Window auxiliary frame for plastic or aluminum plastic co-extrusion door and window dry method installation

An aluminum-plastic and plastic technology is applied in the field of window sub-frames, which can solve the problems of inability to guarantee installation accuracy and installation reliability, and achieve the effects of enhanced energy-saving capability of external windows and buildings, improved thermal insulation performance, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

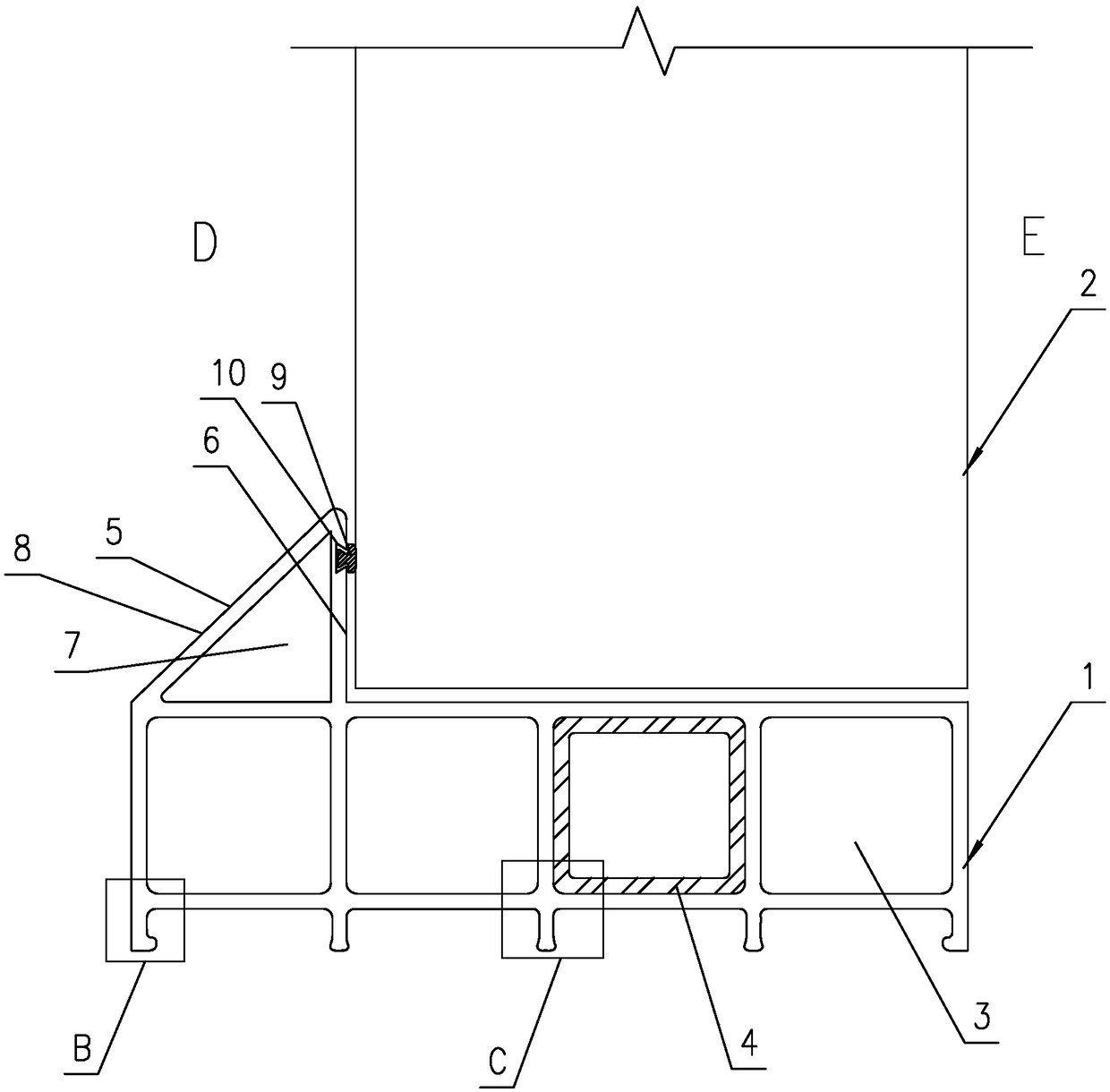

