High-sensitivity up-conversion temperature measurement material as well as preparation method and application thereof

A technology with high sensitivity and the environment to be tested is applied in the field of high-sensitivity up-conversion temperature measurement materials and their preparation. It can solve the problems of large errors in optical temperature measurement materials and low luminous intensity, and achieve improved measurement accuracy and signal-to-noise ratio, the effect of reduced dependence on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Weigh 1.4763g of solid powdered strontium carbonate, 3.9845g of solid powdered lutetium oxide, 0.3941g of solid powdered ytterbium oxide and 0.0956g of solid powdered erbium oxide, and place the above-mentioned raw materials in an agate mortar and thoroughly grind and mix them for 1 hour to obtain a mixture, It is then poured into a corundum crucible and covered;

[0034] 2) Place the corundum crucible in step 1) in a high-temperature furnace, heat it to 1300°C, and heat it at a constant temperature for 6 hours. After the reaction, cool it down to room temperature naturally, and then put the burnt sample into an agate mortar and grind it into powder. That is, the up-conversion phosphor SrLu is obtained 2 o 4 : 5% Er 3+ / 20%Yb 3+ .

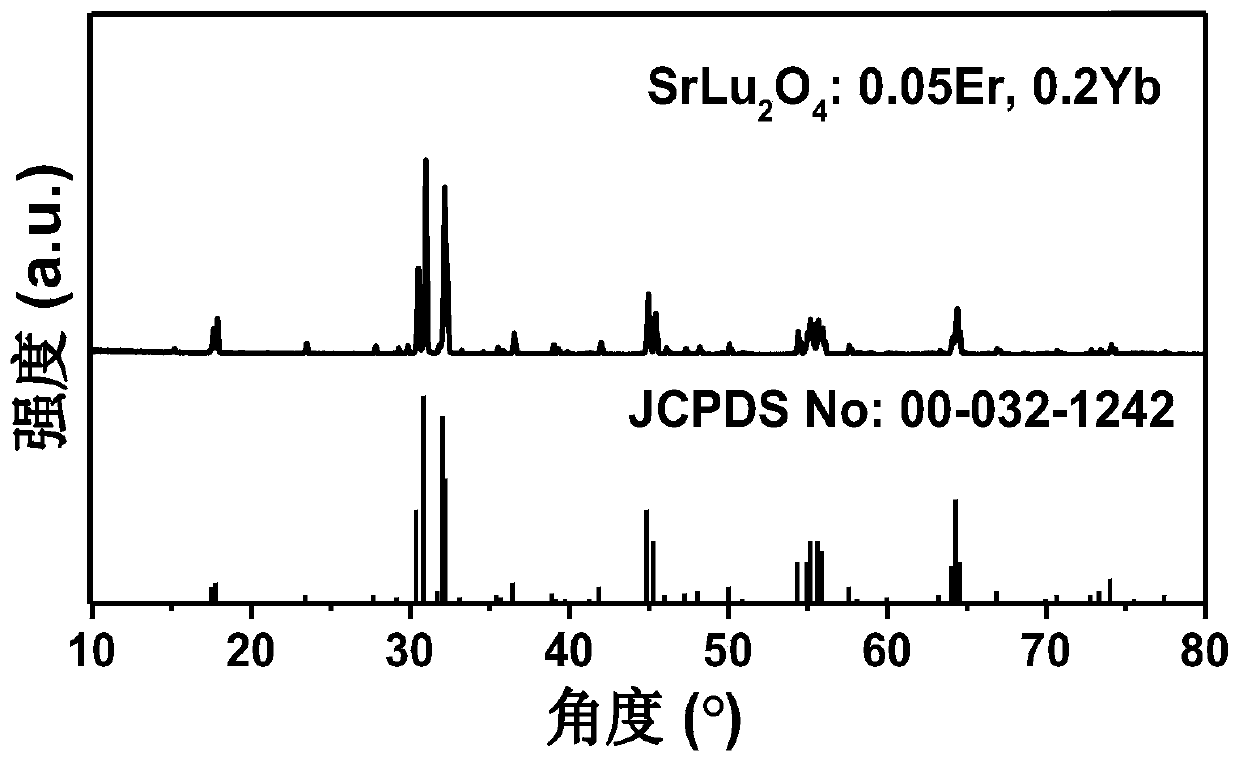

[0035] The up-conversion phosphor SrLu prepared in this embodiment 2 o 4 : 5% Er 3+ / 20%Yb 3+ The X-ray diffraction technique was used to analyze the results as follows: figure 1 shown.

[0036] From figure 1 It can be seen tha...

Embodiment 2

[0038] 1) Weigh 1.0009g of solid powdered calcium carbonate, 3.9845g of solid powdered lutetium oxide, 0.3941g of solid powdered ytterbium oxide and 0.0956g of solid powdered erbium oxide, and place the above-mentioned raw materials in an agate mortar and thoroughly grind and mix them for 1 hour to obtain a mixture. It is then poured into a corundum crucible and covered;

[0039] 2) Place the corundum crucible in step 1) in a high-temperature furnace, heat it to 1300°C, and heat it at a constant temperature for 6 hours. After the reaction, cool it down to room temperature naturally, and then put the burnt sample into an agate mortar and grind it into powder. That is, the up-conversion phosphor CaLu 2 o 4 :5%Er 3+ / 20%Yb 3+ .

Embodiment 3

[0041] 1) Weigh 1.9734g of solid powdered barium carbonate, 3.9845g of solid powdered lutetium oxide, 0.3941g of solid powdered ytterbium oxide and 0.0956g of solid powdered erbium oxide, and place the above-mentioned raw materials in an agate mortar and thoroughly grind and mix them for 1 hour to obtain a mixture, It is then poured into a corundum crucible and covered;

[0042] 2) Place the corundum crucible in step 1) in a high-temperature furnace, heat it to 1300°C, and heat it at a constant temperature for 6 hours. After the reaction, cool it down to room temperature naturally, and then put the burnt sample into an agate mortar and grind it into powder. That is, the up-conversion phosphor BaLu 2 o 4 :5%Er 3+ / 20%Yb 3+ .

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com