A method for separating antimony in hydrochloric acid-chloride solution

A technology of solution and chloride salt, applied in the direction of improving process efficiency, etc., can solve the problems of complicated antimony process, poor antimony selectivity, low antimony recovery rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

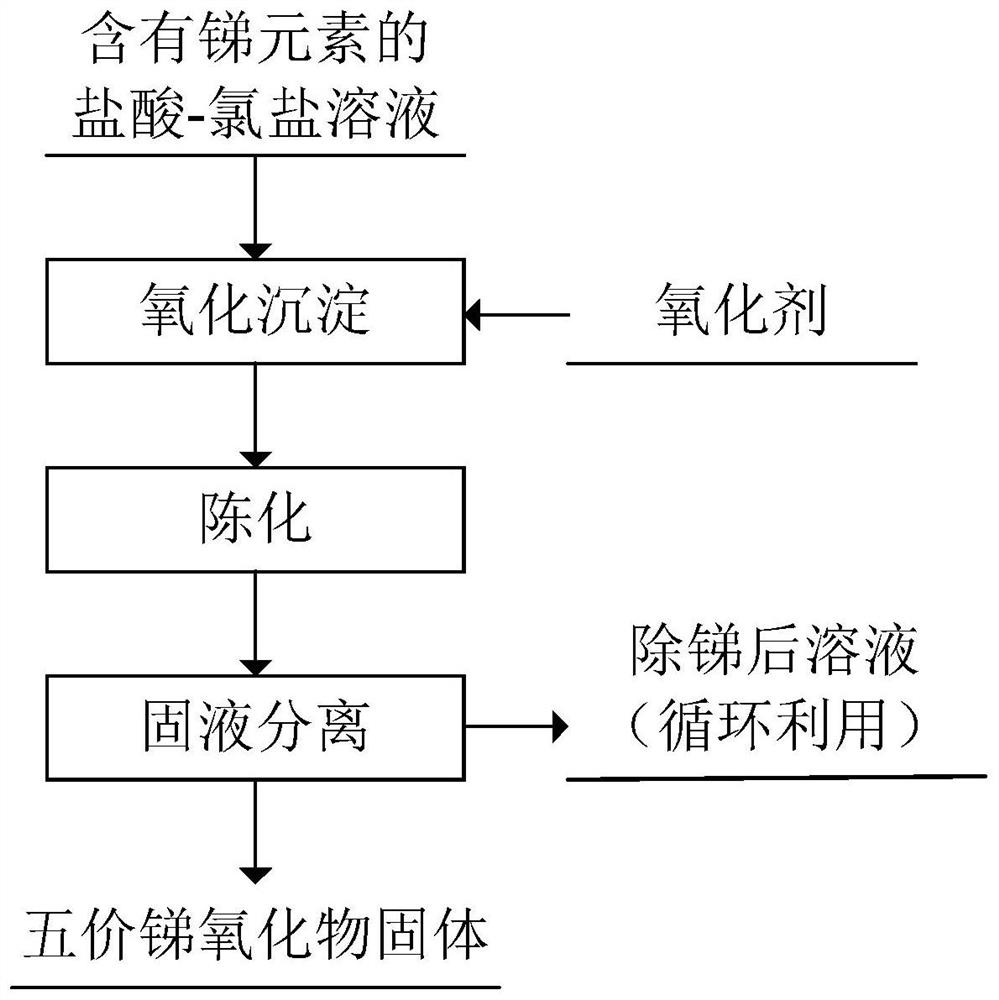

Method used

Image

Examples

Embodiment 1

[0037] The hydrochloric acid-ammonium chloride system leaching the stibnite solution is treated, wherein the concentration of hydrochloric acid is 30g / L, the concentration of calcium chloride is 200g / L, the concentration of iron is 10g / L, and the concentration of antimony is 30g / L. A method for separating antimony in a hydrochloric acid-chloride solution may specifically comprise the following steps:

