Screwdriver

A screwdriver and casing technology, which is applied in the field of screwdrivers, can solve the problems of screw fastening operation constraints, increase in overall width, and reduce workability, etc., to achieve excellent workability, compactness, and space-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described below with reference to the drawings.

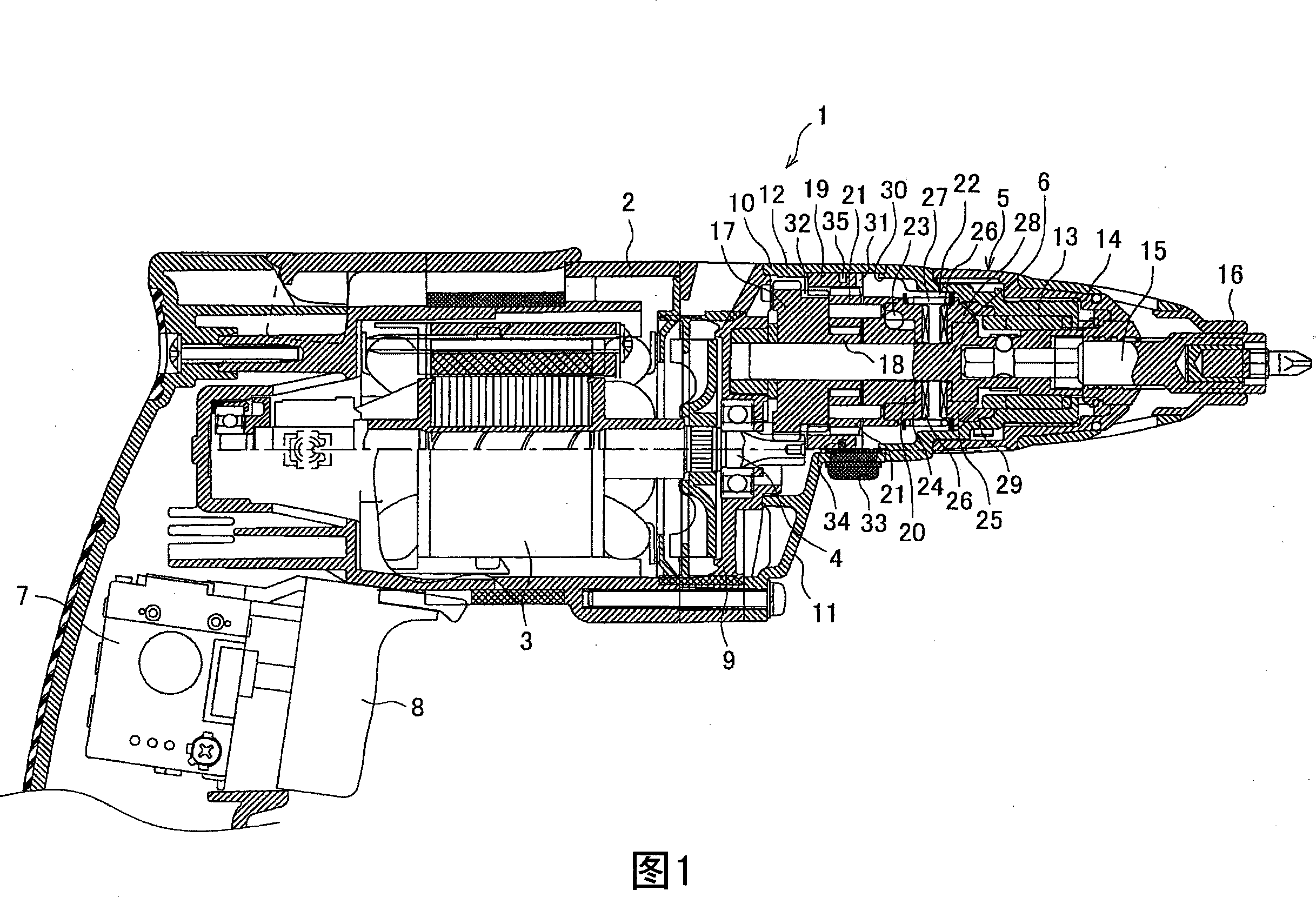

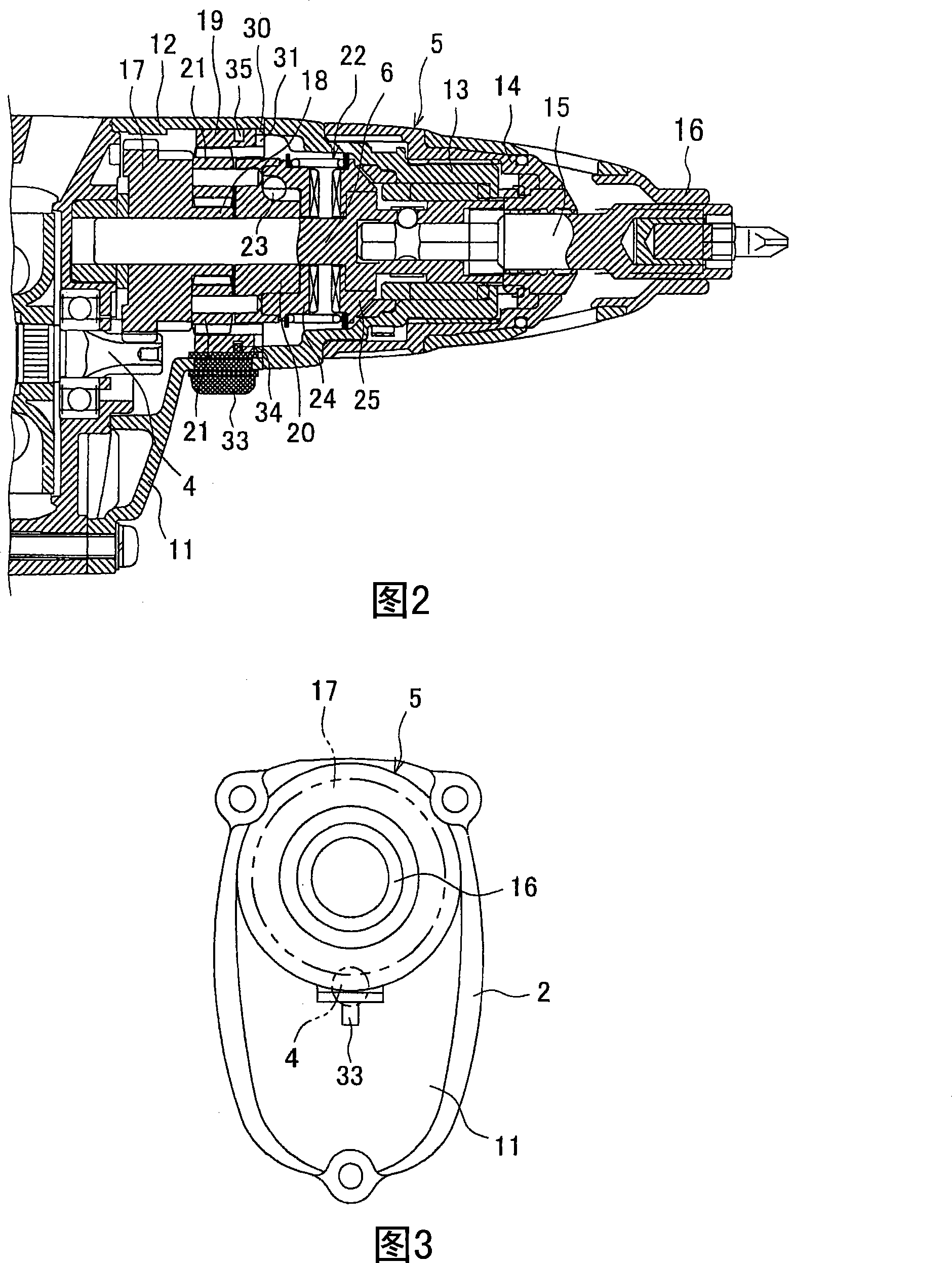

