System for heating and unfreezing winter dump pit of garbage incineration power plant

A waste incineration and waste pit technology is applied in the field of heating and thawing systems for waste pits in waste incineration power plants in winter. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

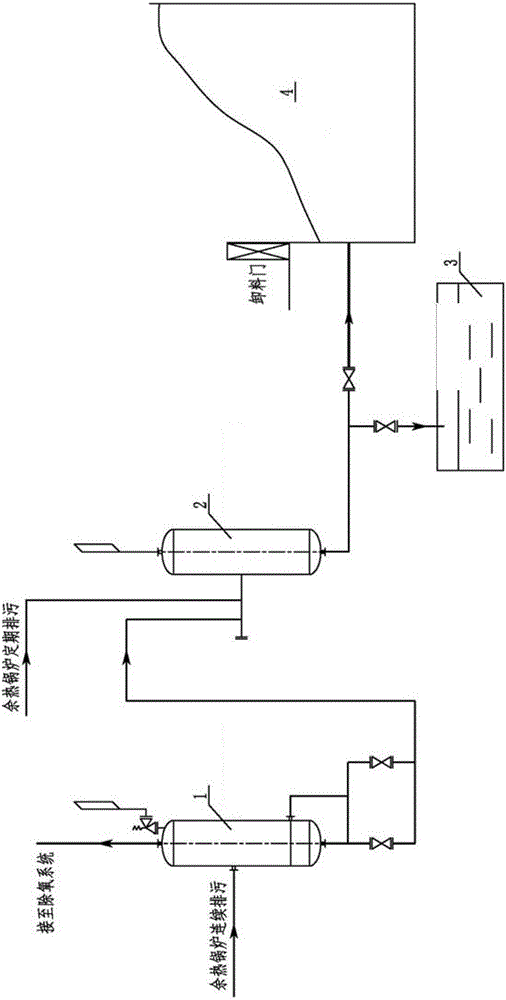

[0009] Such as figure 1 As shown, the present invention is a garbage pit heating system suitable for waste incineration power plants, including continuous blowdown expansion vessel, regular blowdown expansion vessel, blowdown cooling pool and garbage pit. The continuous sewage discharge of the waste heat boiler is connected to the inlet of the continuous sewage expansion vessel 1, and the drainage port of the continuous sewage expansion vessel 1 and the regular sewage discharge of the waste heat boiler are connected to the entrance of the regular sewage expansion vessel 2 through pipes, and the outlet of the regular sewage expansion vessel 2 is drained through a tee , are respectively connected to the discharge hall side of the sewage cooling pool 3 entrance and the garbage pit 4, and are connected to the sewage cooling pool 3 and the branch pipe of the garbage pit 4 to set valves. When the temperature of the garbage pit is high in spring, summer and autumn, the valve connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com