Enhanced heat-insulation composite film spaced by metal wire grating and application thereof

A technology of composite film and metal wire, which is applied in the direction of metal layered products, layered products, chemical instruments and methods, etc., to achieve the effect of reasonable function, easy use and wide application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

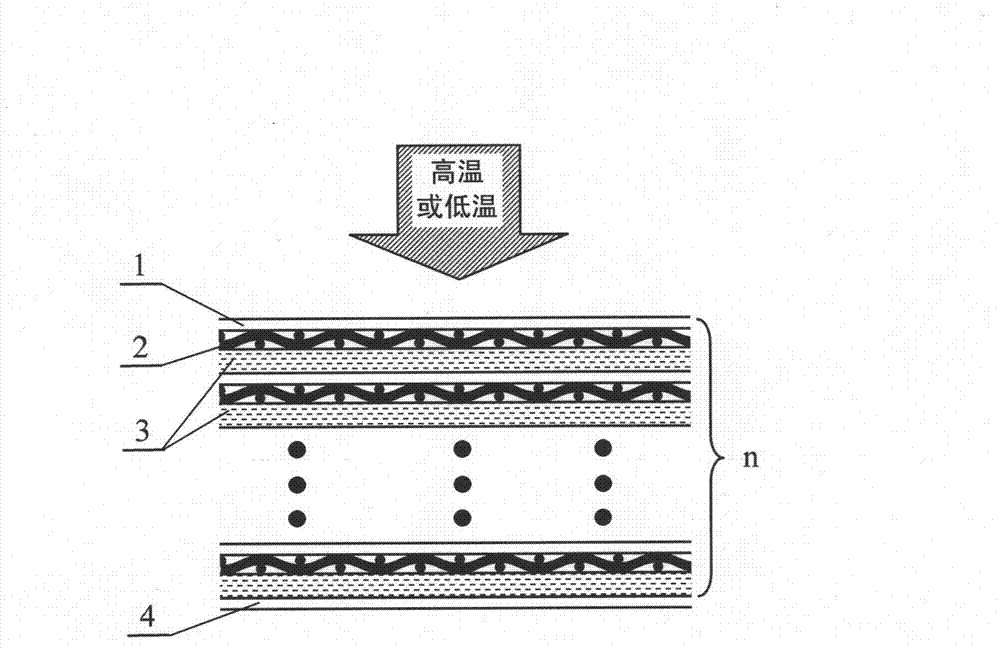

Image

Examples

Embodiment 1

[0036] Using the layered structure of the reinforced heat-insulating composite film with wire grid intervals of the present invention and the materials and processing technology in the following table, and using the heat-insulating composite film prepared by the present invention, place it under the high temperature condition of 200°C, The actually measured steady-state temperature on the inner surface of the composite membrane is shown in column Example 1 of the table below. Actual visual inspection revealed that the surface was intact. This proves that the composite membrane has excellent high temperature resistance.

Embodiment 2

[0038] Using the layered structure of the reinforced heat-insulating composite film with wire grid intervals of the present invention and the materials and processing technology in the following table, and using the heat-insulating composite film prepared by the present invention, place it under the high temperature condition of 240°C, The actually measured steady-state temperature on the inner surface of the composite membrane is shown in column 2 of Example 2 in the table below. Actual visual inspection revealed that the surface was intact. This proves that the composite membrane has excellent high temperature resistance.

Embodiment 3

[0040] Adopt the hierarchical structure of the reinforced heat-insulation composite film with wire grid intervals of the present invention and the materials and processing technology in the following table, and adopt the heat-insulation composite film prepared by the present invention, and place it under the low temperature condition of -220°C , The actual measured composite membrane inner surface steady-state temperature is shown in the column of Example 3 in the table below. Actual visual inspection revealed that the surface was intact. This proves that the composite membrane has excellent low temperature resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com