Pressure sand blasting device for micro-powder sand

A technology of sandblasting device and sand material, which is applied in the field of micropowder sand material with a particle size of 60 to 300 mesh, and the field of micropowder sand material pressure sandblasting device, which can solve the problems of discontinuous, broken sandblasting and other problems, and achieve small pressure loss , Reduced manufacturing costs, and facilitated manufacturing and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

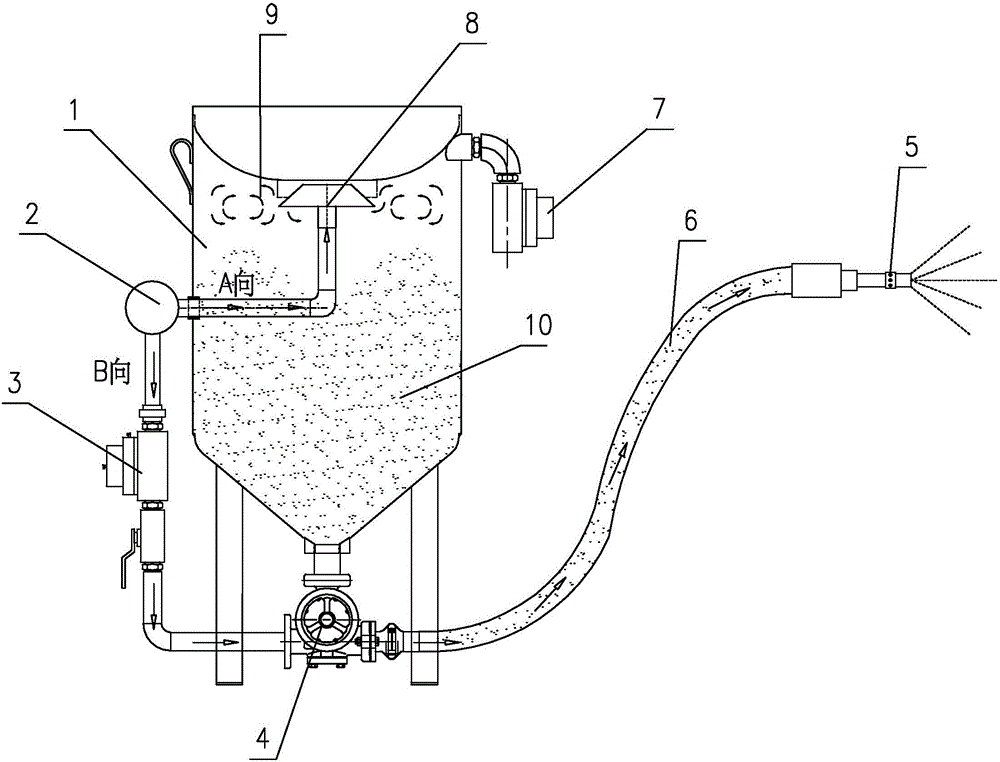

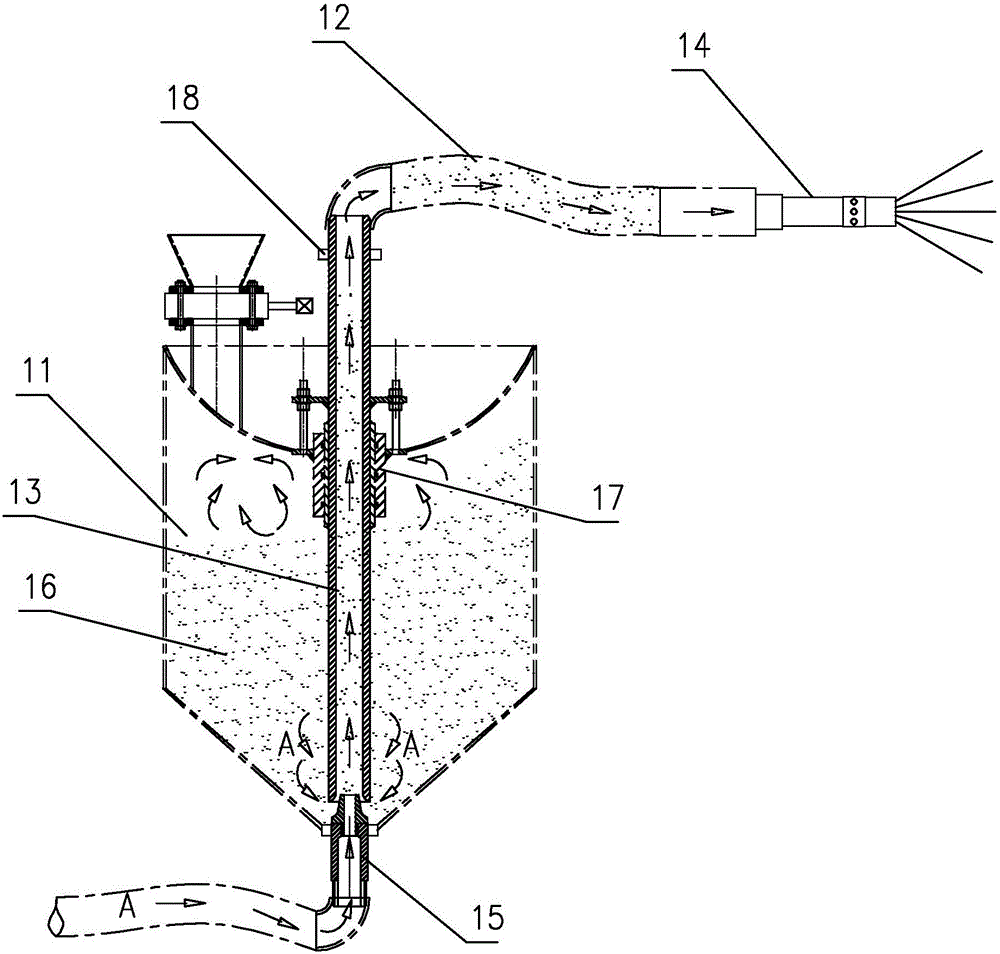

[0025] Such as figure 2 Shown, be a kind of micropowder sand material pressure sandblasting device of the present invention, comprise the pressure tank 11 that is filled with sand material 16, sandblasting pipe 12, spray gun 14 and siphon pipe 13, sandblasting pipe 12 adopts flexible pipe, and spray gun 14 is located at At the pipe end of the sandblasting pipe 12, the sand material is micropowder sand material, and the particle size of the micropowder sand material is 60-300 mesh. The siphon pipe 13 is vertically arranged in the pressure tank 11 and fixed by the fixing structure 17. The siphon pipe 13 passes through the pressure tank upwards. 11 is connected to the sandblasting pipe 12, specifically, the siphon pipe 13 is connected to the sandblasting pipe 12 through a joint 18. Siphon pipe 13 stretches downwards to the bottom of pressure tank 11, and the bottom of pressure tank 11 is provided with the jet jet nozzle 15 that is used to spray compressed gas, and compressed gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com