Constant-temperature control system

A technology of constant temperature control and controller, which is applied in the direction of control/regulation system, temperature control, non-electric variable control, etc. It can solve the problems of poor system portability, large control error and static error, and low precision, and achieve scalability Good performance, improved portability, and easy expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

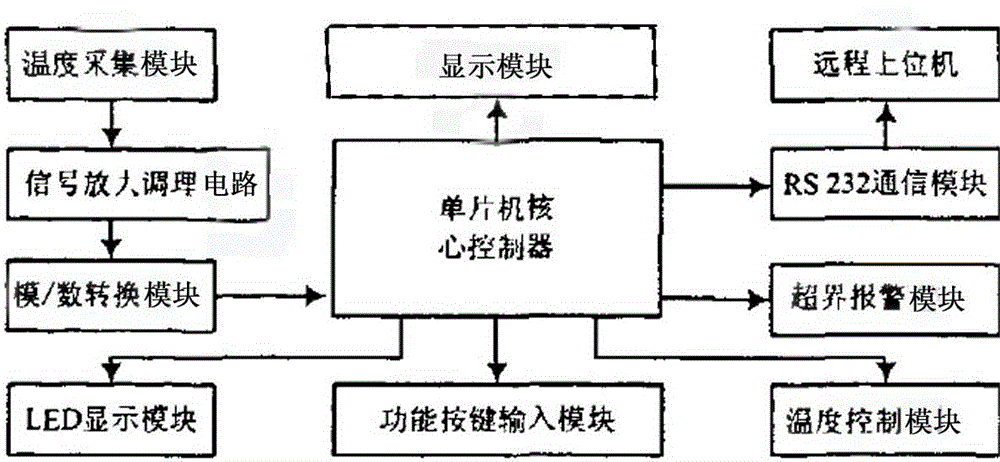

[0016] A constant temperature control system, comprising a single-chip controller, a temperature acquisition circuit, a signal amplification and conditioning circuit, an analog / digital conversion module, an LED display module connected to the single-chip controller, a function button input module, a temperature control module, a communication module and a display module, wherein the temperature acquisition module, the signal amplification conditioning circuit and the analog / digital conversion module are connected in sequence and the analog / digital conversion module is connected to the single-chip controller, and the single-chip controller is connected to the remote host computer through the communication module. The single-chip microcomputer selects AT89C51. Wherein, the signal amplification and conditioning circuit is composed of a voltage follower, a differential subtractor, a voltage amplifier and an inverter circuit connected in series in sequence. The temperature acqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com