rear sides to form a complete modular unit. According to the staggered type modular building structure, only upper and lower layer structural beams are provided with overlapping members, and columns, beams, floor slabs, internal parting walls and the like between adjacent unit modulesare not overlapped, the overlapping members are reduced, unnecessary waste is avoided, and the construction cost is greatly reduced.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

Radix panacis quinquefolii preparation with fatigue-resisting and heart-curing effects and preparation method thereof

InactiveCN107232608ASignificant activitySignificant swelling and pain relief effectFood scienceDigestionBULK ACTIVE INGREDIENT

The invention discloses an anti-fatigue and heart-protecting American ginseng preparation and a preparation method thereof, which are characterized in that the active ingredients are made of American ginseng, Sanqi and Rhodiola rosea, and are also made of fresh American ginseng as raw materials. American ginseng extract, combined with Panax notoginseng extract and Rhodiola rosea extract, mixed, granulated, dried, granulated, then added magnesium stearate and mixed evenly, then filled into capsules, polished, packaged, and irradiated to sterilize Made into capsule preparations. The present invention adopts processing technologies such as the combination of pure physical means and heating ultrasonic hydrolysis treatment, so that the obtained product has high yield and good activity, helps to improve the nutritional value of the product, promotes the digestion and absorption of nutrients, and helps to improve the immune system. At the same time, it promotes the release of cell content and improves the effective utilization of American ginseng. The product has strong human immune function, anti-fatigue and anti-aging, and heart protection. It can be widely promoted and produced.

Owner:江苏新先制药有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com