HDPE multi-rib reinforced winding corrugated pipe and production method and device

A production device and bellows technology, applied in the direction of pipes, rigid pipes, tubular objects, etc., can solve the problems of poor melt quality, damage, pits, etc., to improve drying effect, simple and convenient operation, and improve ring stiffness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

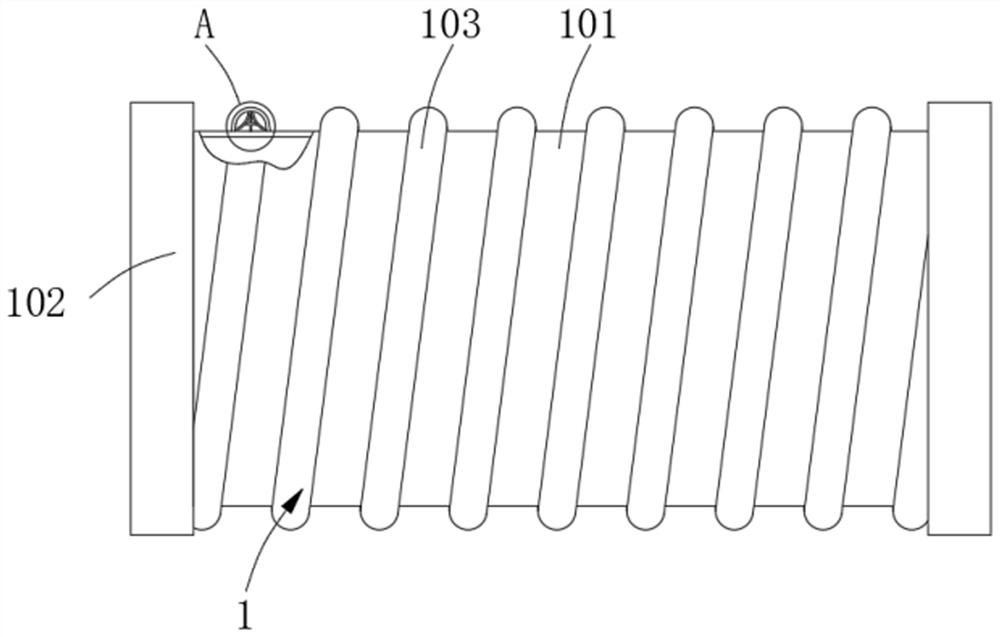

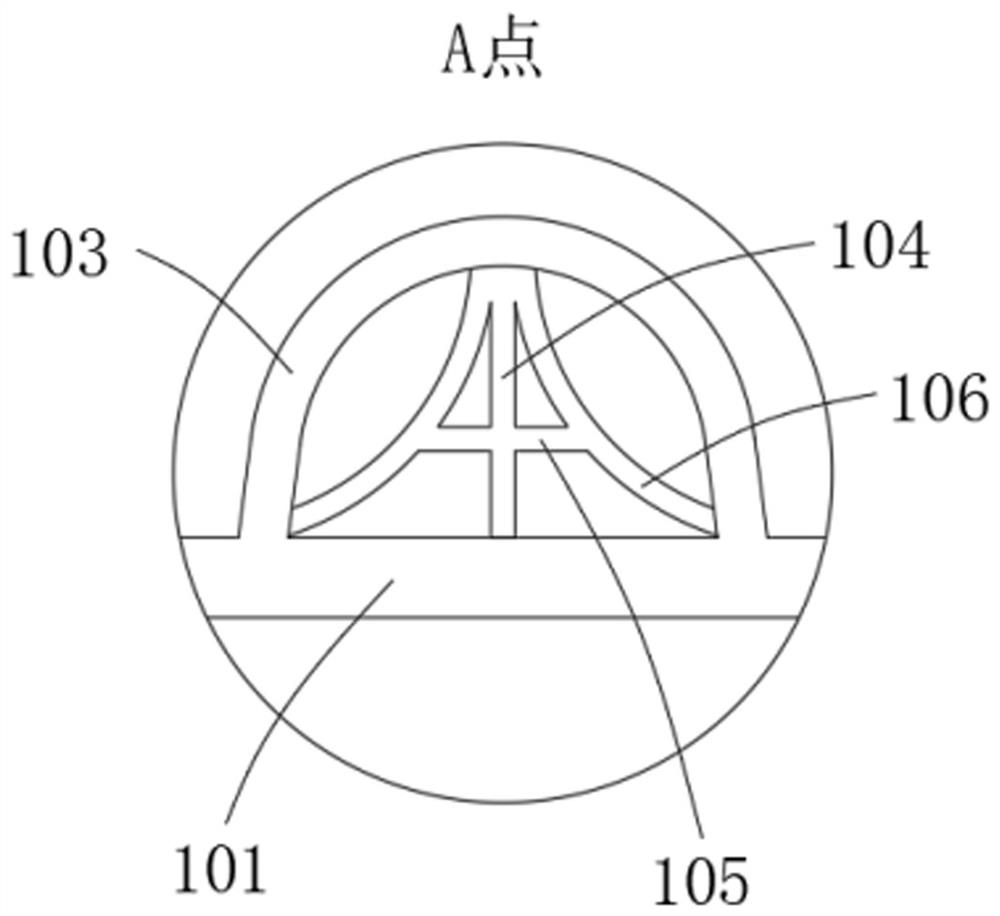

[0055] like Figure 1-2 As shown, the HDPE multi-rib reinforced winding corrugated pipe provided in this embodiment includes:

[0056] Corrugated pipe body 1, the corrugated pipe body 1 includes a pipe wall 101, both ends of the pipe wall 101 are connected with connecting rings 102, the surface of the pipe wall 101 is spirally wound with a winding pipe 103, and the outer wall surface of the pipe wall 101 is connected with the winding pipe 103. A vertical rib 104 is fixedly connected between the inner wall surfaces, and two sides of the vertical rib 104 are fixedly connected with a reinforcing rib 105 that is perpendicular to each other. The ends are fixedly connected to the inner wall surface of the winding tube 103 , and the ends of the two support ribs 106 are fixedly connected to the ends of the vertical ribs 104 .

