Method for producing N375 carbon black from blended oil

A technology for the production of carbon black and carbon black, which is applied in the direction of fibrous fillers, etc., can solve the problems of single raw material oil variety, short supply, high production cost, etc., and achieve the effects of improving efficiency, reducing raw material cost, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

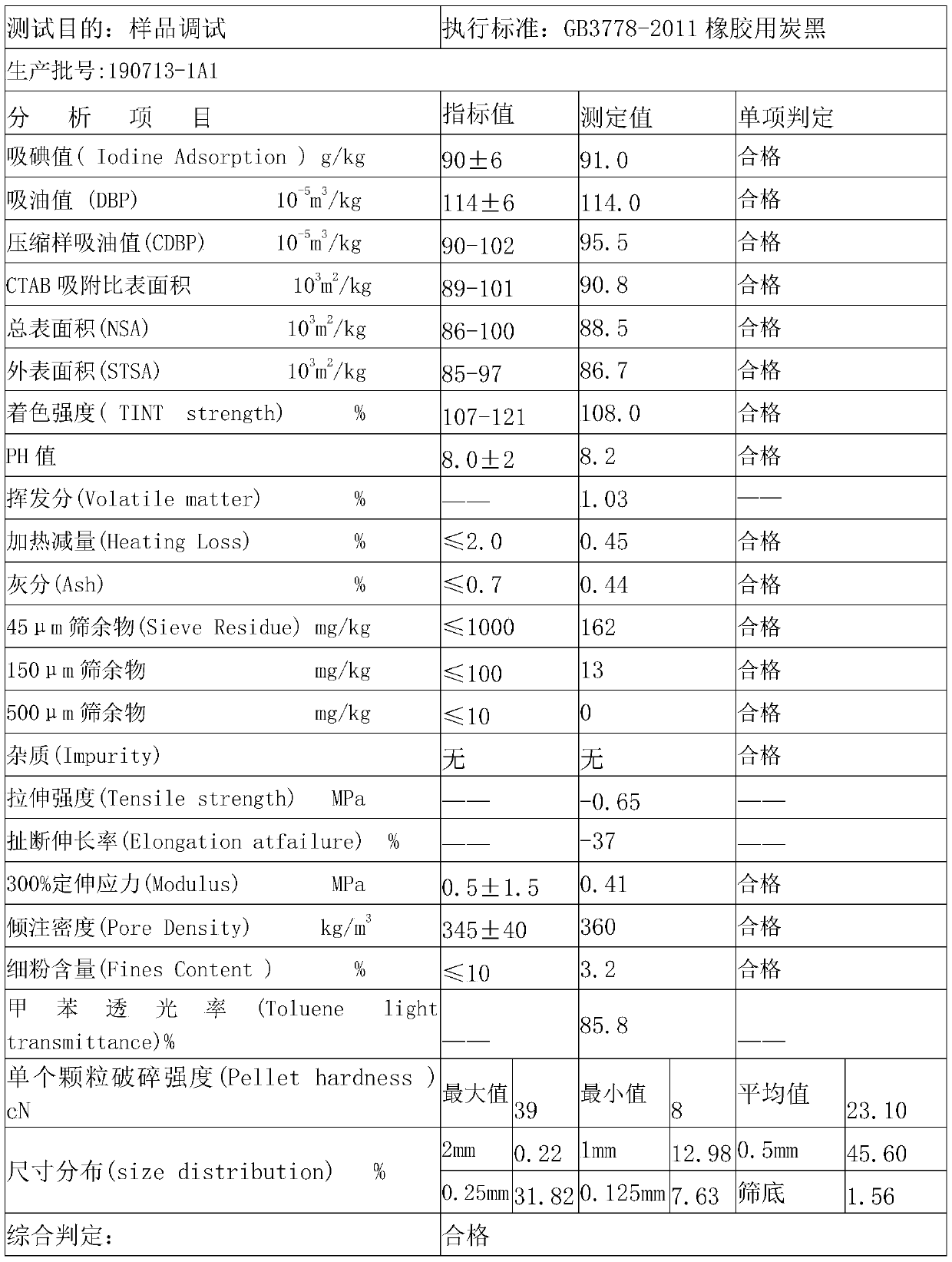

[0022] The present invention is realized in this way, and it is characterized in that: the raw material oil used for carbon black production adopts volume proportions: 50% of ethylene tar, 20% of anthracene oil, 30% of coal tar or 35% of ethylene tar, 35% of anthracene oil %, coal tar 30% ratio; part of the carbon black raw material oil used as fuel and the air provided by the main supply fan and preheated to 750-850°C by the air preheater enter the reaction furnace respectively and mix in the combustion section of the reaction furnace , Combustion, to generate a high-temperature combustion airflow above 1900 ° C, the raw oil is pumped to the online raw oil preheater, preheated to 190 ° C, and then radially sprayed into the throat section of the reaction furnace through a group of raw material oil nozzles, and the high-temperature and high-speed The combustion air is mixed, vaporized and cracked rapidly, and carbon elements gather to form carbon black. At the rear of the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com