Method for judging whether rolling guide position of high-speed wire production line is damaged or not

A production line and guiding technology, applied in the field of steel rolling, can solve problems such as affecting the yield, affecting rolling rhythm, folding, etc., and achieve the effect of avoiding steel holding accidents and quality accidents, broad prospects for promotion and application, and huge economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

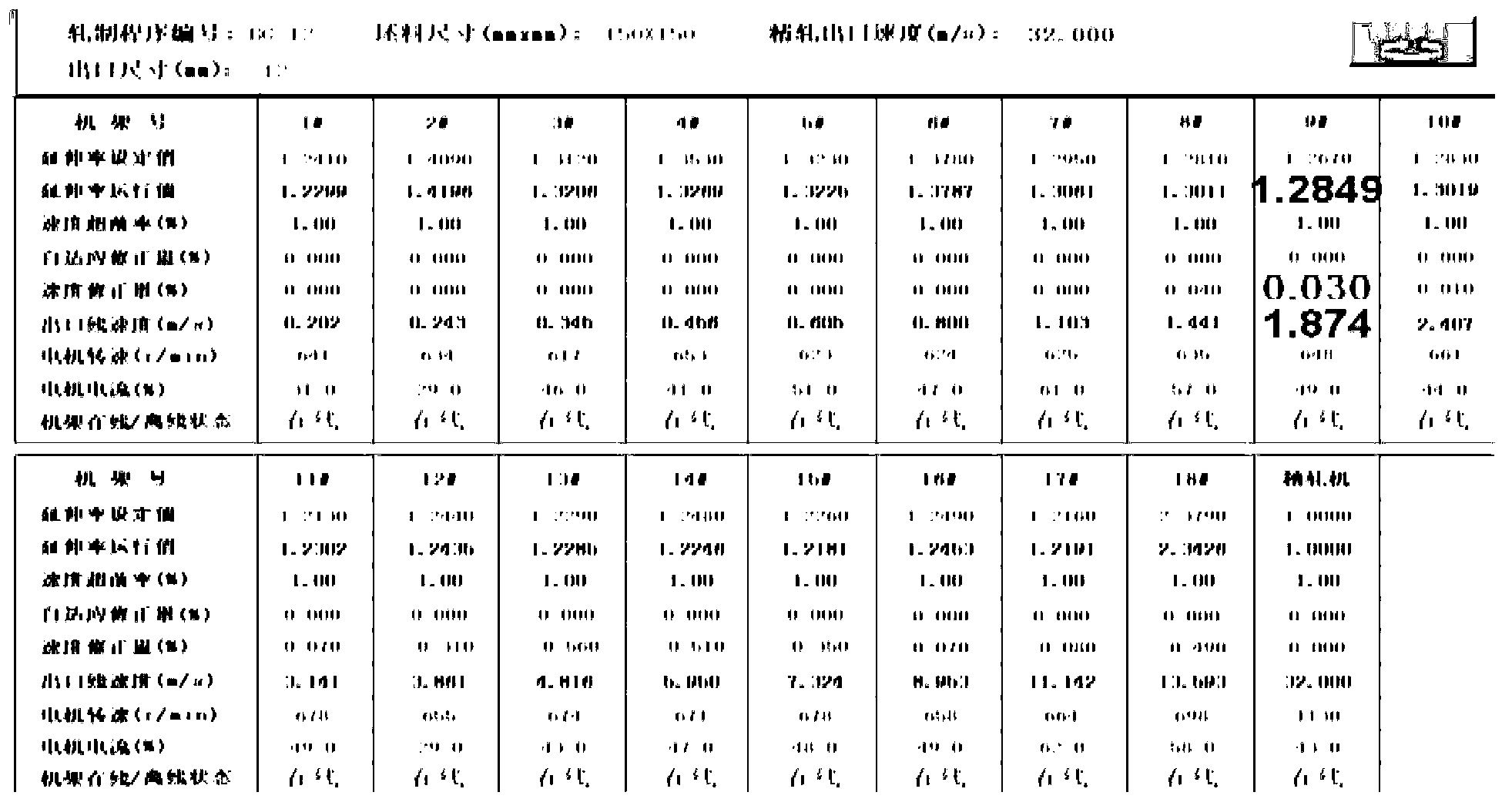

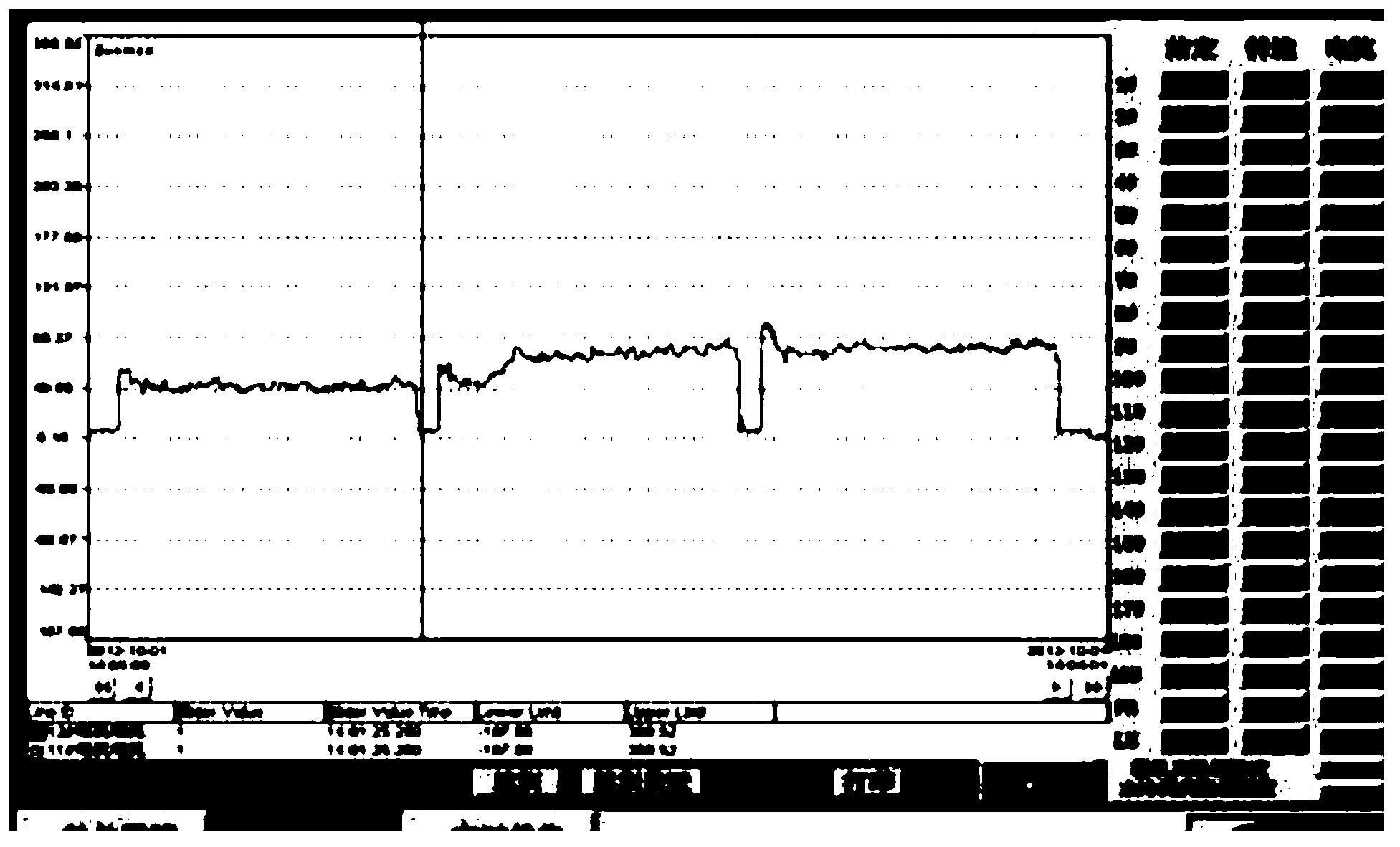

