Tar-type coal water slurry additive prepared from composite raw materials and production technology of tar-type coal water slurry additive

A production process and additive technology, used in fuel additives, petroleum industry, fuels, etc., can solve the problems of low slurry concentration and poor stability, and achieve the effect of wide source and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

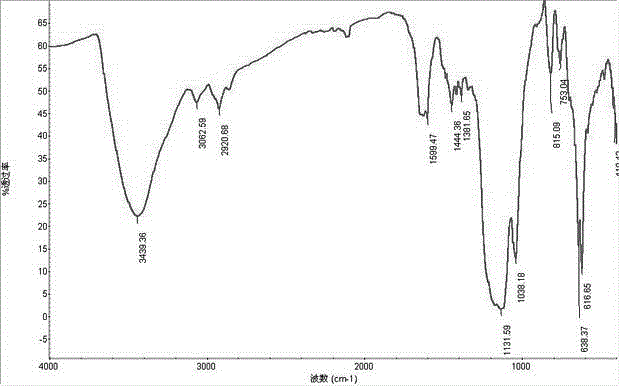

Embodiment 1

[0042] (1) Synthetic tar-type coal water slurry additive: (1) Weigh 30g, 60g, 45g, 15g of washing oil, naphthalene oil, anthracene oil, papermaking waste liquid at a mass ratio of 20:40:30:10, and then weigh The good washing oil, naphthalene oil, and anthracene oil are put into a 1L four-necked flask. According to the average molecular weight of the washing oil, naphthalene oil, anthracene oil, and papermaking waste liquid, the total number of moles is calculated to be 1.5 mol, and 98% 2.3 mol of concentrated sulfuric acid was put into the constant pressure dropping funnel. (2) The temperature of the oil bath is controlled to 155°C, 98% concentrated sulfuric acid is added at a rate of 4d / s, and the temperature is kept at 155°C for 4-5h under stirring to carry out the sulfonation reaction. (3) After the sulfonation reaction is over, the temperature is lowered to 120°C, 55g of water is added, and hydrolyzed at 120°C for 50 minutes, and the weighed papermaking waste liquid is adde...

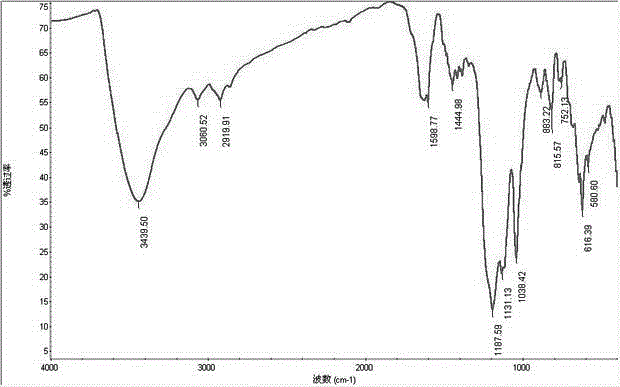

Embodiment 2

[0057] (1) Synthetic tar-type coal-water slurry additives: (1) Weigh the washing oil, naphthalene oil, anthracene oil, and papermaking waste liquid at a mass ratio of 20:40:30:10 to a total of 1.5 mol. The oil was put into a 1L four-necked flask, and 2.3 mol of 98% concentrated sulfuric acid was weighed into a constant pressure dropping funnel. (2) The temperature of the oil bath is controlled to 155°C, 98% concentrated sulfuric acid is added at a rate of 4d / s, and the temperature is kept at 155°C for 4-5h under stirring to carry out the sulfonation reaction. (3) After the sulfonation reaction is over, the temperature is lowered to 120°C, 55g of water is added, and hydrolyzed at 120°C for 50 minutes, and the weighed papermaking waste liquid is added. (4) Add 1.1 mol of 37% formaldehyde dropwise at a rate of 4d / s, and condense at 115°C for 4h. (5) After the condensation reaction is completed, add calcium hydroxide to adjust the pH to 8. (6) Concentrate the filtrate to 50%, add...

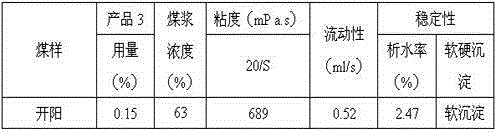

Embodiment 3

[0071] (1) Synthetic tar-type coal water slurry additives: (1) Weigh the washing oil, naphthalene oil, anthracene oil, and papermaking waste liquid at a mass ratio of 25:35:20:20 to 1.5 mol. The oil was put into a 1L four-necked flask, and 1.8 mol of 98% concentrated sulfuric acid was weighed into a constant pressure dropping funnel. (2) The temperature of the oil bath is controlled to 140℃, 98% concentrated sulfuric acid is added at a speed of 4d / s, and the temperature is kept at 140℃ for 5h under stirring to carry out the sulfonation reaction. (3) After the sulfonation reaction is over, the temperature is lowered to 120°C, 55g of water is added, and hydrolyzed at 120°C for 50 minutes, and the weighed papermaking waste liquid is added. (4) Add 37% formaldehyde 0.8mol dropwise at a rate of 4d / s, and condense at 110℃ for 5h. (5) After the condensation reaction is completed, add potassium hydroxide to adjust the pH to 9. (6) Concentrate the filtrate to 50%, add 15 g of ammonium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com