Pressure-maintaining and tail gas treating method and device for material tank of coking plant

A technology of tail gas treatment and material tank, applied in the direction of fluid treatment, container filling method, container discharge method, etc., can solve the problems of secondary pollution, increased cost burden, high treatment cost, etc., and achieve reduction in usage, process and device composition Reasonable and environmentally friendly governance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

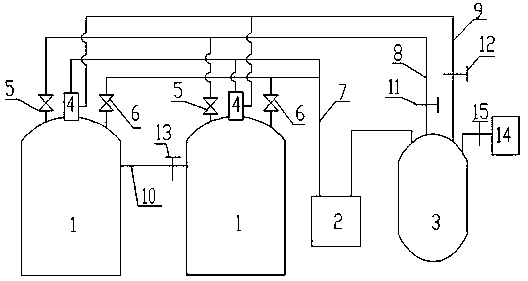

[0020] As shown in the accompanying drawing, a material tank pressure maintaining and tail gas treatment device in a coking plant includes a material tank 1, a gas compressor 2, a high-pressure gas storage tank 3, and the upper end of the material tank 1 passes through the pipeline I7 and gas compression The machine 2 is connected, the material storage tank is equipped with a pressure sensor to measure the inner cavity pressure, the gas compressor 2 is connected with the high-pressure gas storage tank 3, and the tail gas and nitrogen in the material storage tank 1 are stored in the high-pressure gas storage tank 3, and the high-pressure gas storage tank 3. Connect to the material storage tank 1 through the pipeline II8, the pipeline II8 is provided with an electric control valve I11, and the material storage tank 1 is connected to the pipeline I7 through the nitrogen release valve 6.

[0021] Further, it also includes a breathing valve 4, the breathing valve 4 is arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com