Cinnamate type ultraviolet sun-screening agent molecular engram solid-phase extraction column as well as preparation and application thereof

A cinnamic acid ester and solid phase extraction column technology, which is applied in the direction of solid adsorbent liquid separation, material separation, and material analysis, can solve the problems of high extraction recovery rate and poor packing selectivity, and achieve high extraction recovery rate and adsorption Powerful, time-saving and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

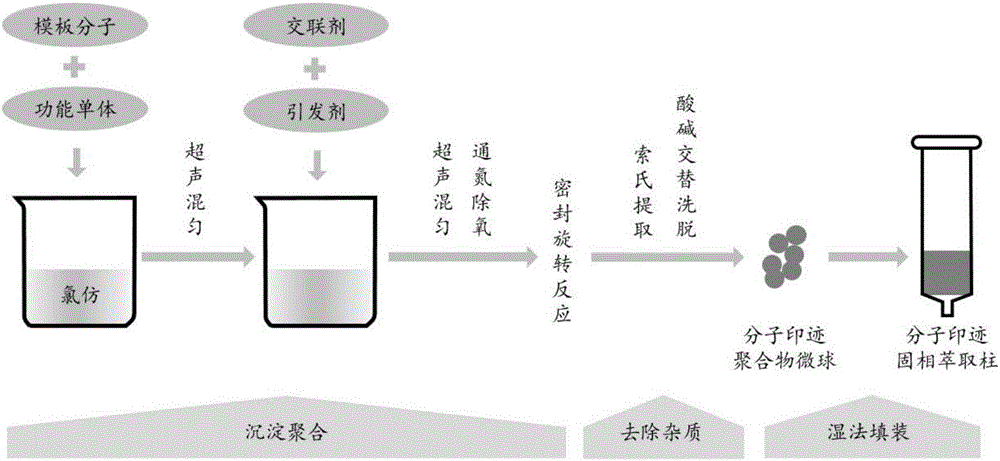

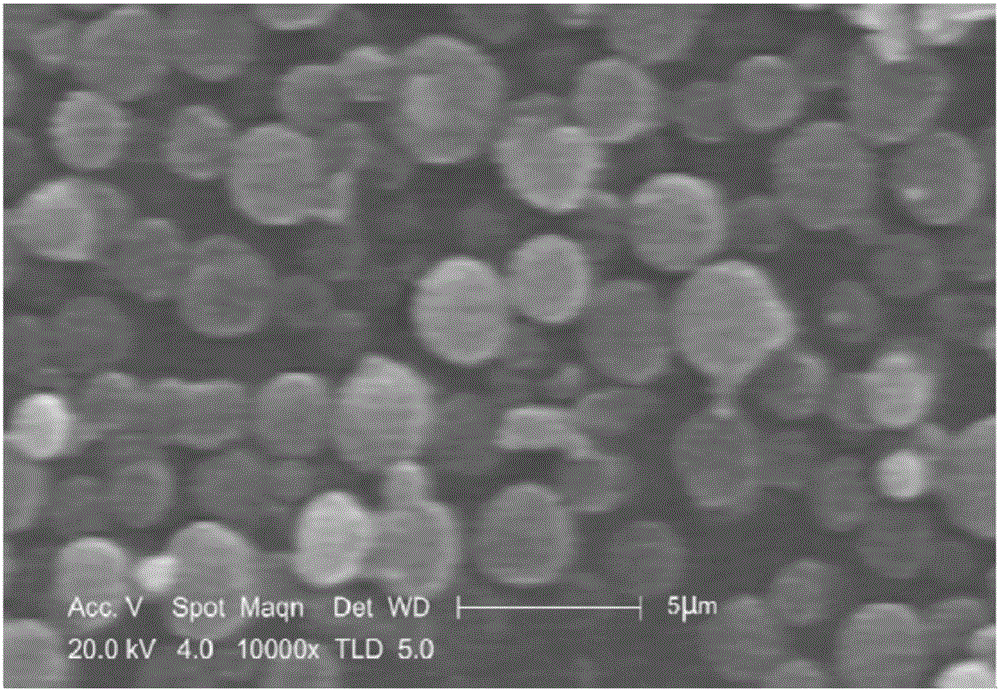

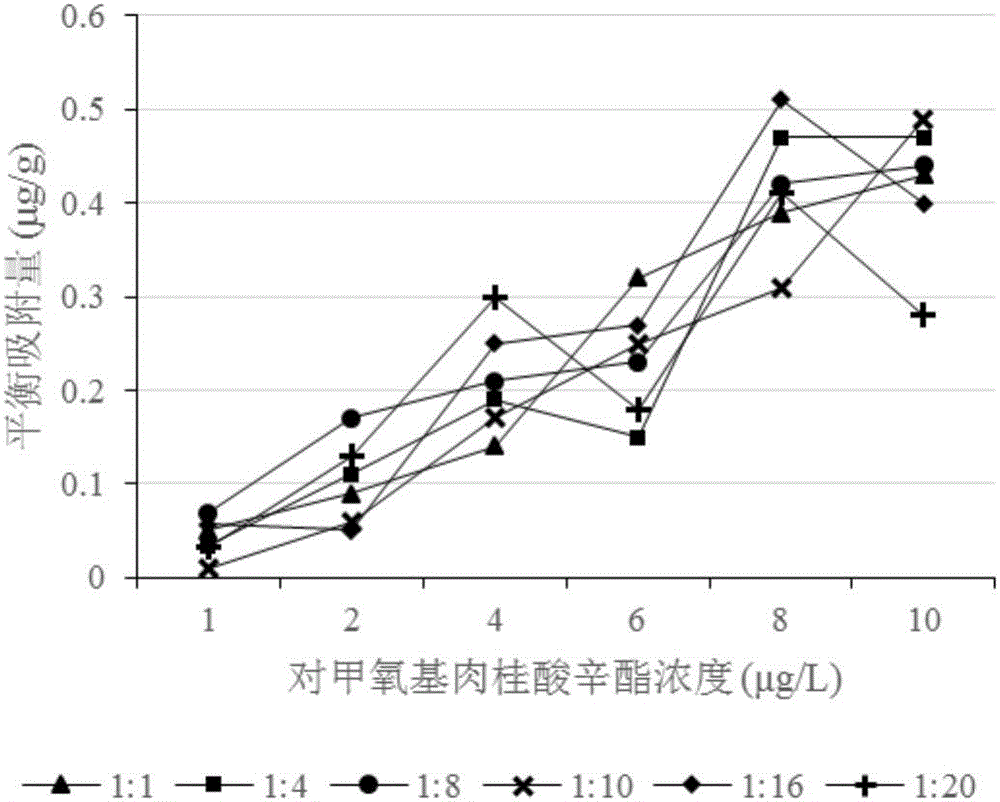

[0033]Dissolve 0.2mmol template molecule octyl p-methoxycinnamate and 0.8mmol functional monomer methacrylic acid in 30mL porogen chloroform, ultrasonically oscillate for 5min until mixed evenly, add 4mmol crosslinking agent ethylene glycol dimethacrylate and 25 mg of initiator azobisisobutyronitrile, ultrasonically disperse and mix, blow nitrogen to deoxygenate to ensure the smooth progress of the polymerization reaction, seal and react in a water bath at 40-60°C under rotating conditions to obtain microspherical molecularly imprinted polymers. The above polymer was wrapped with slow quantitative filter paper, placed in a Soxhlet extractor and extracted with a mixed solution of formic acid and methanol with a volume ratio of 5:95, the extraction time was 48 hours, and the temperature of the water bath was 80°C to remove template molecules and Unreacted compounds are then eluted alternately with base (mixed solution of methanol and water with a volume ratio of 1:1 containing 0....

Embodiment 2

[0035] The difference from Example 1 is that the functional monomer methacrylic acid in Example 2 is 0.2 mmol.

Embodiment 3

[0037] The difference from Example 1 is that the functional monomer methacrylic acid in Example 3 is 1.6 mmol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com