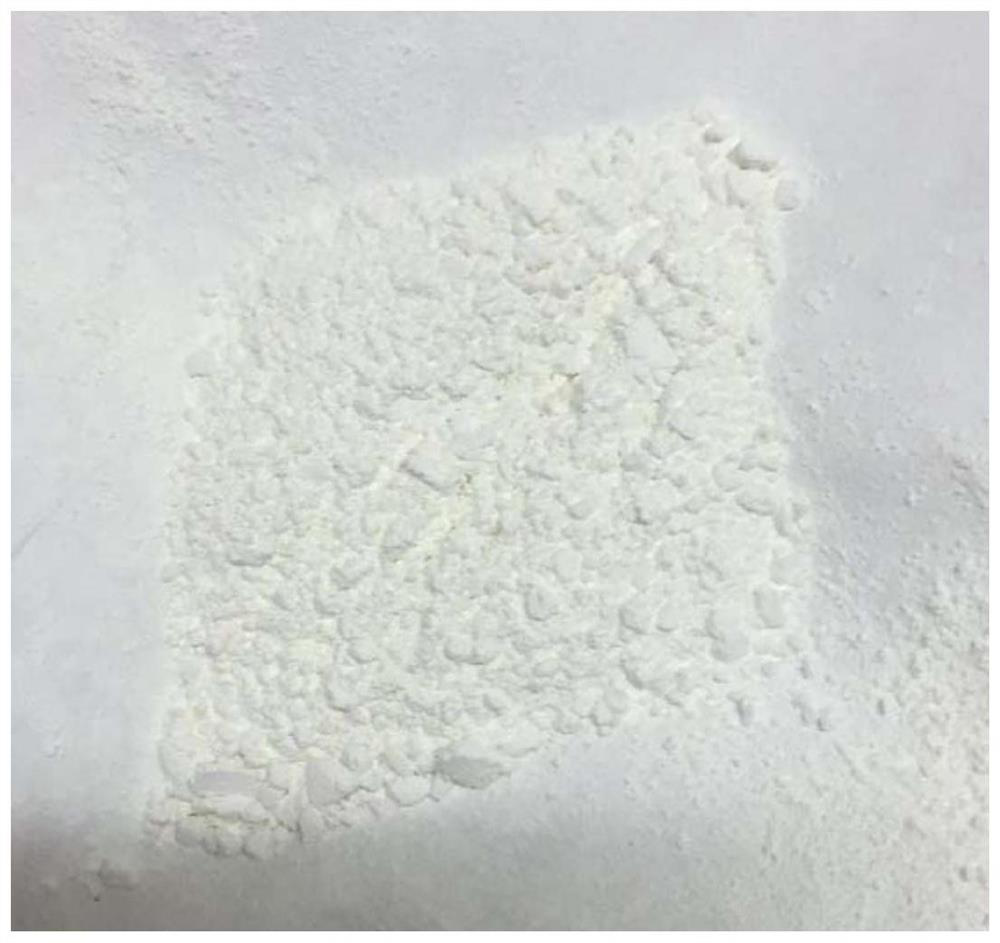

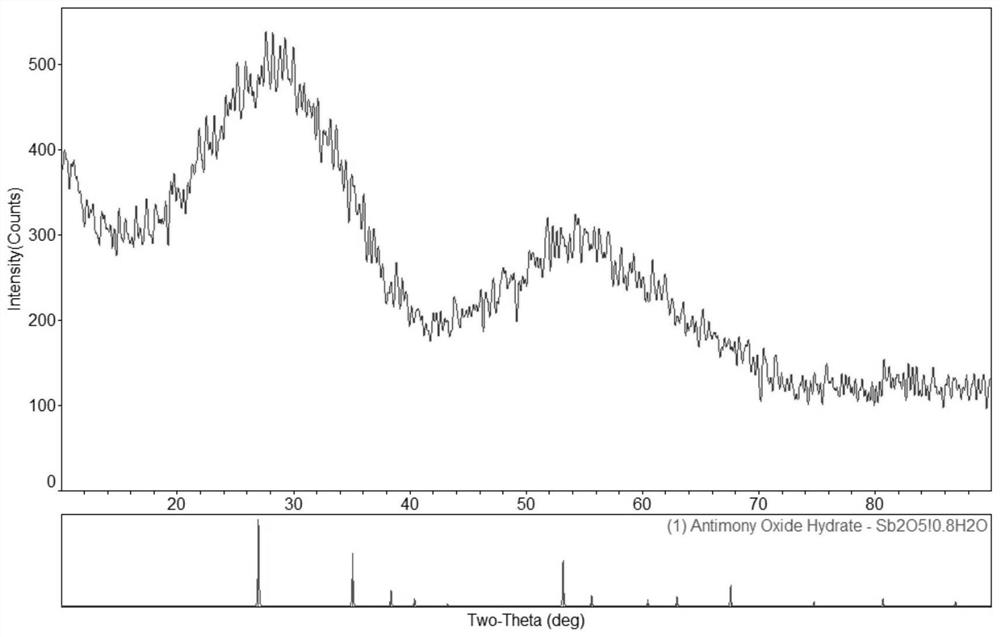

[0038]Step 1a, oxidation precipitation: Add chlorine gas to the above solution for oxidation precipitation, the reaction temperature is 30°C, the stirring speed is 300rpm, the reaction time is 0.5 hours, and the potential of the solution at the end of the reaction is controlled to be greater than 800mV (vs. SHE), so that the three in the solution The valent antimony is oxidized to pentavalent antimony, and the pentavalent antimony is precipitated to form pentavalent antimony oxide, thereby obtaining pentavalent antimony oxide precipitation slurry.

[0039] Step 2a, aging and gro...

Embodiment 2

[0042] The hydrochloric acid-calcium chloride system leaching antimonite solution is processed, wherein the concentration of hydrochloric acid is 40g / L, the concentration of calcium chloride is 250g / L, the concentration of iron is 20g / L, and the concentration of antimony is 60g / L. A method for separating antimony in a hydrochloric acid-chloride solution may specifically comprise the following steps:

[0043] Step 1b, oxidation precipitation: Add chlorine gas to the above solution for oxidation precipitation, the reaction temperature is 40°C, the stirring speed is 300rpm, the reaction time is 1.5 hours, and the potential of the solution at the end of the reaction is controlled to be greater than 900mV (vs. SHE), so that the three in the solution The valent antimony is oxidized to pentavalent antimony, and the pentavalent antimony is precipitated to form pentavalent antimony oxide, thereby obtaining pentavalent antimony oxide precipitation slurry.

[0044] Step 2b, aging and gro...

Embodiment 3

[0047] The electrolyte of the hydrochloric acid-sodium chloride antimony electrolytic refining system is treated, wherein the concentration of hydrochloric acid is 30g / L, the concentration of sodium chloride is 150g / L, and the concentration of antimony is 40g / L. A method for separating antimony in a hydrochloric acid-chloride solution may comprise the following steps:

[0048] Step 1c, oxidation precipitation: Add chlorine gas to the above solution for oxidation precipitation, the reaction temperature is 50°C, the stirring speed is 300rpm, the reaction time is 1 hour, and the potential of the solution at the end of the reaction is controlled to be greater than 800mV (vs. SHE), so that the three in the solution The valent antimony is oxidized to pentavalent antimony, and the pentavalent antimony is precipitated to form pentavalent antimony oxide, thereby obtaining pentavalent antimony oxide precipitation slurry.

[0049] Step 2c, aging and growing up: aging the pentavalent anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com