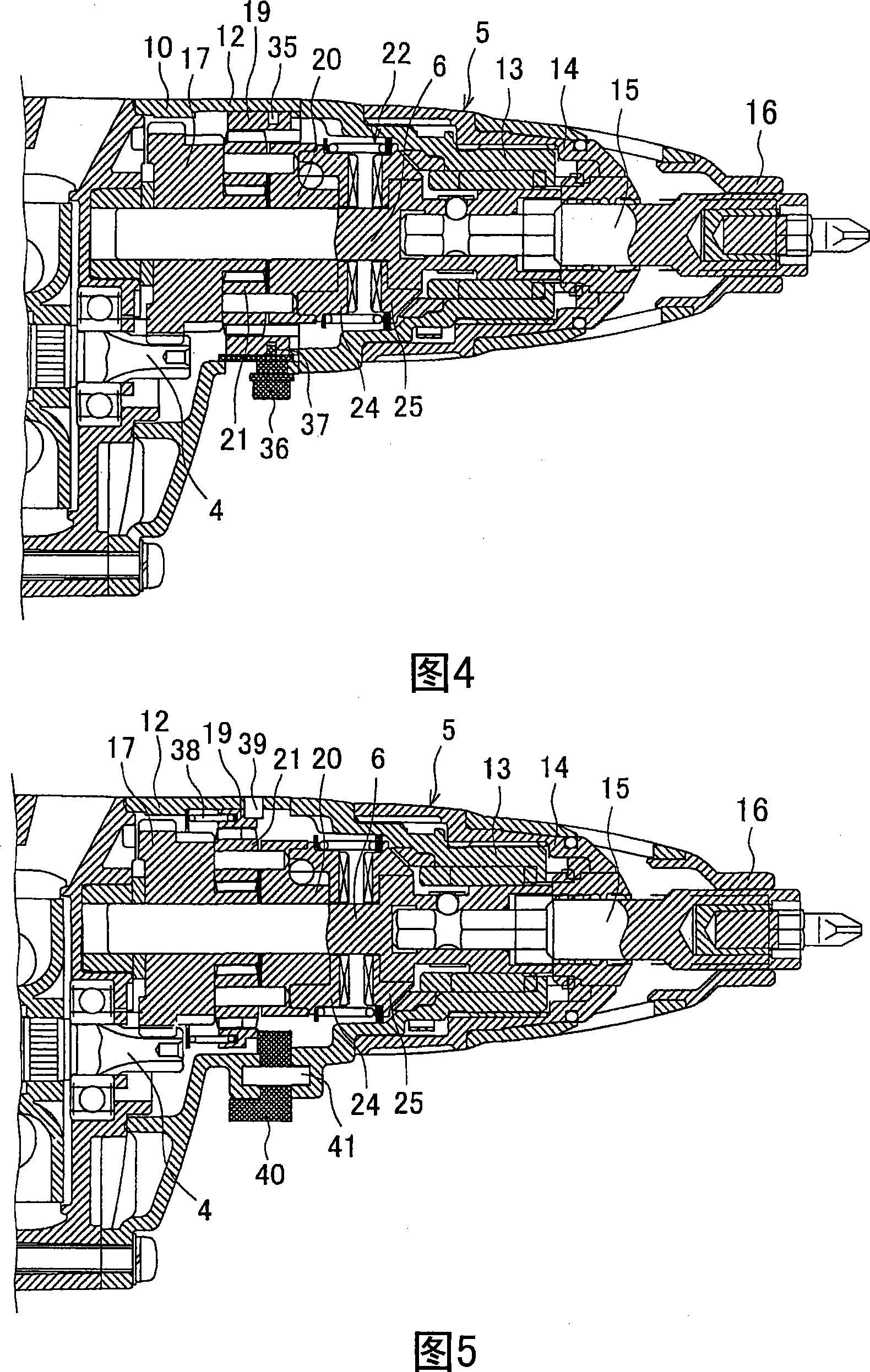

[0018] Fig. 1 is a longitudinal sectional view showing an example of a screwdriver. The screwdriver 1 accommodates a motor 3 at the rear (left side of Fig. 1 ) of a main body casing 2, and is connected to a front casing 5 in front thereof, and the front casing 5 An output shaft 6 is accommodated above the motor shaft 4 of the motor 3, and the output shaft 6 can move back and forth in the axial direction. 7 is the switch of motor 3, and 8 is the trigger that makes switch 7 connected.

[0019] The front housing 5 is formed by sequentially installing a gear case 10, a front end sleeve 13, and a lock ring 14 on the bearing housing 9 which pivotally supports the rear ends of the motor shaft 4 and the output shaft 6 respectively, wherein the gear case 10 has a covering bearing The cover portion 11 of the lower half of the housing 9 is formed with a cylindrical portion 12 above; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com