Opening and Closing Mechanism of Integral Core Shooting Box Mold for Central Guide Frame of Railway Vehicle Side Frame

A technology for railway vehicles and core-shooting boxes, which is applied to cores, manufacturing tools, casting molding equipment, etc. It can solve problems such as wasting time, increasing mold weight, and inconsistent core-pulling speeds, and achieves cost reduction, simple processing, and Versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

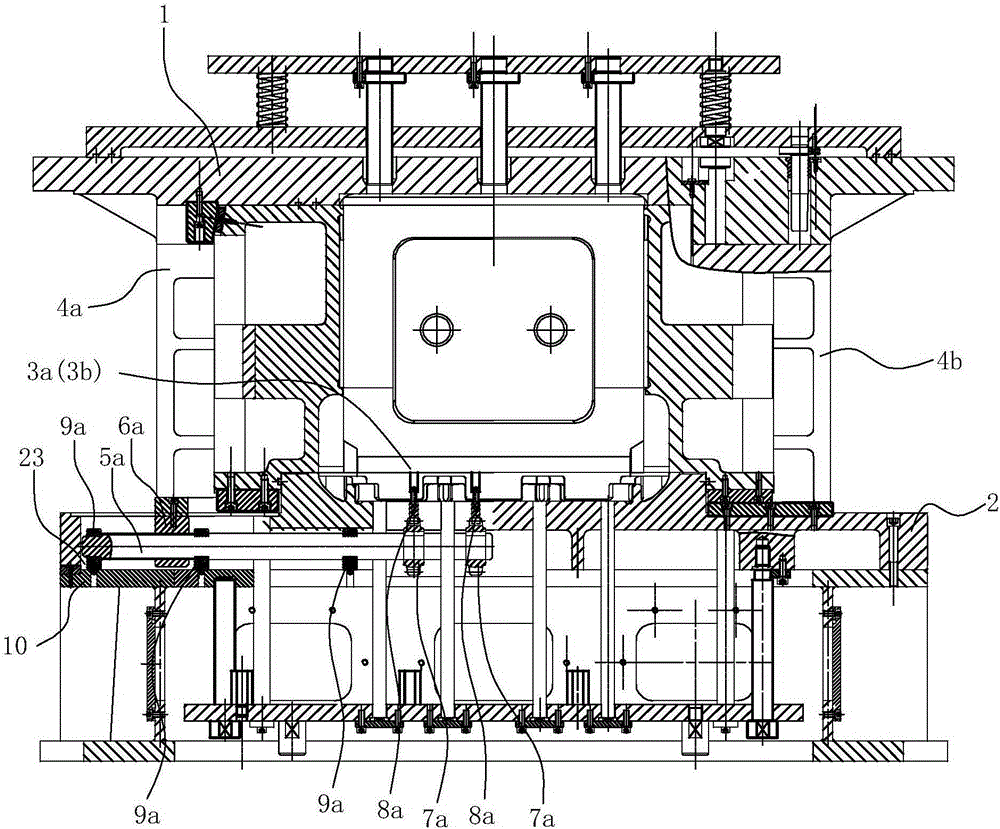

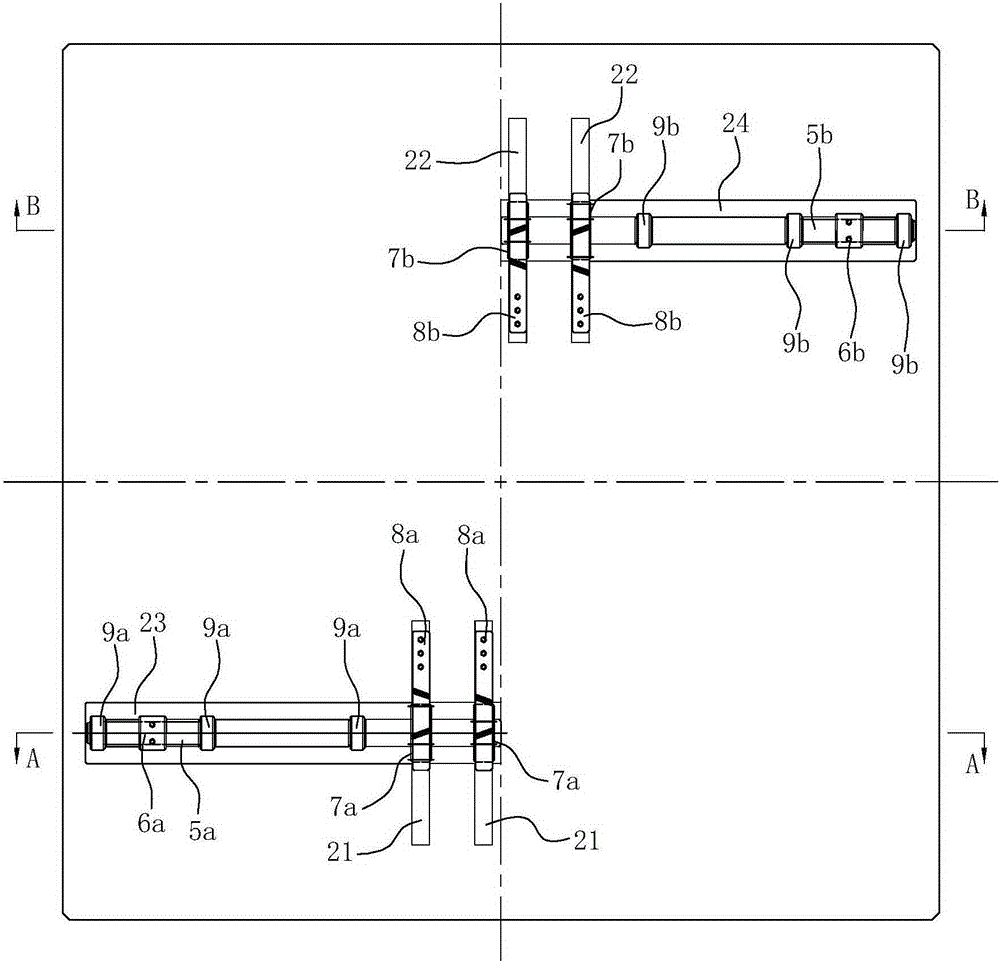

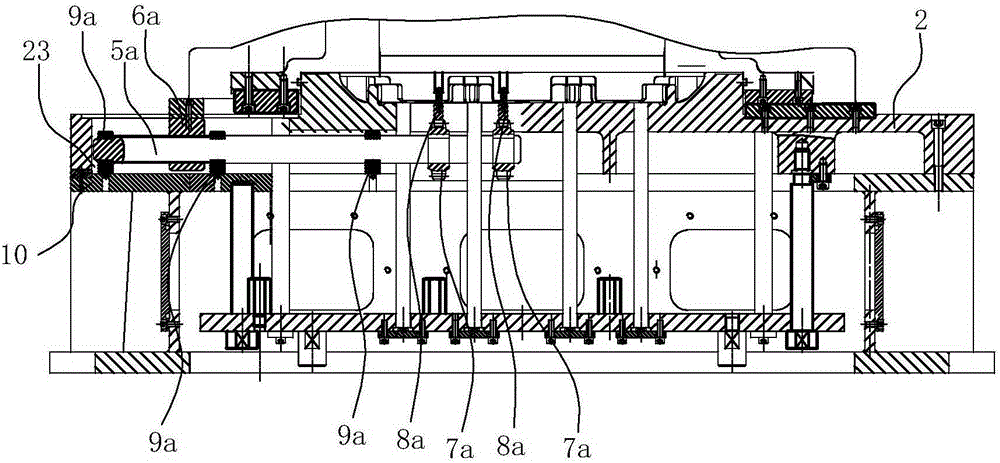

[0024] Such as Figure 1~5 Shown is a preferred embodiment of the present invention.

[0025] A mold opening and closing mechanism for an integral core box mold of a central pedestal frame of a railway vehicle, comprising an upper core box 1, a lower core box 2, and a front core puller 3a and a rear puller constrained on the lower core box 1 that can slide back and forth Core 3b and the left and right cores 4a and 4b that can slide left and right, the lower core box 1 is installed on the lower mold frame 10, the front core 3a and the rear core 3b are installed on the lower core box 2, the front core 3a and The rear core-pulling 3b is connected with the cylinder in the shooting equipment through the connecting block and is driven by the cylinder to slide back and forth. The cylinder is not shown in the drawings. The mold cavity is formed afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com