Mother liquor evaporation system

A mother liquor evaporation and evaporation system technology, applied in the field of ammonium chloride production equipment, can solve the problems of tube and tube heat exchanger mother liquor crystallization clogging, affecting the production efficiency of the evaporation process, and unable to carry out normal production, etc., so as to achieve a small amount of system maintenance , high production efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described by embodiment now in conjunction with accompanying drawing,

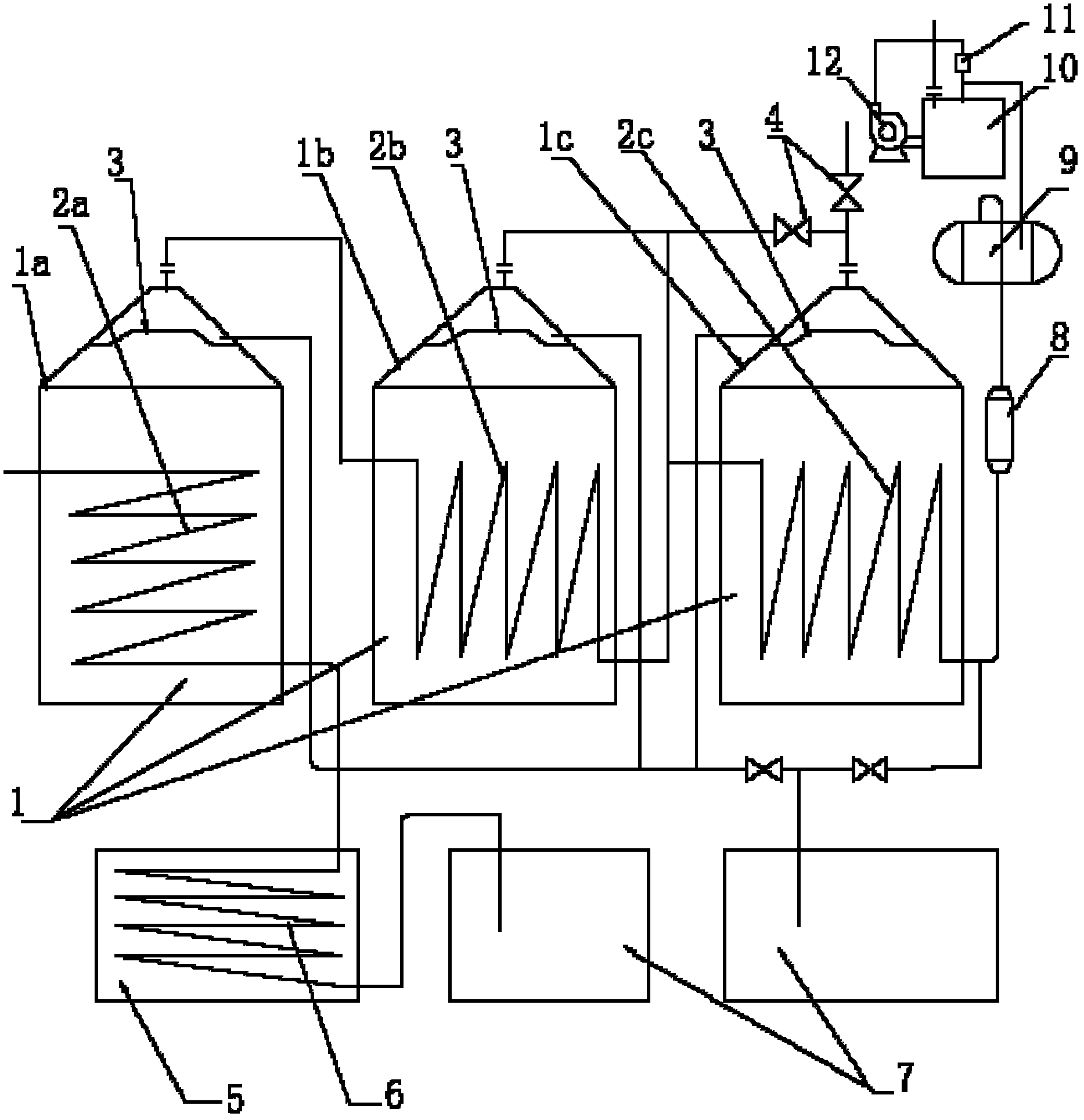

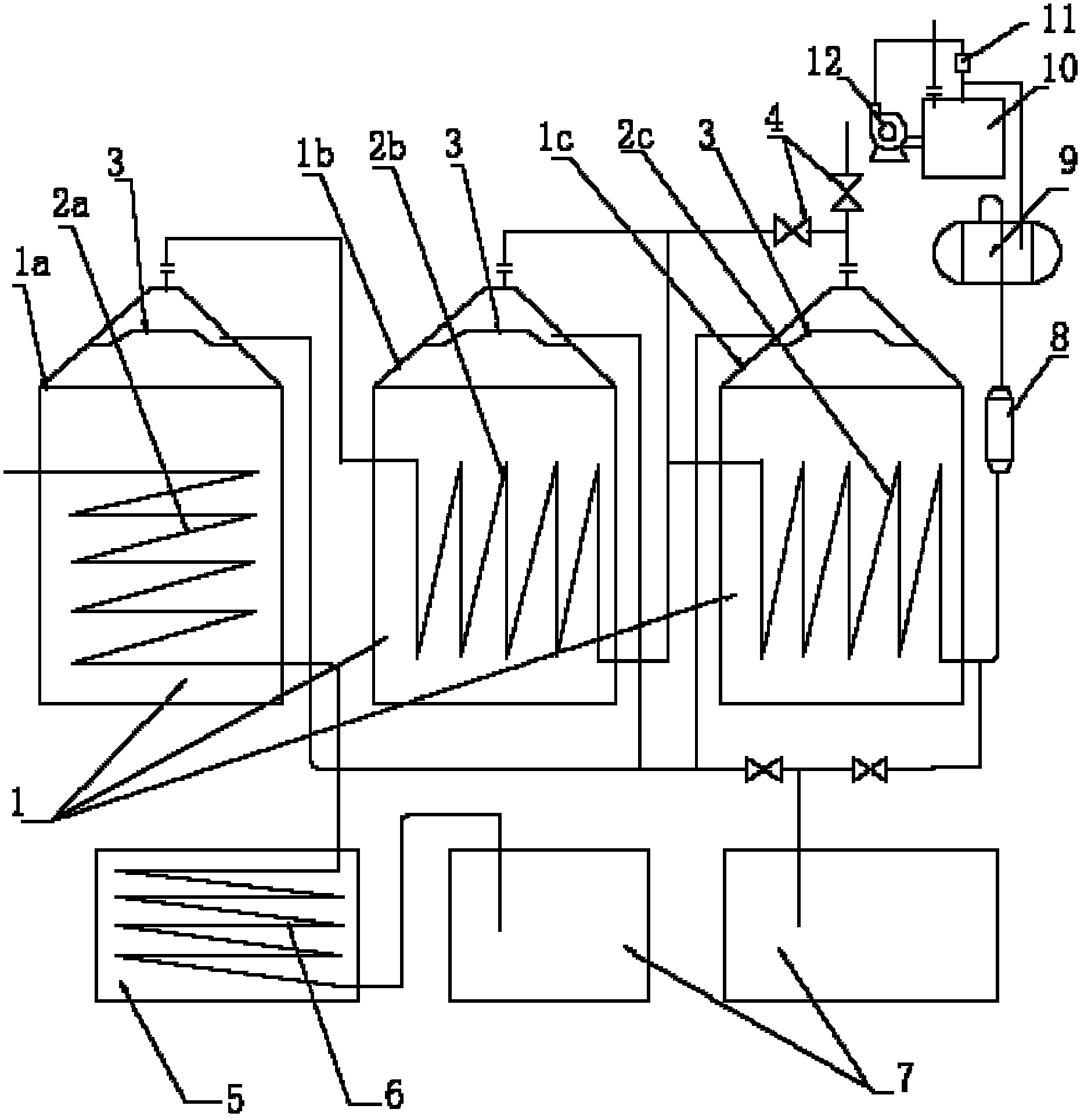

[0017] The mother liquor evaporation process of the present invention adopts a plurality of evaporators to form a multi-effect evaporation system, passes through the heat exchanger tube of the evaporator with steam, and exchanges heat with the mother liquor in the evaporator tank and outside the heat exchanger tube, and the mother liquor Evaporation; the one-effect evaporator of the multi-effect evaporation system uses the primary steam as the heat exchange medium, and the heat exchangers of each evaporator after the one-effect evaporator use the secondary steam generated by the evaporator in front of it separately or simultaneously. The heat exchange medium of the heat exchanger exchanges heat with the mother liquid in the corresponding evaporator tank. And by setting a separation plate on the top of the evaporator, part of the collected condensed water is led ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com