Method and reagent for increasing yield of selectively dispersed semiconducting carbon nanotubes

A semiconducting and carbon nanotube technology, which is applied in the field of improving the yield of selectively dispersed semiconducting single-wall carbon nanotubes and the separation of semiconducting single-wall carbon nanotubes, can solve the problem of high semiconductor purity, low purity and low yield. and other problems, to achieve the effect of improving repeatability and stability, wide source of raw materials, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, polycarbazole (PCO) and polythiophene (rr-P3DDT) are selected as the dual polymer system, and their structural formulas are respectively:

[0046]

[0047] (1) Mix polycarbazole, polythiophene, and single-walled carbon nanotube samples in a ratio of 2:2:1, and then add a certain amount of toluene to the formed mixture so that the concentration of polycarbazole and polythiophene is 0.5 mg / ml;

[0048] (2) Place the above mixed solution in a probe sonicator for sonication, keep the temperature at 20° C., power at 3-10 W / ml, and time for 0.5-2 hours. After the ultrasound is over, use a centrifuge to centrifuge at a centrifugal force of 20,000-100,000g for 0.5-2 hours, and finally take out 80% of the supernatant to obtain a semiconducting single-walled carbon nanotube solution with a purity greater than 99% and a concentration greater than 50ug / ml .

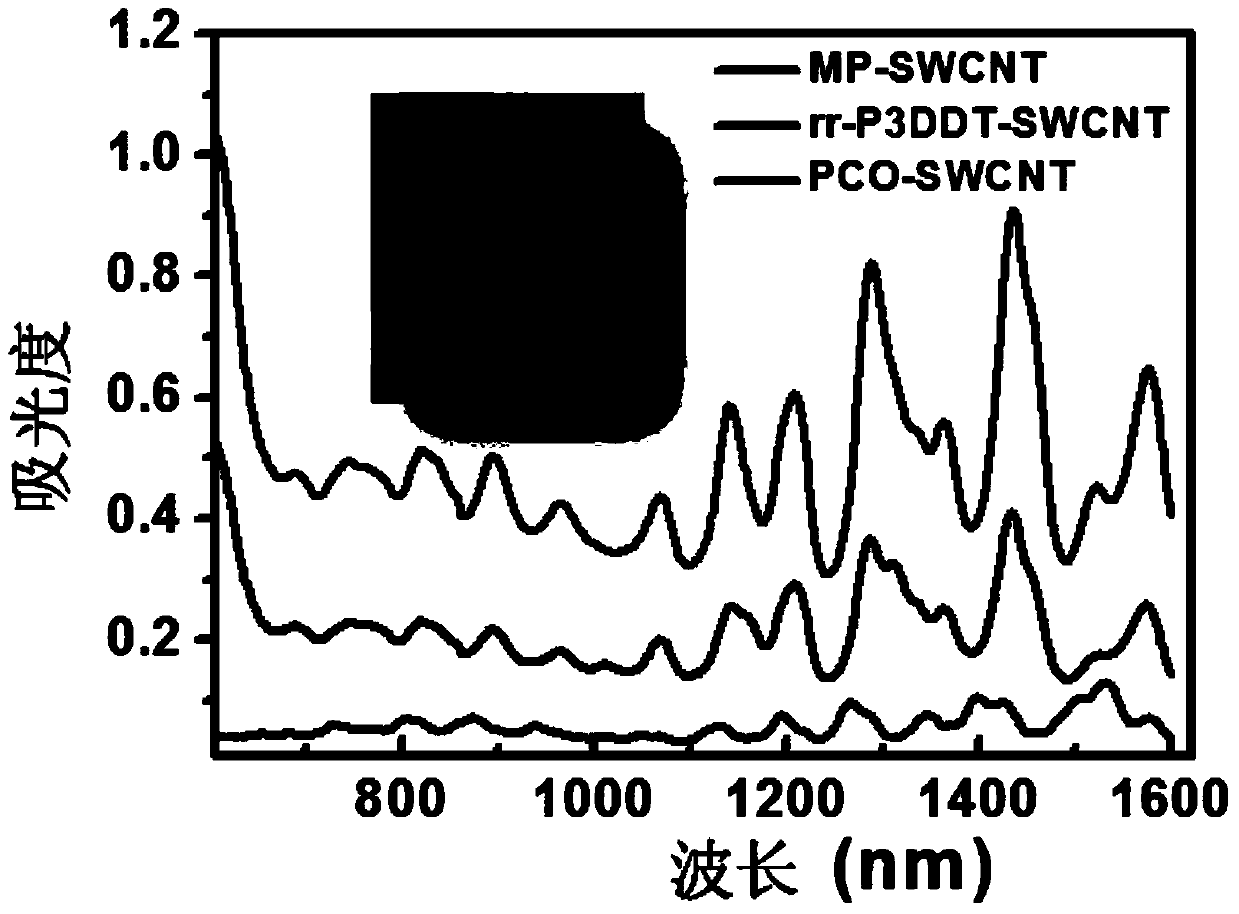

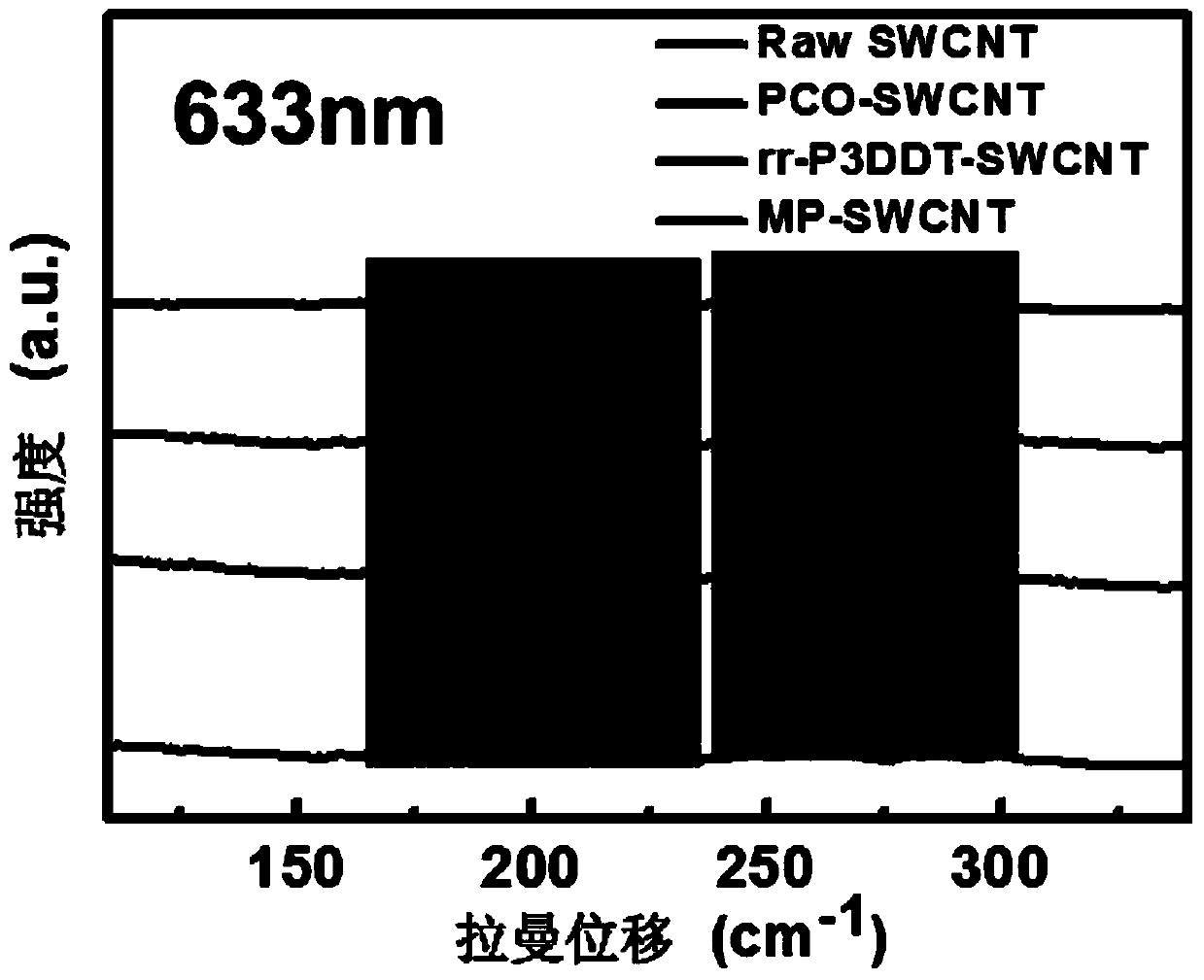

[0049] figure 1 Absorption spectra of PCO, rr-P3DDT and PCO / rr-P3DD mixture dispersed and separate...