[0057] The HDPE multi-rib reinforced winding corrugated pipe adopting the above technical solution is used in conjunction with the vertical ribs 104, the rein...

Embodiment 2

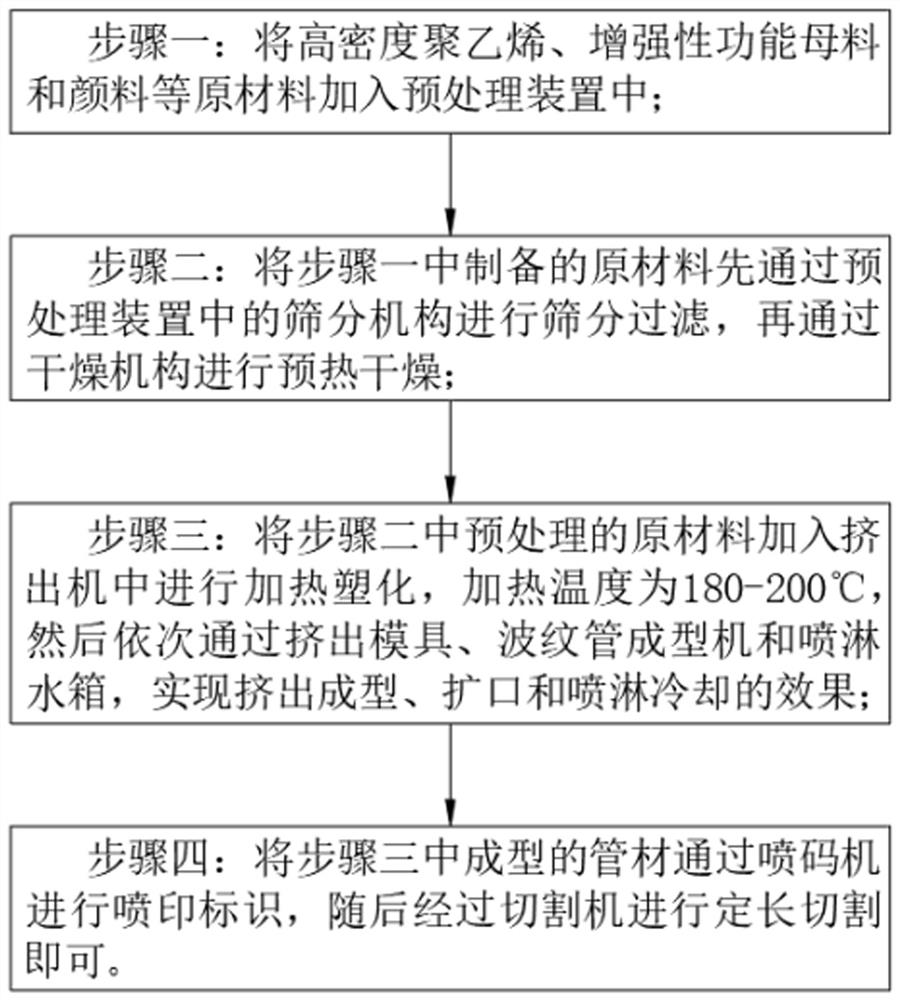

[0059] like image 3 As shown, the present embodiment proposes a production method of HDPE multi-rib reinforced winding corrugated pipe, comprising the following steps:

[0060] Step 1: Add raw materials such as high-density polyethylene, enhanced functional masterbatch and pigments into the pretreatment device;

[0061] Step 2: The raw materials prepared in step 1 are firstly screened and filtered by the screening mechanism 5 in the pretreatment device, and then preheated and dried by the drying mechanism 4;

[0062] Step 3: Add the pretreated raw materials in step 2 into the extruder for heating and plasticizing, and the heating temperature is 180-200 ° C, and then pass through the extrusion die, the bellows forming machine and the spray water tank in turn to achieve extrusion molding, The effect of flaring and spray cooling;

[0063] Step 4: The pipe formed in Step 3 is spray-printed and marked by the inkjet printer, and then cut to a fixed length by the cutting machine. ...

Embodiment 3

[0066] like Figure 4-11 As shown, this embodiment provides a production device for HDPE multi-rib reinforced winding corrugated pipe, which is used to realize the above-mentioned production method of HDPE multi-rib reinforced winding corrugated pipe, including the above-mentioned pretreatment device, and the pretreatment device includes an extruder body 2 , storage mechanism 3, drying mechanism 4, screening mechanism 5, mixing mechanism 6 and transmission mechanism 7;

[0067] Among them, the extruder body 2 is used to fully plasticize and uniformly mix the raw materials and form it through a die, and the extruder body 2 includes a chassis 201 and an extrusion barrel 202, and the extrusion barrel 202 is installed on one side of the chassis 201. upper part;

[0068] The storage mechanism 3 is used to store raw materials and supply materials for the extrusion cylinder 202, and the storage mechanism 3 includes a hopper body 301 connected to the top of the chassis 201. The top a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com