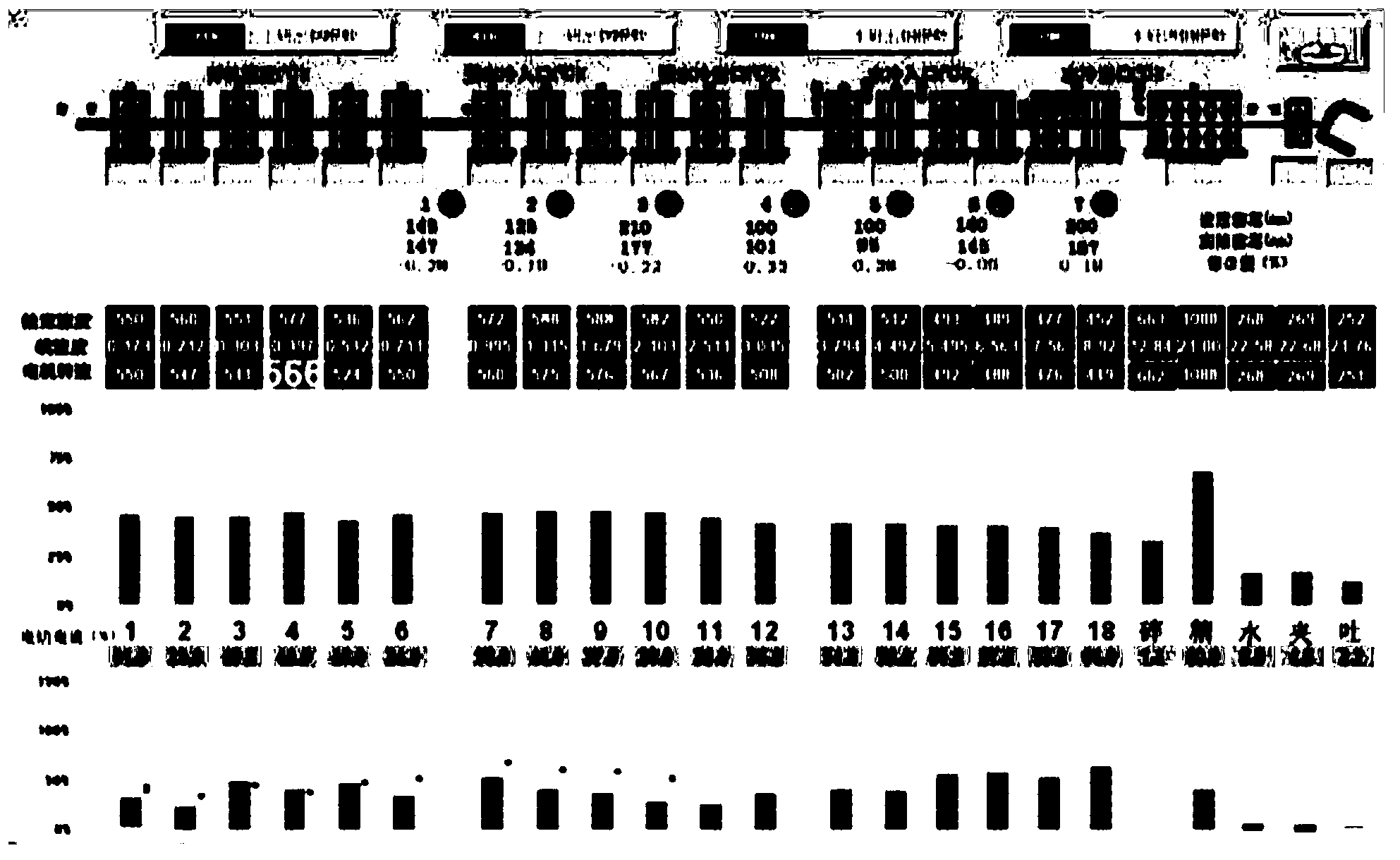

[0023] The present invention judges whether the guide will be damaged by using the change of the rolling mill load current of the stand where the guide guard is located and the change of the rolling mill load current of the adjacent stand. Specifically, after the low-tension rolling of intermediate rolling and the tension-free rolling of pre-finishing are realized through manual joint adjustment (looper control is tension-free rolling), the load current value of the mill stand after the start of rolling is stabilized is The reference current value, by observing the change of the real-time current value of the rack mill and the current value of the front mill, and comparing the real-time current value of the rack mill and the current value of the front mill with the reference current value, the rolling guide position can be judged online status.

[0024] In production practice, guides and auxiliary process components often have subtle signs before damage, which we have analyzed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com