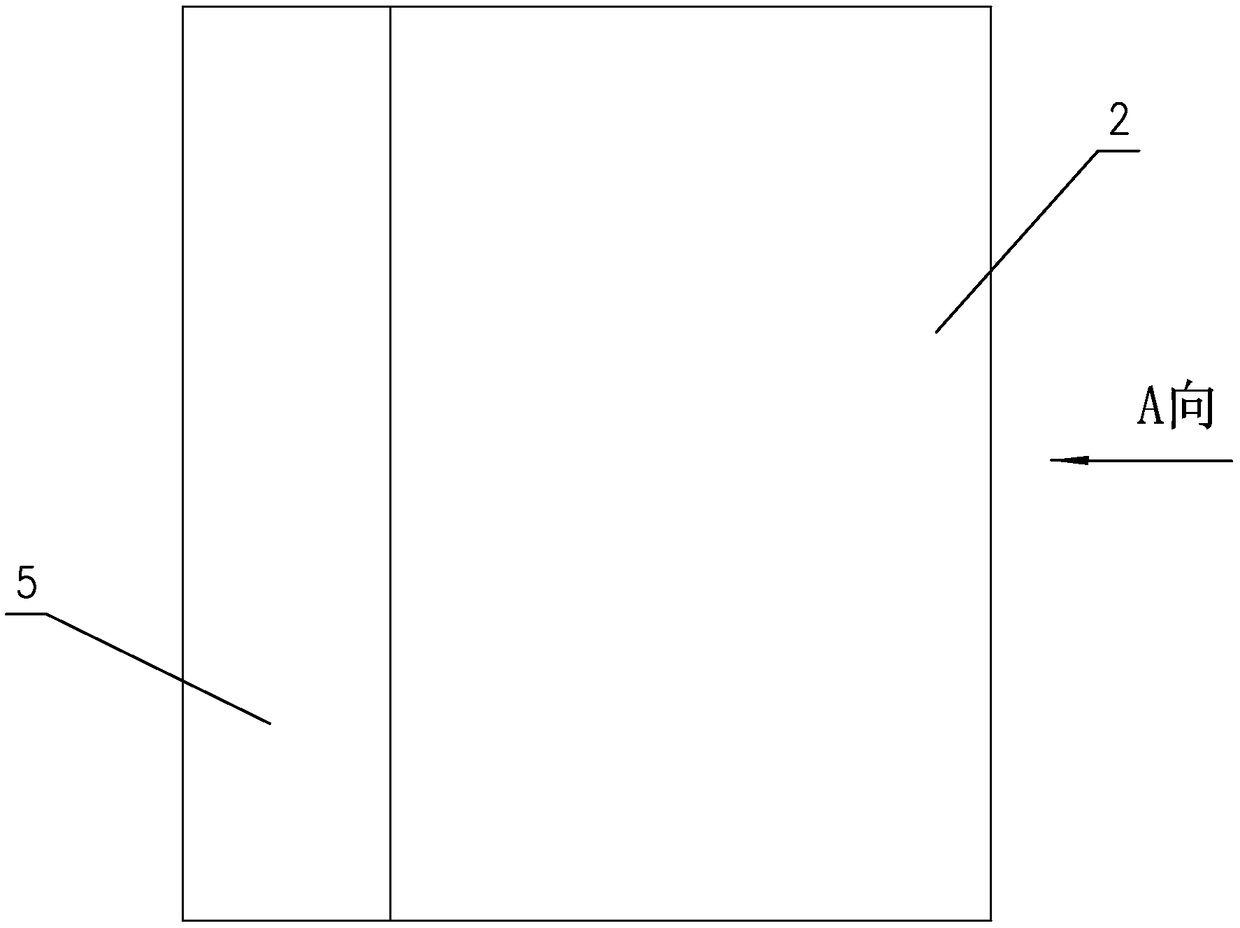

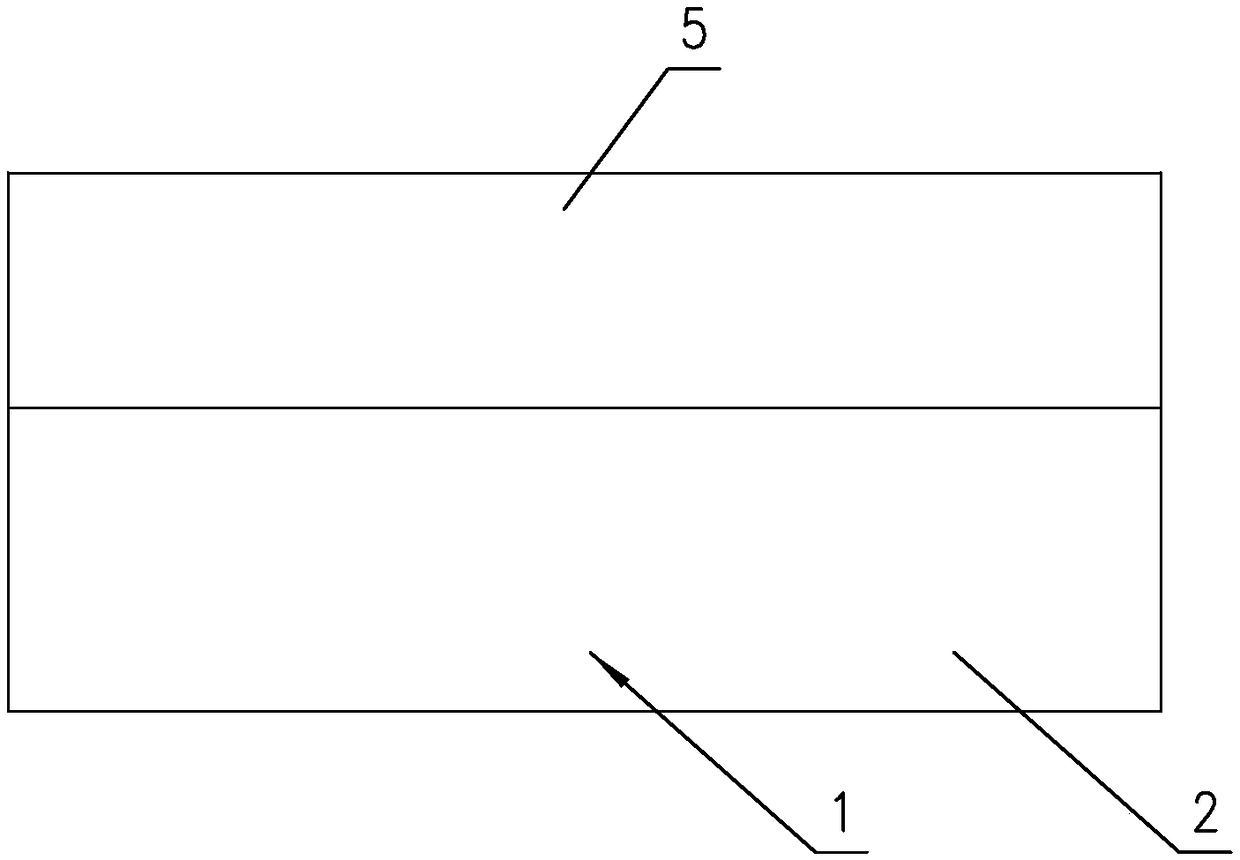

[0038] Such as Figure 1~6 Shown is a window sub-frame 1 for dry installation of plastic or aluminum-plastic co-extruded doors and windows of the present invention, used for dry installation of plastic or aluminum-plastic co-extruded doors and windows, and the material is a sub-frame of steel-plastic co-extruded profiles. The window sub-frame 1 is an elongated block made of elastic-plastic material and arranged along the width direction of the outer window, that is, the elongated block is arranged along the transverse direction, and the upper surface of the window sub-frame 1 is used to connect with the outer window 2 The lower frames are connected, and the sub-frame 1 of the window has several hollow cavities 3 that penetrate horizontally and are arranged side by side in the longitudinal direction. Steel pipes 4 are tightly nested in part or all of the hollow cavities 3 to form a core cavity. body as a cohesive whole. In this embodiment, PVC is used as the elastic-plastic ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com