Method for hydrogenating deeply-drawing carbolineum

A technology of deep anthracene oil and anthracene oil, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problem that the nitrogen content of heavy distillates meets the feed requirements, the activity stability of hydrogenation catalyst is unfavorable, and the Problems such as the operation cycle of the device, to achieve the effect of prolonging the operation cycle of the device, reducing the content of nitrogen and aromatics, and increasing the added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

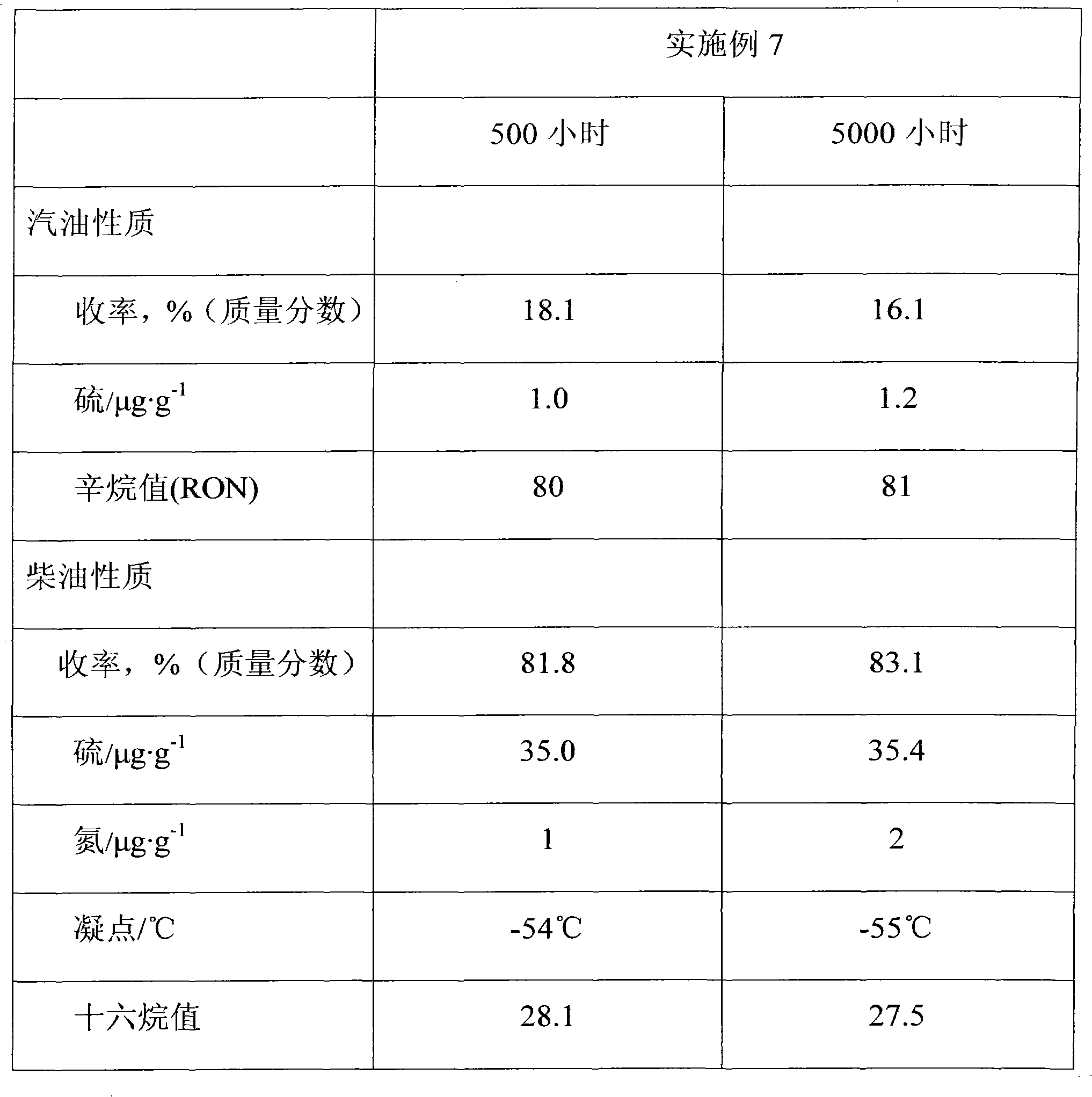

Examples

Embodiment 1~3

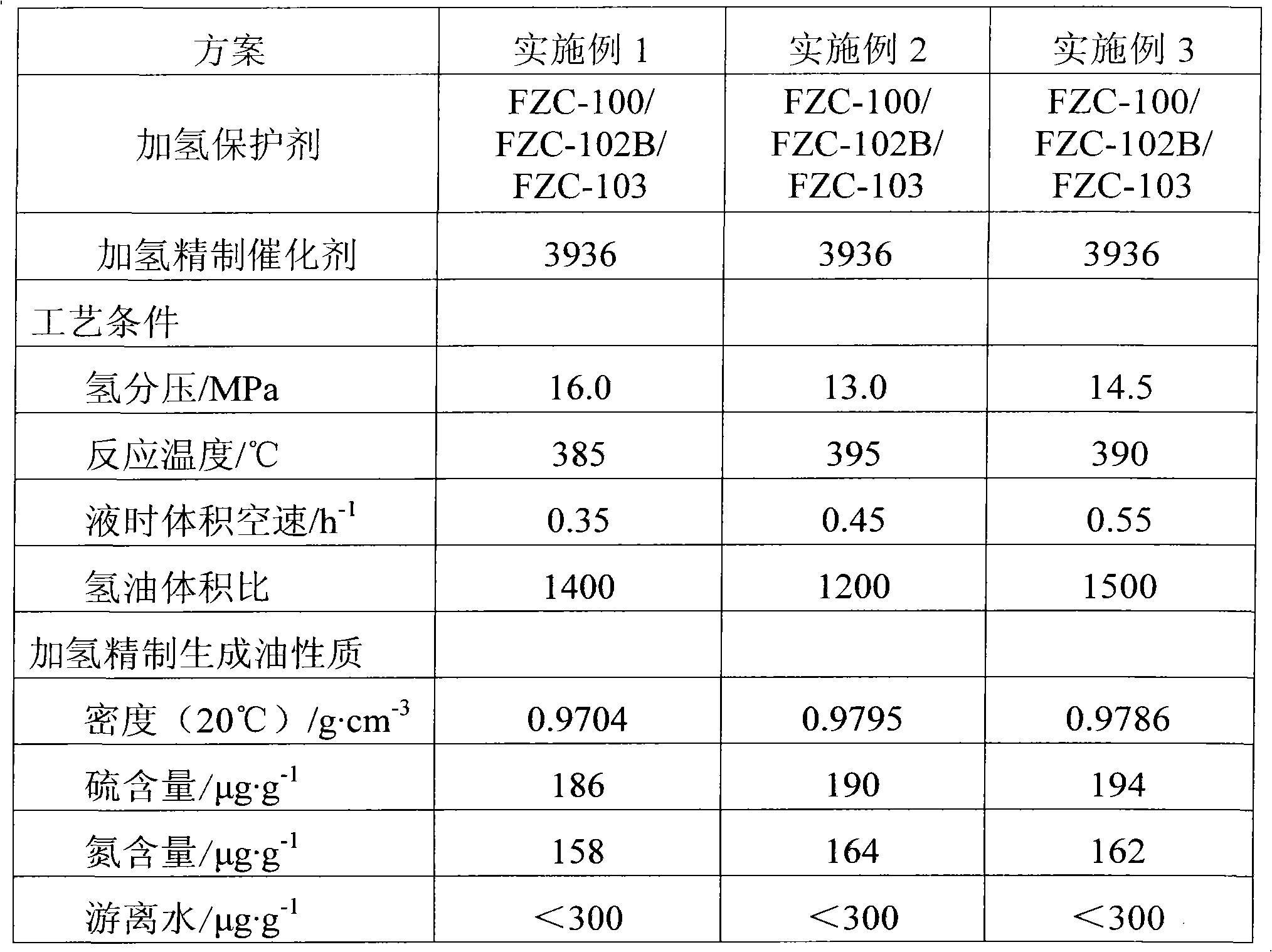

[0052] In the embodiment, the hydrotreating reaction zone adopts two reactors. The first reactor is filled with hydrogenation protection agents FZC-100, FZC-102B and FZC-103 in turn from top to bottom, and the second reactor is filled with hydrotreating catalyst 3936 . In the embodiment, the volume ratio of FZC-100:FZC-102B:FZC-103:3936 is as follows: 6:15:19:60. The results obtained from the reaction are shown in Table 3.