Embodiment 2

[0051] (1) Mix polyfluorene, polythiophene, and single-walled carbon nanotube samples in a ratio of 2:2:1, and then add a certain amount of toluene to the formed mixture so that the concentration of polycarbazole and polythiophene is 0.5mg / ml;

[0052] (2) Place the above mixed solution in a probe sonicator for sonication, keep the temperature at 20° C., power at 3-10 W / ml, and time for 0.5-2 hours. After the ultrasound is over, use a centrifuge to centrifuge at a centrifugal force of 20,000-100,000g for 0.5-2 hours, and finally take out 80% of the supernatant to obtain a semiconducting single-walled carbon nanotube solution with a purity greater than 99% and a concentration greater than 50ug / ml .

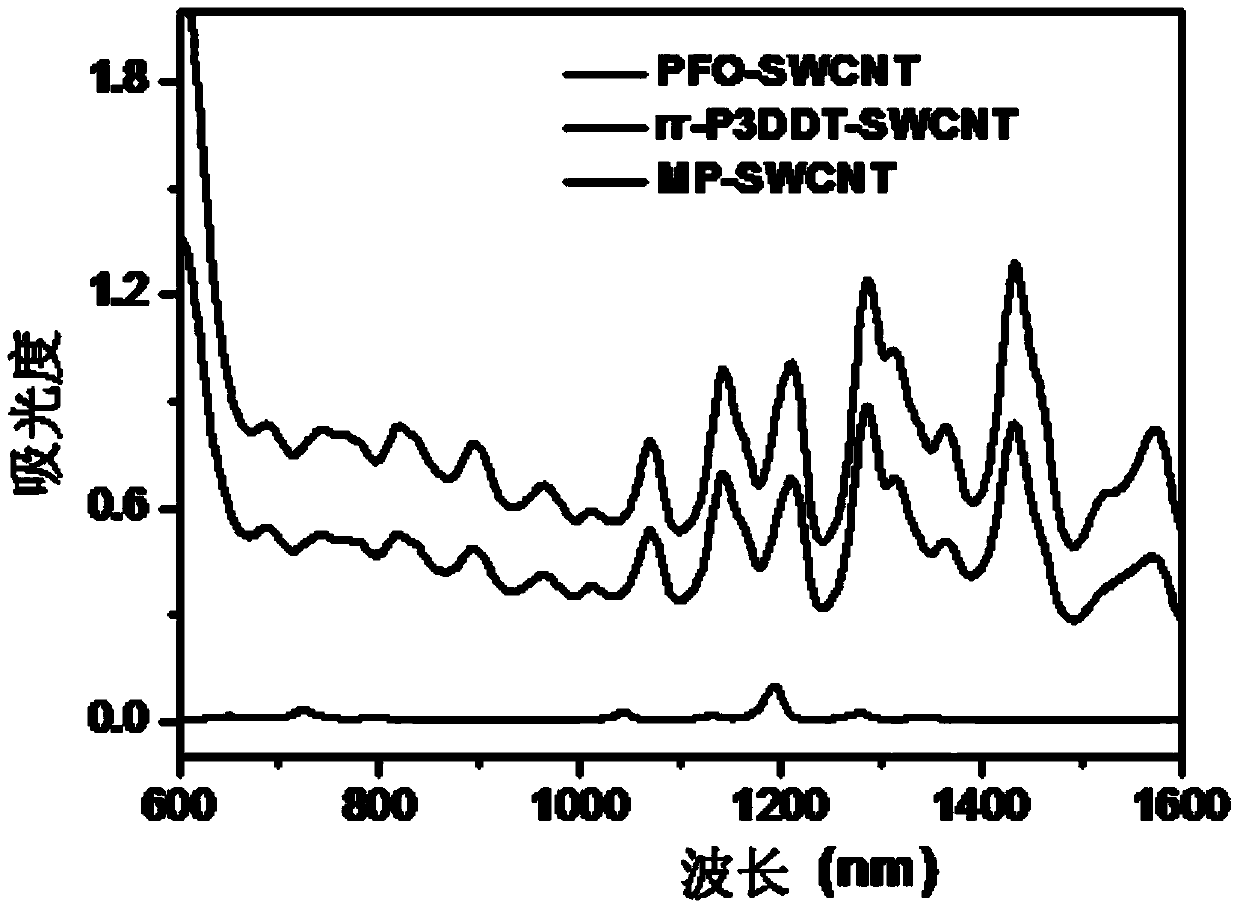

[0053] image 3 The absorption spectra of PFO, rr-P3DDT and PFO / rr-P3DD mixture dispersed and separated single-walled carbon nanotubes, respectively.

[0054] In addition, the inventor of this case also referred to the scheme of the aforementioned Examples 1-2, and carried out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com