Wind power blade surface protection method

A technology of wind power blades and blades, which is applied in wind power generation, wind engines, coatings, etc., can solve the problems of high labor cost, low work efficiency, and bottom exposure, and achieve the effects of improving production efficiency, ensuring quality, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

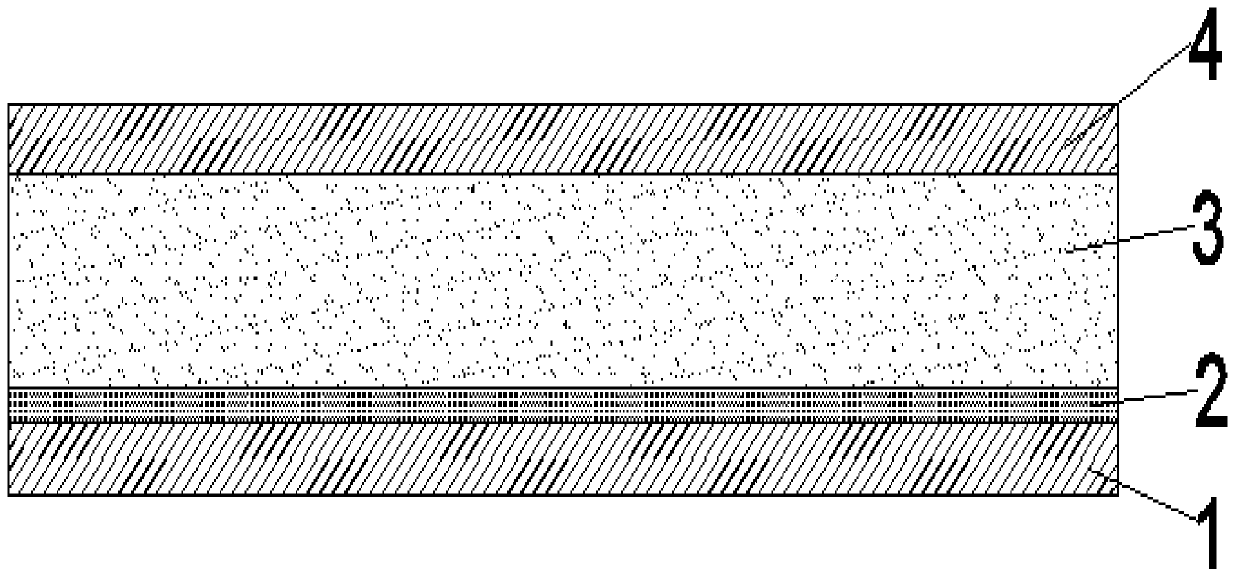

[0014] like figure 1 The prefabricated protective coating shown includes coating protective film A1, adhesive 2, coating 3, and coating protective film B4. On the coating protective film B4 made of polyethylene flexible film, it is coated by uniform roller coating or Spray polyurethane paint to form a layer of coating 3 with a thickness of 300 μm-350 μm. After the coating 3 is formed, evenly coat a layer of adhesive 2 with a thickness of 100 μm-150 μm on the other side. After coating, the adhesive 2 is covered Coating protective film A1 made of a layer of polyethylene material flexible film, through this process to make a prefabricated protective coating, in order to ensure that coating 3 will not be damaged when peeling coating protective film B4, coating protective film B4 and coating 3 The connection between the coating 3 and the adhesive 2 depends on the molecular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com