Billet steel crystallization secondary cooling method and device

A secondary cooling and crystallization technology, which is applied in the secondary cooling and device field of billet crystallization, can solve the problems of unsatisfactory cooling effect, speed, cooling uniformity and water consumption, etc., and achieve obvious energy saving effect, fine water mist and Uniformity, and speed ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

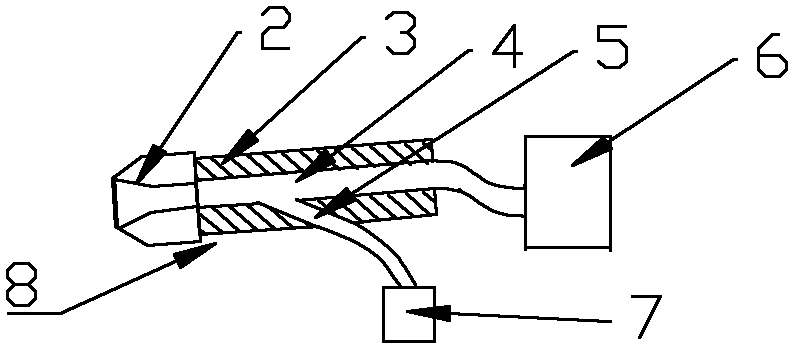

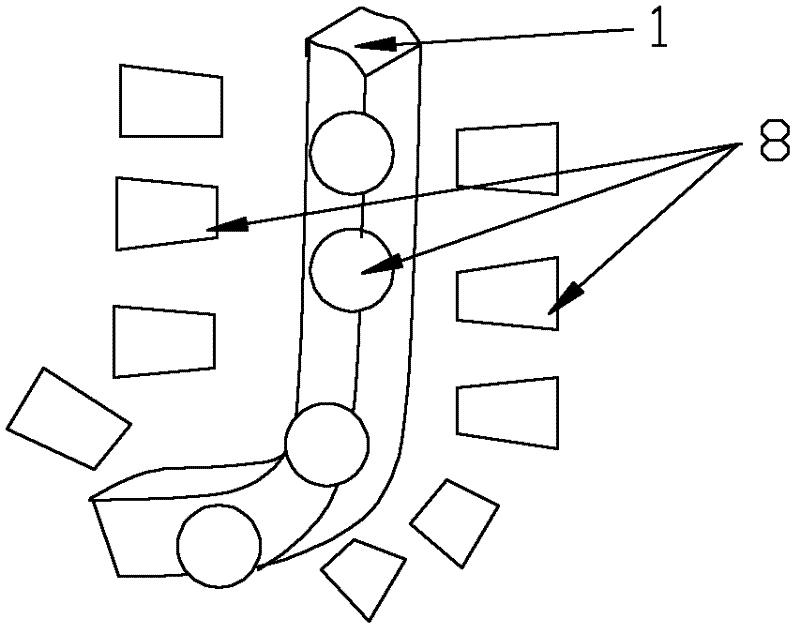

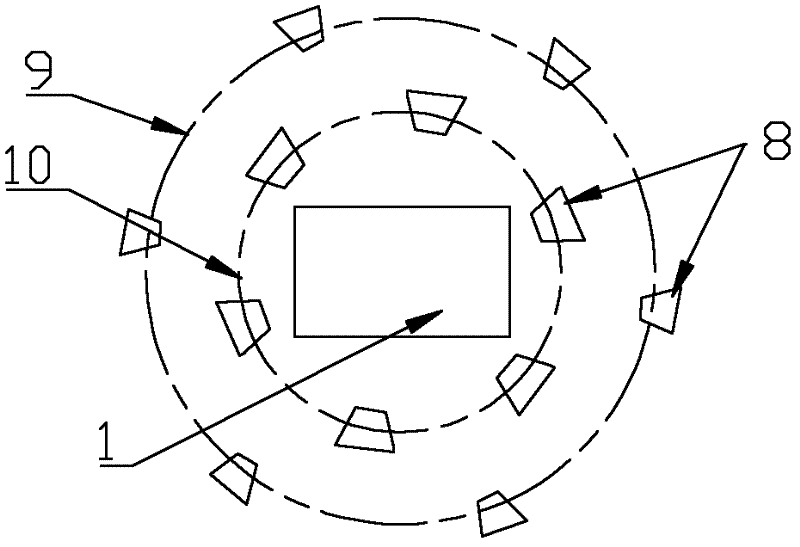

[0016] The present invention will be further described through embodiment now in conjunction with accompanying drawing. The cooling method of the present invention uses inert gas and water as the cooling medium, and around the outer circumference of the corresponding cooling section of the steel billet crystallized as the object to be cooled, the inner and outer multi-layer or evenly arranged spraying devices are arranged at a certain density, and the outer layer is sprayed to cover the corresponding The spraying method of spraying the inner layer of the steel billet is sprayed and cooled. The spraying pressure is 0.001-0.5Mpa, and under the same conditions, the spraying pressure is one-third to two-thirds of the pressure used in the existing cooling method. The spraying devices arranged around the corresponding cooling section for billet crystallization, or the spraying devices of each layer, are located on the same radial and / or axial line with each other, or are offset from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com