Automatic material taking device for vertical air cushion clamping conveyer

An automatic reclaiming and conveyor technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problem of restricting the scope of application of pendulum and double-moving bulk material reclaiming systems, and cannot realize automatic fetching by small conveyors. material function, the inability to realize the automatic reclaiming of the air-cushion conveyor, etc., to achieve the effects of extensive promotion and use value, widening the scope of application, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] This embodiment is only a preferred technical solution, and the various components and connection relationships involved are not limited to the following implementation described in this embodiment. The configuration and connection relationship of the various components in the preferred solution can be Carry out arbitrary permutations and combinations to form a complete technical solution.

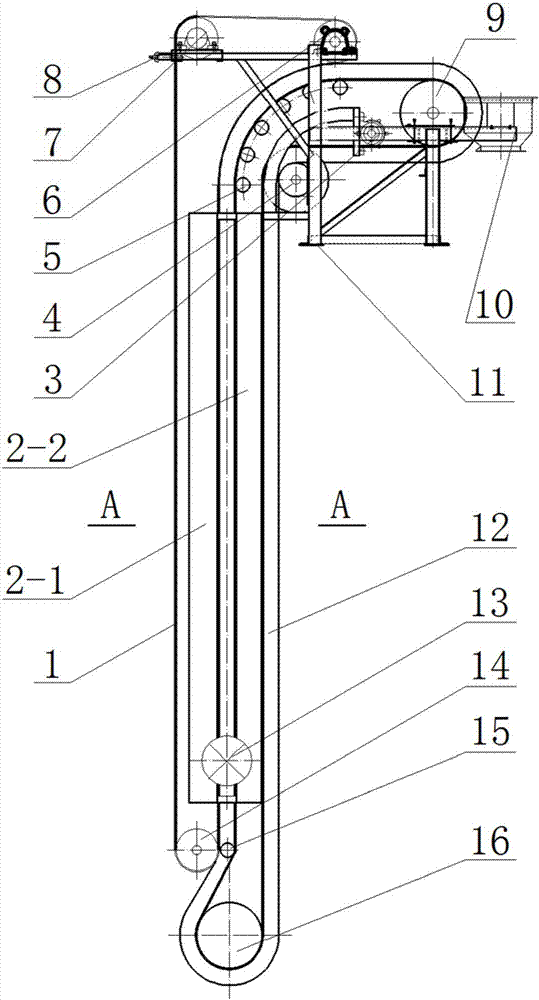

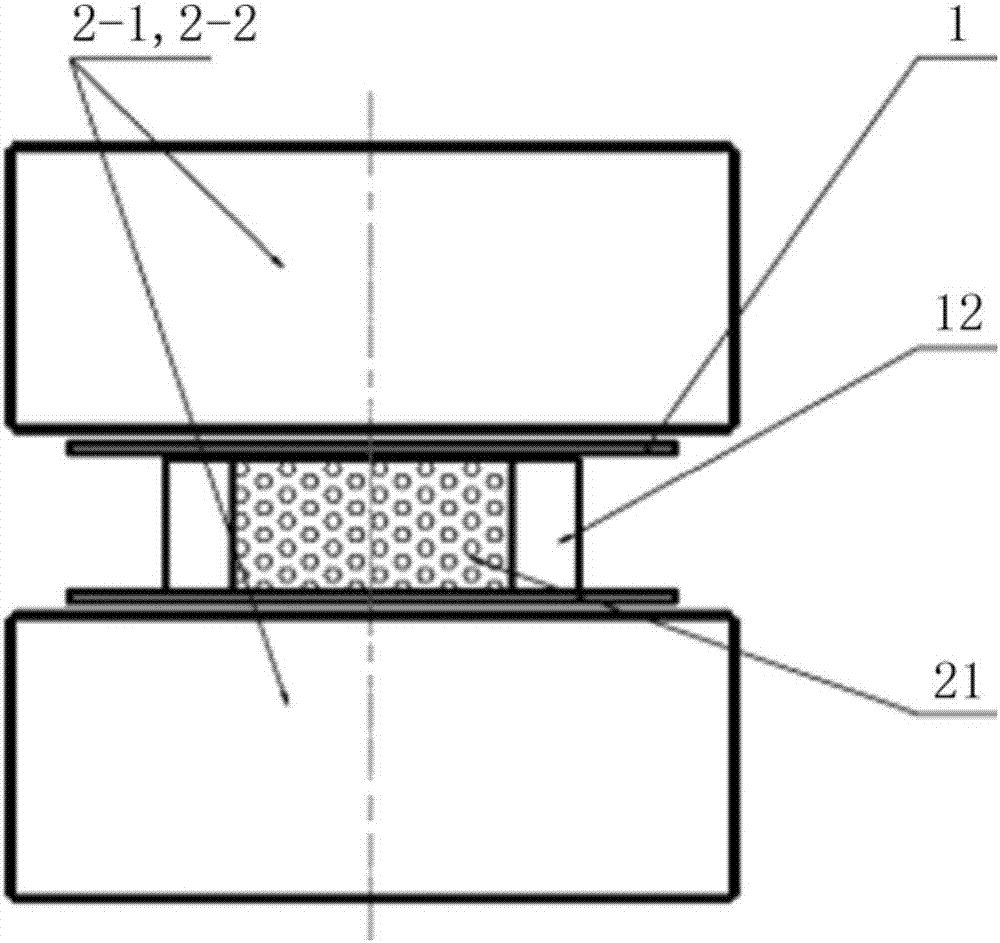

[0042] Combine below Figure 1-8 Describe in detail the technical solution of the automatic reclaiming device of the vertical air cushion clamping conveyor:

[0043] The automatic reclaiming device of the vertical air cushion clamping conveyor includes a vertical lifting section, the vertical lifting section includes a corrugated sidewall conveyor belt 12 and a cover belt 1, the bottom of the vertical lifting section is provided with a retrieving roller 16, and the corrugated sidewall The conveyor belt 12 is wound around the take-up roller 16, and above the take-up roller 16, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com