Method for preparing crown ether functionalized porous microsphere adsorbent by one-step double-emulsion template method

A technology of porous microspheres and double emulsions, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problems of unimproved adsorption performance, complex preparation, poor stability, etc., and achieve the effect of high-efficiency and selective separation of lithium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

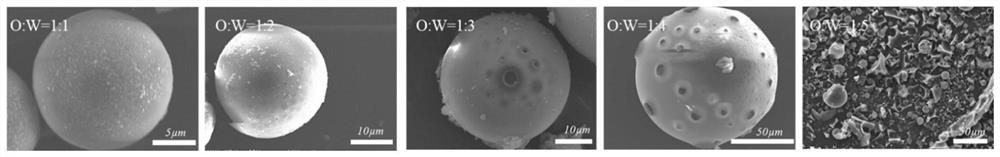

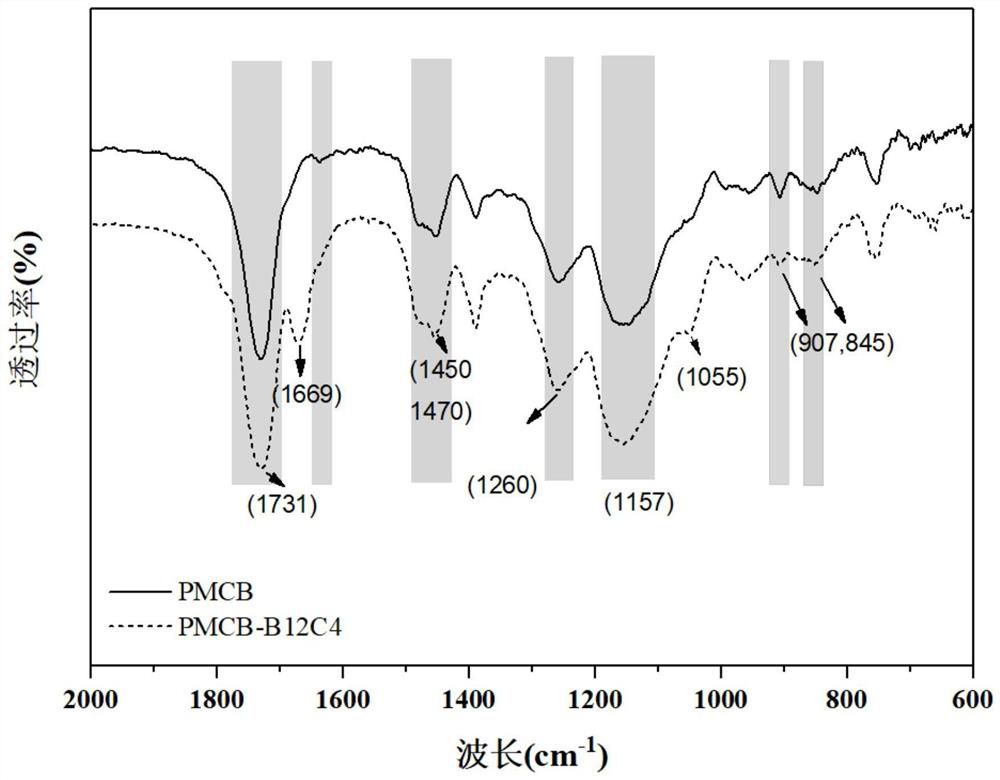

[0030] Preparation of Porous Multichamber Microspheres Rich in Epoxy Groups on the Surface (PMCB) and Microspheres with Capability of Recognizing and Trapping Lithium Ions (PMCB-B12C4)

[0031] (1) First, 5 mg of phenylselenium bromide and 6 mg of PS-b-P4VP were added to 5 mL of dichloromethane solution for 2 min for uniform dissolution and reaction to obtain an amphiphilic surfactant solution;

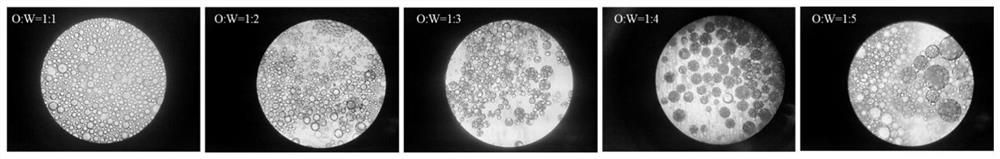

[0032] (2) Add 400 μL amphiphilic surfactant solution, 10 μL glycidyl methacrylate, 20 μL ethylene glycol dimethacrylate, and 10 μL Irgacure-1173 photoinitiator to the centrifuge tube, and then Add 1600 μL of deionized water dropwise under high-speed stirring at 1200 r, and after 2 minutes, prepare the water-in-oil-in-water (W / O / W) double emulsion;

[0033](3) The water-in-oil-in-water (W / O / W) double emulsion obtained in (2) was polymerized under ultraviolet light for 2 hours, and finally washed with ethanol and distilled water several times, and dried in a vacuum oven at 45°C for 6 h...

Embodiment 2

[0036] (1) First, 5 mg of phenylselenium bromide and 6 mg of PS-b-P4VP were added to 5 mL of dichloromethane solution for 2 min for uniform dissolution and reaction to obtain an amphiphilic surfactant solution;

[0037] (2) Add 400 μL amphiphilic surfactant solution, 10 μL glycidyl methacrylate, 20 μL ethylene glycol dimethacrylate, and 10 μL Irgacure-1173 photoinitiator to the centrifuge tube, and then Add 1600 μL of deionized water dropwise under high-speed stirring at 1200 r, and after 2 minutes, prepare the water-in-oil-in-water (W / O / W) double emulsion;

[0038] (3) The water-in-oil-in-water (W / O / W) double emulsion obtained in (2) was polymerized under ultraviolet light for 2 hours, and finally washed with ethanol and distilled water several times, and dried in a vacuum oven at 45°C for 6 hours to obtain PMCB .

[0039] (4) 500mg PMCB and 500mg B12C4-NH 2 The crown ether was mixed and added to 50mL of DMF solution, uniformly dispersed by ultrasonic waves for 4 minutes, a...

Embodiment 3

[0041] Preparation of Porous Multichamber Microspheres Rich in Epoxy Groups on the Surface (PMCB) and Microspheres with Capability of Recognizing and Trapping Lithium Ions (PMCB-B12C4)

[0042] (1) First, 5 mg of phenylselenium bromide and 6 mg of PS-b-P4VP were added to 5 mL of dichloromethane solution for 2 min for uniform dissolution and reaction to obtain an amphiphilic surfactant solution;

[0043] (2) Add 400 μL amphiphilic surfactant solution, 10 μL glycidyl methacrylate, 20 μL ethylene glycol dimethacrylate, and 10 μL Irgacure-1173 photoinitiator to the centrifuge tube, and then Add 1600 μL of deionized water dropwise under high-speed stirring at 1200 r, and after 2 minutes, prepare the water-in-oil-in-water (W / O / W) double emulsion;

[0044] (3) The water-in-oil-in-water (W / O / W) double emulsion obtained in (2) was polymerized under ultraviolet light for 2 hours, and finally washed with ethanol and distilled water several times, and dried in a vacuum oven at 45°C for 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com