An autocrane heating a lifting control room by utilizing cooling water of a lower-vehicle engine

A control room and engine technology, applied in the field of truck cranes, can solve the problems of unfavorable energy saving and emission reduction, high fuel consumption, unfavorable running costs of truck cranes in winter, etc., and achieve the effect of being conducive to heat dissipation, improving heat dissipation efficiency and normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

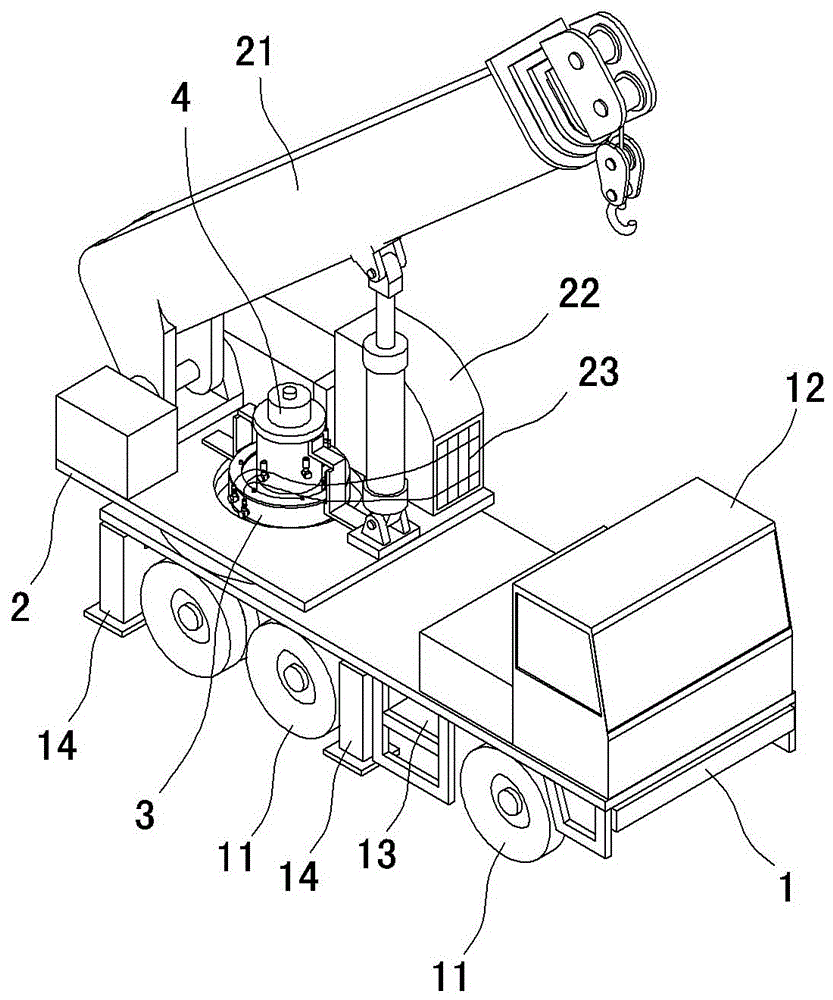

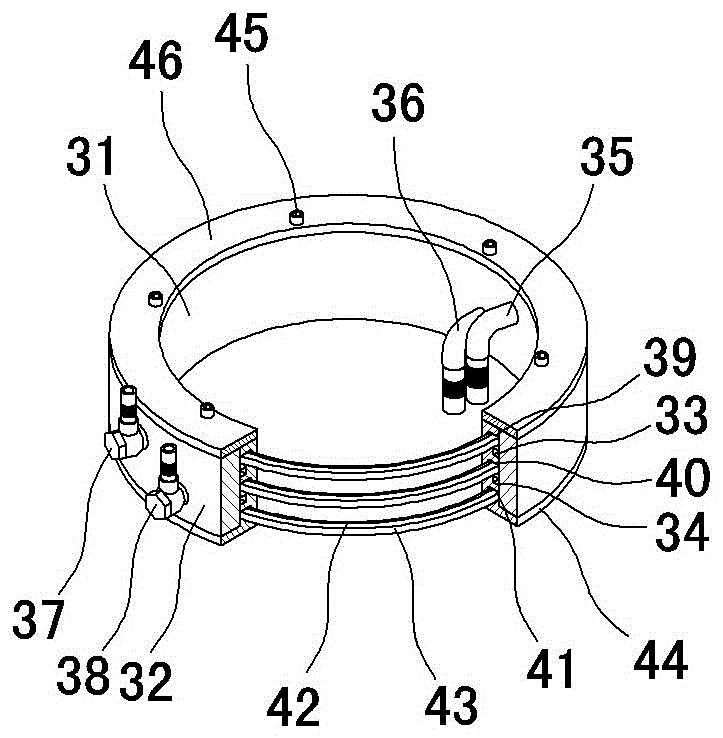

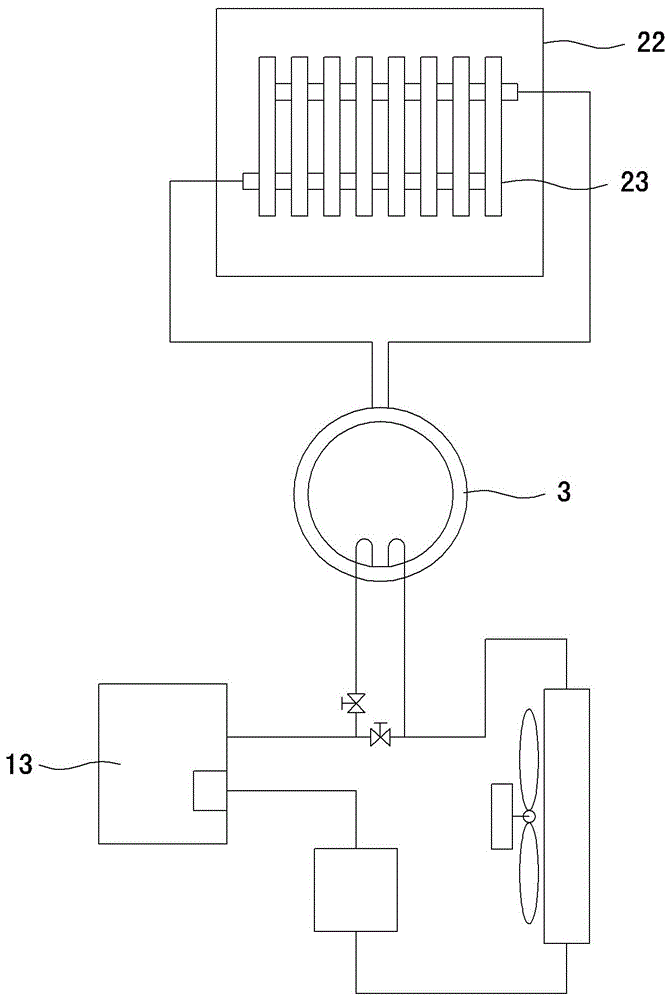

[0009] Such as figure 1 , figure 2 , image 3 As shown, it comprises getting off the car 1 and the boarding car 2 that is rotatably installed on the getting off car 1. The boarding car 2 is provided with a boom 21 and a lifting control room 22. , engine 13 and several supporting legs 14, a rotary water feeder 3 is provided between the getting off the car 1 and the getting on the car 2, and the rotary water feeder 3 includes a fixed body 31 fixedly installed on the getting off the car 1 and a fixed body 31 fixedly installed on the getting on the car 2 The rotating body 32 of the fixed body 31 and the rotating body 32 are rotated and matched, and the rotating mating surface between the fixed body 31 and the rotating body 32 is provided with an annular water channel one 33 and an annular water channel two 34 isolated from each other, and the fixed body 31 is provided with Pipe joint 1 35 and pipe joint 2 36 respectively communicate with annular waterway 1 33 and annular waterw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com