[0053] Table 3 Hydrotreating reaction zone process conditions and hydrotreating oil properties

[0054]

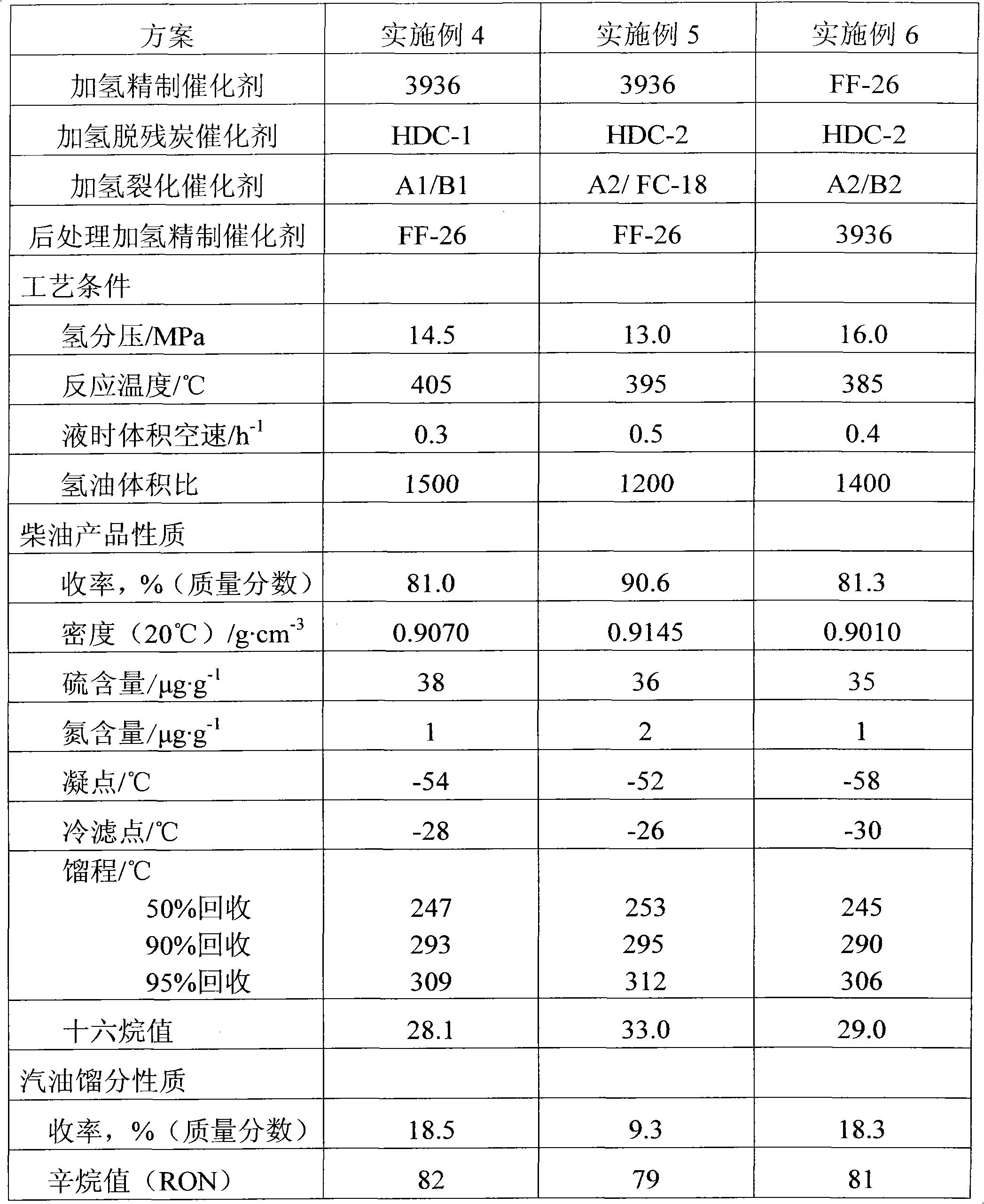

Embodiment 4

[0056] After the hydrorefining oil obtained in Example 1 is subjected to gas-liquid separation through the separation system, the obtained liquid-phase product enters the hydrocracking reaction zone, and successively passes through the hydrorefining catalyst 3936, the hydrotreating carbon residue catalyst, and the hydrocracking catalyst. and post-treatment hydrorefining catalyst FF-26, its volume ratio is 40:15:40:5, wherein the first hydrocracking catalyst loaded on the top of the hydrocracking catalyst is a hydrocracking catalyst containing amorphous silica-alumina and Y molecular sieves , the second hydrocracking catalyst loaded in the lower part is a hydrocracking catalyst containing amorphous silica-alumina and beta molecular sieve, and the volume ratio of the two is 2:1.

Embodiment 5

[0058] The hydrorefining product oil obtained in Example 1 was replaced with the hydrorefining product oil obtained in Example 2, and the rest were the same as those in Example 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com