Method for recovering copper indium gallium selenium from waste of copper indium gallium selenium solar thin film cell

A solar thin film, copper indium gallium selenide technology, applied in the field of secondary resource utilization, can solve the problems of complex operation process, incomplete separation, long process, etc., and achieve the effect of simple process flow, meeting environmental protection requirements, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

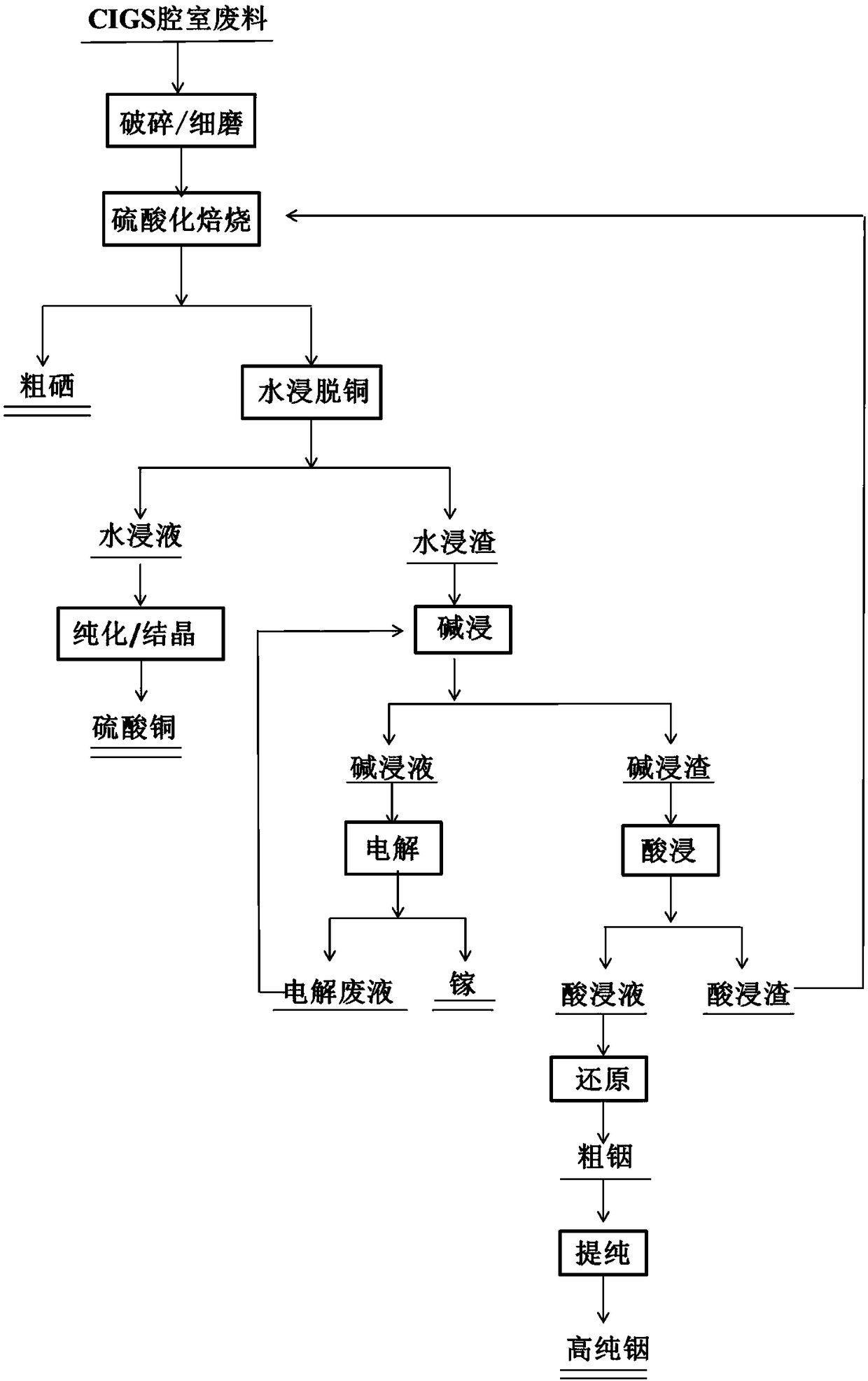

[0042] Such as figure 1As shown, the implementation steps of this embodiment include: taking 50 g of crushed and finely ground CIGS waste, adding concentrated sulfuric acid with a mass fraction of 98%, the consumption of concentrated sulfuric acid is 100 kg / t-waste, and then performing sulfation roasting at a roasting temperature of 300° C., and the roasting time is 2 hours, so as to obtain the roasted material, and separate crude selenium from it, and the purity of the crude selenium is 98.2%. Under normal pressure, the roasted material from which crude selenium has been separated is subjected to water immersion, the leaching temperature is 50°C, the leaching time is 2h, the leaching liquid-solid ratio is 3:1ml / g, and the stirring speed is 400rpm, thereby obtaining the water immersion liquid and water immersion scum. Purify and crystallize the water immersion solution to obtain the copper sulfate product. Wash the water leaching slag, return the washing liquid to the water ...

Embodiment 2

[0044] The implementation steps of this embodiment include: take 50 g of crushed and finely ground CIGS waste, add concentrated sulfuric acid with a mass fraction of 98%, the usage of concentrated sulfuric acid is 700 kg / t-waste, and then carry out sulfate roasting, the roasting temperature is 200 ° C, The roasting time is 5 hours, so as to obtain the roasted material, from which crude selenium is separated, and the purity of the crude selenium is 98.6%. The roasted material from which crude selenium has been separated is water-leached under normal pressure, the leaching temperature is 20°C, the leaching time is 6h, the leaching liquid-solid ratio is 1:1ml / g, and the stirring speed is 200rpm, so as to obtain leaching liquid and leaching residue. The leaching solution obtained by water immersion is purified / crystallized to obtain the copper sulfate product. Wash the water leaching slag, return the washing liquid to the water immersion process, and then carry out alkaline leachi...

Embodiment 3

[0046] The implementation steps of this embodiment include: take 50 g of crushed and finely ground CIGS waste, add concentrated sulfuric acid with a mass fraction of 98%, the usage of concentrated sulfuric acid is 600 kg / t-waste, and then carry out sulfate roasting, the roasting temperature is 700 ° C, The roasting time is 0.5h, thereby obtaining the roasted material, from which crude selenium is separated, and the purity of the crude selenium is 99.1%. Under normal pressure, the roasted material after the separation of crude selenium is immersed in water, the leaching temperature is 20°C, the leaching time is 6h, the leaching liquid-solid ratio is 10:1ml / g, and the stirring speed is 200rpm, so as to obtain the water immersion liquid and water Leach residue. Purify and crystallize the water immersion solution to obtain the copper sulfate product. Wash the water leaching slag, return the washing liquid to the water immersion process, and then carry out atmospheric pressure alk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com